Rolling Strengthening Method for Engine Crankshaft Fillet

An engine and fillet technology, which is applied in the field of engine crankshafts, can solve problems such as crankshaft fatigue failure, and achieve the effects of increased strengthening, simple processing, and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

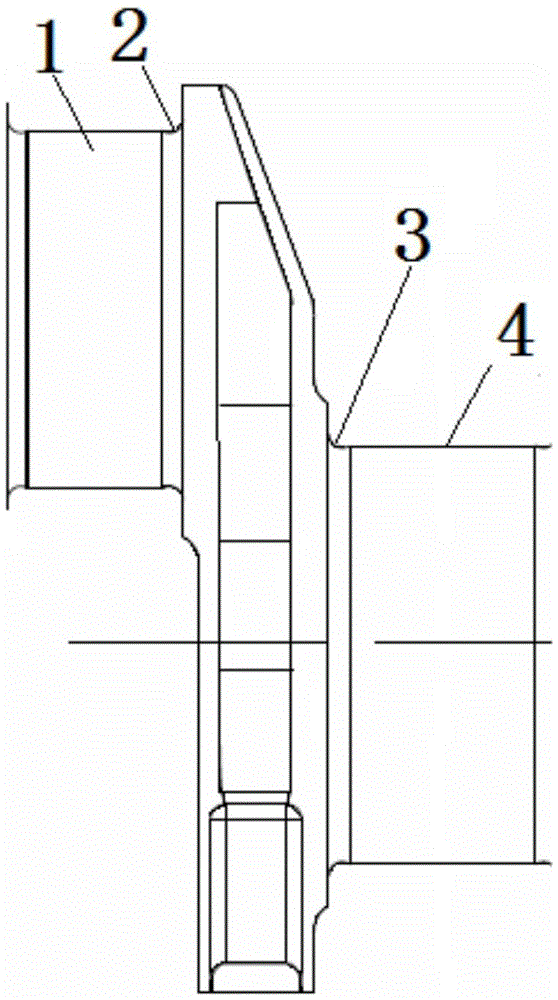

[0029] Such as figure 1 with figure 2 As shown, the crankshaft fillets where crankshaft fracture is likely to occur are the connecting rod journal fillet 2 at the connecting rod journal 1 and the main journal fillet 3 at the main journal 4 respectively.

