Curing barn structure with adjustable volume and use method thereof

A technology of curing room and capacity, applied in the application and preparation of tobacco, tobacco and other directions, can solve the problems of insufficient maturity of tobacco leaves, large workload, energy waste, etc., and achieve the effect of improving the quality of flue-cured tobacco and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

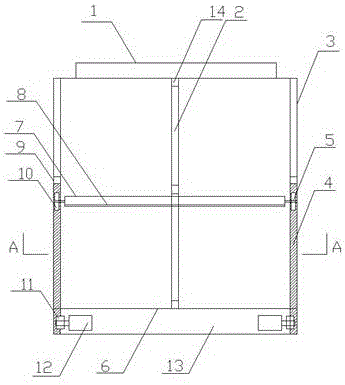

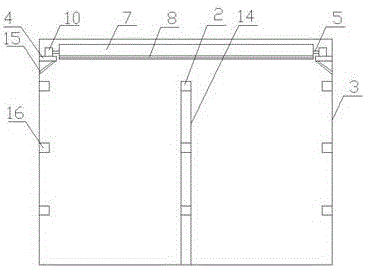

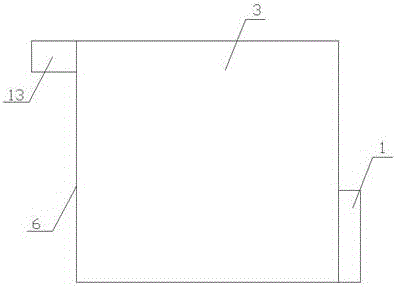

[0084] The present invention will be described below in conjunction with the accompanying drawings. Such as Figure 1-6 as shown, figure 1 It is a structural schematic diagram of the barn in the top view direction of the present invention. figure 2 for figure 1 Sectional schematic of part A-A. image 3 It is a structural schematic diagram of the side view direction of the barn of the present invention. Figure 4 It is a schematic diagram of the state after the thermal insulation curtain of the present invention hangs down. Figure 5 It is a schematic diagram of the state of the thermal insulation curtain of the present invention after it is hung down and both sides are unfolded. Figure 6 It is a structural schematic diagram of the elastic clip of the present invention.

[0085] The invention includes a barn 3, the rear of the barn 3 is fixedly equipped with a heating and ventilation system 1, the front hinge of the barn 3 is connected with a door 6, and the two sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com