Method for simulating self-assembly behavior of rigid segmented block copolymer solution

A technology of rigid block and simulation method, which is applied in the fields of informatics, computer material science, instrumentation, etc., can solve problems such as the inability to effectively control the rigidity of polymer bonds, and achieve the effect of accurate calculation results and high operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

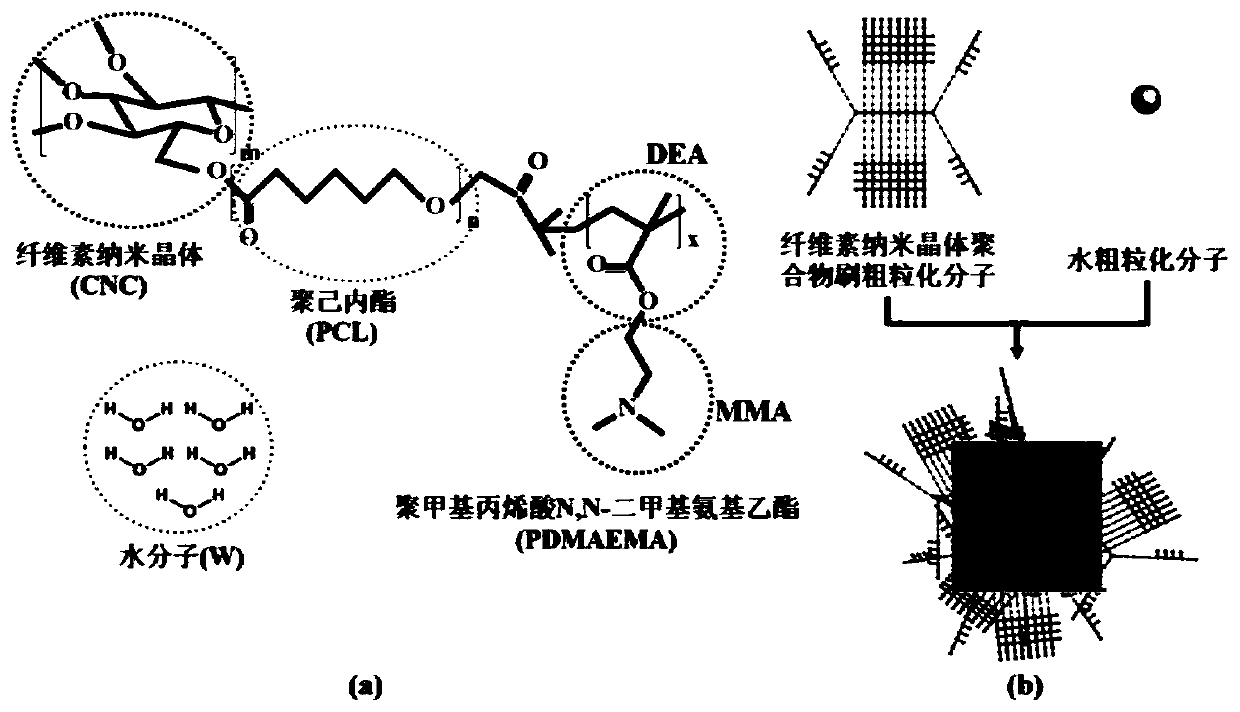

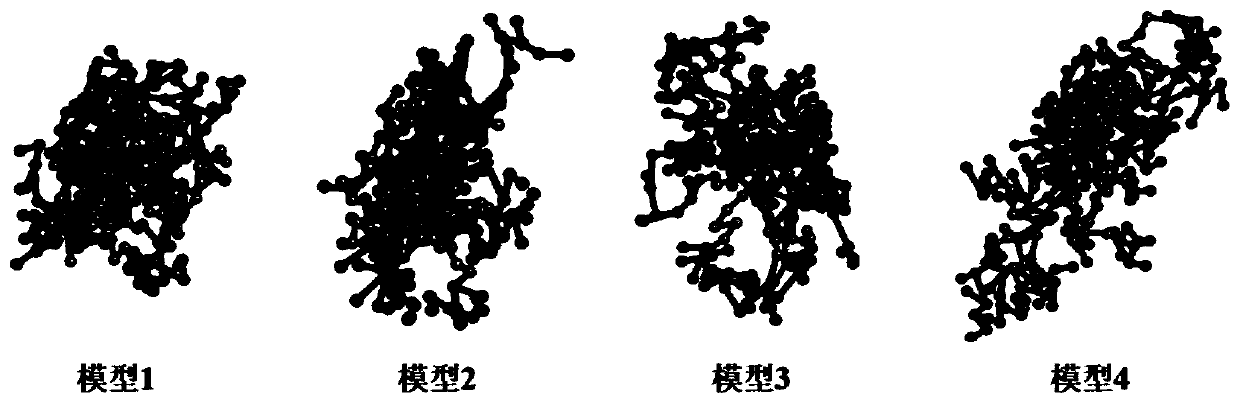

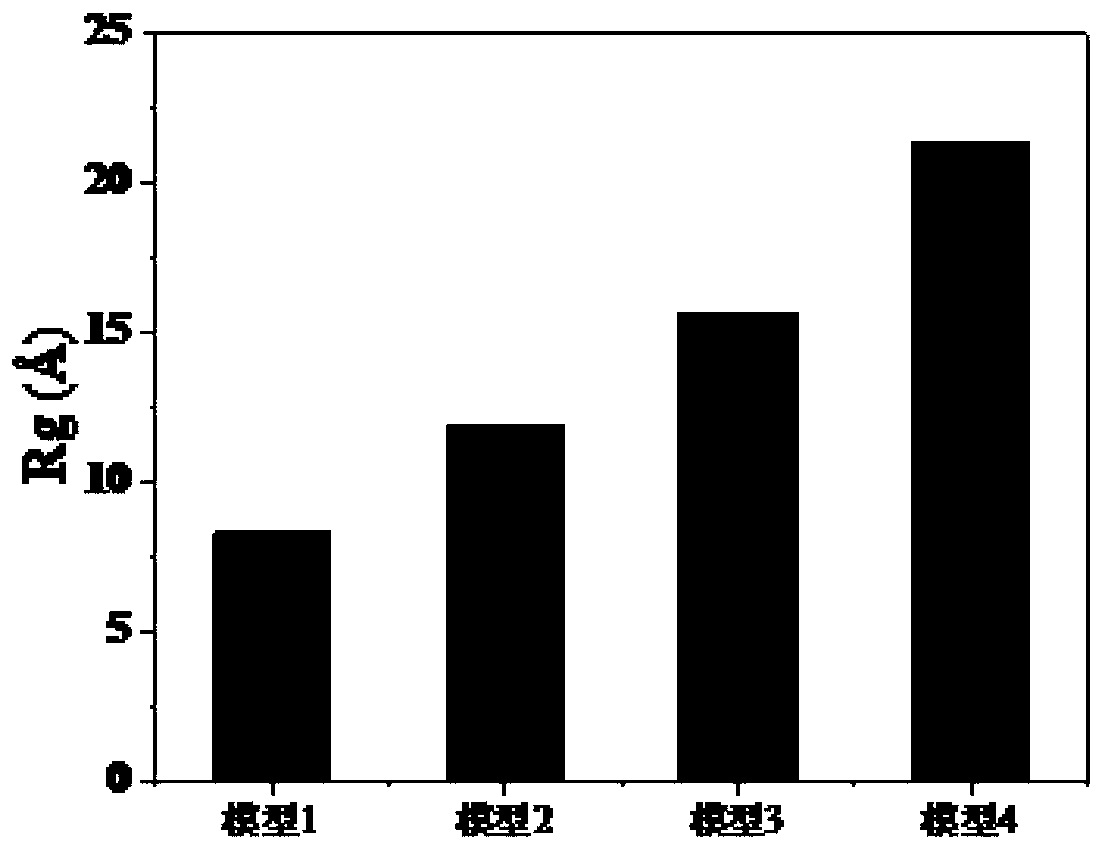

[0036] The present invention selects a rigid cellulose nanocrystal polymer brush (CNC-g-PCL-b-PDMAEMA) to simulate its self-assembly behavior in water.

[0037] The preparation steps of the cellulose nanocrystal polymer brush described in this implementation are as follows:

[0038](1) In a 100mL flask, weigh 1g of cellulose microcrystals and 15mL of sulfuric acid solution (64wt%), mix, stir and react at 35°C for 65min; 1 day until the pH of the distillate is stable at 5; afterward, use a Branson 450 sonicator to sonicate the product for 20 min at an amplitude of 60%, filter and freeze-dry at last, and the white powder obtained is cellulose nanocrystals ( CNC);

[0039] (2) The cellulose nanocrystals prepared in 0.5g step (1), 2gε-caprolactone, 0.02g Sn(Oct) 2 and 8mL of toluene were added to a 50mL dry eggplant-shaped bottle, put in a magnet, and after sealing, evacuate the argon three times; put the flask in an oil bath and heat it to 60°C and react at this temperature for...

Embodiment 2

