Five-layer composite freshness-keeping isolating membrane and preparation method thereof

A separation film, layer composite technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc. Firmly stretched, not easy to stretch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

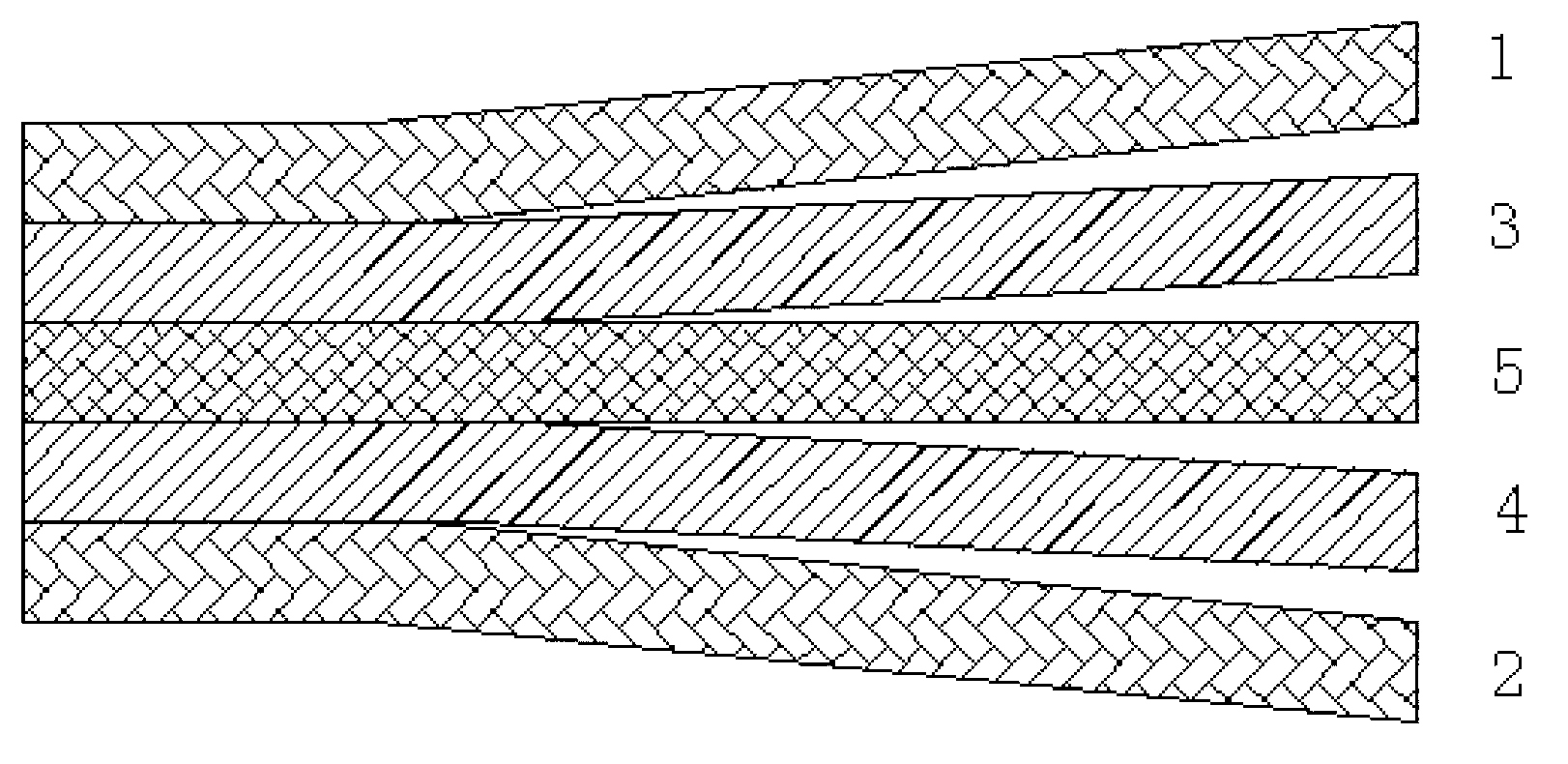

[0024] Such as figure 1 As shown, the five-layer composite fresh-keeping isolation film, the five-layer film is as follows: the first polyethylene layer (1), the first polyolefin layer (3), the woven wire mesh (5), the second polyolefin layer (4), The second polyethylene layer (2); the woven wire mesh (5) forms a staggered fiber mesh structure.

[0025] The thickness of the first polyethylene layer (1) and the second polyethylene layer (2) is 0.2-0.5mm.

[0026] The thickness of the first polyolefin layer (3) and the second polyolefin layer (4) is 0.3-0.6mm.

Embodiment 2

[0028] The preparation method of the five-layer composite fresh-keeping isolation film, in parts by weight:

[0029] (1) Preparation of polyethylene layer: mix according to the ratio of 20 parts of high-density polyethylene HDPE, 5 parts of plasticizer, 3 parts of anti-blocking agent, 15 parts of low-density polyethylene LDPE, and 30 parts of LLDPE, heat to 180°C, Extruded under the pressure of 10MPa;

[0030] (2) Preparation of polyolefin layer: mix according to the ratio of 20 parts of high-density polyethylene HDPE and 80 parts of low-density polyethylene LDPE, heat to 19 ° C, and extrude under a pressure of 5 MPa;

[0031] (3) Preparation of woven wire mesh: use chemical fiber fibers to weave into a mesh shape, and the mesh size of the wire mesh is 0.01mm;

[0032] (4) Composite cooling: according to the first polyethylene layer (1), the first polyolefin layer (3), the braided wire mesh (5), the second polyolefin layer (4), and the second polyethylene layer (2) Sequentia...

Embodiment 3

[0038] The preparation method of the five-layer composite fresh-keeping isolation film, in parts by weight:

[0039] (1) Preparation of polyethylene layer: mix according to the ratio of 30 parts of high-density polyethylene HDPE, 8 parts of plasticizer, 7 parts of anti-blocking agent, 20 parts of low-density polyethylene LDPE, and 35 parts of LLDPE, heat to 180°C, Extruded under the pressure of 5MPa;

[0040] (2) Preparation of polyolefin layer: mix according to the ratio of 15 parts of high-density polyethylene HDPE and 85 parts of low-density polyethylene LDPE, heat to 19 ° C, and extrude under a pressure of 5 MPa;

[0041] (3) Preparation of woven wire mesh: use chemical fiber fibers to weave into a mesh shape, and the mesh size of the wire mesh is 0.05mm;

[0042] (4) Composite cooling: according to the first polyethylene layer (1), the first polyolefin layer (3), the braided wire mesh (5), the second polyolefin layer (4), and the second polyethylene layer (2) Sequential...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com