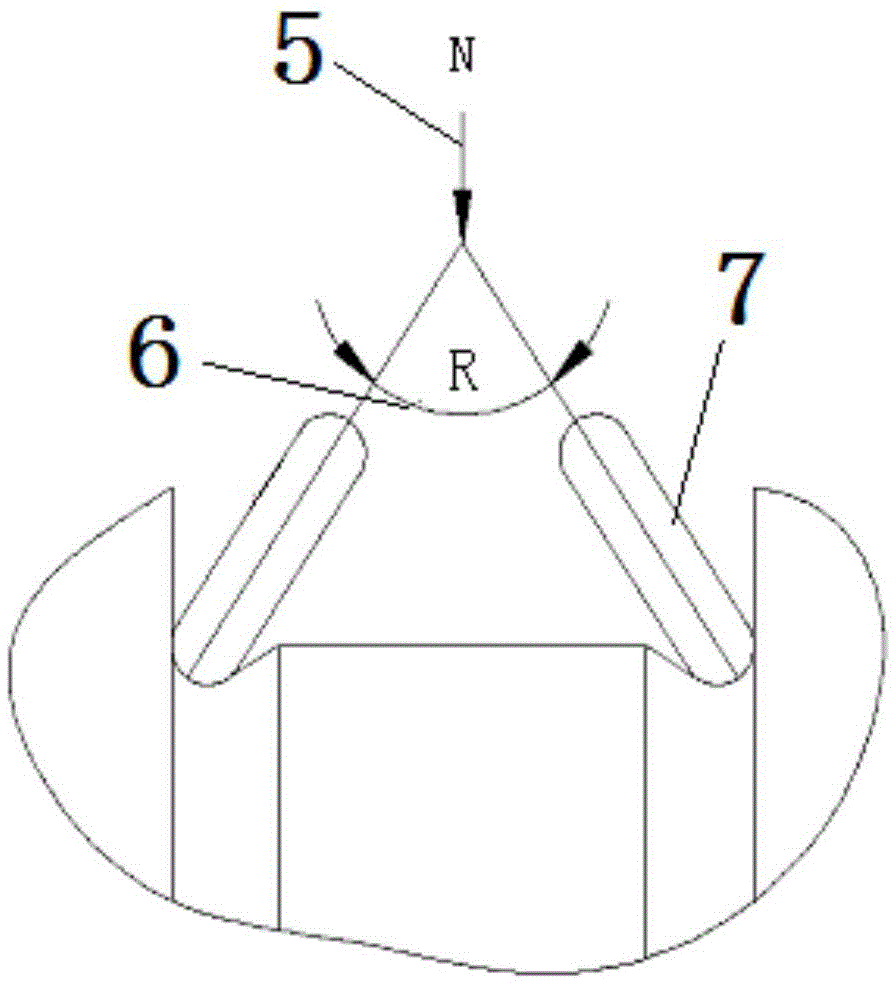

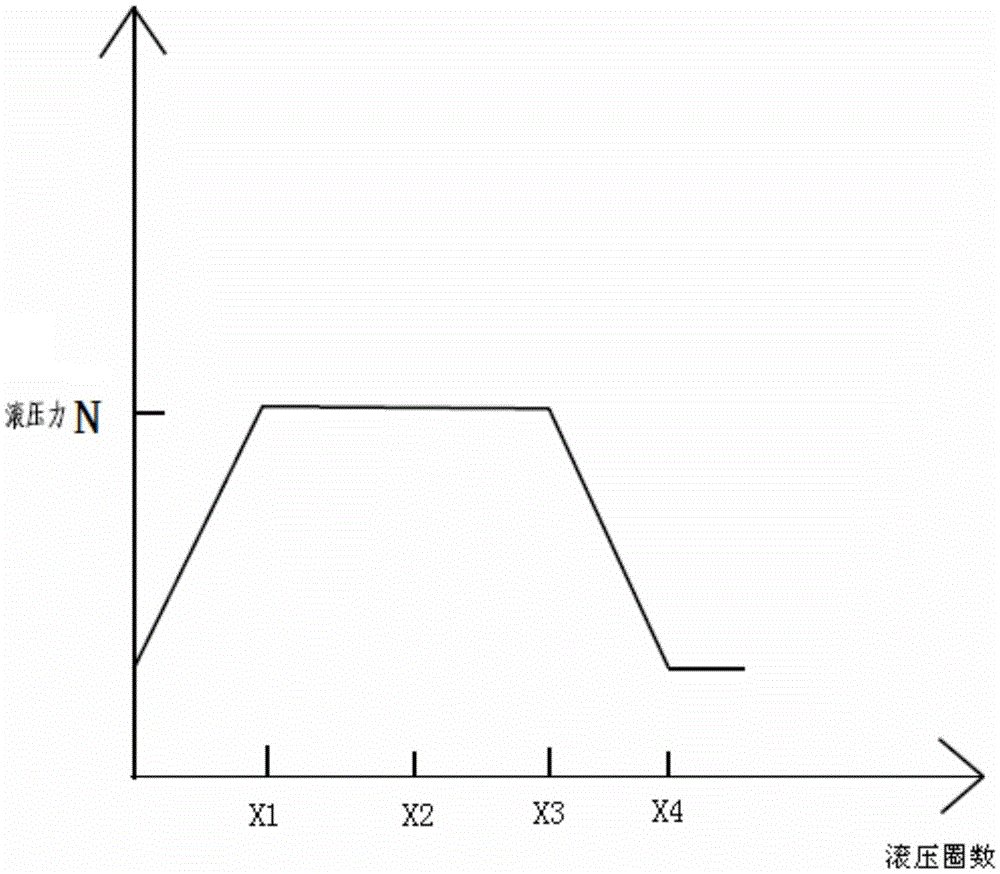

[0030] The engine crankshaft fillet rolling strengthening method uses a rolling head 7 to perform rolling strengthening processing of the crankshaft fillet, and the rolling head 7 is connected to a power source, including the following steps;

[0031] (1) Build the engine crankshaft model on the computer; specifically: different engine specifications, different engine crankshafts; according to the specific engine crankshaft, use computer modeling software to input the length, width, height and height of each section of the engine cranksh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com