[0078] The simulation method of self-assembly behavior of polyphenylene copolymer PS-b-P2VP-b-PEG in water, the preparation method of described PS-b-P2VP-b-PEG sees literature (Khanal A, Inoue Y, Yada M, et al. al. Synthesis of silicahollow nanoparticles templated by polymeric micelle with core-shell-coronastructure [J]. Journal of the American Chemical Society, 2007, 129 (6): 1534-1535). The specific steps of the simulation method are as follows:

[0079] (1) PS-b-P2VP-b-PEG polymer solution initial model construction;

[0080] Figure 5 (a) is a schematic diagram of PS-b-P2VP-b-PEG polymer coarse-grained structure and water coarse-grained structure, where PS-b-P2VP-b-PEG polymer and water coarse-grained structure are divided as follows : 1 polystyrene (PS) group for 1 PS bead, 1 poly 2-vinylpyridine group for 1 P2VP bead, 1 polyethylene glycol group for 1 PEG bead, 8 water The molecule is 1 W bead. Wherein the PS and P2VP groups are the rigid part of the polymer molecule...

Embodiment 3

[0099] The simulation method of the self-assembly behavior of the polypeptide copolymer PBLG-b-PEG in water, the specific steps are as follows:

[0100] The preparation method of the PBLG-b-PEG is shown in the literature (Li T, Lin J, Chen T, et al. Polymeric micelles formed by polypeptide graft copolymer and its mixtures with polypeptide block copolymer [J]. Polymer, 2006, 47 (13): 4485-4489).

[0101] (1) Initial model construction of PBLG-b-PEG polymer solution;

[0102] Figure 8 (a) is a schematic diagram of the coarse-grained structure of the polypeptide copolymer PBLG-b-PEG and the coarse-grained structure of water, wherein the division of the PBLG-b-PEG molecule and the coarse-grained structure of water is as follows: 1 polyglutamic acid Benzyl ester groups make 1 PBLG bead, 3 polyethylene glycol groups make 1 PEG bead, and 9 water molecules make 1 W bead. Wherein the PBLG group is the rigid part of the polymer molecule;

[0103] Use the Mesomolecule tool in the Ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com