Roller chain and chain transmission system

A technology of rollers and chains, which is applied in the field of roller chains and chain transmission systems, can solve the problems of small chain load capacity, poor fatigue resistance and wear resistance, and achieve improved load capacity, tensile performance, and resistance The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

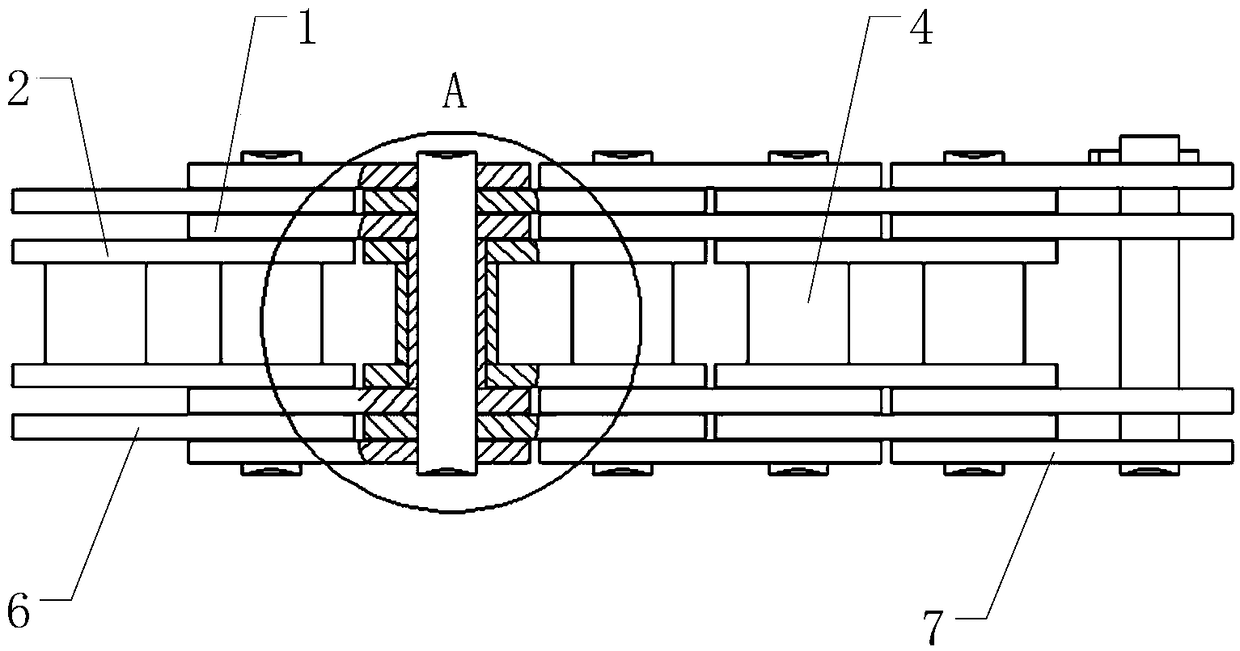

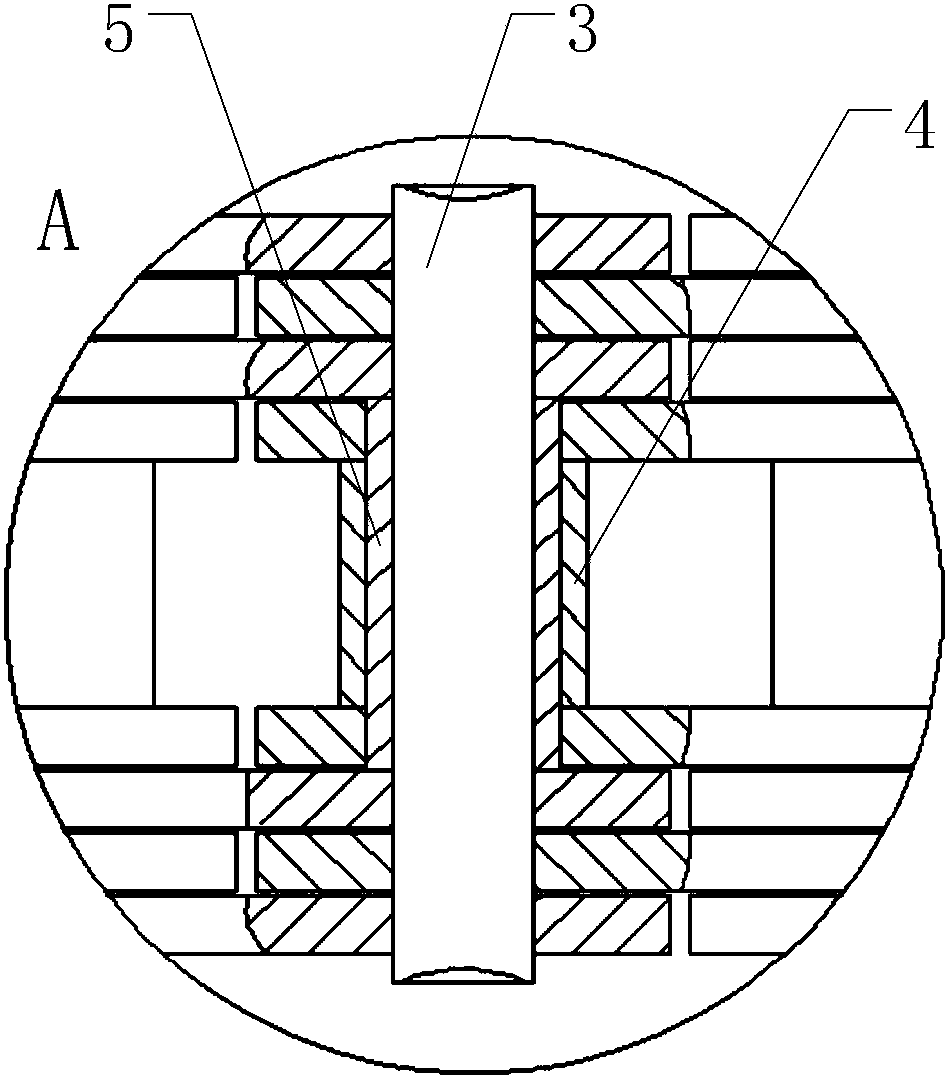

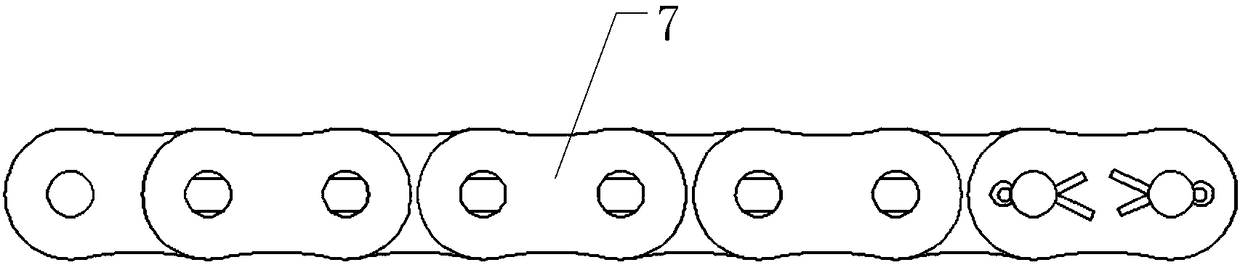

[0044] see Figure 1-Figure 3 shown, where, in order to clearly show the structure, figure 1 The middle part of the structure is shown in a partially sectioned state. This embodiment provides a roller chain, including an outer chain plate 1, an inner chain plate 2, a pin shaft 3, a roller 4, a sleeve 5, a first reinforcing plate 6 and a second reinforcing plate 7;

[0045] Both ends of the sleeve 5 along the axial direction are respectively fixed on the two inner chain plates 2 oppositely arranged; the pin shaft 3 is sleeved in the sleeve 5, and the pin shaft 3 is connected to the shaft The two ends of the direction are connected to the inner link plate 2 through the outer link plate 1, and the pin shaft 3 can rotate relative to the sleeve 5;

[0046] The roller 4 is sleeved outside the sleeve 5, and the roller 4 can rotate relative to the sleeve 5;

[0047] The first reinforcement plate 6 is arranged on the side of the outer chain plate 1 away from the inner chain plate 2,...

Embodiment 2

[0085] Embodiment 2 provides a chain transmission system, which includes the roller chain described in Embodiment 1. The technical features of the roller chain disclosed in Embodiment 1 are also applicable to this embodiment. Embodiment 1 has The technical features of the disclosed roller chain will not be described repeatedly. The implementation of the chain transmission system will be further described in detail below in conjunction with the accompanying drawings.

[0086] In order to save space, the improved features of this embodiment are also reflected in Figure 1-Figure 3 in, therefore, combined with Figure 1-Figure 3 The configuration of this example will be described.

[0087] see Figure 1-Figure 3 As shown, the chain transmission system provided by this embodiment includes the above-mentioned roller chain.

[0088] It further solves the technical problems in the prior art that the chain has a small load-bearing capacity, poor fatigue resistance and wear resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com