Methyl orange flow linear parallel control equipment

A technology of parallel control and orange flow, which is applied in the direction of analyzing materials through chemical reactions and analyzing materials through observing the influence of chemical indicators. It can solve the problems of low control precision and high labor intensity, and achieve control precision. High, reduce labor intensity, good movement stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

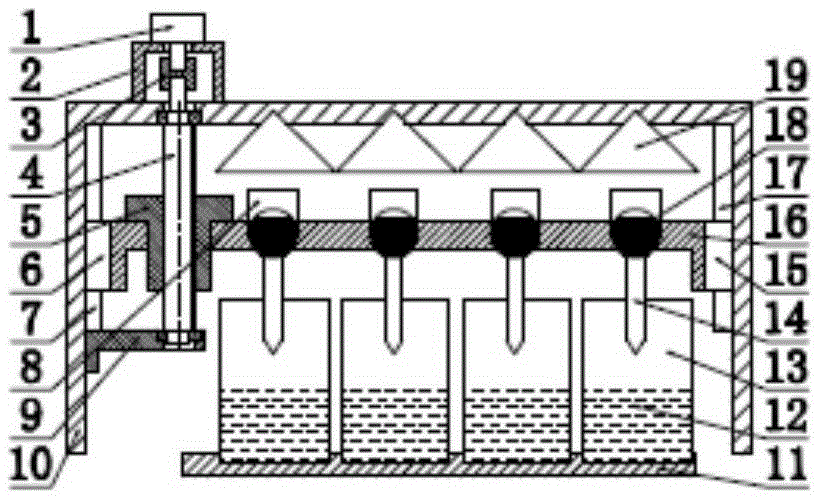

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0012] see figure 1 As shown, a methyl orange flow linear parallel control device of the present invention includes a U-shaped frame 10, a motor frame 2 installed on the U-shaped frame 10, a screw frame 9, a first guide rail 7 and a second guide rail 17 , the motor 1 installed on the motor frame 2, the first slider 6 installed on the first guide rail 7, the second slider 15 installed on the second guide rail 17, and one end installed on the U-shaped frame 10 The upper and the other end are installed on the leading screw 4 on the leading screw frame 9, the nut 5 installed on the leading screw 4, the lifting plate 16 installed on the nut 5 and connected to the two sliders at both ends respectively, Four cameras 19 arranged on the U-shaped frame 10 in a straight line along the X-axis direction, four manipulators 8 arranged on the liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com