Patents

Literature

32results about How to "The process conditions are mature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

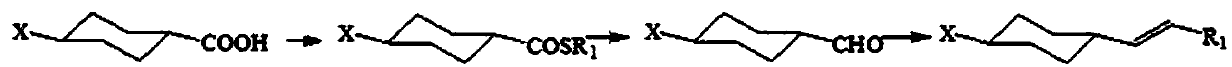

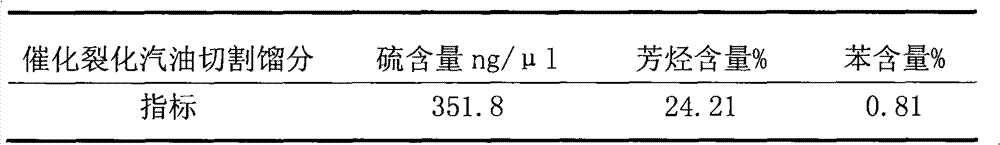

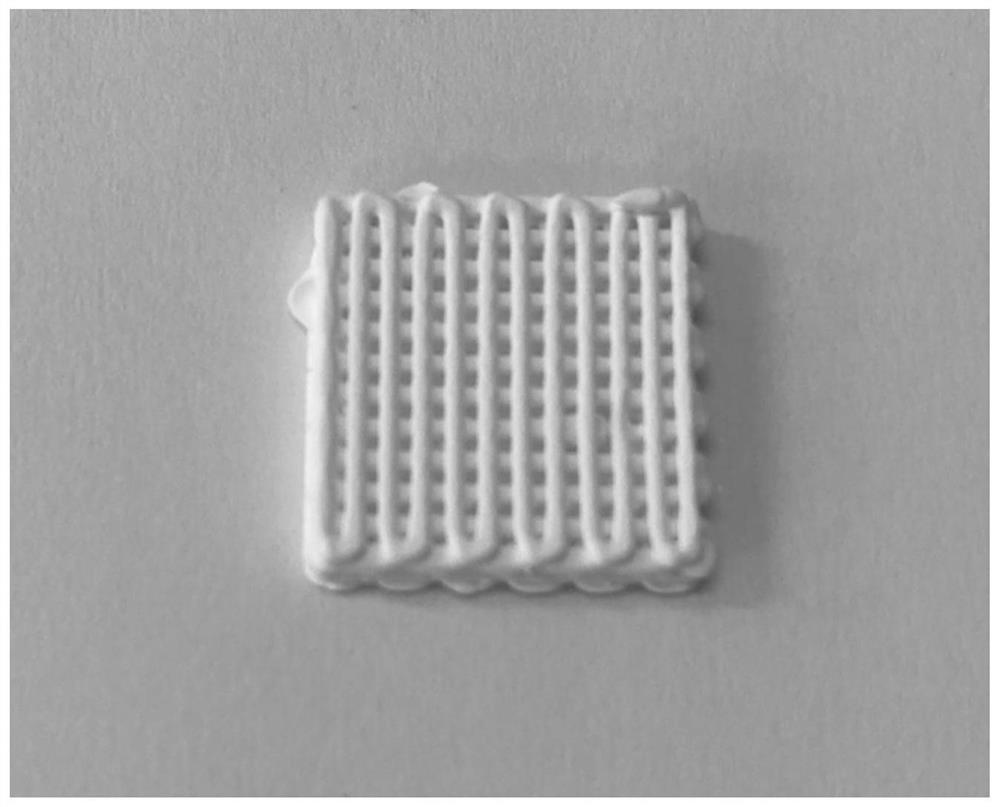

Method for producing reforming feedstock by light and medium gasoline distillates

ActiveCN101649221ASolve protection problemsRelieve pressureCatalytic naphtha reformingHydrocarbon oils refiningCatalytic reformingFractionation

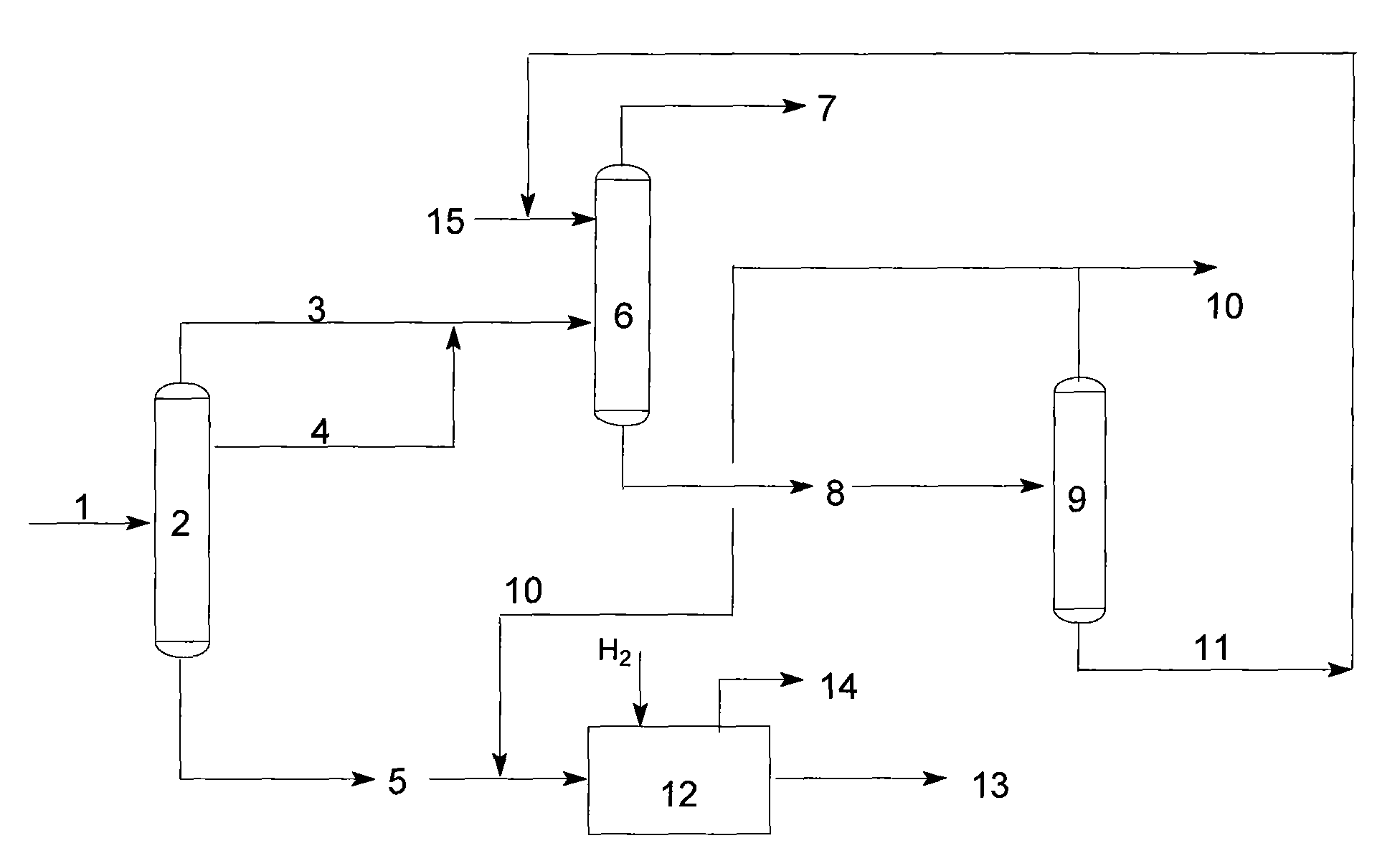

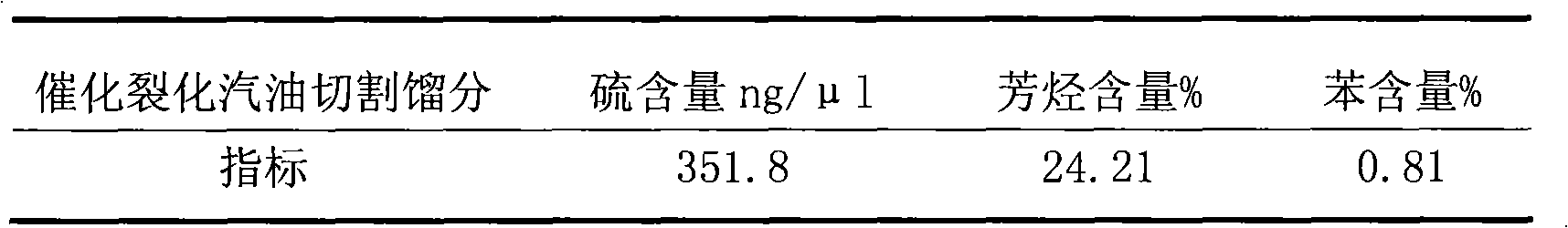

The invention relates to a method for producing catalytic reformed feedstock by taking light and medium gasoline distillates as raw materials and extracting selective solvent to extract and rectify catalytically cracked gasoline in the absence of hydrogen. The method comprises the following steps: 1, fractionation prefabrication of light and medium distillate raw materials of catalytically cracked gasoline; and 2, extraction, rectification, desulfuration and dearomatization of light and medium distillates of catalytically cracked gasoline, wherein light and medium distillates of catalyticallycracked gasoline obtained in step 1 are fed into the middle-lower part of an extraction-rectification tower, while fresh extraction agent or recycled extraction agent is added from the upper part of the extraction-rectification tower; thus, the light and medium distillates contact the extraction agent inside the tower to generate desulfurized and dearomatized light-component raffinate phase (i.e.catalytic reformed feedstock product) rich in olefin hydrocarbon at the top of the tower after extraction, rectification, desulfuration and dearomatization. The method carries out desulfuration and dearomatization of catalytically cracked gasoline at the same time and reclaims solvent, thereby having the advantages of simple process, moderate operation conditions, hydrogen source saving and low production cost.

