Additive and subtractive compound manufacturing equipment

A technology for manufacturing equipment and adding and subtracting materials, applied in the field of 3D printing, can solve the problems of unprintable substrate temperature control, increase the cost of tool use, and affect the service life of the tool, and achieve diversification of printing methods, prolong service life, and reduce long-term use. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

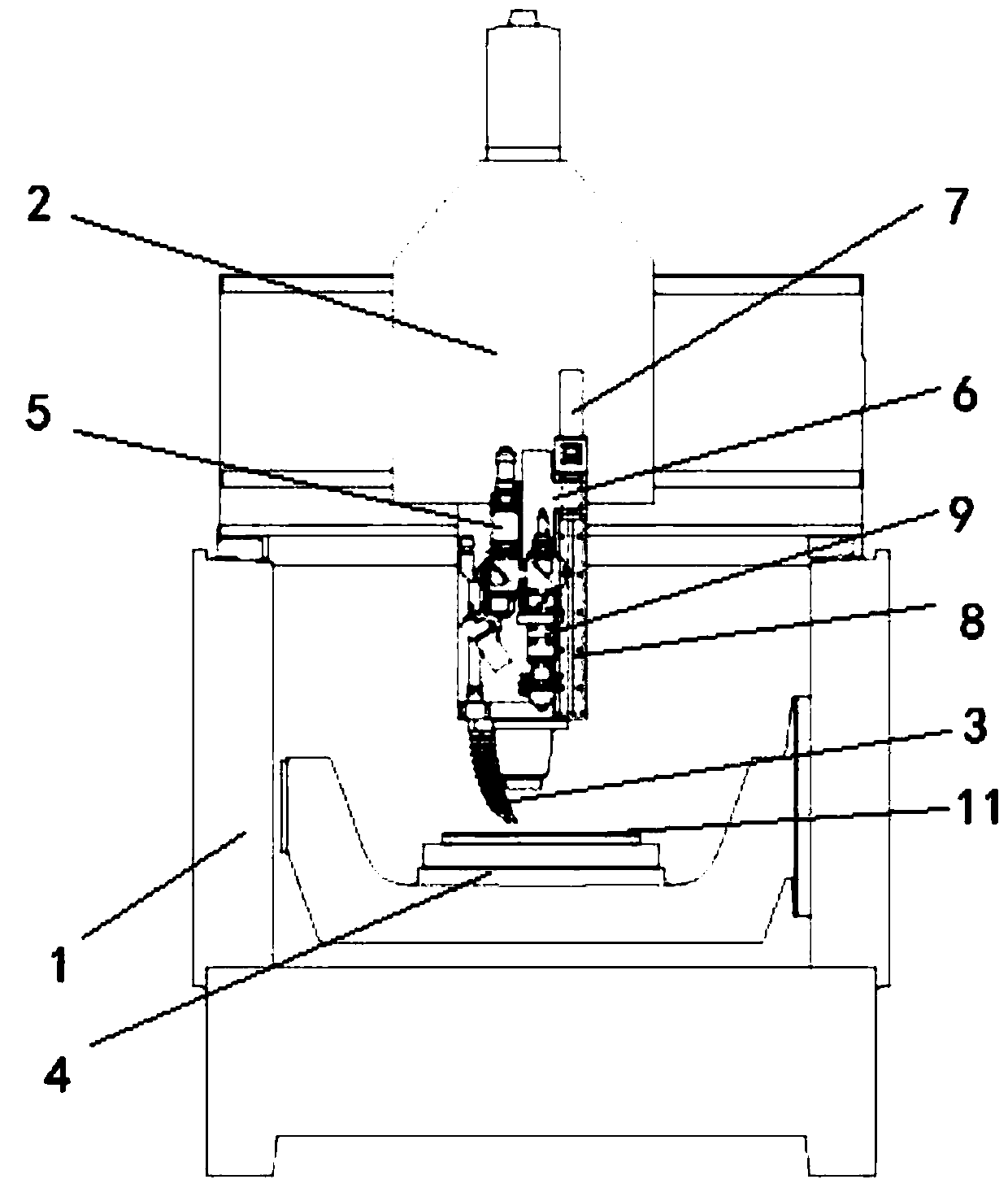

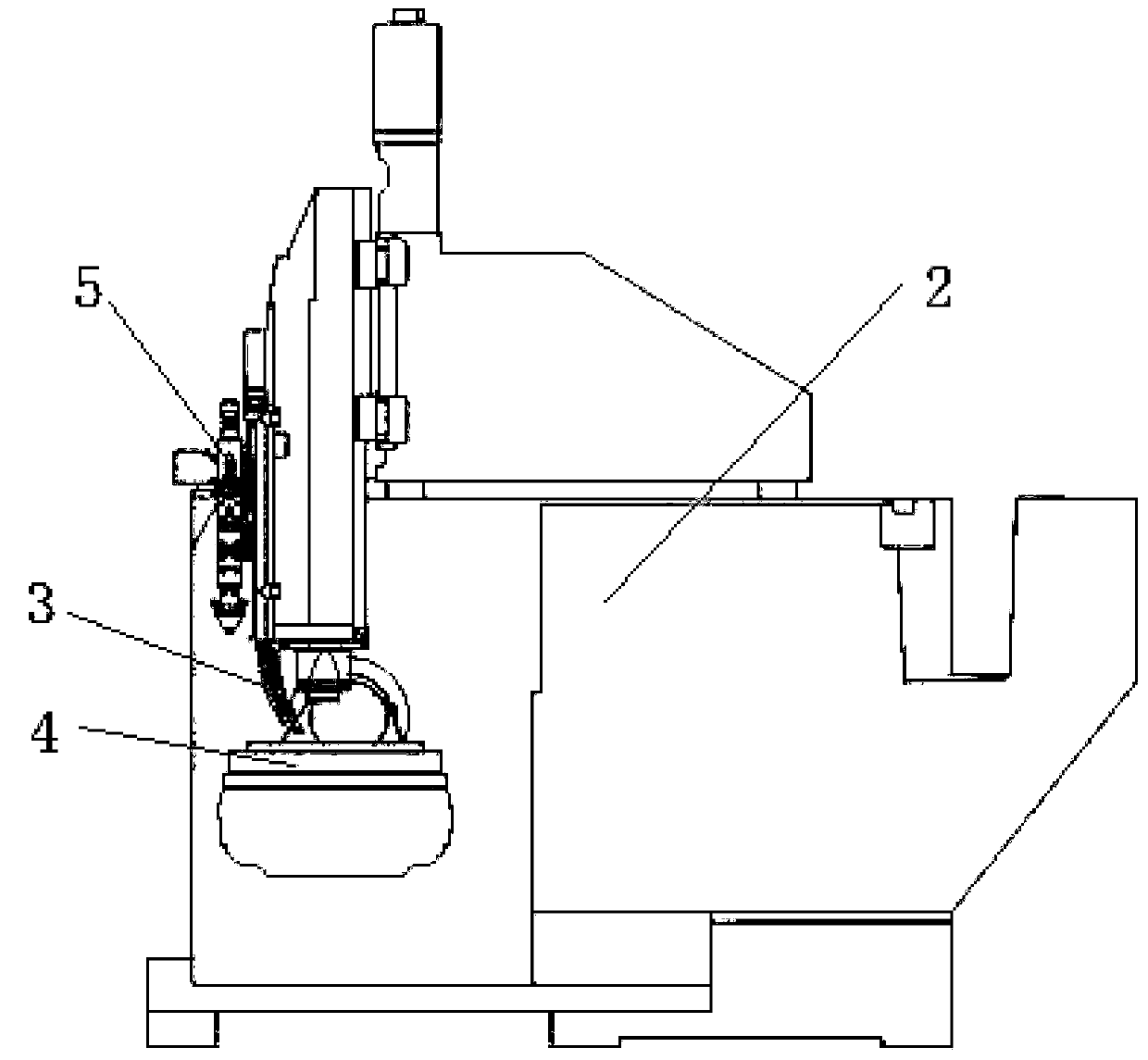

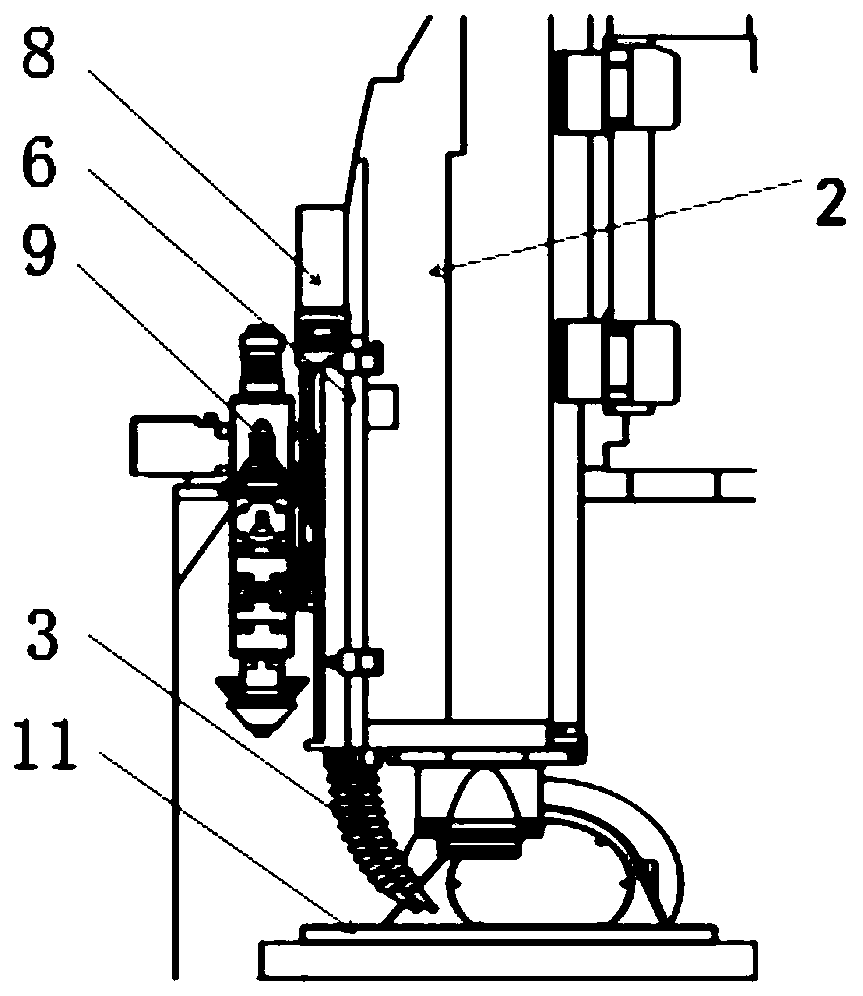

[0040] see Figure 1-3 As shown, the equipment includes a machining center 1, an additive forming component 5 and a cooling nozzle 3;

[0041] The additive forming component 5 includes a connecting plate 6, a motor 7, a linear motion linear module 8 and an energy deposition metal additive forming device (a laser cladding head 9 is used in this embodiment);

