Annealing system for multi-strand superfine copper wires and annealing method of annealing system for multi-strand superfine copper wires

A copper wire and annealing technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of ultra-fine copper wire processing speed and production capacity constraints, weak oxidation resistance of ultra-fine copper wire, etc., to shorten the production cycle, improve Annealing quality, the effect of faster drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

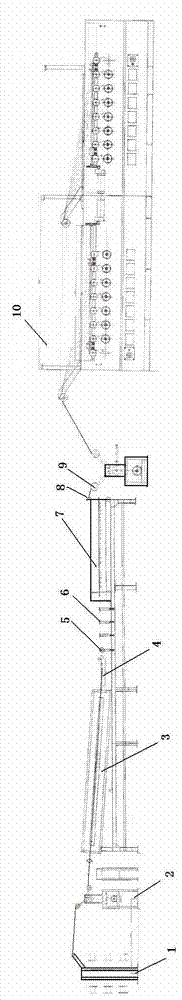

[0022] A multi-strand ultra-fine copper wire annealing system, including from front to back: pay-off rack 1, first fixed speed wheel 2, first oven 3, water tank 4, high-pressure spray gun 5, felt 6, second oven 7, cooling Gas blowing tank 8, second fixed speed wheel 9, take-up reel 10; the air outlet of the cooling gas blowing tank is located at the outlet of the second oven; the first oven is provided with 10 pipelines, and the pipelines are stacked vertically .

[0023] Use the multi-strand ultra-fine copper wire annealing method of above-mentioned multi-strand ultra-fine copper wire annealing system, concrete method is as follows:

[0024] (A) The copper wire with a diameter of 0.03mm released from the pay-off frame enters the first oven after being fixed by the first fixed speed wheel. The copper wire is baked with 400°C steam in the first oven. The length is 4m;

[0025] (B) The copper wire baked in the first oven enters the water tank, and the water in the water tank i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com