Owner:PETROCHINA CO LTD +1

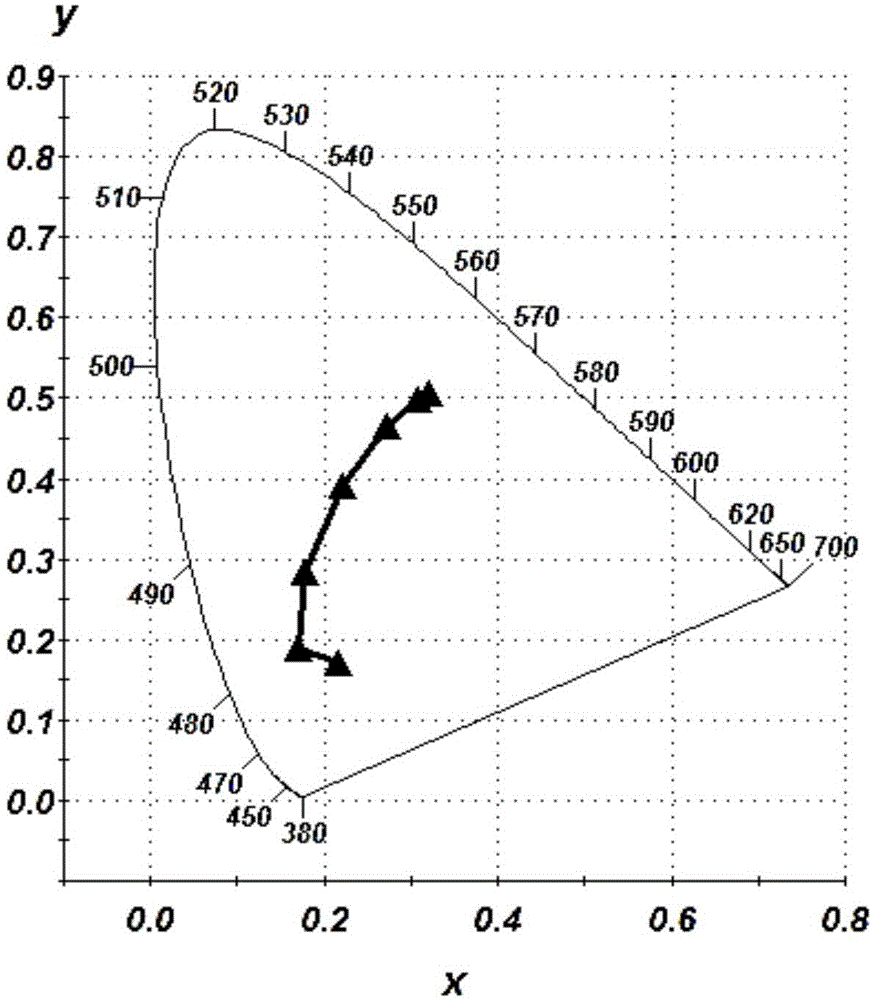

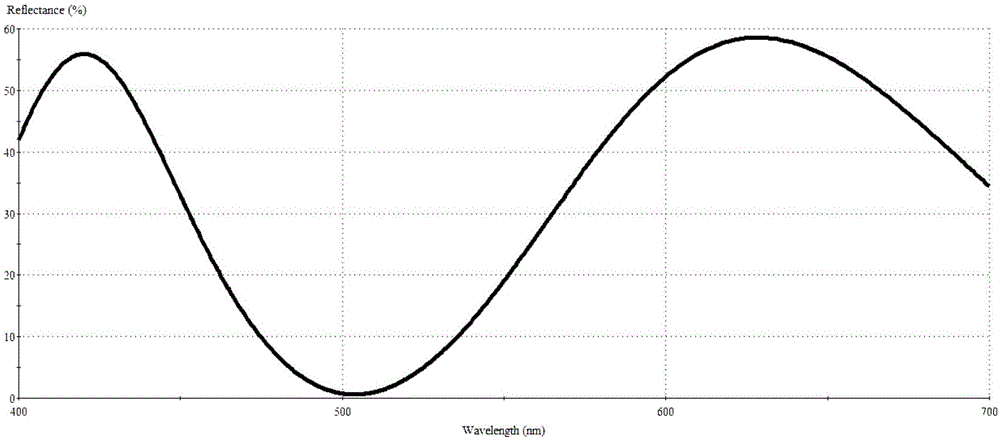

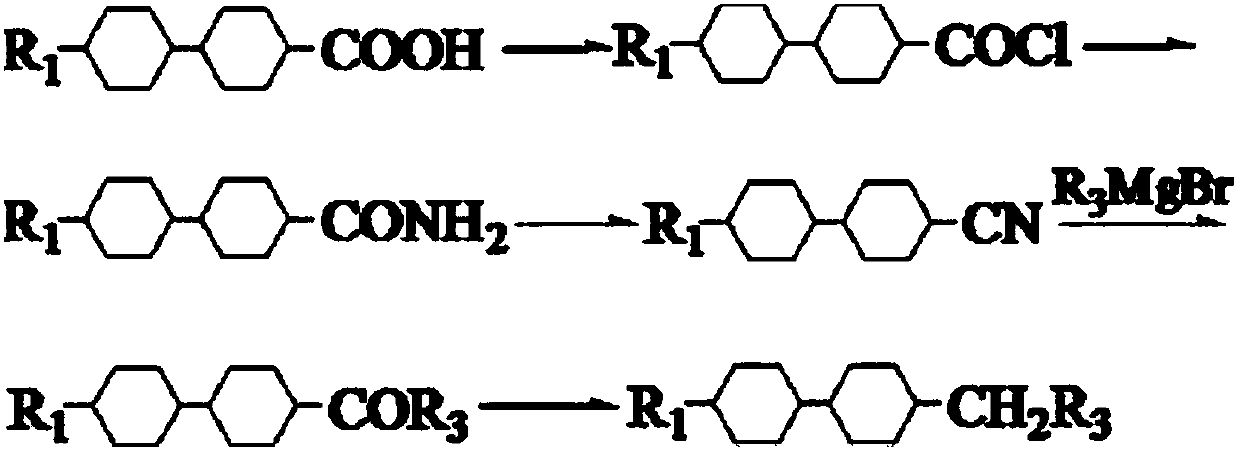

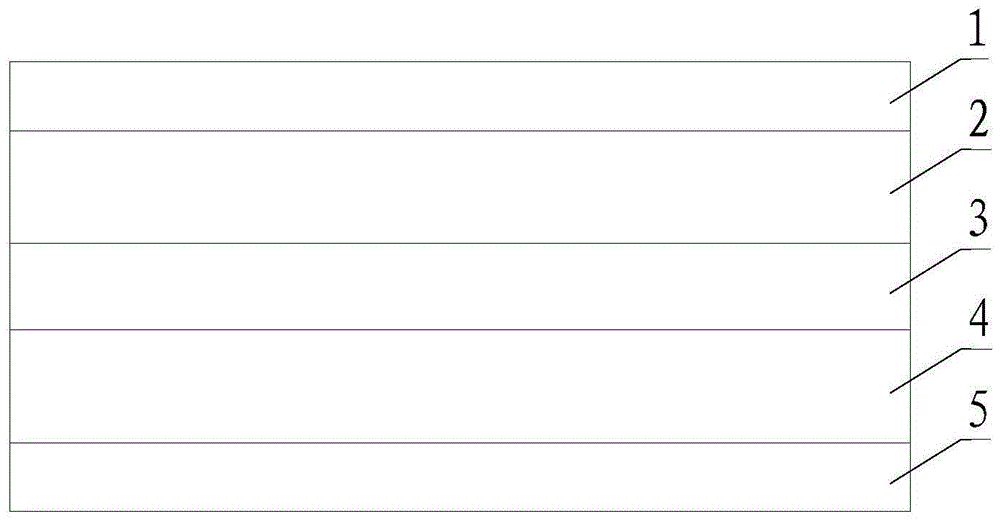

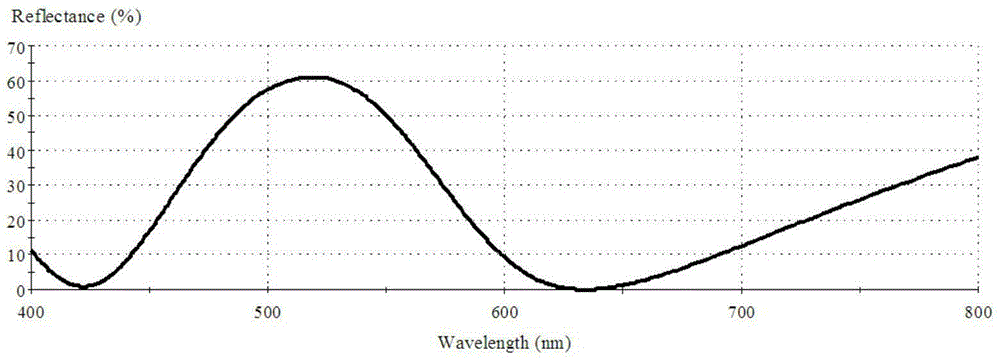

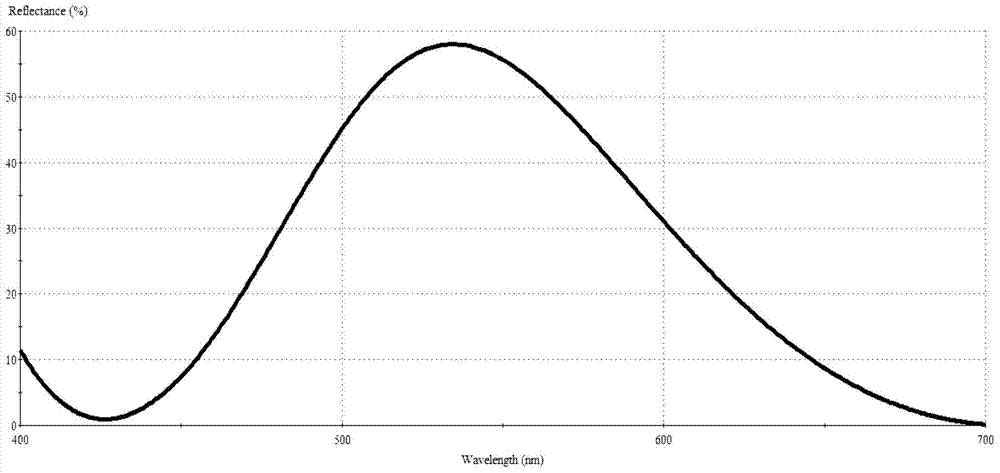

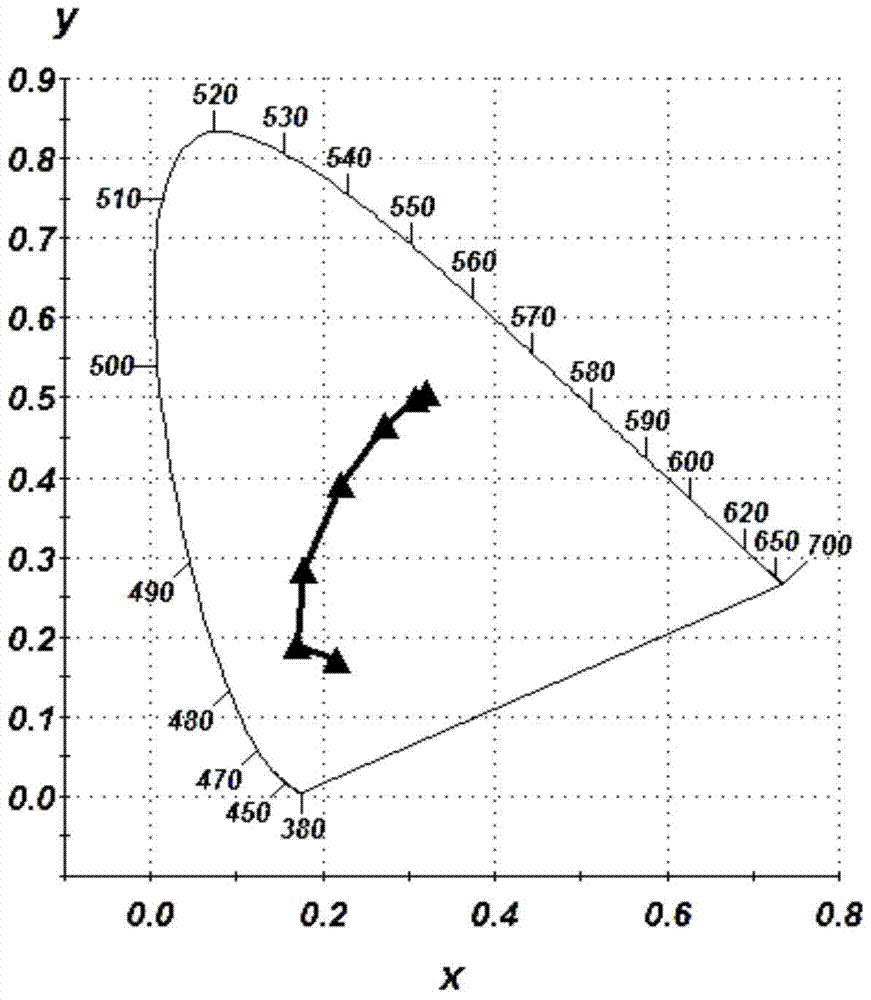

Optically variable anti-counterfeiting pure red pigment and preparation method thereof

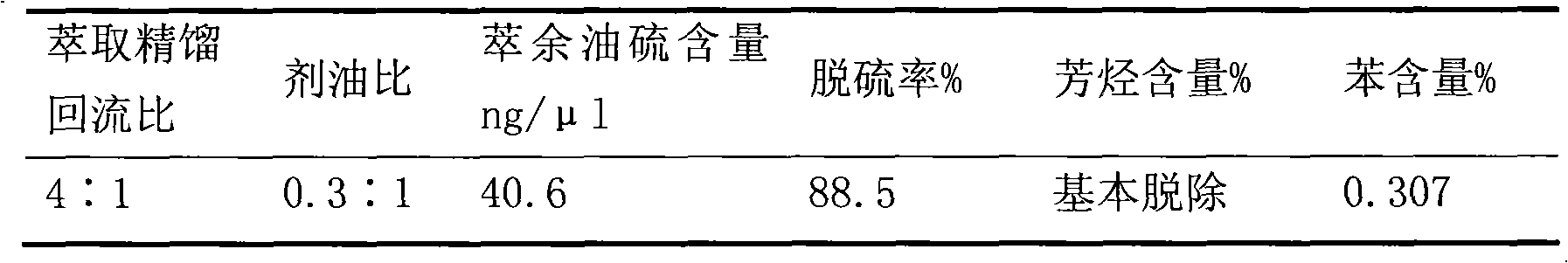

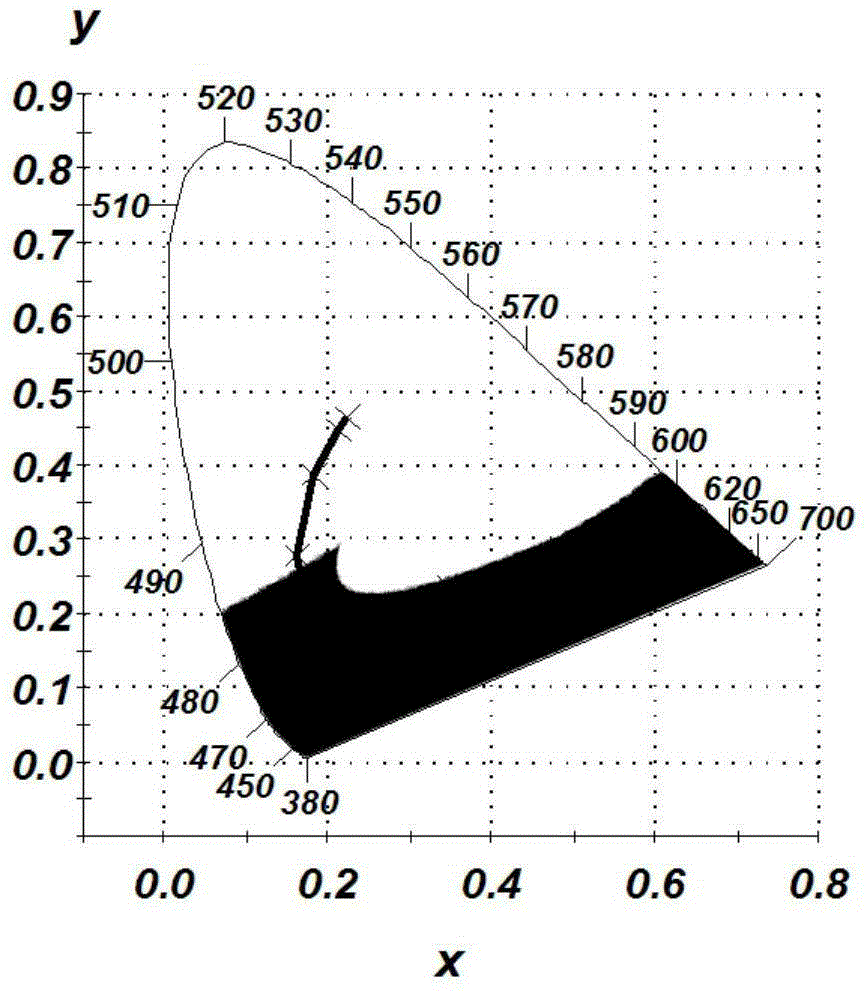

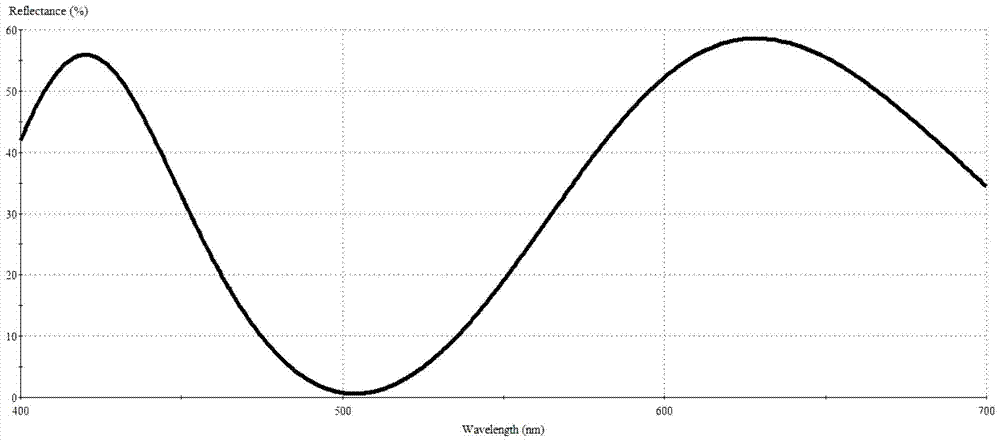

ActiveCN105137519AOvercoming the phenomenon of short-wave reflection sub-peaksFill in inherent defectsInorganic pigment treatmentOptical elementsLight beamGreen-light

The invention provides an optically variable anti-counterfeiting pure red pigment. The anti-counterfeiting pigment comprises a central reflecting layer, a first dielectric layer, a first half-absorption layer, a second dielectric layer and a second half-absorption layer. The first dielectric layer and the first half-absorption layer are outwardly, sequentially, circularly and symmetrically arranged from the central reflecting layer. As the outermost layer of the anti-counterfeiting pigment, the second dielectric layer and the second half-absorption layer are symmetrically arranged on the two sides of the central reflecting layer. The rest can be done in the same manner. That means, along with the increasement of the total number of the layers, the layers are outwardly and symmetrically in radiation distribution from the central reflecting layer. According to the technical scheme of the invention, the pigment is of a N-layer symmetrical structure, and is constructed based on the multi-beam destructive interference condition for reflection beams within the wavelength range of blue and green light beams, wherein N=7, 9, 11, 13....,7+(2n). Meanwhile, the multi-beam constructive interference for reflection beams within the wavelength range of red light beams is ensured at the same time. Therefore, the pigment is displayed within the color range of pure red chromaticity.

Owner:厦门汉盾光学科技有限公司

Method for regenerating eluant in organic polluted soil eluent

InactiveCN102211795AAchieve removalThe process conditions are matureWater contaminantsWater/sewage treatment by sorptionActivated carbonPollution

The invention belongs to the technical field of soil pollution repair for environment protection and relates to a method for treating an organic polluted soil synergistic eluent. The method comprises the step: mixing the eluent obtained by eluting and repairing the organic polluted soil with activated carbon according to the absorbability difference of the activated carbon on organic pollutants and a synergistic eluant for selectively absorbing and removing the pollutants in the eluent so as to achieve the regeneration and reuse of the eluant. The method is environmentally-friendly, has the advantages that the operation is simple, the cost is low and the like, and is an effective method for treatment of organic polluted soil synergistic eluents and regeneration of eluents.

