Processing method of ramie and pennisetum purpureum mixed silage

A technology of mixing silage and processing methods, applied in the preservation method of animal feed raw materials, animal feed, animal feed and other directions, can solve the problems of lactic acid bacteria providing sufficient nutrient substrate, high soluble carbohydrate content, low nutritional value of feed, etc. To achieve the effect of low volatility, inhibit the production of acetic acid, and promote fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

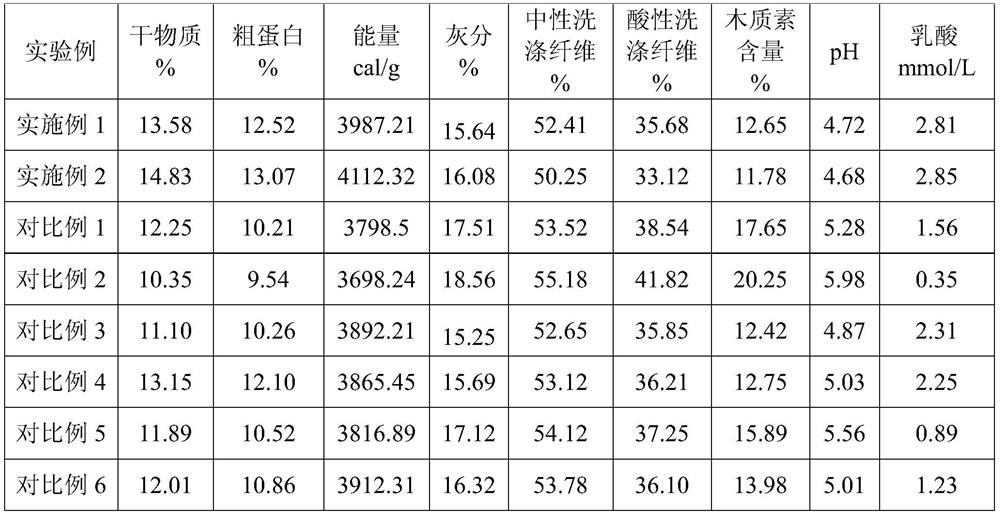

Examples

Embodiment 1

[0032] A processing method of ramie and elephant grass mixed silage, comprising the following steps:

[0033] S1. Harvest fresh elephant grass, remove impurities, and crush to obtain elephant grass.

[0034] S2. Harvest fresh ramie, remove impurities, and crush to obtain ramie material.

[0035] S3. Mix elephant grass feed and ramie feed to obtain silage, and the silage includes 80% elephant grass feed and 20% ramie feed.

[0036] S4. Spraying fermentation broth and additives to the silage, and then fermenting.

[0037] Described fermented liquid comprises complex bacterium, complex enzyme and water, and described complex bacterium comprises plantaractobacillus, lactobacillus brinneri, Pediococcus pentosaceae and Bacillus subtilis; Described complex enzyme comprises cellulase, xylanase and Laccase.

[0038] The additives include calcium propionate, molasses, urea, ethanol and water.

[0039] The number of effective bacteria of the Lactobacillus plantarum ≥ 10 10 cfu / g, th...

Embodiment 2

[0045] A processing method of ramie and elephant grass mixed silage, comprising the following steps:

[0046] S1. Harvest fresh elephant grass, remove impurities, and crush to obtain elephant grass.

[0047] S2. Harvest fresh ramie, remove impurities, and crush to obtain ramie material.

[0048] S3. Mix elephant grass feed and ramie feed to obtain silage, and the silage includes 70% elephant grass feed and 30% ramie feed.

[0049] S4. Spraying fermentation broth and additives to the silage, and then fermenting.

[0050] Described fermented liquid comprises composite bacteria, composite enzyme and water, and described composite bacteria comprises the mass ratio of 1:1:1:1 Lactobacillus plantarum, Lactobacillus brinneri, Pediococcus pentosaceae and Bacillus subtilis; According to silage The mass meter, the added amount of the complex bacteria is 200mg / kg, then add 20 times the weight of water to dilute, and mix uniformly to obtain the fermentation broth. The number of effecti...

Embodiment 3

[0054] A processing method of ramie and elephant grass mixed silage, comprising the following steps:

[0055] S1. Harvest fresh elephant grass, remove impurities, and crush to obtain elephant grass.

[0056] S2. Harvesting fresh ramie, removing impurities, crushing, kneading and processing to obtain ramie material. The kneading process uses a straw kneading machine.

[0057] S3. Mix elephant grass feed and ramie feed to obtain silage, and the silage includes 70% elephant grass feed and 30% ramie feed.

[0058] S4. Spraying fermentation broth and additives to the silage, and then fermenting.

[0059] The fermented liquid includes composite bacteria, composite enzymes and water, and the composite bacteria include Lactobacillus plantarum, Lactobacillus brinneri, Pediococcus pentosaceae and Bacillus subtilis with a mass ratio of 1:1:1:1; according to silage In terms of the mass of the material, the added amount of the complex bacteria is 200mg / kg, and then add 20 times the weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com