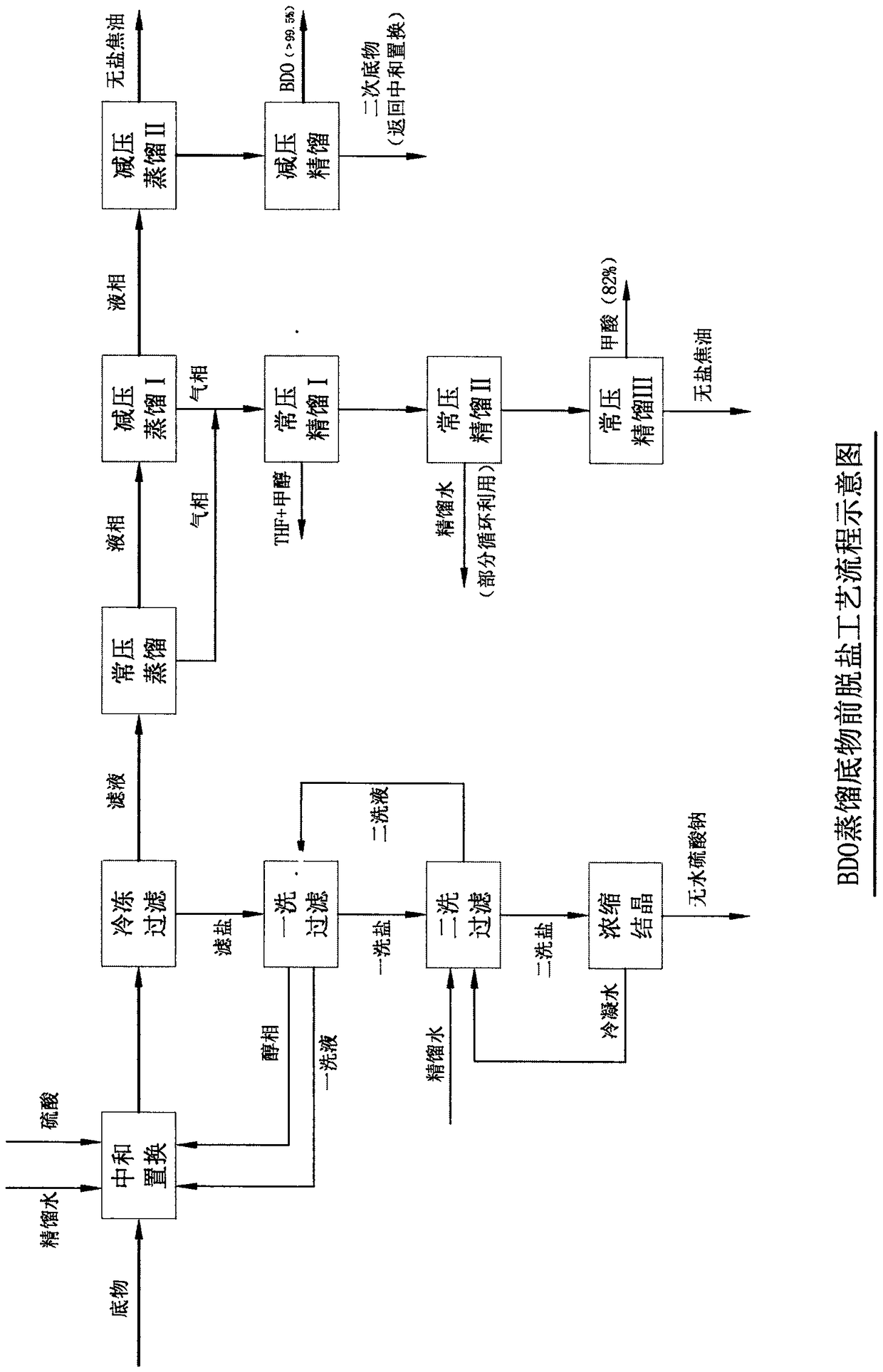

Continuous desalination technology before steaming for resource utilization of BDO device waste liquid

A resource recovery and waste liquid technology, which is applied in the field of continuous desalination before steaming, can solve the problems of difficult product specification stability, insufficient use of waste liquid, inconvenient promotion and application, etc., and achieves reduced recycling costs, is conducive to environmental protection, The effect of high added value of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The specific steps of a continuous desalination process before steaming for resource utilization of BDO device waste liquid are as follows:

[0031] (1) Neutralization and replacement

[0032] The waste liquid of the BDO unit, together with the return washing brine and the alcohol phase of the salting device, enters the normal temperature neutralization tank, keeps the water content in the mixed liquid at 30%, and adds 98% concentrated sulfuric acid according to a certain proportion to oxidize the hydrogen in the substrate Most of the sodium and sodium formate are replaced by sodium sulfate and volatile formic acid. The temperature of the neutralization tank is controlled at 10°C, and the pH of the solution is 3.0. At this time, some sodium sulfate crystals will be produced in the solution. After continuous centrifugal filtration, the filtrate enters the low-temperature neutralization tank, and a certain proportion of 98% concentrated sulfuric acid is added to strictly ...

Embodiment 2

[0042] A continuous desalination process before steaming for resource utilization of BDO device waste liquid, same as implementation case 1, wherein:

[0043] In step (1), keep the water content in the mixed solution as 35%, control the temperature of the neutralization tank at 15° C., and the pH of the solution to be 3.2; after adding sulfuric acid, the pH of the solution is 2.3, and the temperature is replaced at -7° C.

[0044] In the (2) step, the temperature of the salt-dissolving kettle is dissolved at 60°C; the temperature of the lower floor water phase crystallizer is -2°C, and the temperature of the second wash filtrate crystallizer is -2°C to complete the sodium sulfate crystallization; the second wash filter salt crystallizer The temperature was controlled at 90°C.

[0045] In the (3) step, in the atmospheric distillation concentrator, control the outlet temperature of 115°C; in the vacuum wiped film evaporator I, the operating pressure is 7kPa, and the liquid phase...

Embodiment 3

[0049] A continuous desalination process before steaming for resource utilization of BDO device waste liquid, same as implementation case 1, wherein:

[0050] In step (1), keep the water content in the mixed solution as 40%, control the temperature of the neutralization tank at 20° C., and the pH of the solution to be 3.5; the pH of the solution after adding sulfuric acid is 2.4, and the temperature is replaced at -5° C.

[0051] In the (2) step, the temperature of the salt-dissolving kettle is dissolved at 65°C; the lower floor water phase crystallizer temperature is 0°C, and the second washing filtrate crystallizer temperature is 0°C to complete the sodium sulfate crystallization; the second washing filter salt crystallizer is at temperature Controlled at 105°C.

[0052] In the (3) step, in the atmospheric distillation concentrator, control the outlet liquid temperature to 120°C; in the vacuum wiped film evaporator I, the operating pressure is 10kPa, and the liquid phase out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com