Owner:HUAZHONG UNIV OF SCI & TECH

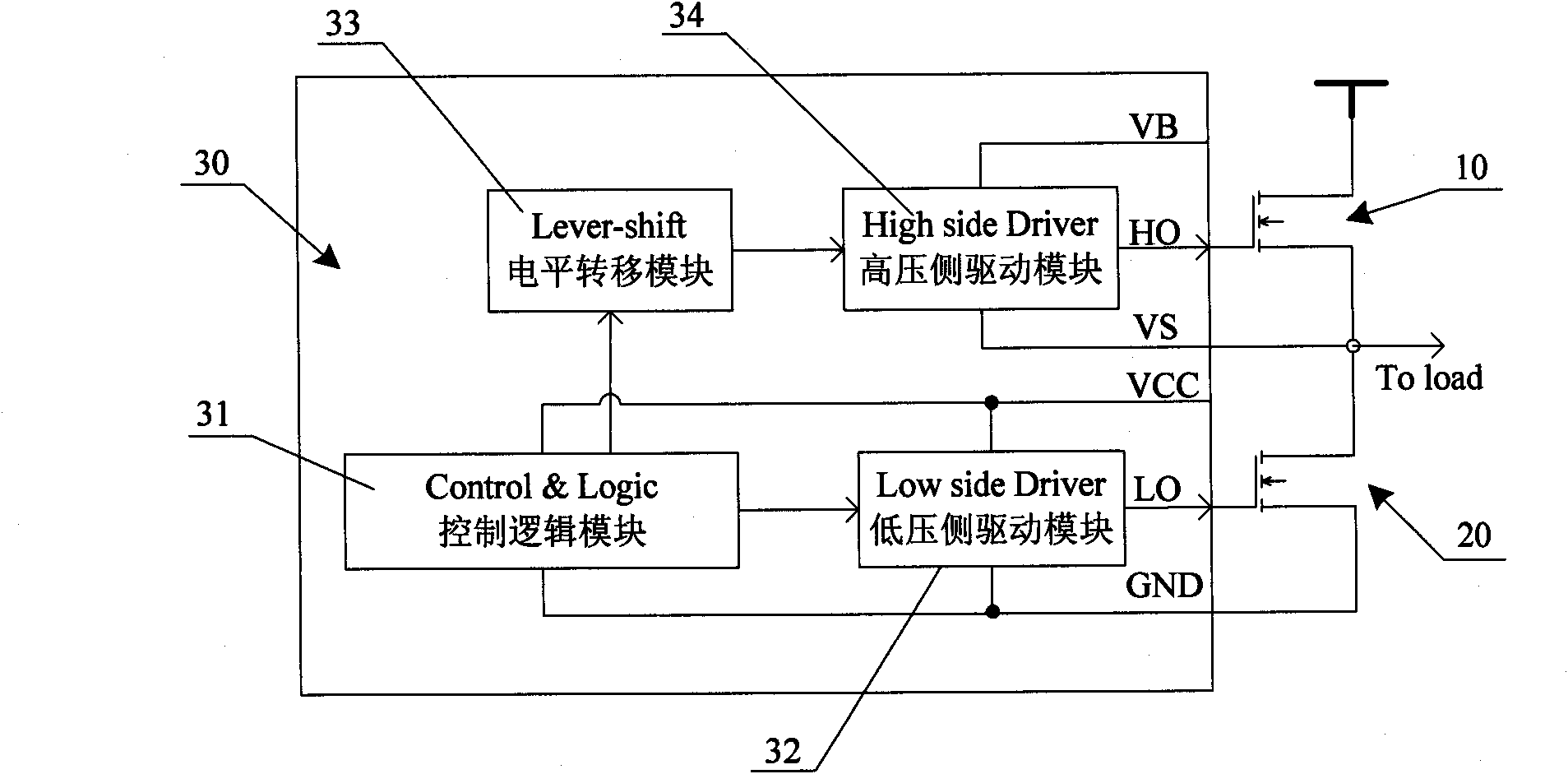

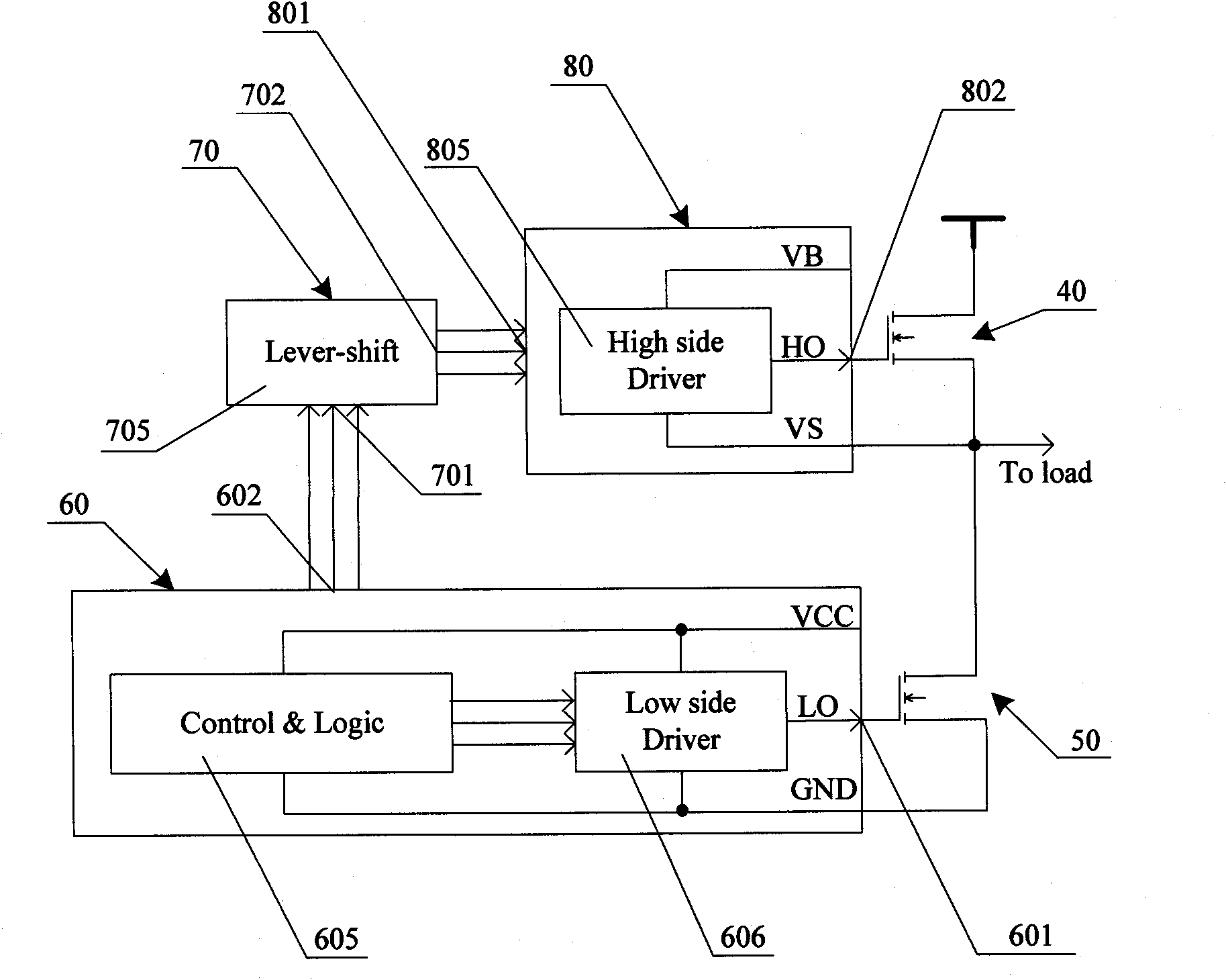

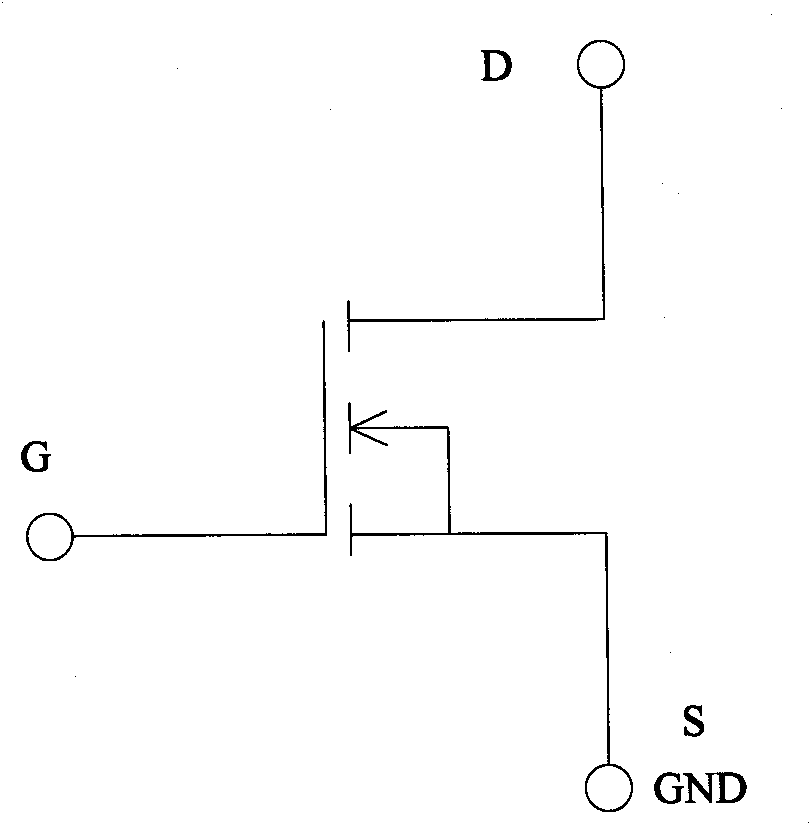

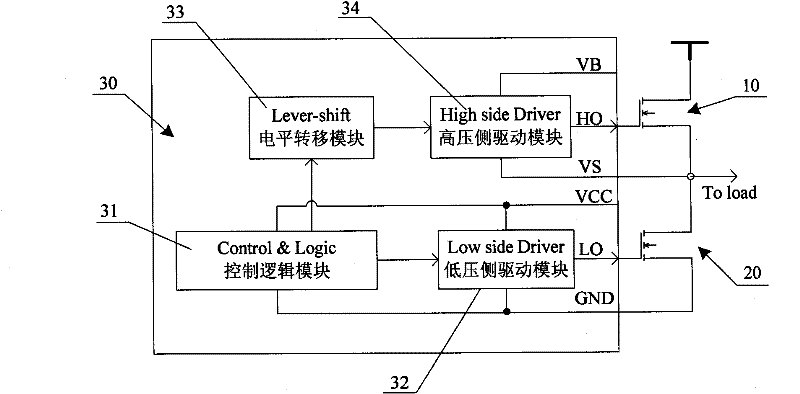

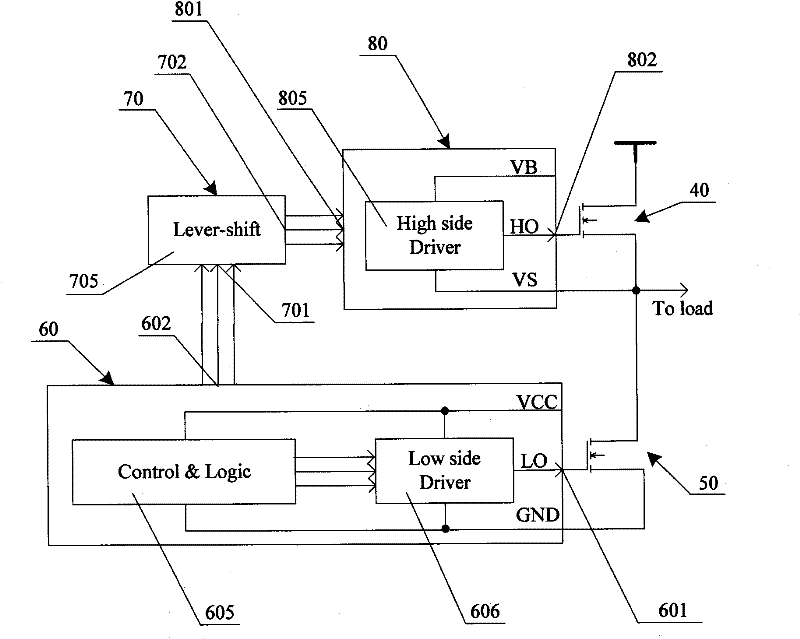

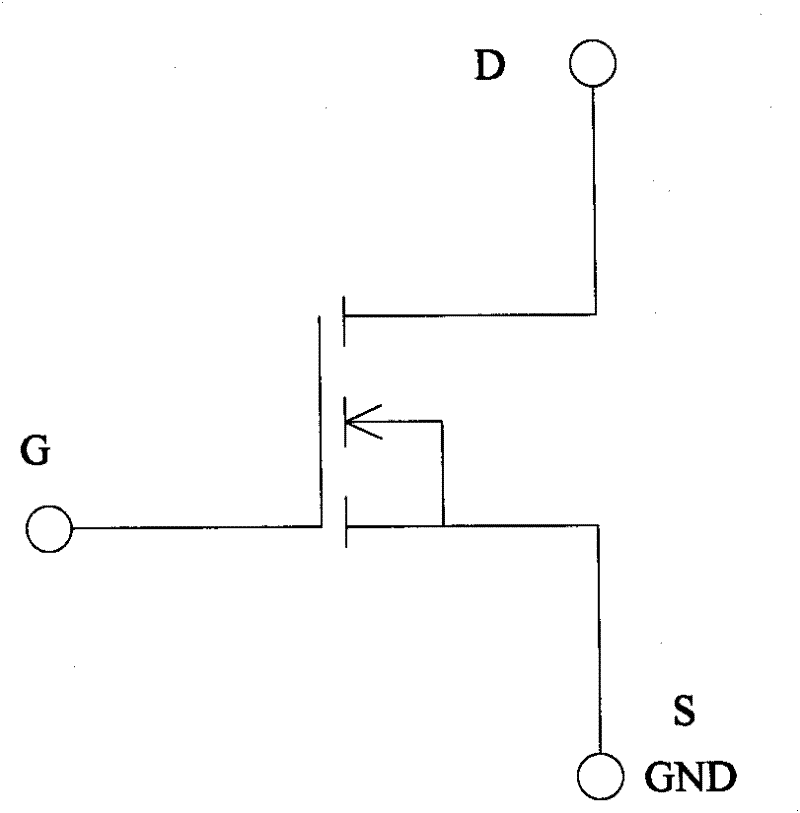

Grid drive circuit for controlling bridge type drive circuit

The invention discloses a grid drive circuit for controlling a bridge type drive circuit. The grid drive circuit comprises a low-voltage side control chip, a high-voltage side control chip and a level shifting chip, wherein the low-voltage side control chip and the high-voltage side control chip are produced by adopting a complementary metal oxide semiconductor (CMOS) process; the level shifting chip is produced by a high-voltage isolation manufacturing process; the low-voltage side control chip is mainly integrated by a control logical module and a low-voltage side drive module; the level shifting chip is mainly integrated by a level shifting module; and the high-voltage side control chip is mainly integrated by a high-voltage side drive module. The grid drive circuit has the advantages that: singlechips for integrating all the modules are realized by being divided into three chips, the level shifting module is produced only by adopting the high-voltage isolation manufacturing process, and the control logical module, the low-voltage side drive module and the high-voltage side drive module are produced by adopting the CMOS process; and the grid drive circuit is encapsulated into an integrated circuit, so compared with the conventional grid drive chip, the complexity of the production process is reduced, the chip area is reduced, the production cost is reduced, and a circuit with more complicated properties can be designed favorably.

