Heat-expandable microcapsules, production method therefor, and foamed molded article

A heat-expandable microcapsule technology, applied in the field of heat-expandable microcapsules, can solve problems such as increased expansion rate and achieve the effect of easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0123] Hereinafter, the present invention will be described in more detail with reference to examples, but the present invention is not limited thereto.

[0124]

[0125]

[0126] To 198 g of ion-exchanged water, 12.5 g of a silica sol aqueous dispersion (trade name "SNOWTEX-O", manufactured by Nissan Chemical Industries, Ltd.), 0.075 g of polyvinylpyrrolidone, and 52 g of sodium chloride were added with a solid content of 20% by mass. It mixed and added 36 mass % of hydrochloric acid so that pH might become 3.0, and adjusted the aqueous dispersion medium.

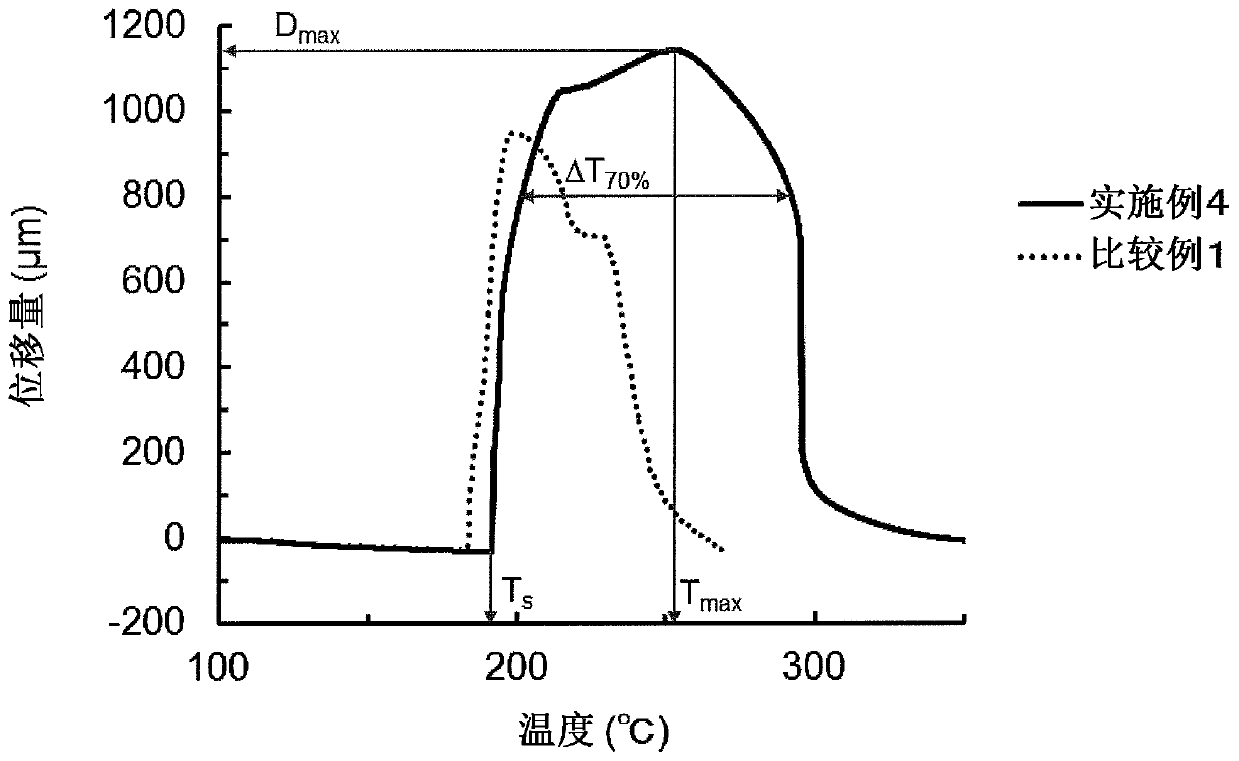

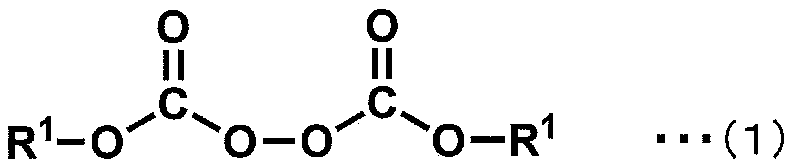

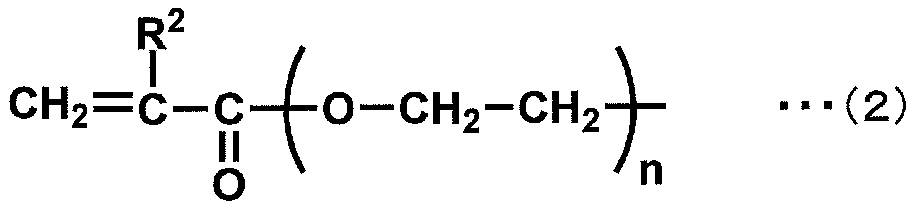

[0127] On the other hand, 20.0 g of acrylonitrile, 19.2 g of methacrylonitrile, 10.9 g of methacrylic acid (mass ratio: acrylonitrile / methacrylonitrile / methacrylic acid=40 / 38 / 22), 15.0 g of isooctane (30 parts by mass relative to 100 parts by mass of the monomer mixture) as a volatile substance, bis(2-methacryloxyethyl) as an organic peroxide represented by general formula (1) base) 3.26 g of peroxydicarbonate (purity...

Embodiment 2~7 and comparative example 1~7

[0132] Thermally expandable microcapsules were produced in the same manner as in Example 1, except that the various components constituting the oily liquid mixture used in Example 1, their amounts, and polymerization temperature were changed to those shown in Table 1. In addition, a polymerization initiator and the organic peroxide represented by the general formula (1) are used together, or a polymerization initiator is used instead of the organic peroxide represented by the general formula (1). The usage-amount of the organic peroxide represented by General formula (1) and a polymerization initiator shows the net amount except a diluent. Table 1 shows the results of evaluating various physical properties of the obtained heat-expandable microcapsules.

[0133]

[0134] In Table 1, DPHA represents a mixture of dipentaerythritol pentaacrylate and dipentaerythritol hexaacrylate (Sigma-Aldrich reagent);

[0135] TMPTA means trimethylolpropane triacrylate (Tokyo Chemical Indus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com