Process for producing lees-burnt baijiu by using first-stage yellow wine lees

A technology of rice distiller's grains and white wine, which is applied in the field of wine making. It can solve the problems of no digestion of distiller's grains, low added value of products, waste of starchy raw materials, etc., and achieve the effect of low fusel oil, light after-bitterness and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

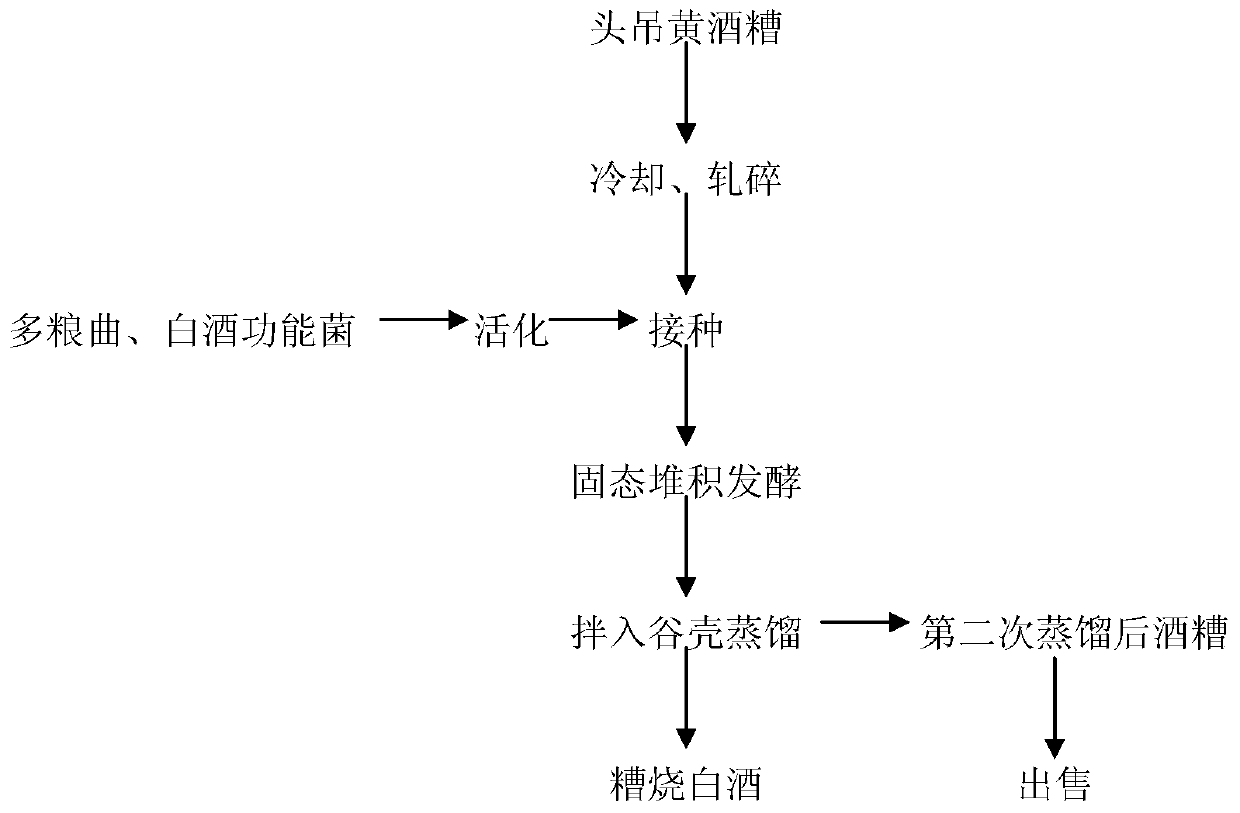

Method used

Image

Examples

Embodiment 1

[0026] A process for producing distiller's distiller's distiller's grains from the first hanging distiller's grains. The main conditions are that the inoculation amount of Angel Yeast Co., Ltd.'s multi-grain distiller's koji is 0.4%, and the inoculation amount of Angel Yeast Co., Ltd.'s "Xiangba" liquor functional bacteria is 0.1% %. The final distilled liquor yield is about 7.5% (converted into 50% vol of alcohol), the total ester (calculated as ethyl acetate) is 1.23g / L, and the fusel oil (calculated as isobutanol+isoamyl alcohol) is 662mg / L, typical wine style, soft and sweet taste, light aftertaste.

[0027] A kind of technology of the present invention utilizes distiller's grains to produce distiller's grains, comprising the following steps:

[0028] ①Cooling and crushing: Cool the distiller's grains after the head hanging to 28°C, and crush the distiller's grains with a grain rolling machine without large lumps.

[0029] ②Activation: According to the weight of rice di...

Embodiment 2

[0034] A process for producing distiller's distiller's distiller's grains from distillers' dregs. The main conditions are that the inoculation amount of multi-grain distiller's koji of Angel Yeast Co., Ltd. is 0.6%, and the inoculation amount of "Xiangba" liquor functional bacteria of Angel Yeast Co., Ltd. is 0.15% %. The final distilled liquor yield is about 8.7% (converted into 50% vol of alcohol), total ester (calculated as ethyl acetate) is 1.38g / L, and fusel oil (calculated as isobutanol+isoamyl alcohol) is 705mg / L, typical wine style, soft and sweet taste, light aftertaste.

[0035] A kind of technology of the present invention utilizes distiller's grains to produce distiller's grains, comprising the following steps:

[0036] ①Cooling and crushing: Cool the distiller's grains after the head hanging to 28°C, and crush the distiller's grains with a grain rolling machine without large lumps.

[0037] ②Activation: According to the weight of rice distiller's grains, accord...

Embodiment 3

[0042] A process for producing distiller's distiller's distiller's grains made from distiller's grains. The main conditions are that the inoculation amount of Angel Yeast Co., Ltd.'s multi-grain distiller's koji is 0.8%, and the inoculation amount of Angel Yeast Co., Ltd.'s "Xiangba" liquor functional bacteria is 0.2% %. The final distilled liquor yield is about 10% (converted into 50% vol of alcohol), the total ester (calculated as ethyl acetate) is 1.73g / L, and the fusel oil (calculated as isobutanol+isoamyl alcohol) is 765mg / L, typical wine style, soft and sweet taste, light aftertaste.

[0043] A kind of technology of the present invention utilizes distiller's grains to produce distiller's grains, comprising the following steps:

[0044] ①Cooling and crushing: Cool the distiller's grains after the head hanging to 28°C, and crush the distiller's grains with a grain rolling machine without large lumps.

[0045] ②Activation: According to the weight of rice distiller's grai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com