Owner:NINGBO SEMICON INT CORP

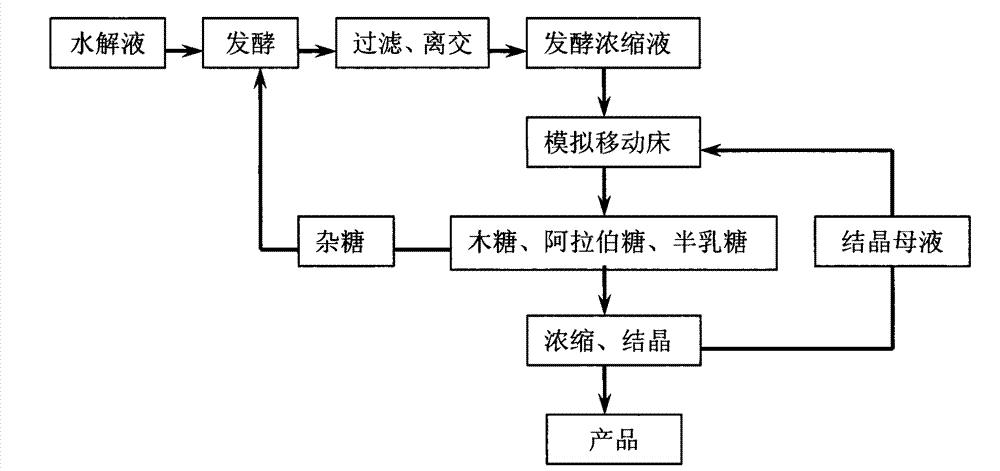

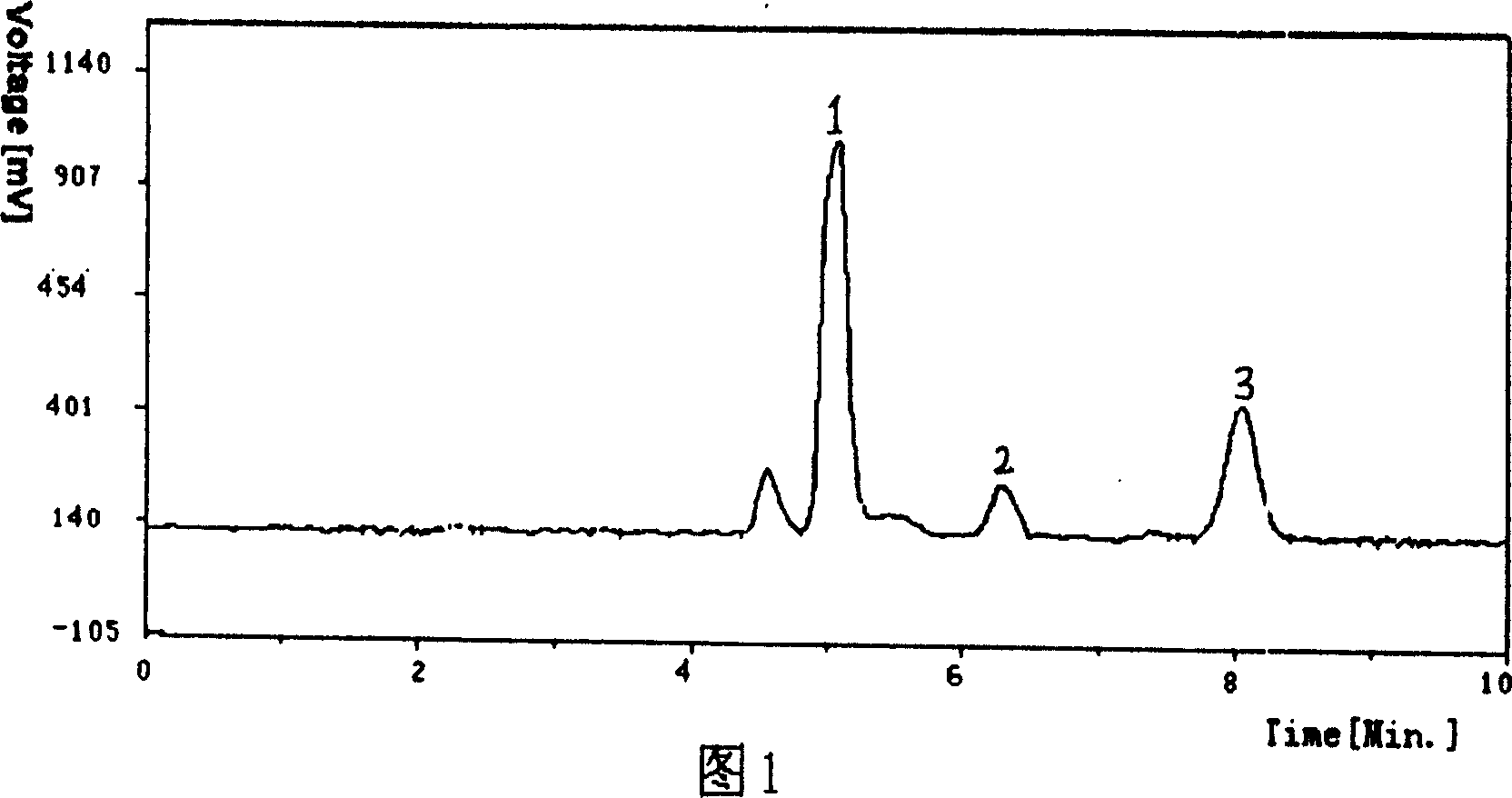

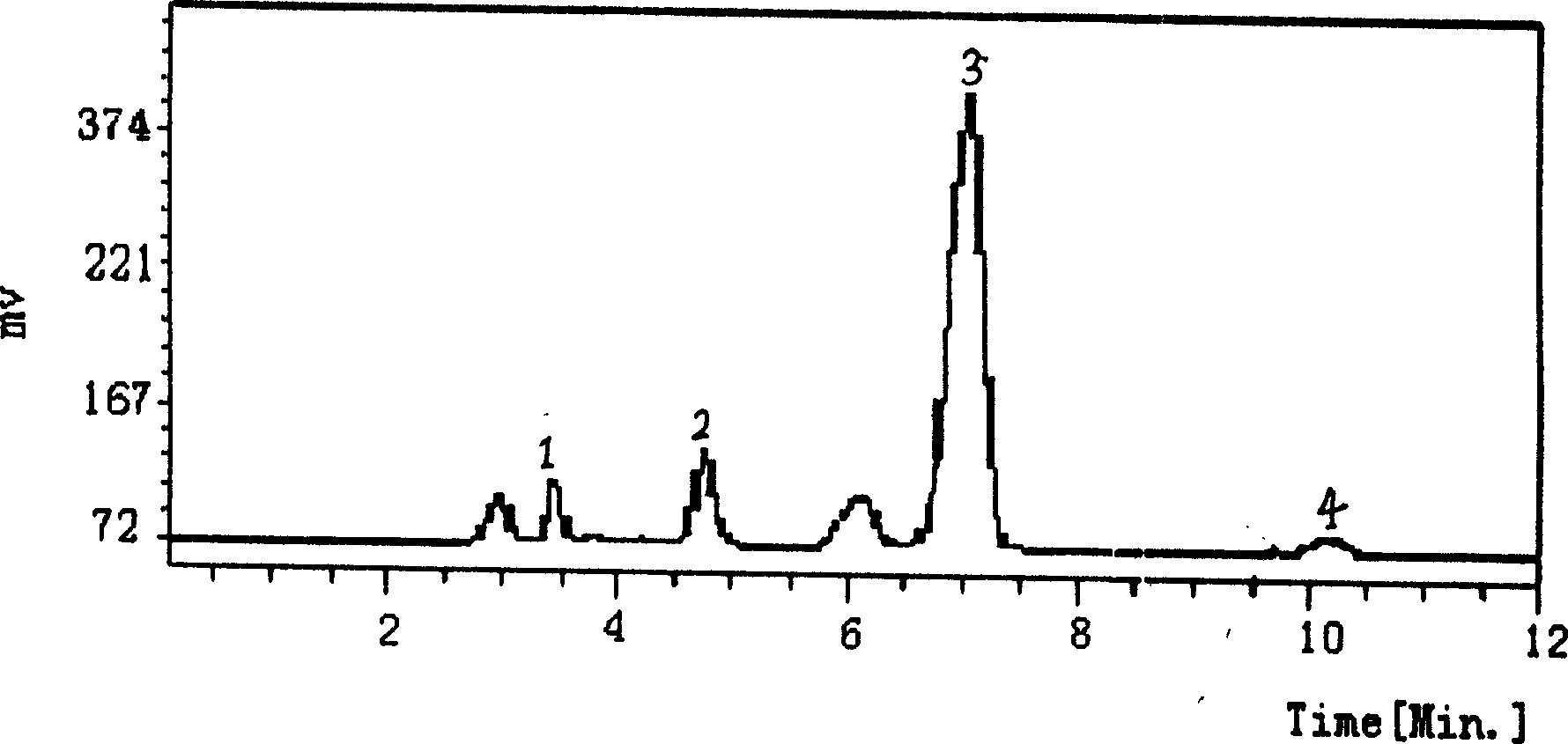

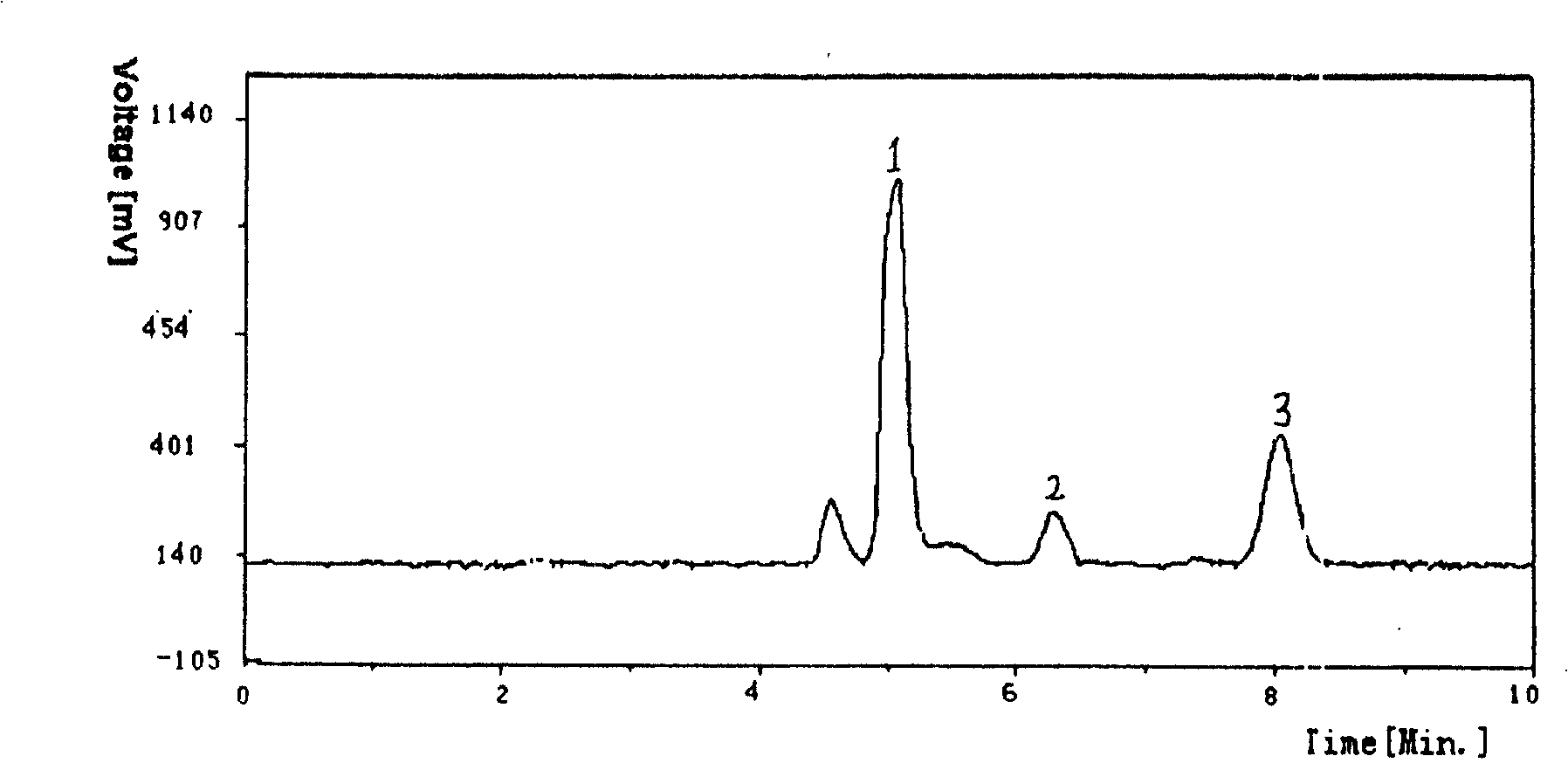

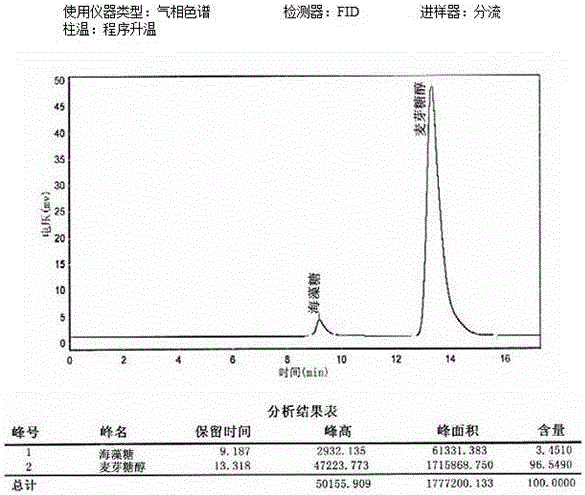

Method for extracting xylose, arabinose and galactose from xylose fermentation broth or xylose mother liquor

InactiveCN102924538AEasy to operateAchieve separationSugar derivativesSugar derivatives preparationXylose fermentationChromatographic separation

The invention provides a method for extracting xylose, arabinose and galactose from xylose fermentation broth or xylose mother liquor. According to the method, a simulated moving bed chromatographic separation device of sugar alcohol separating resin special for filling is adopted, water serves as an eluent, the separation temperature is 30-90DEG C, the flow rate of feed liquid is controlled at 2-50cm / min, continuous separation and purification of the xylose, the arabinose and the galactose in the xylose fermentation broth or the xylose mother liquor is achieved, and high-purity xylose, arabinose and galactose products are obtained through concentration and crystallization. The method has the advantages of being wide in application range, good in separation effect, high in product purity, environment-friendly and the like.

Owner:JIANGNAN UNIV

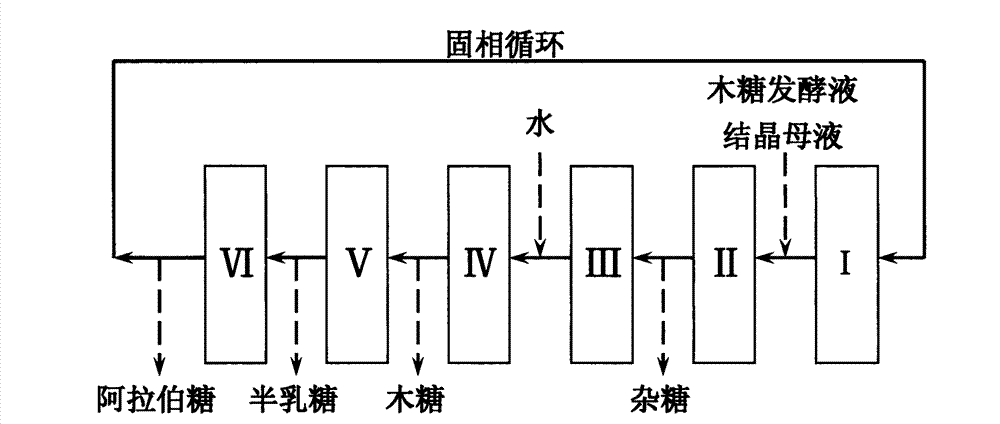

Method for separating and refining high-purity L-arabinose and D-xylose with simulated moving bed

ActiveCN103113422AReduce demandReduce generationSugar derivativesSugar derivatives preparationSimulated moving bedHigh sugar

The invention discloses a method for separating and refining high-purity L-arabinose and D-xylose with a simulated moving bed, which comprises the following steps: by using bagasse, bagasse pith or sugarcane leaf as a raw material, hydrolyzing, purifying, separating with a simulated moving bed chromatographic separator to obtain an L-arabinose solution with the purity of higher than 90% and a D-xylose solution with the purity of higher than 85%, and crystallizing to obtain the L-arabinose and D-xylose with the purity of up to 99%. The method has the advantages of simple technological operation, high sugar purity, high yield, low cost and high equipment stability, and is suitable for industrial production.

Owner:广西轻工业科学技术研究院有限公司

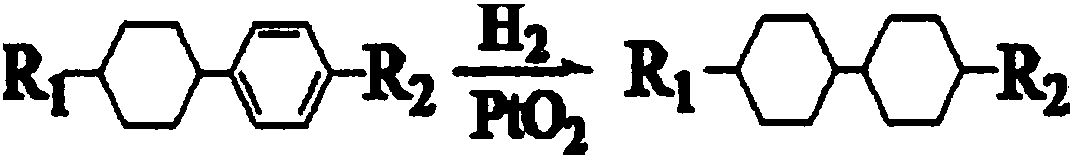

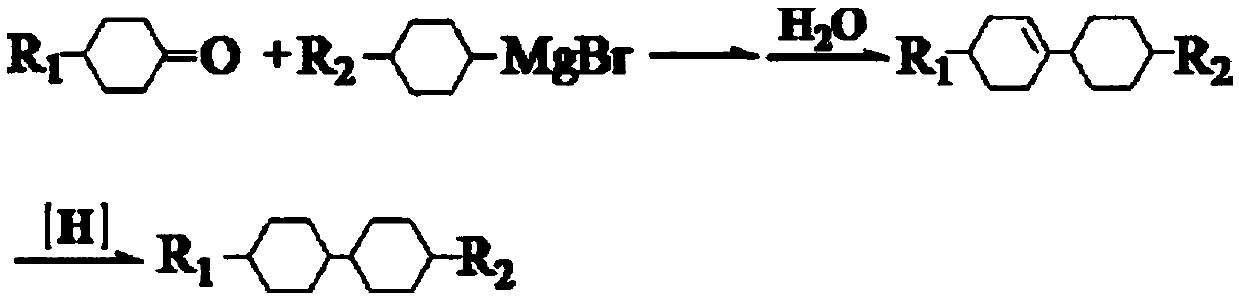

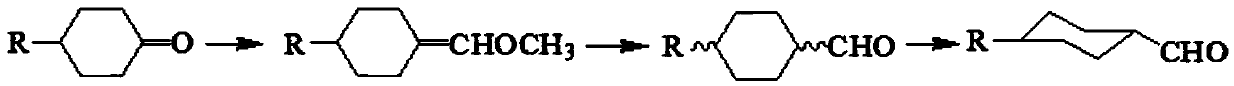

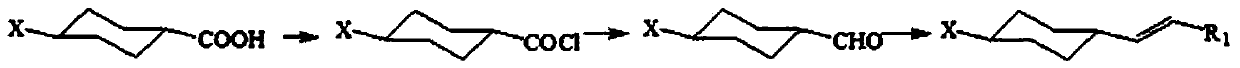

New preparation method of trans-trans dicyclohexyl alkane liquid crystal compounds

InactiveCN109534948ARealize green chemical industryHigh yieldLiquid crystal compositionsPreparation by isomerisationAlkaneChemical industry

The invention discloses a preparation method of trans-trans dicyclohexyl alkane liquid crystal compounds. According to the preparation method, 1-(4-(4-alkylcyclohexyl)phenyl)alkyl-1-one is used as a raw material; a benzene ring is converted into a cyclohexyl ring by means of a catalytic hydrogenation reaction; transposition is performed under the alkaline condition, so that 1-(4-(4-alkylcyclohexyl)cyclohexyl)alkyl-1-ol is obtained; the trans-trans dicyclohexyl alkane liquid crystal compounds are finally obtained by carrying out an oxidation reaction and a reduction reaction. The preparation method provided by the invention is unique in synthetic route, not only realizes green chemical industry, but also enables the product yield to be greatly increased, improves the product quality, and reduces the cost.

Owner:YANTAI DERUN LIQUID CRYSTAL MATERIALS

Optical chromotropic anti-counterfeiting pigment

InactiveCN105182458ASpectral performance is stableEnvironmentally friendlyInorganic pigment treatmentOptical elementsRefractive indexHuman health

The invention discloses an optical chromotropic anti-counterfeiting pigment. A pigment coating comprises a reflection layer; one side surface of the reflection layer is outwardly sequentially and circularly provided with dielectric layers and half-absorption layers; the reflection layer is made of materials selected from one or more than two from Ti, TiN or TiNx; the dielectric layer is made of a material with refractive index smaller than 1.68; and the half-absorption layer is made of materials selected from one or more than two from Ti, TiN or TiNx. According to the environmental protection-type optical chromotropic anti-counterfeiting pigment, the spectral properties are stable; environmental protection properties are also provided when similar grain size properties with the existing chromotropic anti-counterfeiting structure, uniform metal effect luster and angle-dependent optical effects can be ensured; the material combination is non-toxic and harmless to a human body; environmental stability is good; and the optical chromotropic anti-counterfeiting pigment is particularly applicable to safety anti-counterfeiting packaging printing of food, drinks and drugs closely related to human health.

Owner:厦门汉盾光学科技有限公司

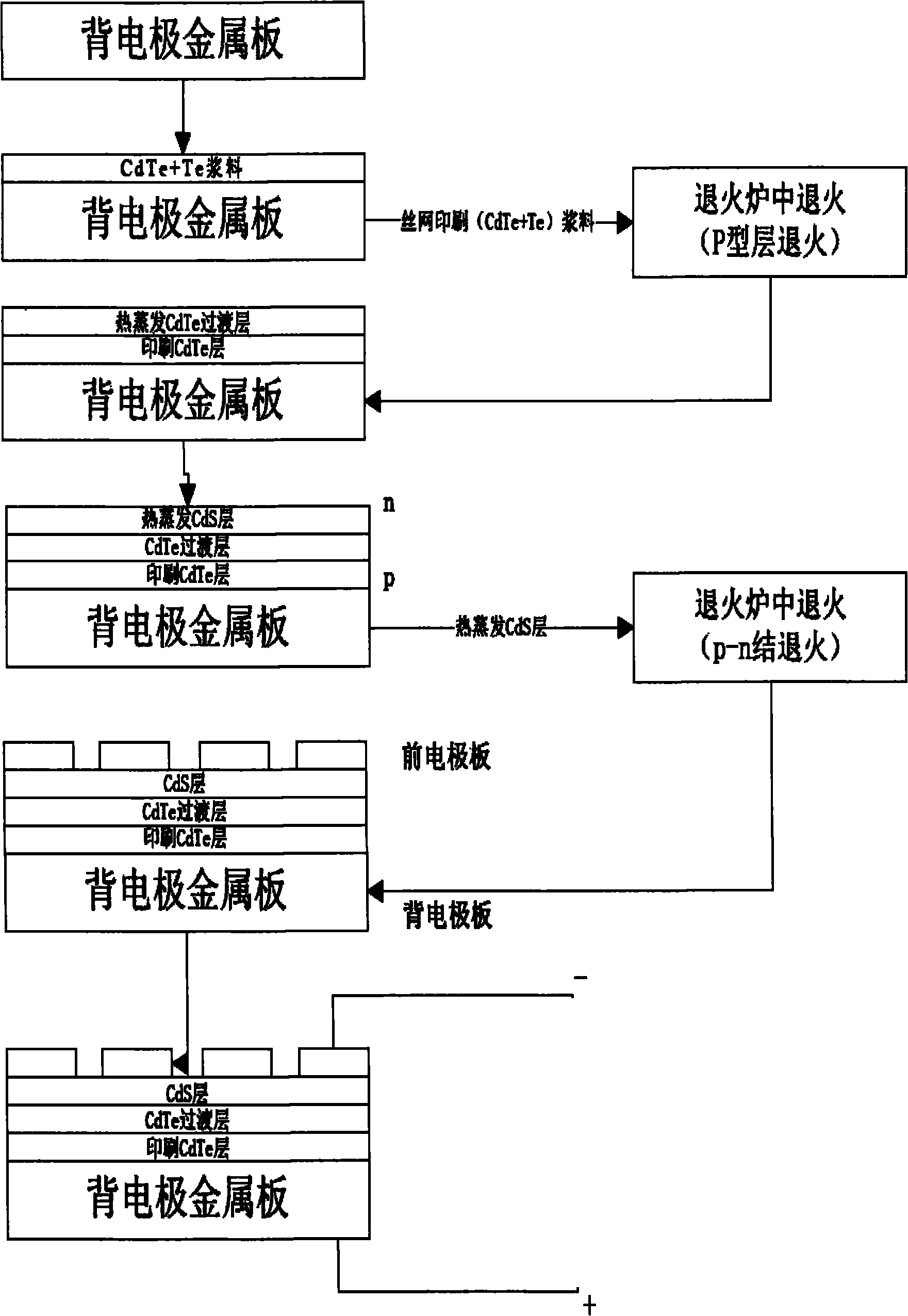

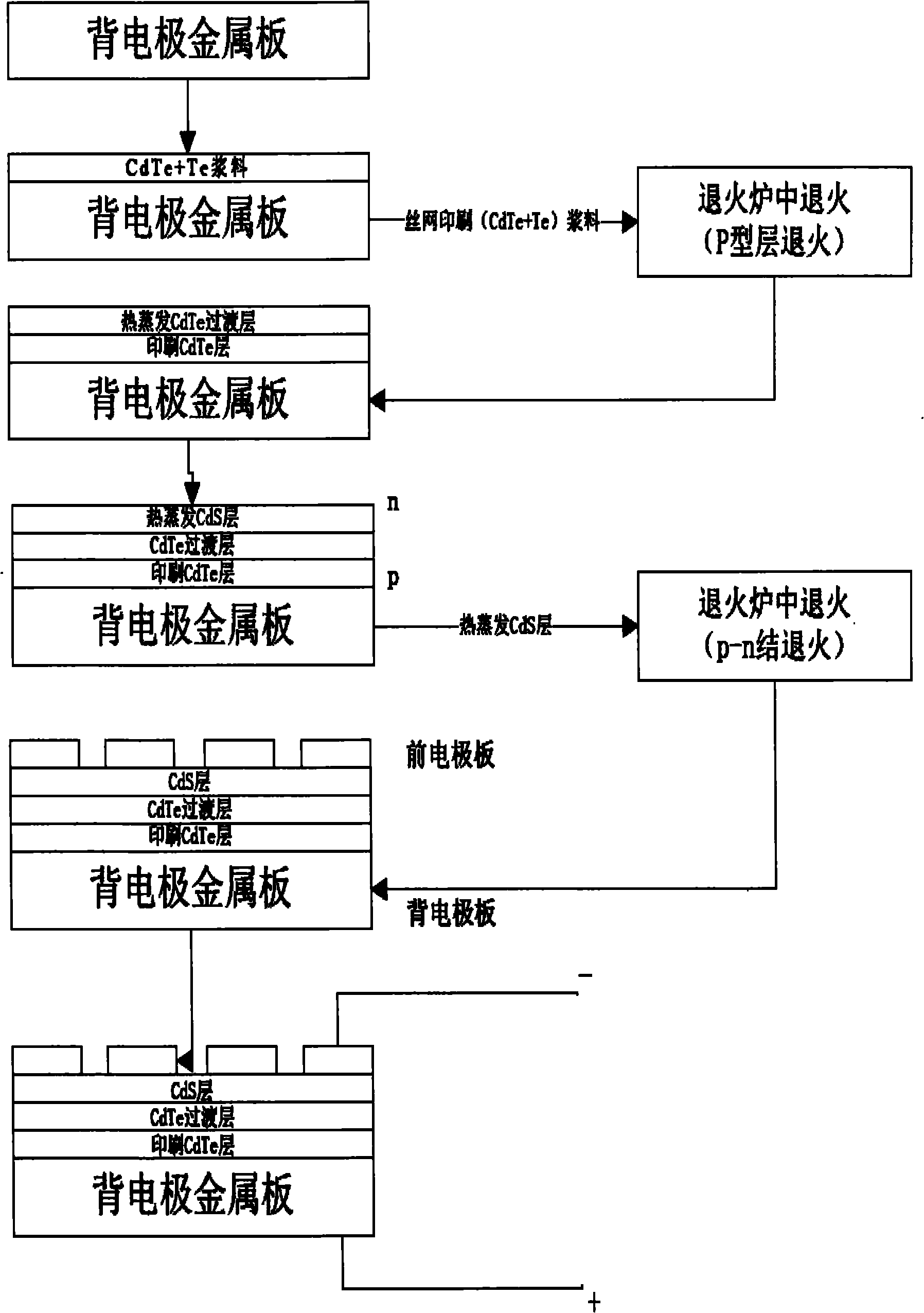

Manufacturing method of cadmium telluride film solar cell

ActiveCN101931031AReduce manufacturing costImprove photoelectric conversion efficiencyFinal product manufactureSemiconductor devicesScreen printingSlurry

The invention discloses a manufacturing method of a cadmium telluride film solar cell, which is characterized by comprising the following steps of: (1) by adopting a copper sheet or a stainless steel sheet as a back electrode of the cadmium telluride film solar cell, coating p (Positve) type cadmium telluride slurry on the metal sheet by a screen printing method to manufacture a p type cadmium telluride film; controlling the annealing temperature of the coated p type layer at 600 DEG C, wherein annealing time is 40 minutes; and then raising the temperature to 850 DEG C and preserving for 1 hour; (2) manufacturing an intermediate transition layer and an n (Negative) type cadmium telluride window layer on the p type cadmium telluride film to form a p-n junction; (3) evaporating or printing a comb-shaped front electrode on the cadmium telluride film of the window layer; and (4) wiring and welding the front and the back electrodes to finish the manufacture of the cadmium telluride film solar cell. The method is simple and convenient as well as easy for scale production, and can promote the scale production, largely reduce the cost and the price of the cadmium telluride film solar cell, and enhance the photovoltaic conversion efficiency of the cell.

