Pholiota nameko(T.Tto)S.Ito et Imai) facility culture substrate prescription and production process thereof

A cultivation substrate and production process technology, applied in the fields of botanical equipment and methods, horticulture, fertilization devices, etc., can solve the problems of loss of water-soluble nutrients, loss of nutritional value of mushrooms, slow growth of miscellaneous bacteria, etc. The standardization and quality are consistent, reducing the amount of wood chips and shortening the growth cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 40M at 5°C 2 Take the fresh-keeping warehouse as an example, build a mushroom rack: 0.9m in width, 9 floors in height, 0.25m in layer spacing, and 0.7m in the aisle; there are three vents inside, the size is 30*30cm, and the height of the vents is 0.7m according to the roof. Press and release one on one side of the door, and two on the other side; the indoor light is controlled by four 60w waterproof lights; the indoor humidity is controlled by a humidifier.

[0025] The cultivation matrix formula of the present invention is by weight percentage: 30% of soybean straw, 55% of hard miscellaneous broad-leaved sawdust, 10% of bran, 4% of rice bran, 1% of gypsum, material-water ratio 1: 1.2-1.3, pH value 6- 6.5.

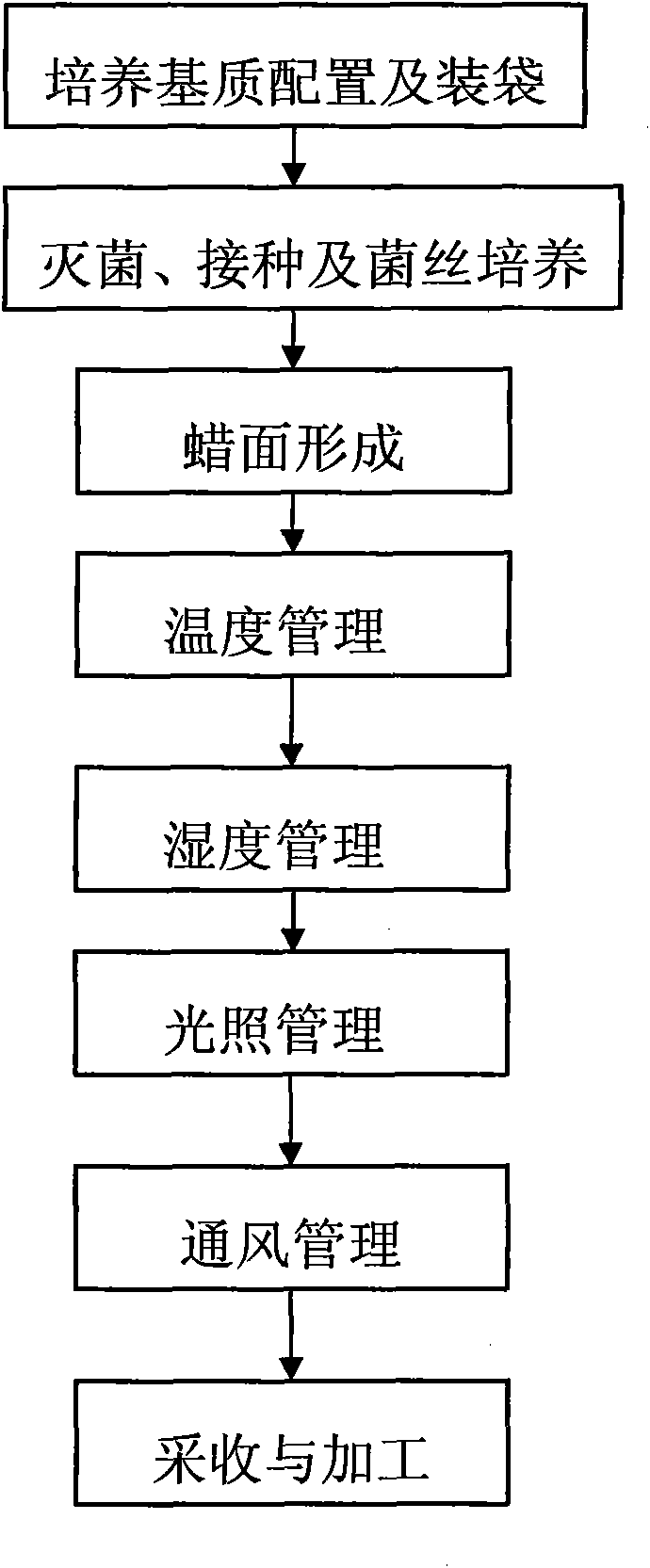

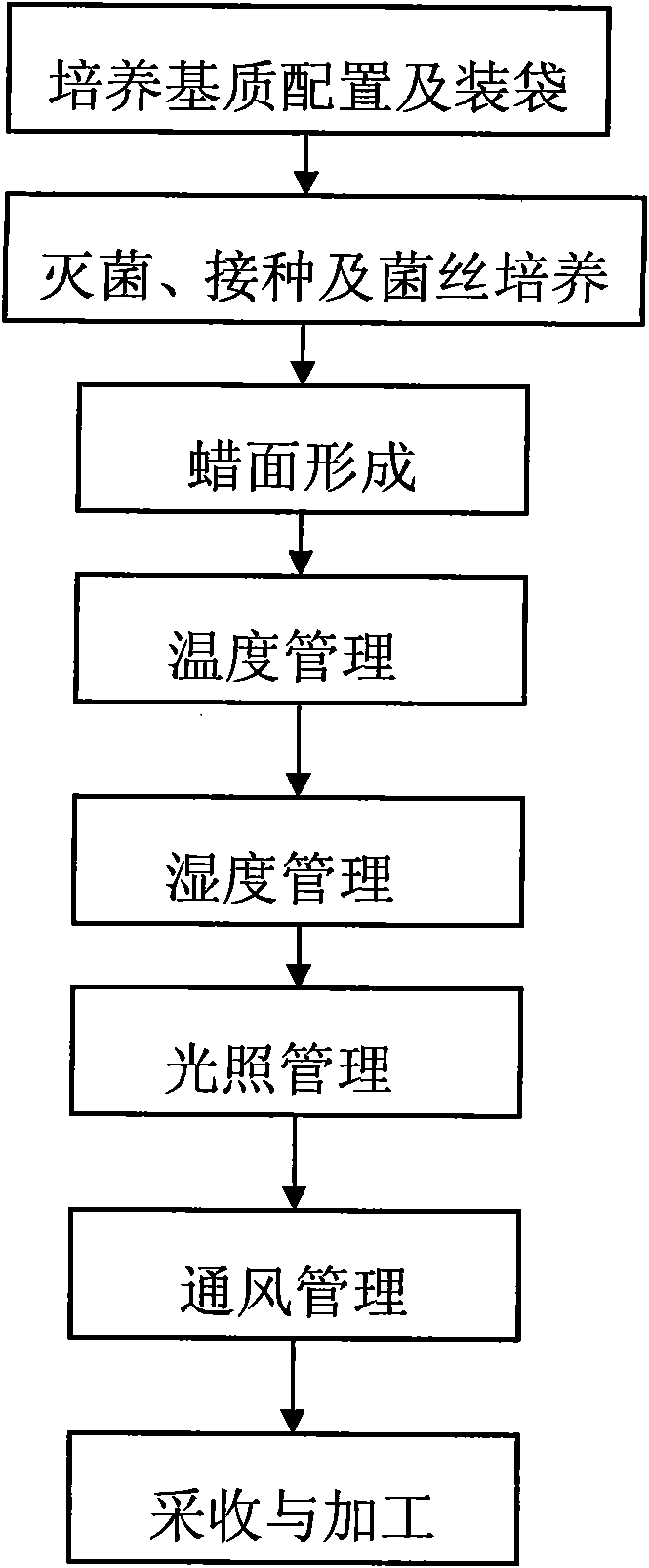

[0026] The technical process of the facility-based cultivation of Pleurotus ostreatus of the present invention includes strain production, cultivation substrate configuration, bacteria bag production, wax surface formation, temperature management, humidity managem...

Embodiment 2

[0044] The cultivation matrix formula of the present invention is: 25% of soybean straw, 57% of hard miscellaneous broad-leaved sawdust, 10% of bran, 7% of rice bran, 1% of gypsum, material-water ratio 1: 1.2-1.3, pH value 6- 6.5.

[0045] The technical process for the facility cultivation of Pleurotus ostreatus of the present invention includes the production of strains, the configuration of cultivation substrates, the production of bacteria bags, the cultivation of sterilized inoculation mycelia, the formation of wax surface, temperature management, humidity management, light management, ventilation management, harvesting and Processing, concrete operation is as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com