Method for reducing content of lignin in peduncle shred of tobacco

A technology of tobacco stems and lignin, applied in the directions of tobacco, tobacco processing, application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Example 1: Reducing Lignin Content in Tobacco Shredded Stems

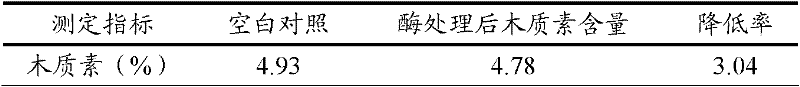

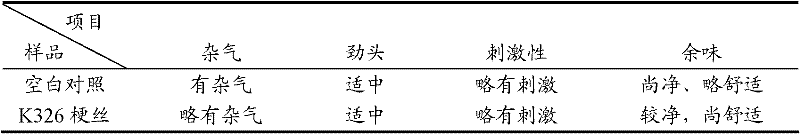

[0079] Take by weighing Yuxi K326 long cut tobacco stalk 30g, sterilize 3min under the condition of power 800-1200W in microwave oven, cool naturally, at room temperature 0.4% by weight lignin degradation compound enzyme aqueous solution (containing Lip, Mnp and Lac ) is sprayed on the surface of the cut tobacco stem raw material, the lignin-degrading compound enzyme is 3.0 g, mixed thoroughly and then placed in a constant temperature and humidity incubator for enzymolysis, and the enzymolysis time is 12 hours at an enzymolysis temperature of 30°C. At the same time, sterile distilled water was used as a control. After enzymatic hydrolysis, heat in a microwave oven at 800w power for 1min to inactivate the enzyme, air-dry naturally until the moisture content is 12% based on the total weight of the tobacco, and equilibrate at a temperature of 22°C and a relative humidity of 60% for 48h. The method described in...

Embodiment 2

[0084] Embodiment 2: Reducing the lignin content in cut tobacco stems

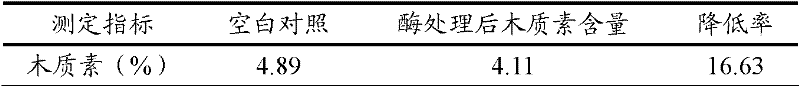

[0085] Weigh 30g of Yuxi K326 long cut tobacco stems, sterilize for 3min under the condition of power 1200W in a microwave oven, cool naturally, and spray 0.6% by weight lignin degradation compound enzyme aqueous solution (containing Lip, Mnp and Lac) at room temperature On the surface of cut tobacco stem raw materials, 9.0 g of the lignin-degrading compound enzyme is mixed thoroughly and placed in a constant temperature and humidity incubator for enzymolysis, and the enzymolysis time is 72 hours at an enzymolysis temperature of 60°C. Bacterial distilled water was used as a control. After enzymatic hydrolysis, heat in a microwave oven at 1200w power for 5 minutes to inactivate the enzyme, and air-dry it naturally so that its moisture content reaches 12% based on the total weight of enzymatically degraded cut tobacco stems. Equilibrate under conditions for 48h. The lignin content of the shredded tobacco s...

Embodiment 3

[0090] Embodiment 3: reduce the lignin content in the shredded tobacco stem

[0091] Weigh 30g of Yuxi K326 long cut tobacco stems, sterilize for 3min under the condition of power 1000W in a microwave oven, cool naturally, and spray 0.8% by weight lignin degradation compound enzyme aqueous solution (containing Lip, Mnp and Lac) at room temperature On the surface of cut tobacco stem raw material, 6.0 g of the lignin-degrading compound enzyme is mixed thoroughly and placed in a constant temperature and humidity incubator for enzymolysis. The enzymolysis time is 42 hours at an enzymolysis temperature of 45° C. Bacterial distilled water was used as a control. After enzymatic hydrolysis, heat in a microwave oven at 1000w power for 3 minutes to inactivate the enzyme, and air-dry it naturally so that the moisture content reaches 12% based on the total weight of enzymatically degraded cut tobacco stems, at a temperature of 22°C and a relative humidity of 60%. Equilibrate under condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com