Owner:XIAN JIAOTONG LIVERPOOL UNIV

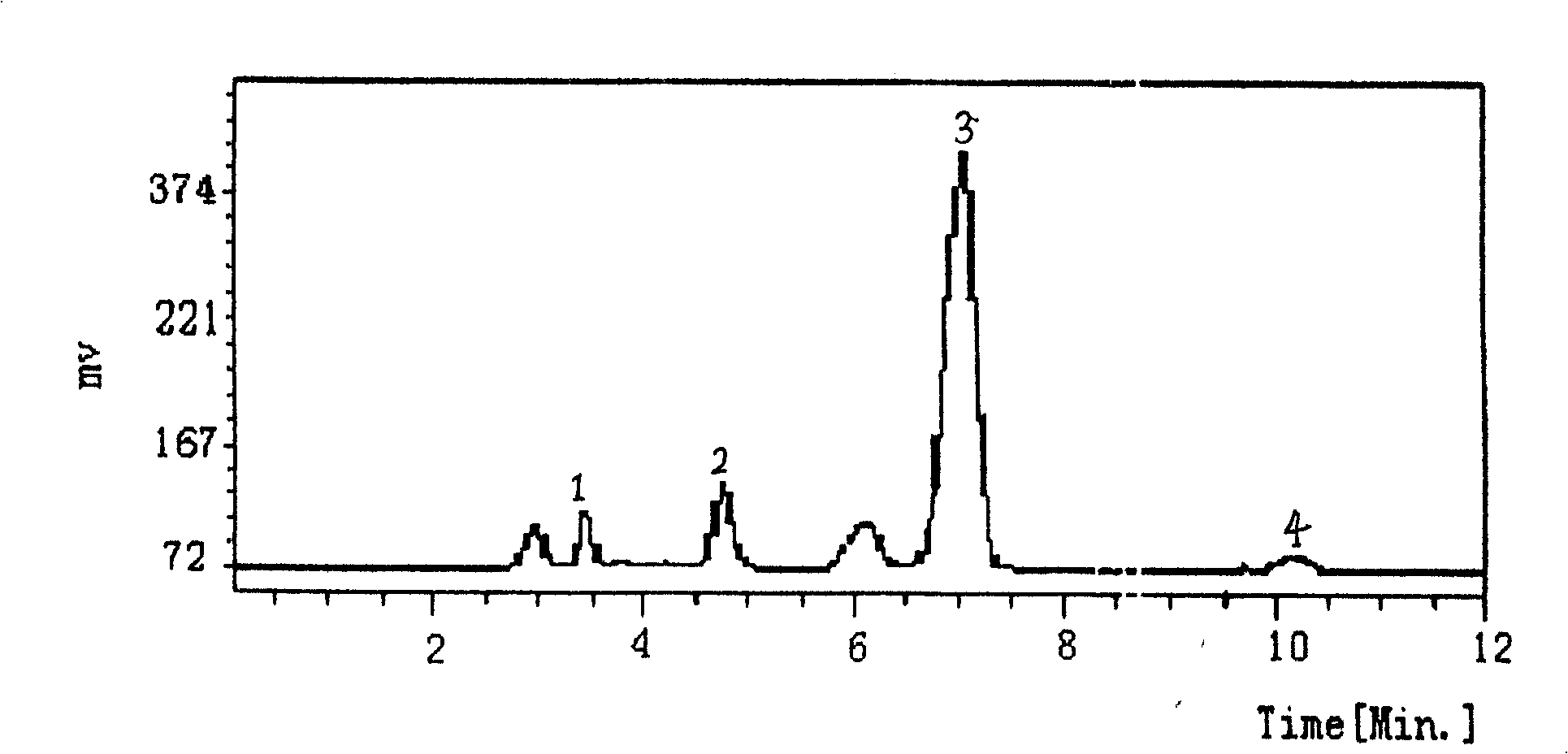

Method for separating and purifying oligosaccharide in high purity

InactiveCN1696140AHigh puritySuitable for useSugar derivativesOligosaccharidesOligosaccharideSalt solution

A process for separating and purifying the high-purity oligose includes treating the resin HZ001 sequentially by acid, alkali and salt solution, and using the treated resin to prepare high-purity oligose from low-purity one. The process for treating and regenerating resin HZ001 is also disclosed.

Owner:NORTH CHINA PHARMA GROUP CORP

A pure red optically variable anti-counterfeit pigment and preparation method thereof

ActiveCN105137519BOvercoming the phenomenon of short-wave reflection sub-peaksFill in inherent defectsInorganic pigment treatmentOptical elementsGreen-lightColor changes

The invention provides an optically variable anti-counterfeiting pure red pigment. The anti-counterfeiting pigment comprises a central reflecting layer, a first dielectric layer, a first half-absorption layer, a second dielectric layer and a second half-absorption layer. The first dielectric layer and the first half-absorption layer are outwardly, sequentially, circularly and symmetrically arranged from the central reflecting layer. As the outermost layer of the anti-counterfeiting pigment, the second dielectric layer and the second half-absorption layer are symmetrically arranged on the two sides of the central reflecting layer. The rest can be done in the same manner. That means, along with the increasement of the total number of the layers, the layers are outwardly and symmetrically in radiation distribution from the central reflecting layer. According to the technical scheme of the invention, the pigment is of a N-layer symmetrical structure, and is constructed based on the multi-beam destructive interference condition for reflection beams within the wavelength range of blue and green light beams, wherein N=7, 9, 11, 13....,7+(2n). Meanwhile, the multi-beam constructive interference for reflection beams within the wavelength range of red light beams is ensured at the same time. Therefore, the pigment is displayed within the color range of pure red chromaticity.

Owner:厦门汉盾光学科技有限公司

Method for separating and purifying oligosaccharide in high purity

InactiveCN100439382CHigh puritySuitable for useSugar derivativesOligosaccharidesSalt solutionOligosaccharide

Owner:NORTH CHINA PHARMA GROUP CORP

A kind of production method of triglycidyl isocyanurate

InactiveCN101367796BReduce consumptionHigh yieldOrganic chemistryPowdery paintsSynthetic materialsEpichlorohydrin

Owner:CHANGZHOU NIUTANG CHEM PLANT CO LTD

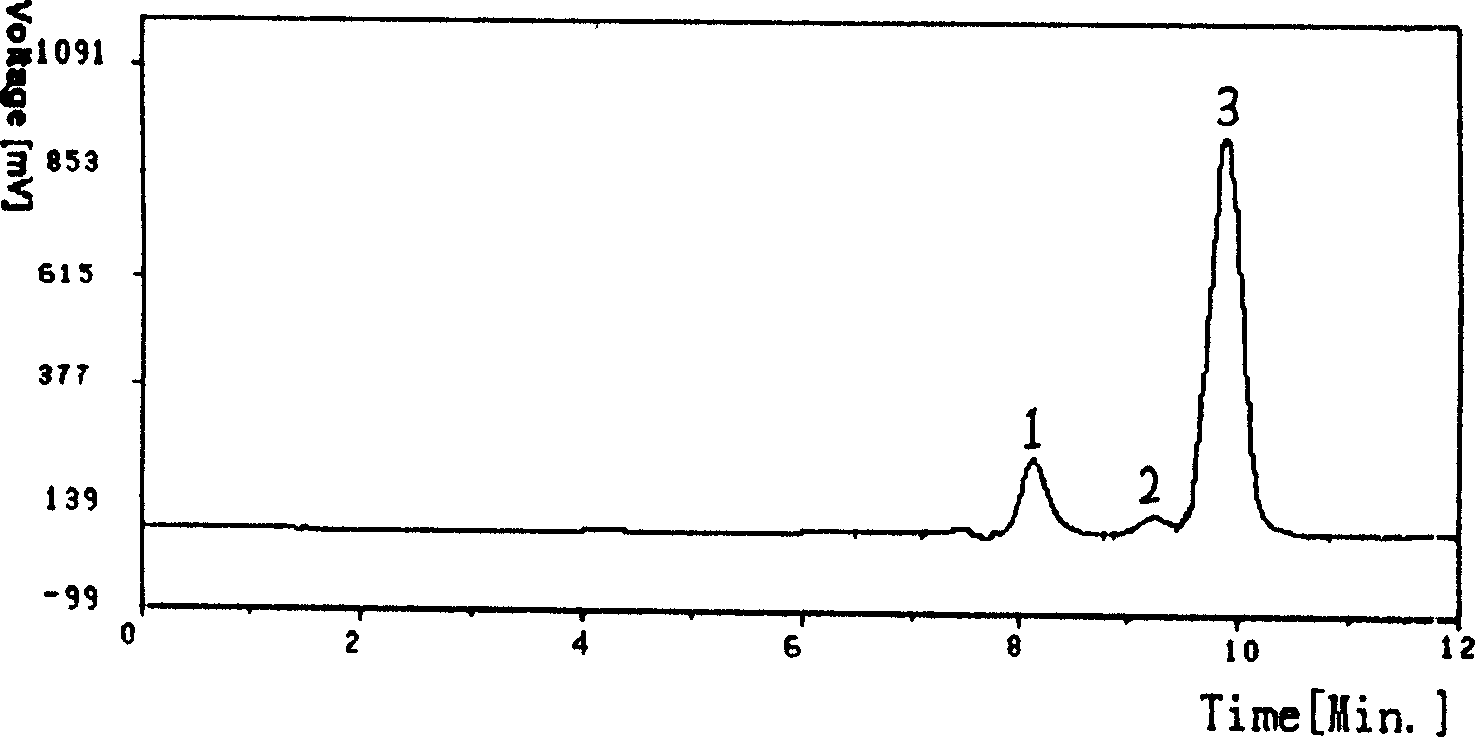

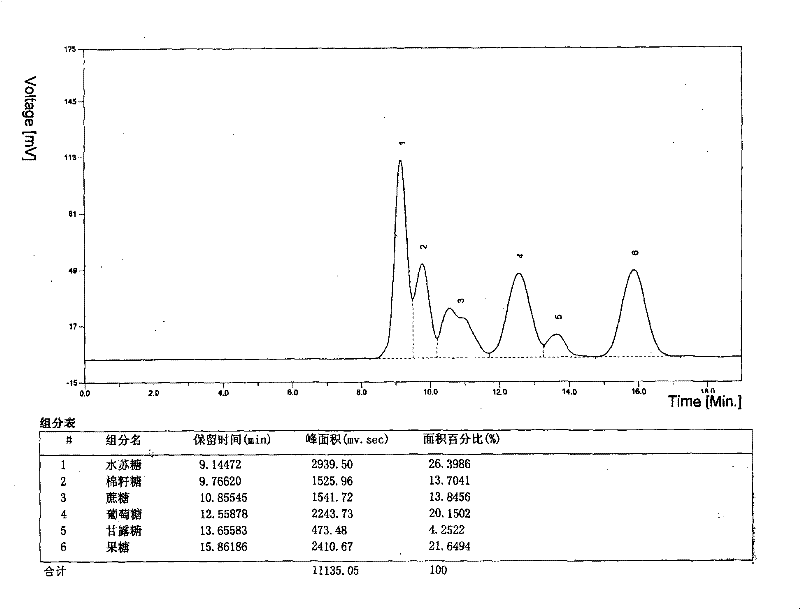

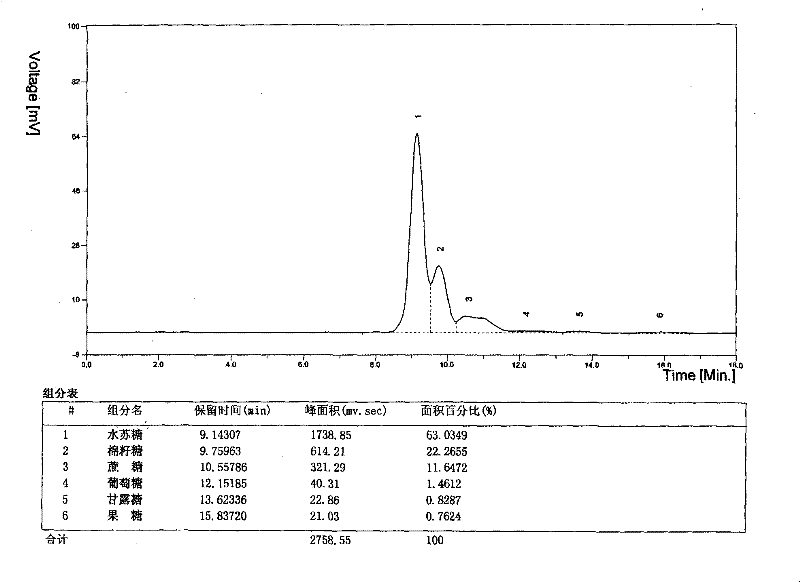

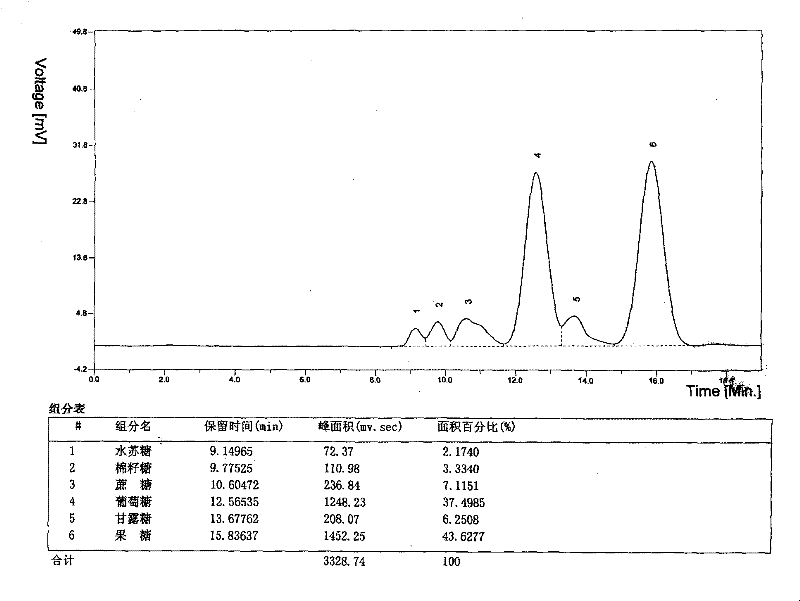

Method for preparing high content soybean oligosaccharide by simulated moving bed separation

InactiveCN101538291BThe process conditions are matureShort processCation exchanger materialsOrganic anion exchangersChromatographic separationFructose

The invention discloses a method for purifying soybean oligosaccharides. The soybean oligosaccharides with a content of 40% are separated by a simulated moving bed chromatographic separation device at a separation temperature of 45-80°C, using a cation exchange resin as an adsorbent, and using purified water as an eluent. Two kinds of products are obtained: one is the high-purity soybean oligosaccharide liquid with a soybean oligosaccharide (stachyose and raffinose) content greater than 85%, which is the main product; the other is a disaccharide and monosaccharide-containing component The fructose solution is a by-product. The yield of soybean oligosaccharides is greater than 90%.

