Ripening technology and ripening device in fine dried noodle production

A curing and crafting technology, applied in dough processing, baking, food preparation, etc., can solve the problems of unstable steam, difficult operation and control, complicated device structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

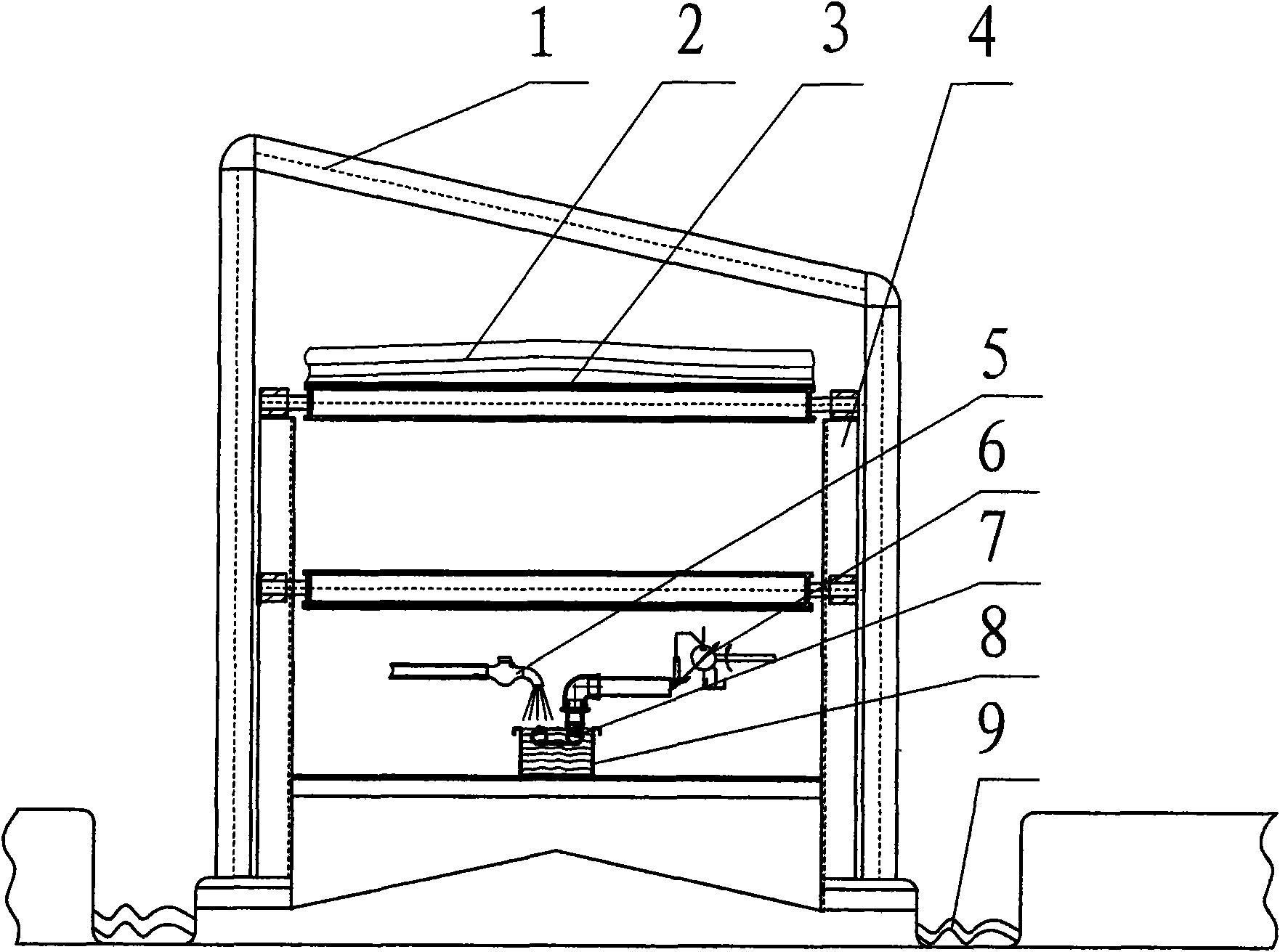

[0020] A curing process in the production of fine dried noodles, which puts the dough sheet 2 compositely pressed by a dough mixer and a compound calender into a heat-preserving and moisturizing cover 1 for curing, and during the curing process, the time is controlled within 15 minutes to 25 minutes (this The embodiment is 20 minutes), the temperature is controlled at 25°C-32°C (32°C in this embodiment), and the relative humidity is controlled at 80%-90% (85% in this embodiment).

[0021] As can be seen from the accompanying drawings, a curing device using the above-mentioned curing process includes a transfer device connecting the compound calender and the continuous calender. The cover 1 is provided with a heating and humidifying device.

[0022] The conveying device of the present invention is the power installed on the frame 4, idler rollers and conveyor belt 3.

[0023] The heating and humidifying device of the present invention is a water tank 8 arranged on the frame 4,...

Embodiment 2

[0030] For making the curing effect of dough sheet 2 good and to the control of curing process, the curing process of the present invention is divided into:

[0031] (1) The beginning section of curing, the time is controlled at 3 minutes-8 minutes (5 minutes in this embodiment), the temperature is controlled at 25°C-30°C (30°C in this embodiment), and the relative humidity is controlled at 80%-85% (80% in this example). After the flour is kneaded by a dough mixer, it is pressed into a dough sheet 2 by a compound calender. The water content of the dough sheet 2 is generally about 30%, and the gluten network structure is relatively evacuated. The water content of sheet 2 after this section of ripening is about 31%, and the gluten network organization at this time is preliminarily formed, but has no elasticity, and is easy to be broken.

[0032] (2) The middle section of aging, the time is controlled at 8 minutes-15 minutes (12 minutes in this embodiment), the temperature is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com