Forming equipment capable of adjusting glass substrate thickness distribution uniformity and method for adjusting glass substrate thickness distribution uniformity by adopting forming equipment

A technology for forming equipment and thickness distribution, which is applied in the field of forming equipment that can adjust the uniformity of thickness distribution of glass plates. It can solve the problem that the thickness is too thick and cannot be thinned, and achieve the effect of adjusting the uniformity of thickness distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

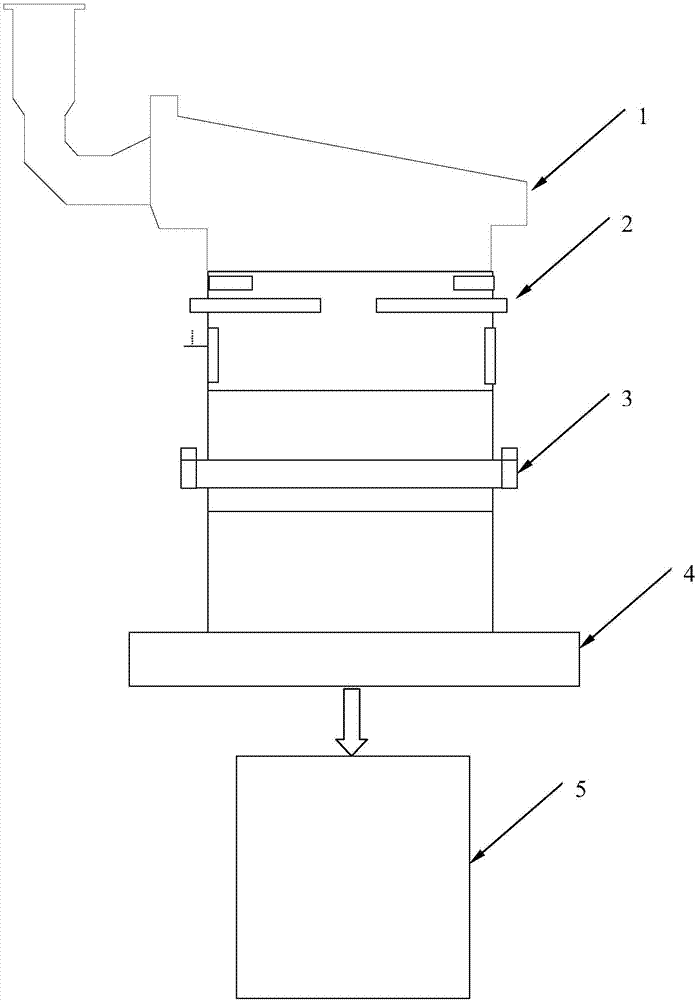

[0034] In the production process of the existing flat glass produced by the overflow down-draw method, the molten glass flows into the overflow tank 1 through the feed pipe, and flows out from both sides of the tank after the overflow tank 1 is full, and fuses at the tip of the overflow tank 1 Together, a glass sheet is formed which is drawn down by pulling rolls 3 and a cutting device 4 cuts the drawn glass sheet into individual sheet-like glass sheets 5 . Due to reasons such as the process, the thickness of the glass fluctuates to a certain extent in the width direction of the glass plate.

[0035] In order to adjust the thickness distribution uniformity of the glass plate, such as figure 1 As shown, a cooling socket is provided on the side wall of the molding device, and a cooling insert 2 is arranged in the cooling socket. The cooling insert 2 is located between the overflow device 1 and the pulling roller assembly 3, and is placed close to but not in contact with the glas...

Embodiment 2

[0045] Embodiments of the cooling cannula are described in detail below.

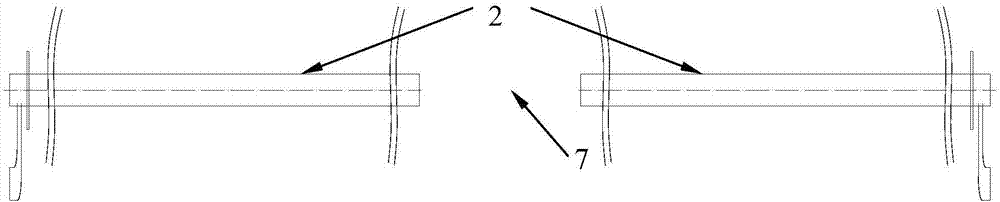

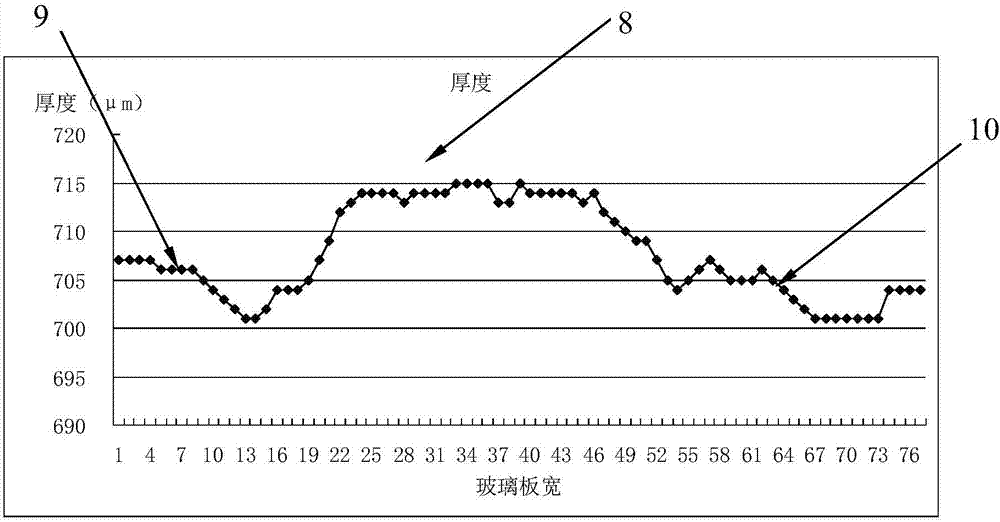

[0046] refer to figure 2 and image 3 , which shows the relationship between the cooling insert 2 and the glass thickness when using the cooling insert to adjust the glass thickness. The intubation tube is a circular rod body with a uniform diameter cooling section, the length of the intubation tube is less than half of the width of the molding equipment, and the cooling intubation tube 2 is inserted from both ends of the molding equipment, and the insertion depth can be adjusted freely. During operation, a cooling liquid (such as water) flows through the cooling insert 2 and absorbs the heat emitted from the glass sheet through the surface of the rod body, and the cooling liquid removes heat from the area of the glass sheet in the forming apparatus. When the thickness of the glass sheet varies with the width of the windshield sheet as image 3 When shown, that is, the thickness on both sides of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com