Owner:南京凯通粮食生化研究设计有限公司

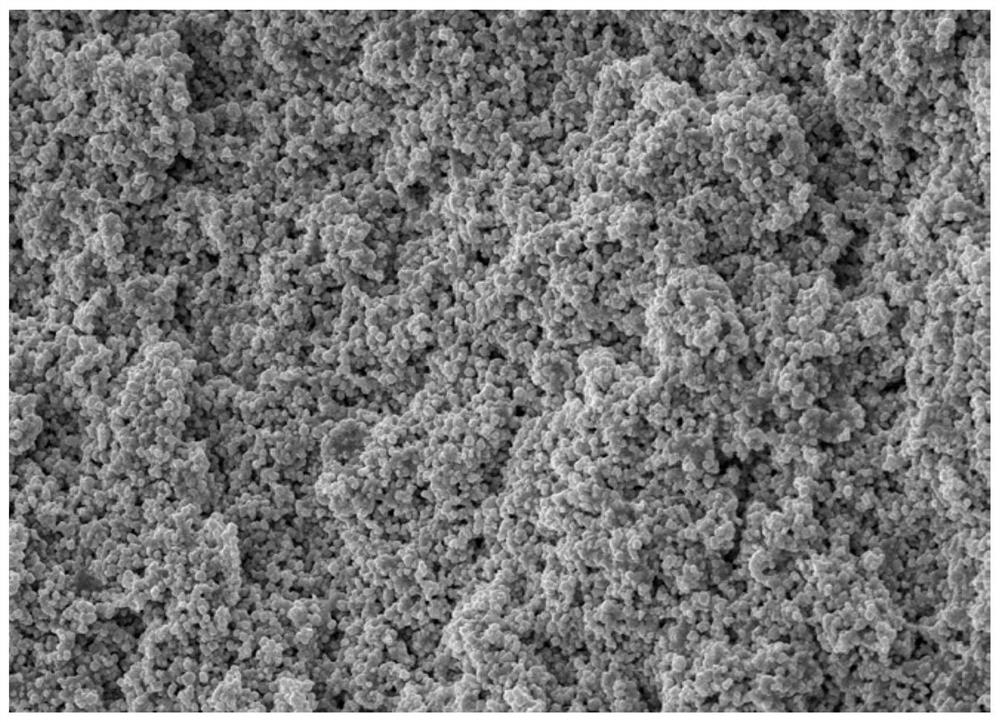

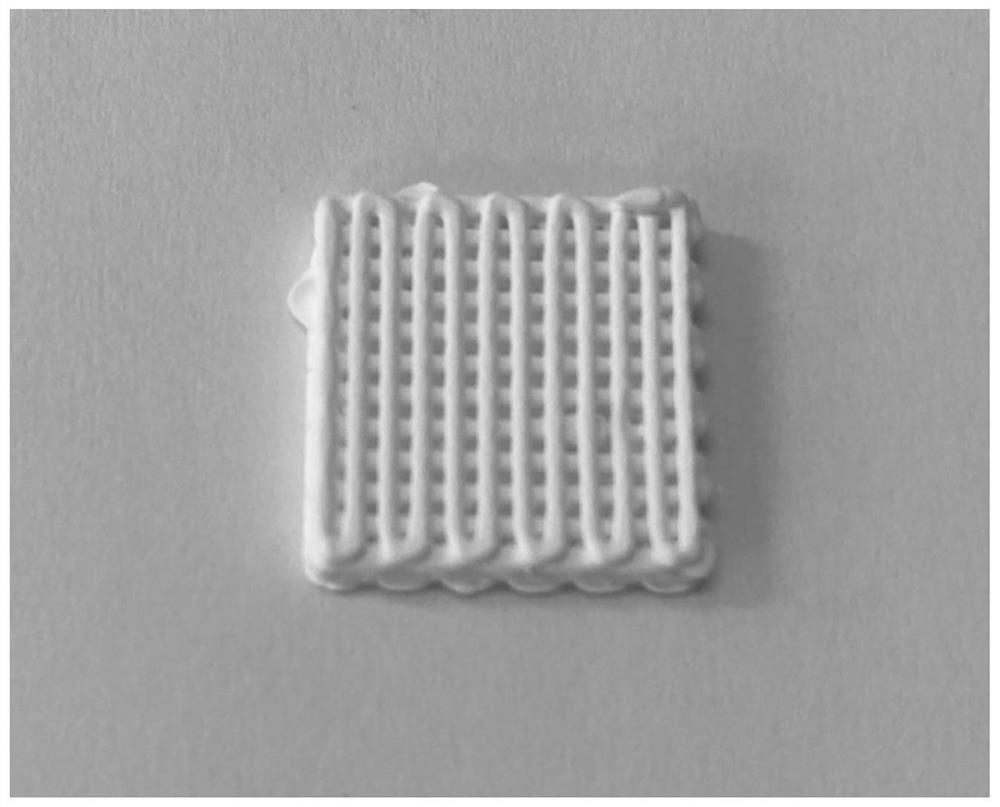

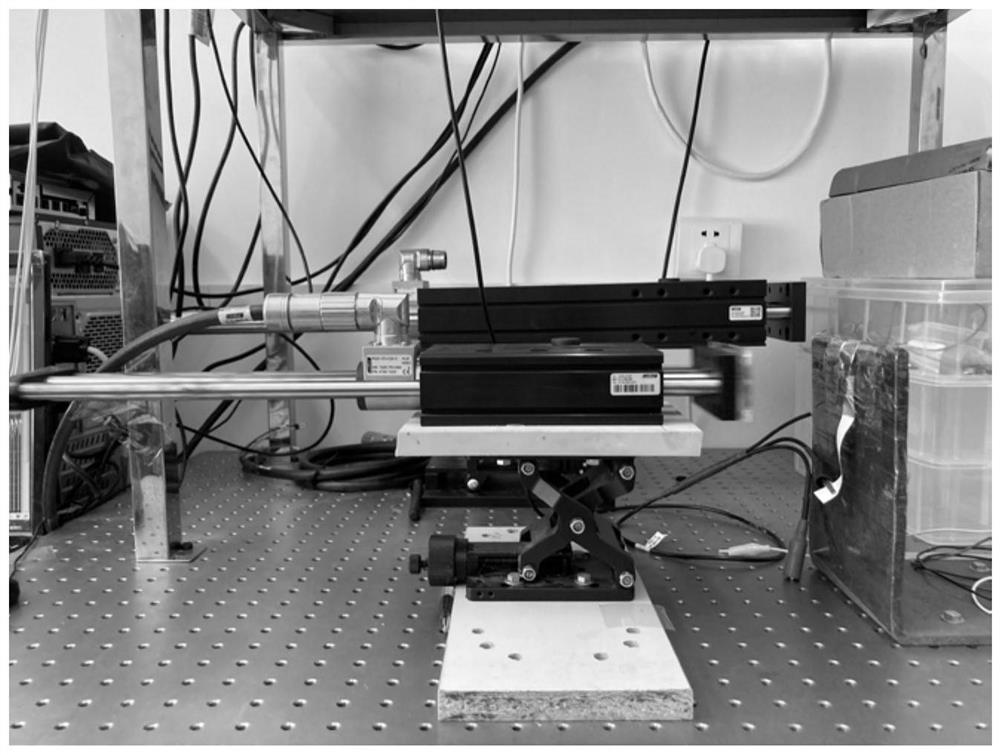

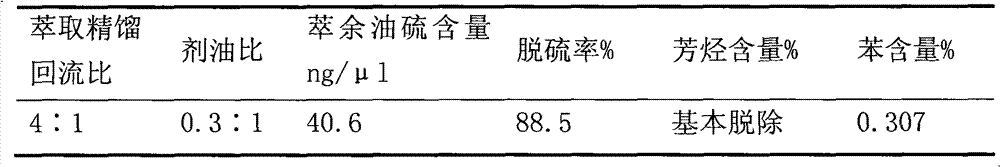

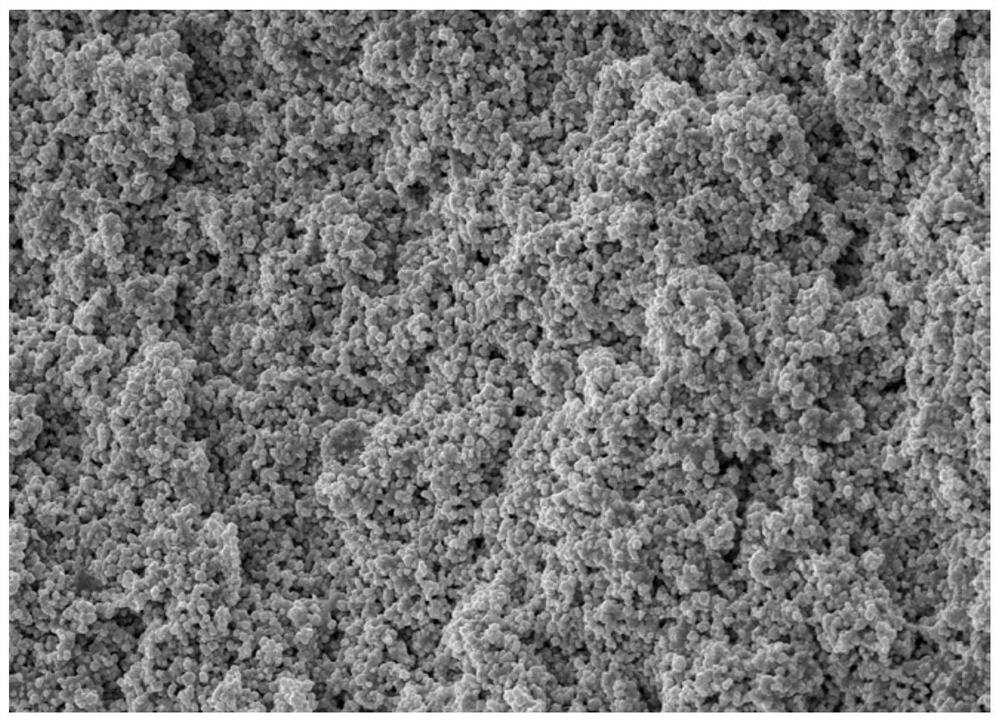

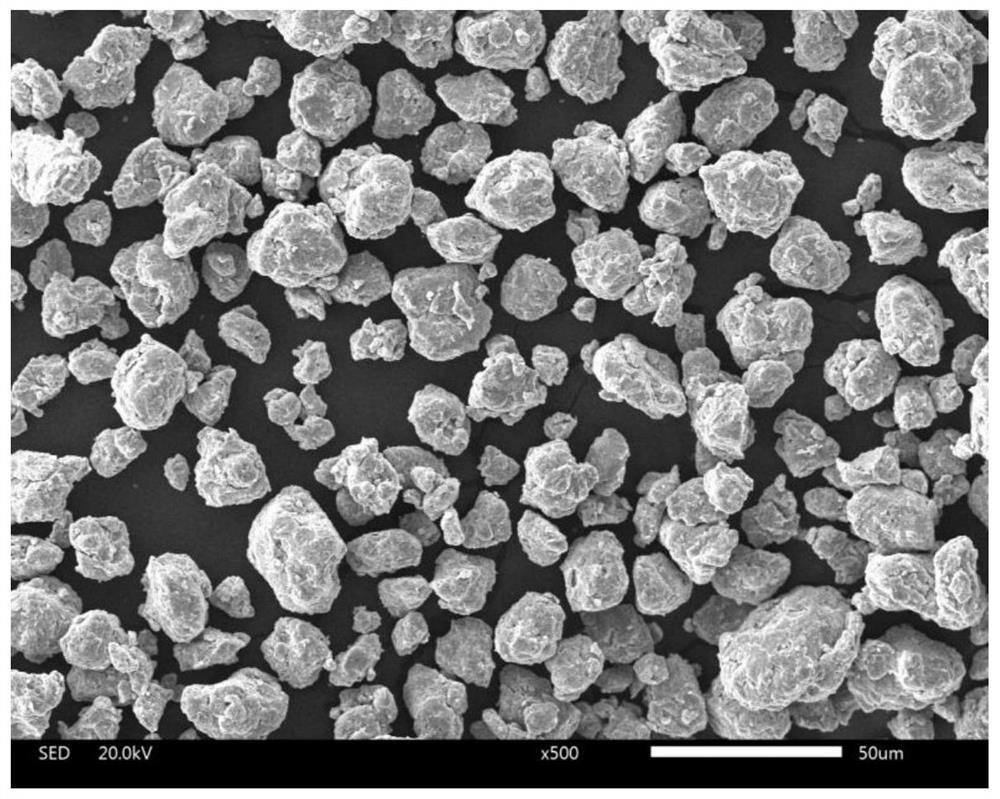

A piezoelectric ceramic super-filled silicon rubber composite ink material for ink direct writing printing and its preparation method and application

ActiveCN113621238BImprove performanceModerate viscosityAdditive manufacturing apparatusSilicon rubberCeramic materials

The invention provides a piezoelectric ceramic ultra-high filling silicone rubber composite ink material for ink direct writing printing and its preparation method and application. The raw materials of the composite ink material mainly include silicone rubber resin, piezoelectric ceramic filler and solvent components , wherein the amount of piezoelectric ceramic filler can reach 90wt%. Its preparation method is to fully disperse the piezoelectric ceramic filler in a solvent, then add silicone rubber resin to fully mix, and finally get it through thickening treatment, which can be directly applied to ink Direct write 3D printing. After testing, the composite ink material has good printing ability, good dispersion and strong supporting force, and the printed piezoelectric parts have good flexibility and piezoelectric output.

Owner:SICHUAN UNIV

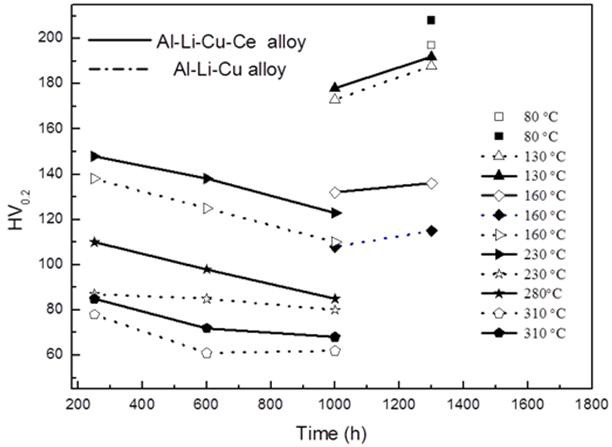

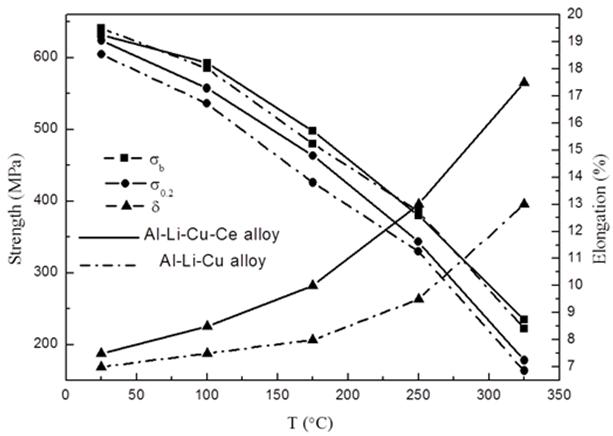

Preparation method of heat-resistant high-strength Al-Li-Cu-Ce alloy plate

The invention relates to a preparation method of a heat-resistant high-strength Al-Li-Cu-Ce alloy plate. The preparation method improves the heat resistance (heat exposure and high-temperature stretching) of an Al-Li-Cu alloy and realizes the preparation of the heat-resistant high-strength Al-Li-Cu-Ce alloy plate through microalloying of Ce and effective control of the whole process of the preparation process. On the one hand, the precipitation ratio of a T1 (Al2CuLi) phase with heat-resistant potential in the alloy is increased by improving the synergistic effect of Cu / Li in the alloy and pre-deformation before aging, and meanwhile, by adding a trace amount of Ce, coarsening of the T1 (Al2CuLi) phase and refinement of Ce-containing intermetallic compounds can be effectively inhibited by inhibiting diffusion of a main element Cu in the alloy; and the thermal stability and the high-temperature deformation uniformity of the alloy are greatly improved. The method is simple in equipment requirement, high in repeatability and suitable for large-scale commercial production, can be used as a novel aircraft heat-resistant structural part material in the aerospace field, and has a practical application value.

Owner:YANTAI NANSHAN UNIV

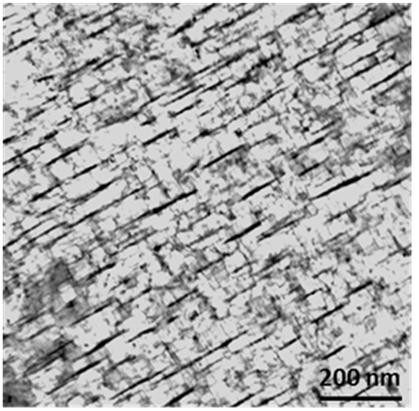

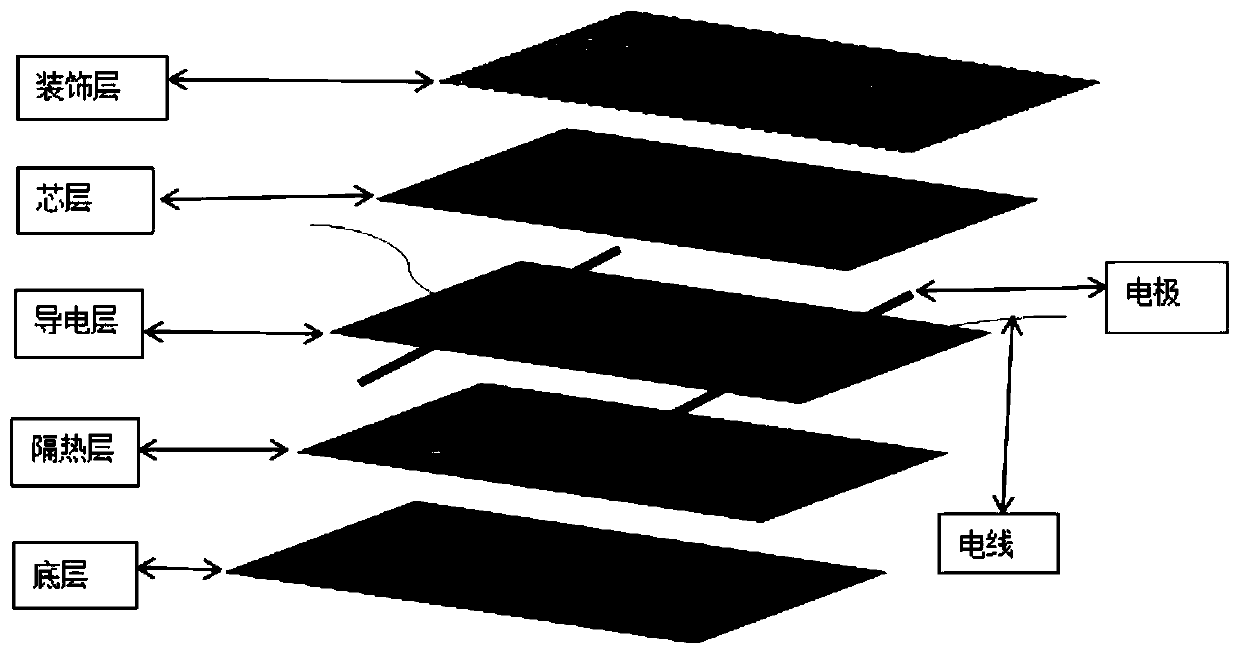

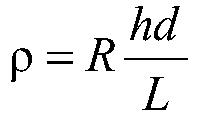

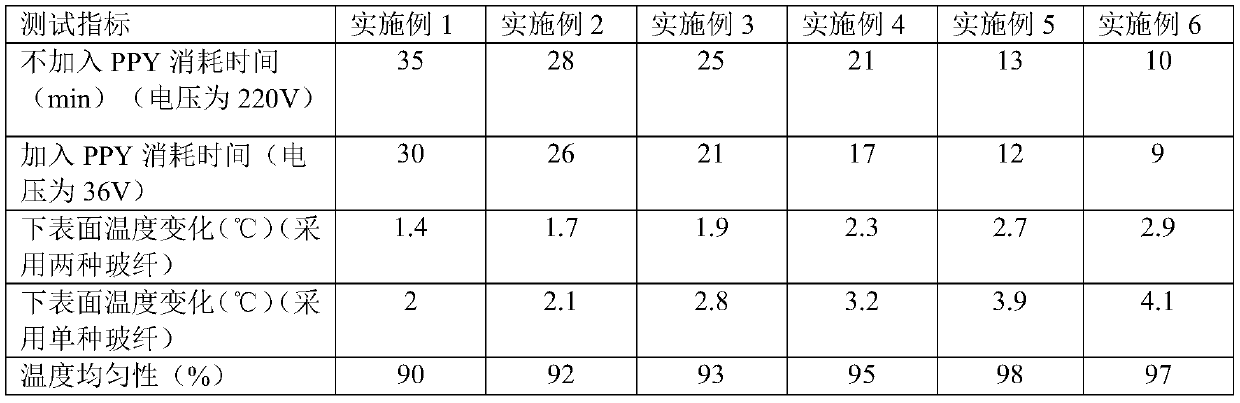

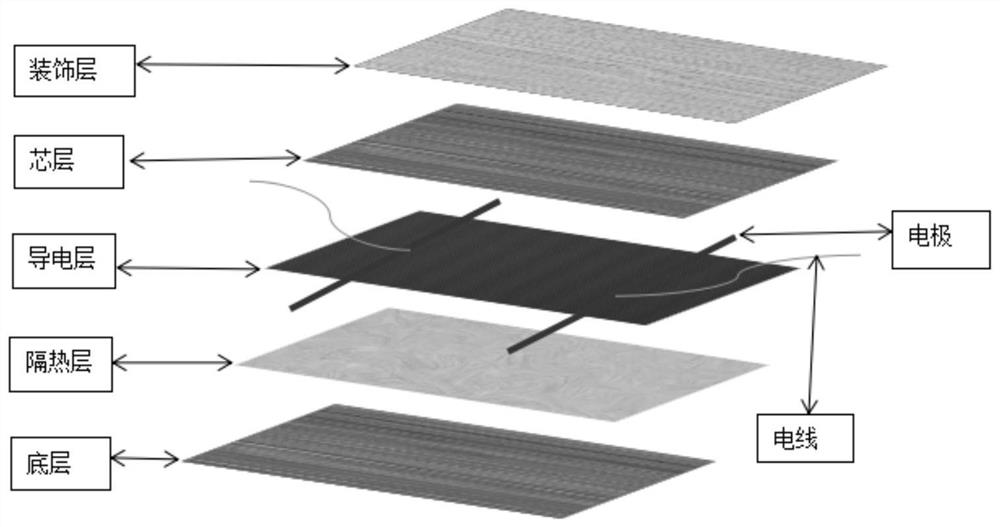

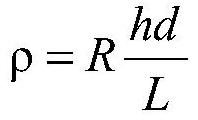

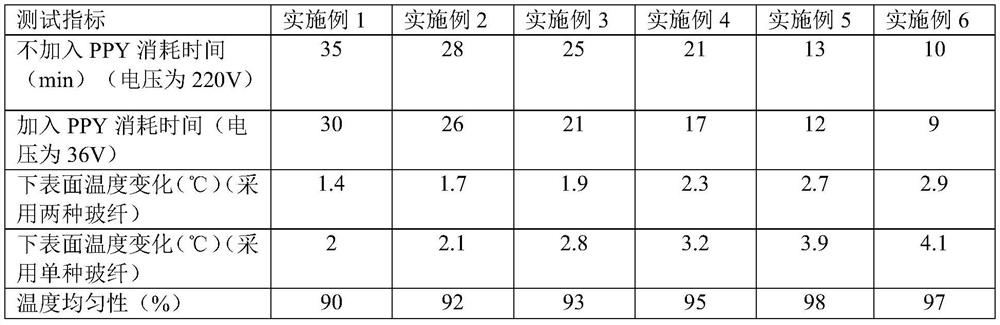

Wood floor based on carbon paper as heating layer and preparation method of wood floor