[0042] The linear motion linear module 8 is fixed on the spindle box 2 of the machining center 1, and the linear motion linear module 8 is slidably connected to the connection plate 6; the laser cladding head 9 is fixedly installed on the connection plate 6; the motor 7 moves to the linear motion linear module 8 provides power so that the connecting plate drives the laser cladding head 9 to move up and down; the purpose of this design is to separate the up and down movement of the laser cladding head 9 from the up and down movement of the main shaft. The upper linear motion linear module 8 lowers the laser cladding head 9...

Embodiment 2

[0050] In order to quickly adjust the atmosphere environment in the process of adding and subtracting materials in real time, avoid the influence on the atmosphere in the process of adding and subtracting materials, and effectively ensure the processing quality of parts, the invention also provides an increasing Subtractive composite manufacturing equipment.

[0051] Such as Figure 6 As shown, the atmosphere regulating cycle device includes a first sealed box 16, a second sealed box 17, an inert gas source 18 and a purification unit 19;

[0052] The first sealed box 16 communicates with the second sealed box 17 through a first pipeline 20 and a second pipeline 21;

[0053] The first sealed box 16 and the second sealed box 17 need to be designed in an environment close to anhydrous and oxygen-free according to the characteristics of different materials in the printing process, and can directly print various metal materials such as titanium alloys, avoiding water in the printi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com