Section-color bamboo joint filament fabric

A technology of slub yarn and segment color, applied in the direction of filament/thread forming, single-component polyester rayon, textile, etc., it can solve the problem that the roving is difficult to achieve synchronization, drafting at the same point, and can not meet the occasional The requirements for yarns used in color fabrics, the restrictions on the wide application of colored yarns, etc., can achieve good market promotion value, good economic value, and improve the effect of strengthening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A segmented color slub fabric, which is prepared by spinning segmental color slub yarn, the preparation steps of the segmental color slub fabric include: preparing segmental color slub yarn, yarn spinning, weaving, finishing; the segmental color slub yarn The preparation method comprises the following steps:

[0046] (1) Drying of polyester slices, hot air drying of polyester slices and color masterbatch respectively; the drying process can also include a pre-crystallization process;

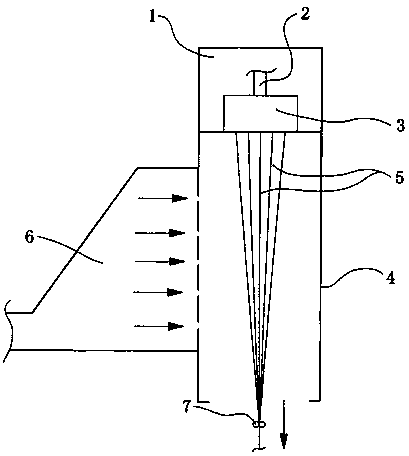

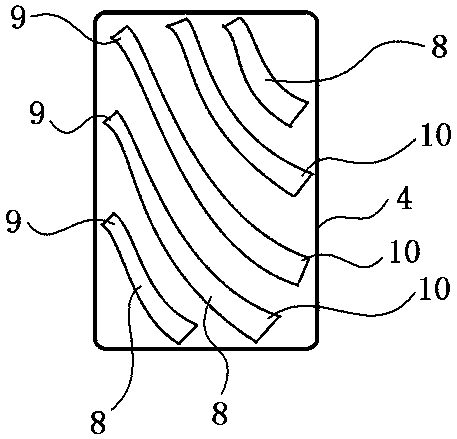

[0047] (2) The polymer slices and masterbatches are mixed in proportion and sent to the screw extruder. The screw extruder is divided into six zones. The first two zones are the feeding section, the middle two zones are the compression section, and the last two zones are the metering section. Mixing section: concave-convex anti-adhesion mechanisms are provided on the surface in contact with the polymer melt inside the screw extruder, and the concave-convex anti-adhesion structures are eve...

Embodiment 2

[0062] Adopt semi-dull polyester chip to prepare yarn and fabric as spinning raw material, its concrete implementation process is identical with embodiment 1, concrete parameter is:

[0063] The temperature during spinning is 250 degrees Celsius, the initial pressure during spinning is 16mpa, and the density of spinneret holes is 3 holes / cm 2 , the diameter of the spinneret hole is 0.35mm, the wind speed of side blowing is 0.6m / s, and the range of wind speed fluctuation is ±0.6m / s.

[0064] According to actual needs, the specification of the single-ply yarn is 20s, and the specification of the double-ply yarn is 20 / 2s.

[0065] The finishing solution includes 10wt% of modified nitrile emulsion, 10wt% of phosphates, 6wt% of nano-silver, and the balance is water.

[0066] In order to improve the appearance of the fabric, calendering and singeing are also included after drying and setting. The calendering temperature is 190°C, the speed is 5m / min, the singeing speed is 15m / min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com