Steel wrapper feed frame device

A technology for feeding racks and ladles, which is applied in the directions of transportation and packaging, thin material handling, winding strips, etc., and can solve the problems of easy stretching of materials, poor lamination accuracy, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

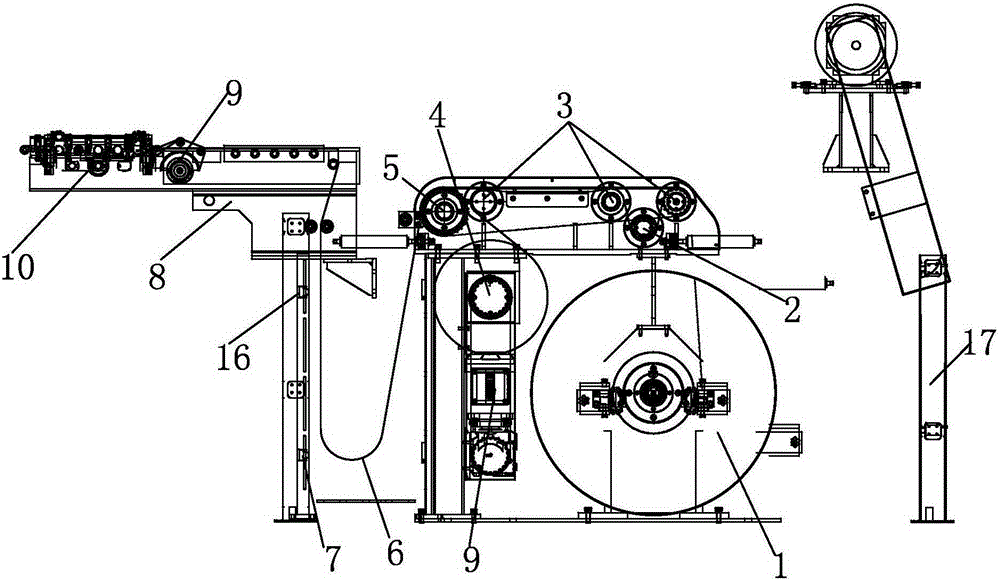

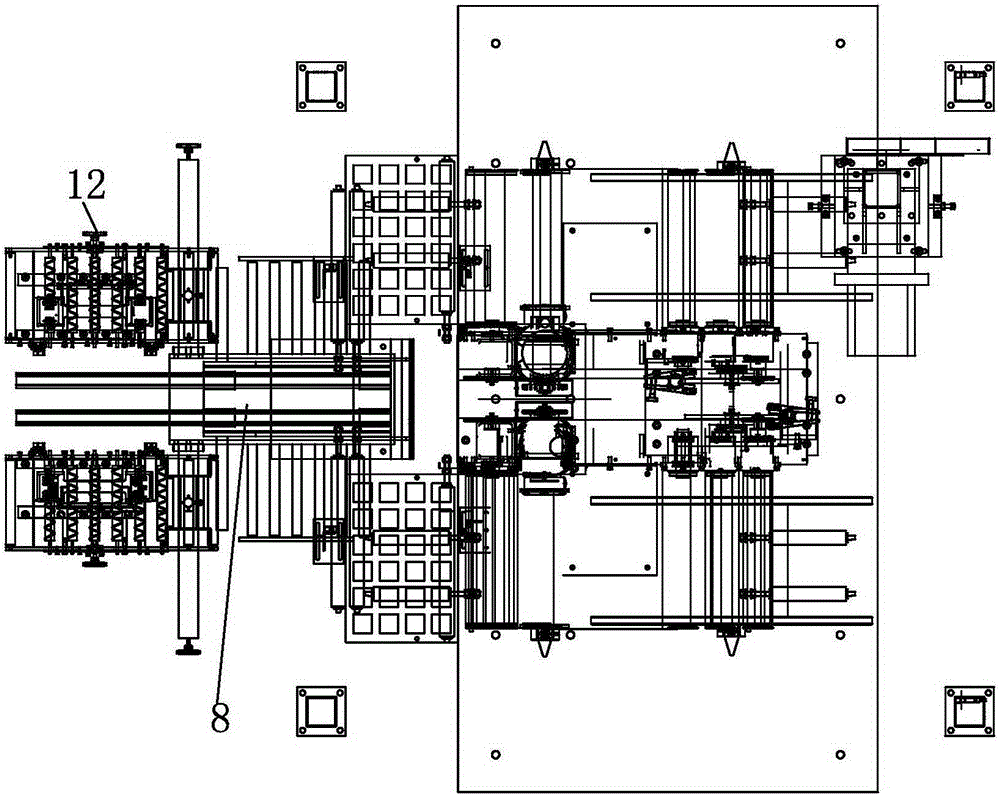

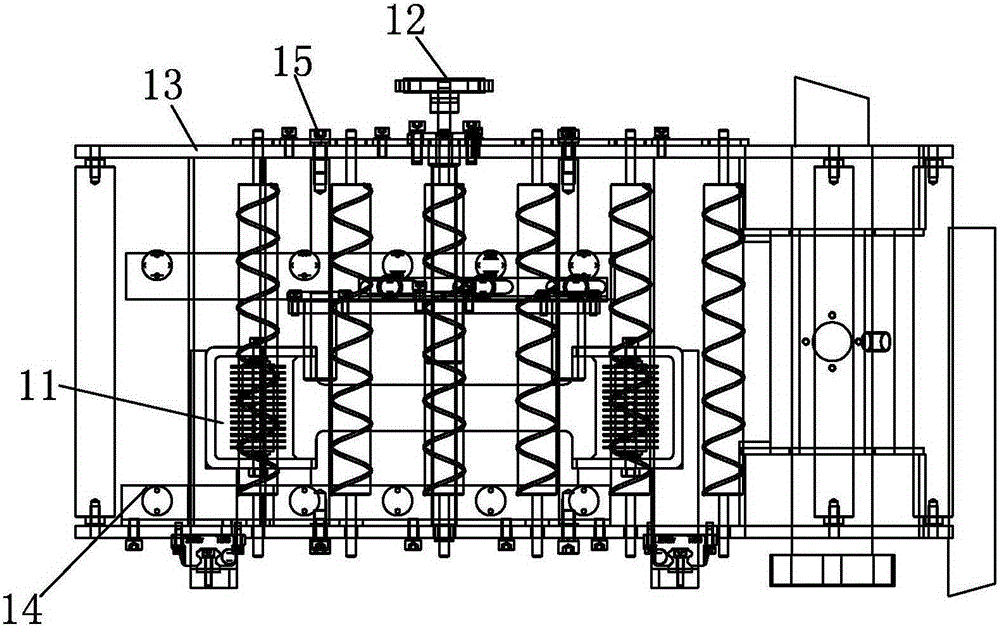

[0023] Such as Figure 1-3 As shown, a ladle feeding rack device includes a material guide mechanism, a material conveying mechanism and a deviation correction mechanism. The material guide mechanism includes an I-shaped wheel 1, and a first support rod is arranged in front of the I-shaped wheel 1, and the I-shaped wheel 1 is provided with a support plate, the end surface of the support plate is provided with the first conveying roller 2 and the second conveying roller 3, and the side of the first support rod close to the I-shaped wheel 1 is provided with a guide motor 9 and a guide motor reducer 4. The material conveying mechanism includes a cloth storage pocket 6, one end of the cloth storage pocket 6 is connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com