The invention discloses a wood floor based on carbon paper as a heating layer and a preparation method of the wood floor, and belongs to the technical field of decoration and heating. According to thepreparation method, a papermaking wet-process forming technology is adopted to prepare a carbon fiber paper layer, moreover, polypyrrole is uniformly distributed on the carbon fiber paper layer through impregnation and hot pressing technology to prepare a low-resistance heating layer, the function of low-voltage rapid heating can be realized, and the electric heating conversion efficiency can reach up to 98%; and the heating layer has the characteristics of being thin, light and good in uniformity, so that compared with other products prepared from carbon fibers, heating is more uniform, andthe temperature uniformity is up to 98%. The preparation method method has the advantages of being simple, green and environment-friendly, mature in process technology, low in cost, beneficial to human health, and is suitable for industrial production.

Owner:JIANGSU AOSHEN HI TECH MATERIALS CO LTD +3

Preparation method of trans-4-substituted cyclohexyl formaldehyde

InactiveCN108047015AThe synthesis steps are simpleMolecular utilization is highOrganic compound preparationOrganic chemistry methodsHydrogenGas phase

The invention discloses a preparation method of trans-4-substituted cyclohexyl formaldehyde, which is characterized by including steps of reacting trans-4-substituted cyclohexyl methanoic acid and oxalyl chloride under the condition of catalyst I and preparing trans-4-substituted cyclohexyl formyl chloride; performing hydrogen reduction reaction in the presence of palladium catalyst II, promoter III, promoter IV; preparing the trans-4-substituted cyclohexyl formaldehyde. The design is reasonable in reaction route and matured in technical condition; the reaction process of the modular preparation route is green and environment-friendly, and good for industrial production; the prepared product has high quality, the gas chromatography purity of the product is over 99.9%; a monomer liquid crystal material compounded by a midbody is good in quality and able to completely adapt to the need of TN-LCD, STN-LCD, and TFT-LCD.

Owner:YANTAI DERUN LIQUID CRYSTAL MATERIALS

Method for producing reforming feedstock by light and medium gasoline distillates

ActiveCN101649221BSolve protection problemsRelieve pressureCatalytic naphtha reformingHydrocarbon oils refiningFractionationGasoline

The invention relates to a method for producing catalytic reformed feedstock by taking light and medium gasoline distillates as raw materials and extracting selective solvent to extract and rectify catalytically cracked gasoline in the absence of hydrogen. The method comprises the following steps: 1, fractionation prefabrication of light and medium distillate raw materials of catalytically cracked gasoline; and 2, extraction, rectification, desulfuration and dearomatization of light and medium distillates of catalytically cracked gasoline, wherein light and medium distillates of catalyticallycracked gasoline obtained in step 1 are fed into the middle-lower part of an extraction-rectification tower, while fresh extraction agent or recycled extraction agent is added from the upper part of the extraction-rectification tower; thus, the light and medium distillates contact the extraction agent inside the tower to generate desulfurized and dearomatized light-component raffinate phase (i.e.catalytic reformed feedstock product) rich in olefin hydrocarbon at the top of the tower after extraction, rectification, desulfuration and dearomatization. The method carries out desulfuration and dearomatization of catalytically cracked gasoline at the same time and reclaims solvent, thereby having the advantages of simple process, moderate operation conditions, hydrogen source saving and low production cost.

Owner:PETROCHINA CO LTD +1

Piezoelectric ceramic ultra-high filling silicone rubber composite ink material for ink direct writing printing and preparation method and application of piezoelectric ceramic ultra-high filling silicone rubber composite ink material

ActiveCN113621238AImprove performanceModerate viscosityAdditive manufacturing apparatusCeramic compositeSilicon rubber

The invention provides a piezoelectric ceramic ultrahigh filled silicone rubber composite ink material for ink direct writing printing and a preparation method and application thereof, the composite ink material mainly comprises the following raw materials: silicone rubber resin, piezoelectric ceramic filler and solvent component, the addition amount of the piezoelectric ceramic filler can reach 90 wt%, and the addition amount of the solvent component can reach 90 wt%. The preparation method comprises the following steps: fully dispersing the piezoelectric ceramic filler in a solvent, then adding the silicone rubber resin, fully mixing, and finally carrying out thickening treatment, thereby obtaining the piezoelectric ceramic composite material which can be directly applied to ink direct writing 3D printing. Tests show that the composite ink material is good in printing capacity, good in dispersity and high in supporting force, and a printed piezoelectric workpiece has good flexibility and piezoelectric output.

Owner:SICHUAN UNIV

A kind of wooden floor based on carbon paper as heating layer and preparation method thereof

Owner:JIANGSU AOSHEN HI TECH MATERIALS CO LTD +3

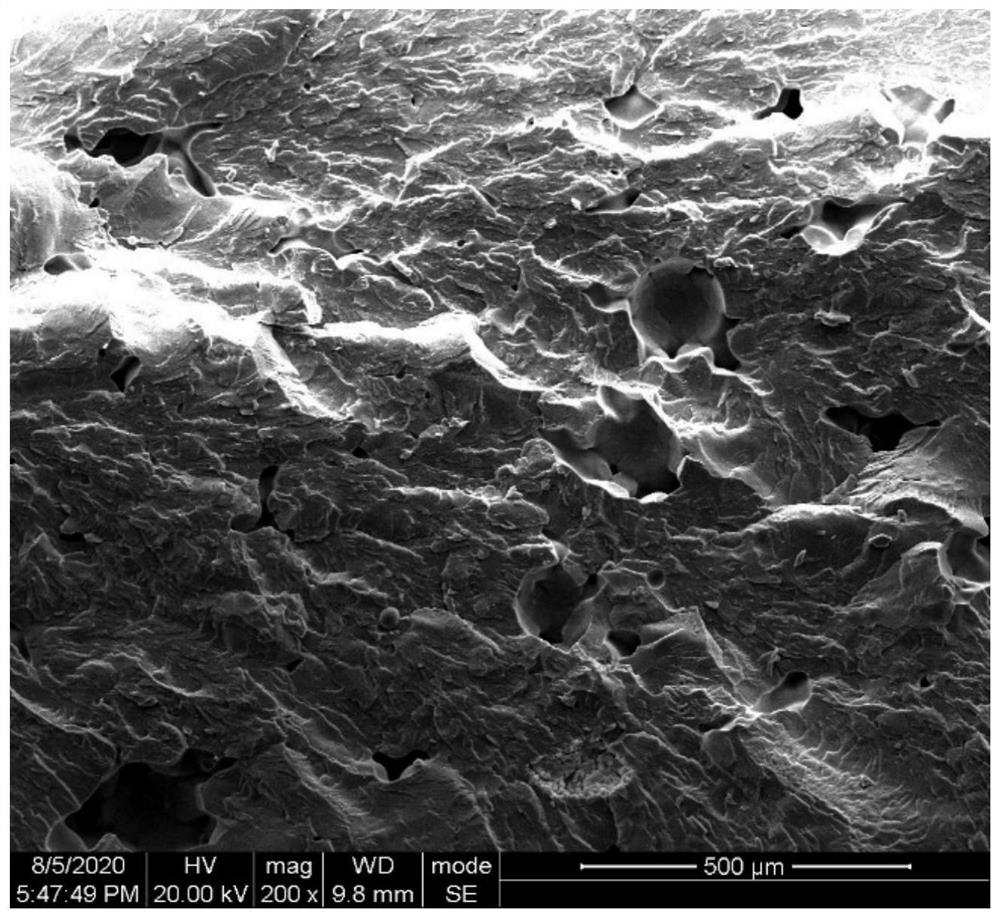

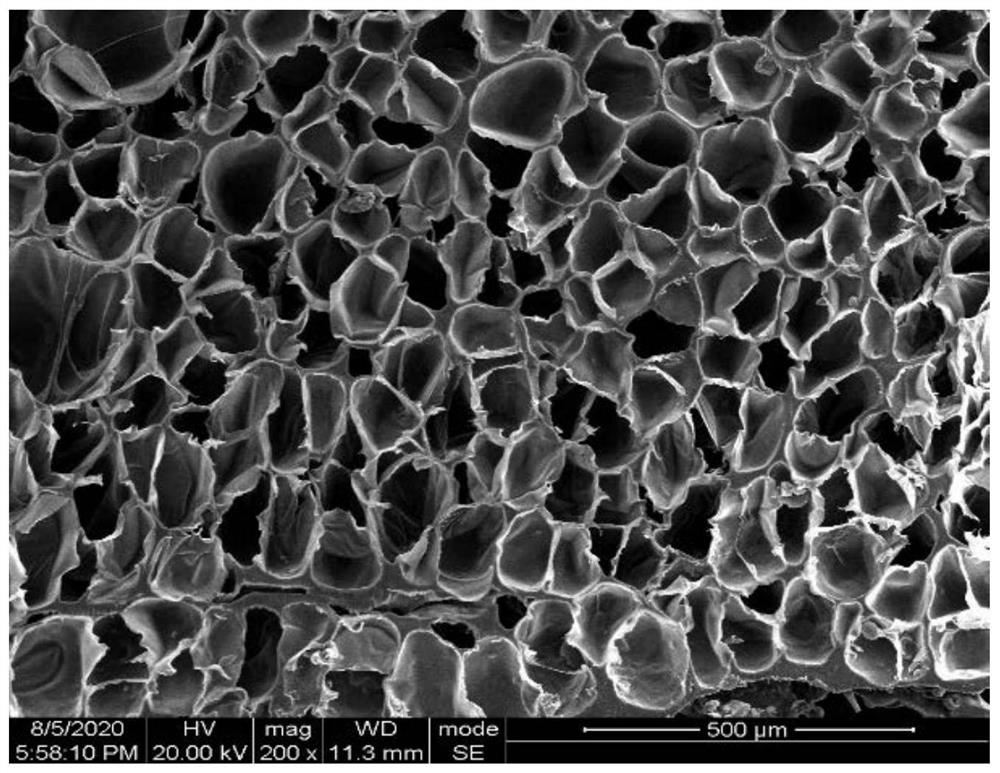

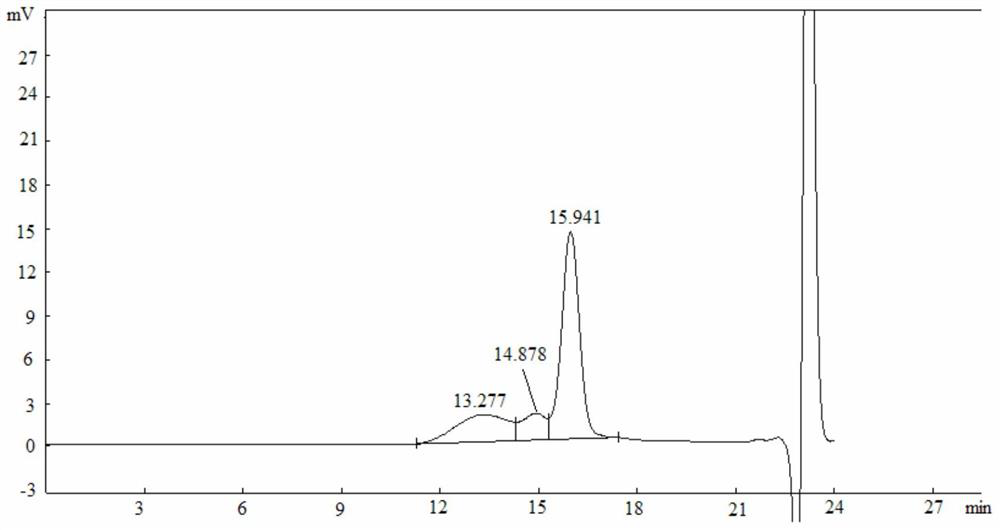

A through sls with scfco 2 Combined method for preparing polymer-based piezoelectric foam parts

ActiveCN112895436BPiezo output highHave mechanical strengthAdditive manufacturing apparatus3D object support structuresPolymer scienceSelective laser sintering

Owner:SICHUAN UNIV

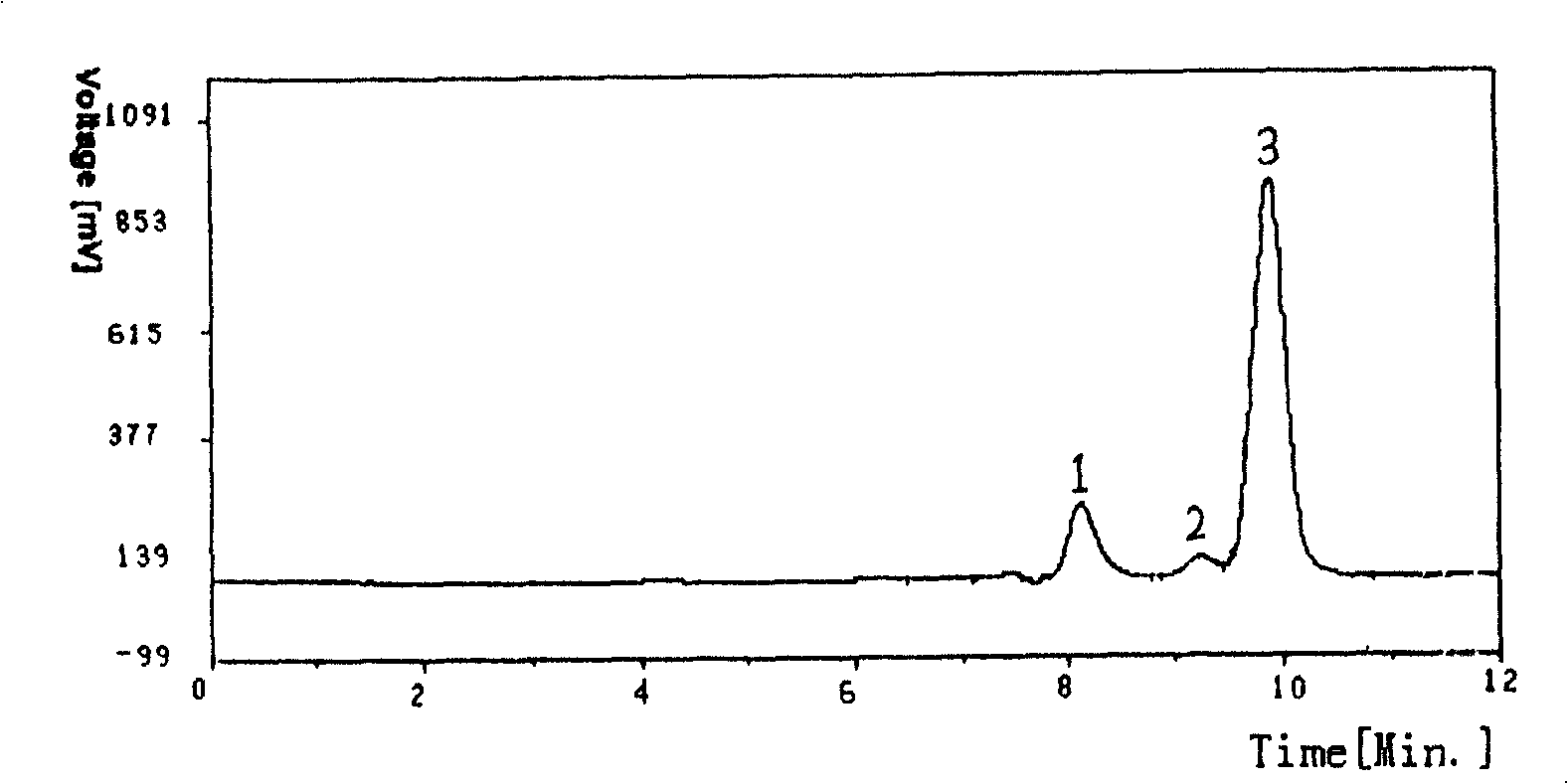

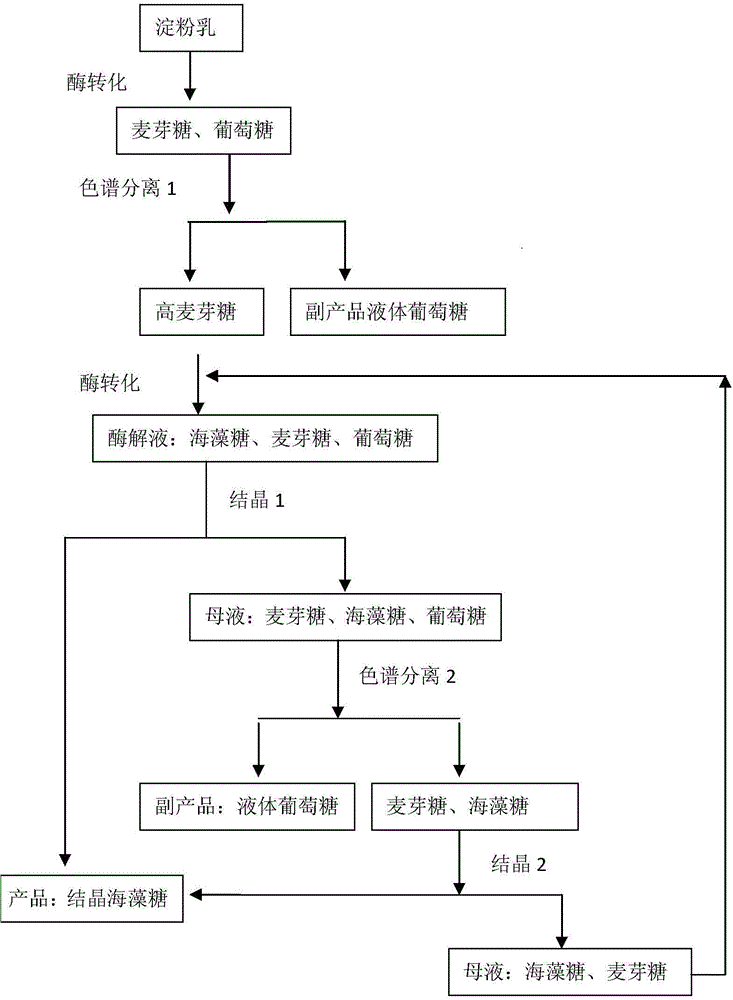

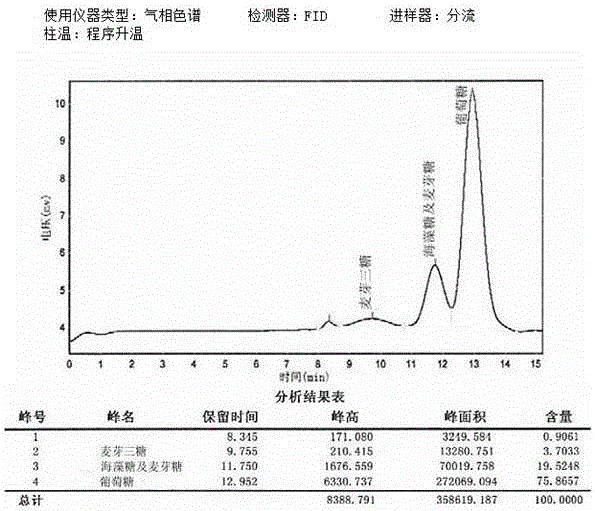

A kind of production method of trehalose

ActiveCN104418919BIncrease profitThe process conditions are matureSugar derivativesDisaccharidesChromatographic separationMaltitol

