Logistics turning transfer system

A technology for goods and lateral transportation, applied in the field of logistics systems, can solve the problems of difficulty in guaranteeing the stability of the change-of-direction transfer, complicated structure of the change-of-direction transfer system, influence on the service life of the drive chain, etc. , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

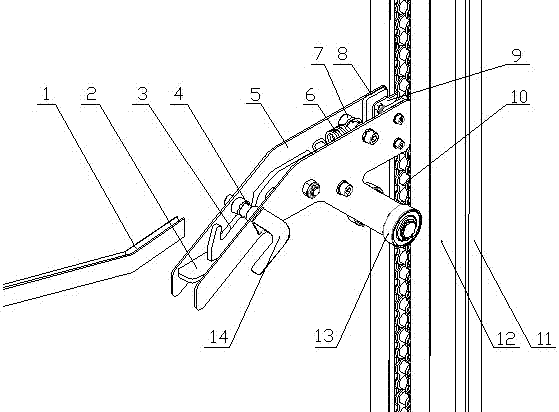

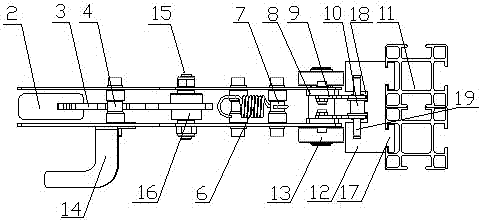

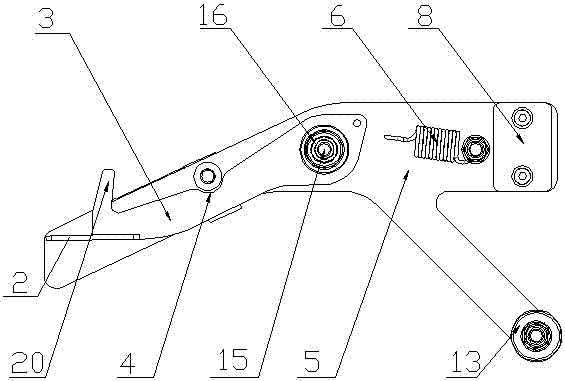

[0022] As shown in the figure, this logistics direction transfer system is used to be installed between the vertical conveying device and the lateral conveying device to realize the transfer of goods from the vertical conveying device to the lateral conveying device. The structure of the transfer system includes several delivery racks. The vertical conveying device includes a column 11, and a closed driving chain 10 is arranged on the outer periphery of the column 11, and the inner end of the delivery rack is fixed on the driving chain 10.

[0023] This transfer system is used to classify and transfer goods to corresponding areas. Before the goods are transferred, they need to be classified and packaged, that is, similar goods are packaged together, and hooks are set on the packaged goods. A hinged rod 3 is hinged on the delivery rack, and a movable bayonet for clamping cargo hooks is formed between the hinged rod 3 and the delivery rack. When loading goods at a low position, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com