High-strength high-conductivity enameled copper alloy wire

A copper alloy wire, enameled copper technology, applied in the direction of metal/alloy conductors, conductors, insulated conductors, etc., can solve the problems of softening and deformation of conductors, high-pressure hot stamping deformation, easy to be thinned, etc., to achieve high electrical conductivity, good Good stability and windability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

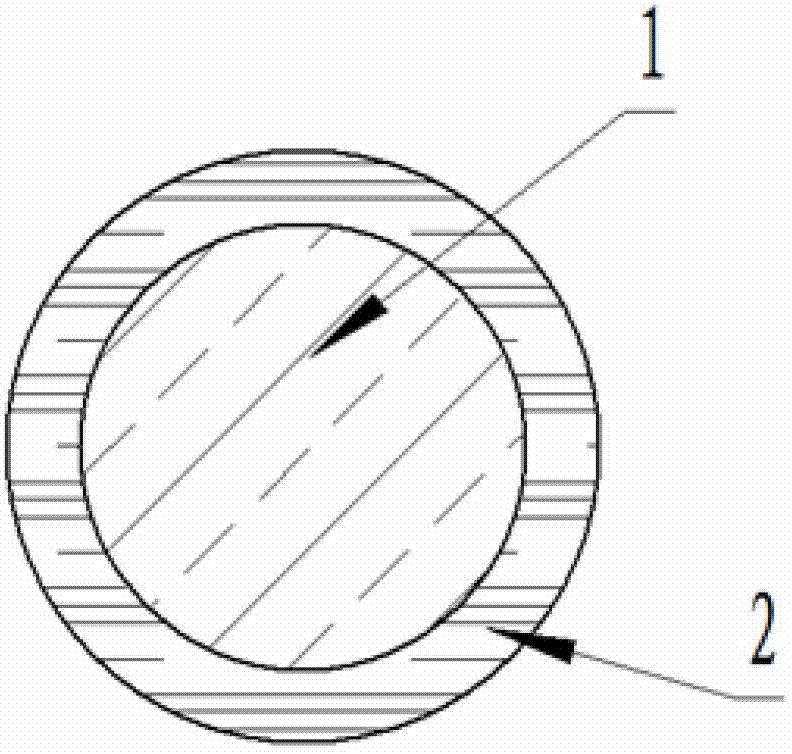

[0015] refer to figure 1 , high-strength and high-conductivity enamelled copper alloy wire, including a conductor layer 1 and an insulating layer 2 coated outside the conductor layer, the conductor layer 1 is a copper alloy wire made of copper-magnesium, copper-silver or copper-chromium-zirconium alloy materials .

[0016] Further, the magnesium content in the copper-magnesium alloy is 0.1-0.35 mass %; the silver content in the copper-silver alloy is 0.6-2.0 mass %; the chromium content in the copper-chromium-zirconium alloy is 0.3 mass %, and the zirconium content is 0.1-0.3 mass %.

[0017] The invention does not soften under high-temperature environment, does not deform and shrink after being subjected to high-pressure thermal shock, and does not elongate the enameled wire during the winding process of electrical appliances, ensuring that the resistivity of the enameled wire is controlled, so that electrical appliances can obtain better stability. The invention is particu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com