The invention provides an efficient clean production process for mycose. According to the production process, a chromatographic separation technology is flexibly applied to industrial production of mycose. An enzymatic hydrolysis liquid of mycose is prepared by using maltose, is subjected to decoloring and ion-exchange refining processing, and then enters a chromatographic separation system for separation. A common calcium type separating agent used in industry in large scale is selected for separating glucose and disaccharides, wherein disaccharides mean maltose and mycose. The extraction liquid is abundant in maltose and mycose. Maltitol obtained through reduction of maltose and mycose are both products with extremely high added value. The mixed solution is hydrogenated at a high temperature under a high pressure, maltose is reduced into maltitol through hydrogenation, and mycose does not possess reductivity and is not hydrogenated, so that a hydrogenation mixed solution containing maltitol and mycose is obtained. The hydrogenation mixed solution is subjected to purification processing and then enters a second chromatographic separation system for separation, the extraction liquid have a high-content mycose material, and the extraction liquid is subjected to evaporation heat crystallization or cooling crystallization, so as to obtain crystallized mycose.

Owner:南京凯通粮食生化研究设计有限公司

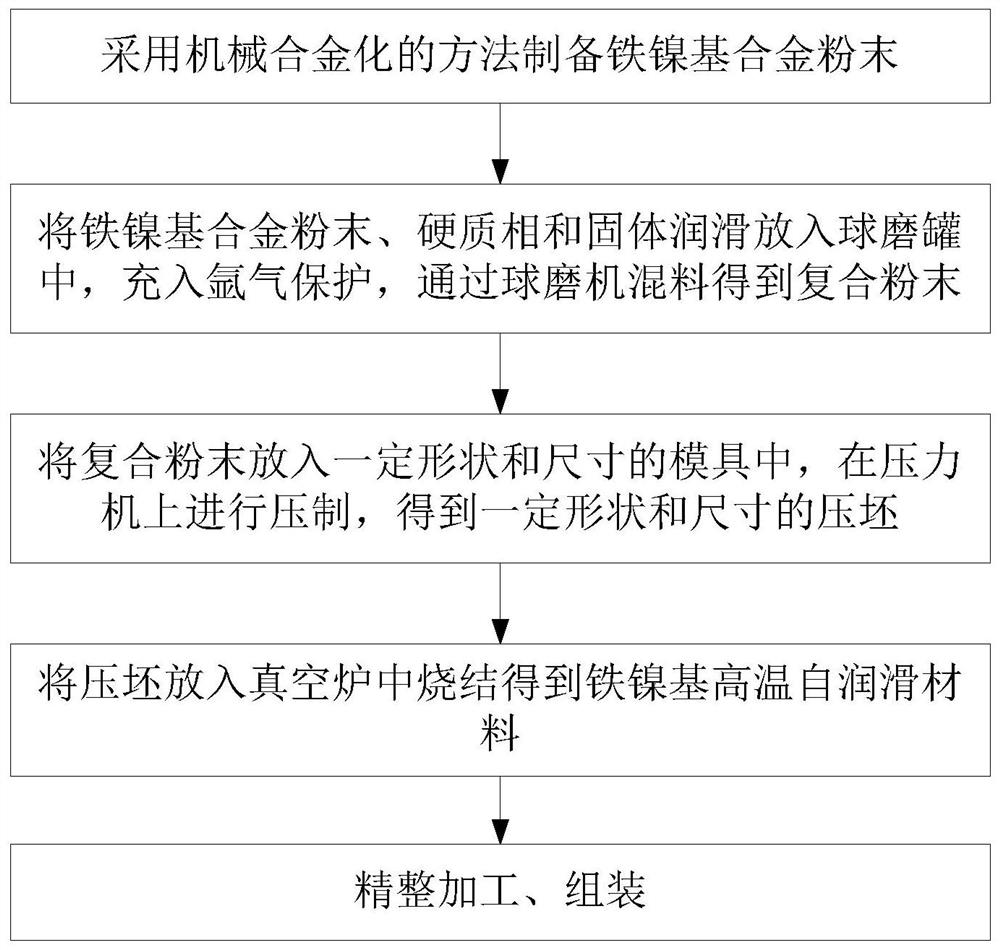

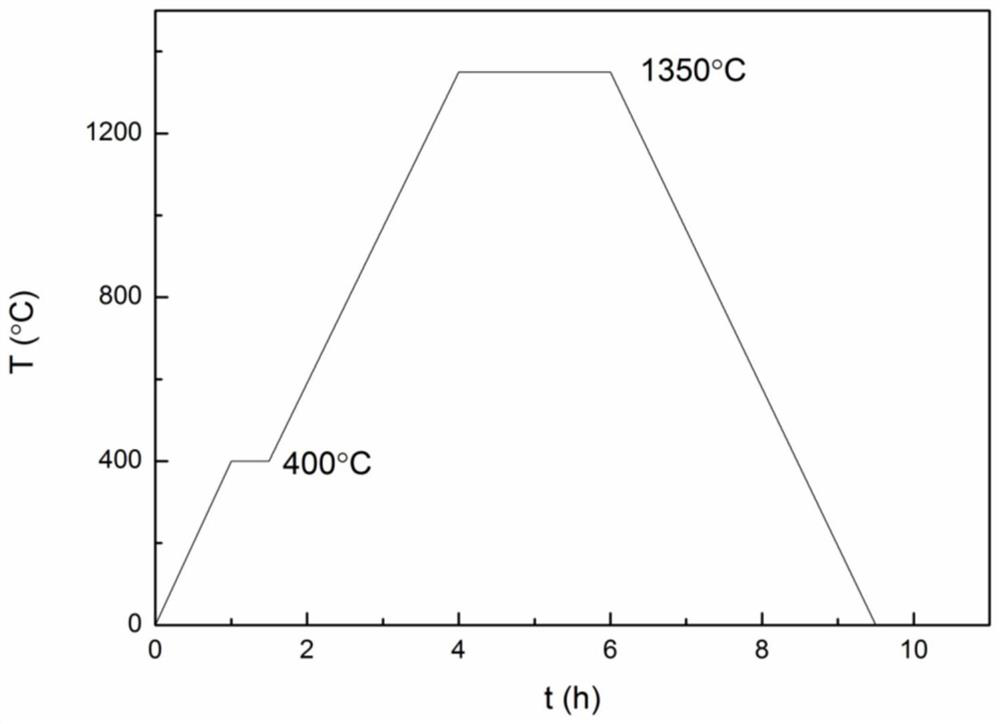

Iron-nickel-based high-temperature self-lubricating hot work die material and its preparation method

The invention discloses an iron-nickel-based high-temperature self-lubricating hot-working die material which comprises an alloy matrix, a solid lubricant and a hard phase, wherein an ingredient of the alloy matrix is iron-nickel-based alloy powder, and the alloy matrix is prepared by taking a GH2135 ingredient as the standard; the solid lubricant is CaF2; the hard phase is Cr2O3; three phases ofpowder of the alloy matrix, the solid lubricant and the hard phase are uniformly mixed by a ball mill, and then a hot-working die is prepared by a powder metallurgy method. The iron-nickel-based high-temperature self-lubricating hot-working die disclosed by the invention can implement self-lubrication under the condition of no oil or little oil, and meanwhile, is low in production cost.

Owner:WUHAN UNIV OF TECH

Colon-targeted drug delivery soft capsule and preparation method thereof

ActiveCN101167765BMake up for the gap in development and applicationEasy to prepareDigestive systemCapsule deliveryCellulose acetateMedicine

The invention discloses a colon-targeted drug delivery soft capsule, which comprises Brucea javanica oil soft capsule and a polymer coating film, and the polymer coating film is a pH-sensitive enteric coating containing ethyl cellulose or cellulose acetate vegetarian ingredients. The present invention provides precise composition of the polymer coating film, realizes that the coated soft capsule does not disintegrate in the buffer solution of pH<7, but disintegrates in the buffer solution of pH>7, and achieves the ideal colon The requirements of localized drug release, the preparation method is simple, and the process conditions are mature, which makes up for the development and application of soft capsules that do not have colonic drug delivery in China.

Owner:惠州市九惠药业有限公司

Grid drive circuit for controlling bridge type drive circuit

The invention discloses a grid drive circuit for controlling a bridge type drive circuit. The grid drive circuit comprises a low-voltage side control chip, a high-voltage side control chip and a level shifting chip, wherein the low-voltage side control chip and the high-voltage side control chip are produced by adopting a complementary metal oxide semiconductor (CMOS) process; the level shifting chip is produced by a high-voltage isolation manufacturing process; the low-voltage side control chip is mainly integrated by a control logical module and a low-voltage side drive module; the level shifting chip is mainly integrated by a level shifting module; and the high-voltage side control chip is mainly integrated by a high-voltage side drive module. The grid drive circuit has the advantages that: singlechips for integrating all the modules are realized by being divided into three chips, the level shifting module is produced only by adopting the high-voltage isolation manufacturing process, and the control logical module, the low-voltage side drive module and the high-voltage side drive module are produced by adopting the CMOS process; and the grid drive circuit is encapsulated into an integrated circuit, so compared with the conventional grid drive chip, the complexity of the production process is reduced, the chip area is reduced, the production cost is reduced, and a circuit with more complicated properties can be designed favorably.

Owner:NINGBO SEMICON INT CORP

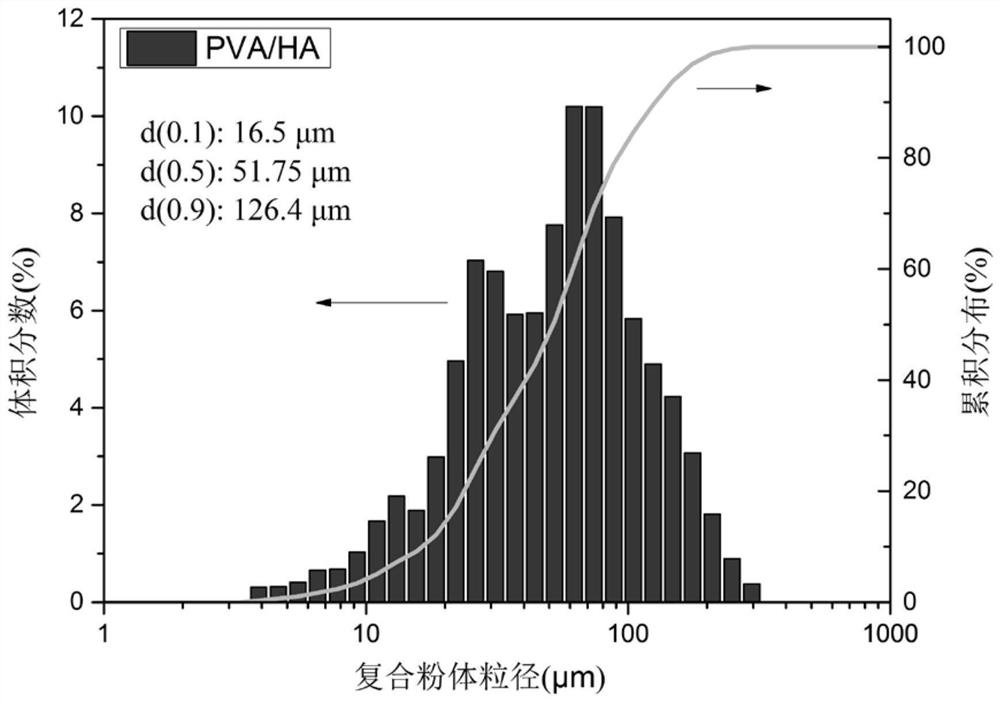

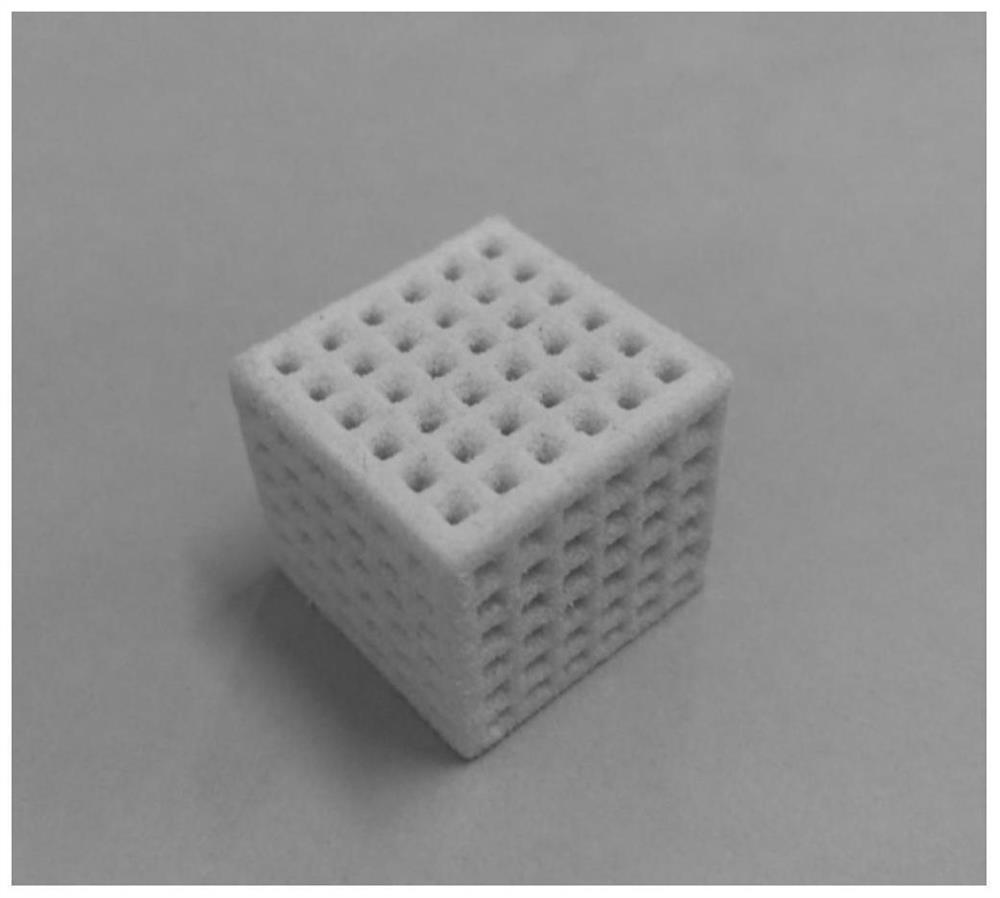

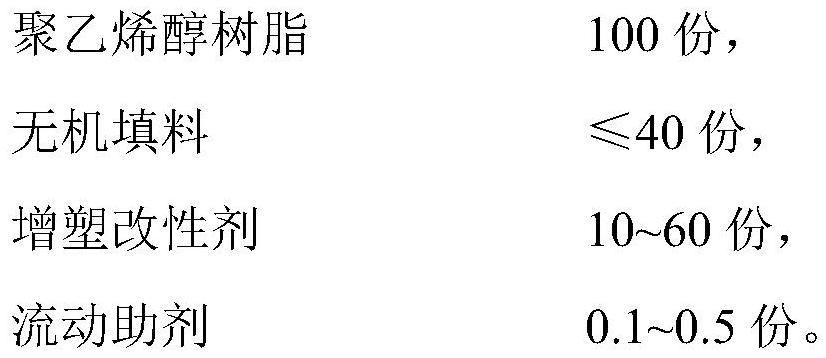

Polyvinyl alcohol-based composite powder for selective laser sintering and preparation method thereof

ActiveCN111234430BImprove performanceSintering window widthAdditive manufacturing apparatusSelective laser sinteringPolyvinyl alcohol

The invention provides polyvinyl alcohol-based composite powder for selective laser sintering and a preparation method thereof. The composite powder comprises the following raw materials in parts by weight: 100 parts of polyvinyl alcohol resin, less than or equal to 40 parts of an inorganic filler, 10-60 parts of a plasticizing modifier and 0.1-0.5 part of a flow aid. The preparation method of thecomposite powder includes plasticizing and modifying the polyvinyl alcohol, and mixing with the inorganic filler to prepare the powder material suitable for selective laser sintering. The addition amount of the inorganic filler in the polyvinyl alcohol-based composite powder can reach 40 wt% of the addition amount of polyvinyl alcohol, the functionality of the high-addition-amount filler can be brought into full play, the sintering window is wide, the fluidity is good, and the polyvinyl alcohol-based composite powder is suitable for selective laser sintering 3D printing processing.

Owner:SICHUAN UNIV

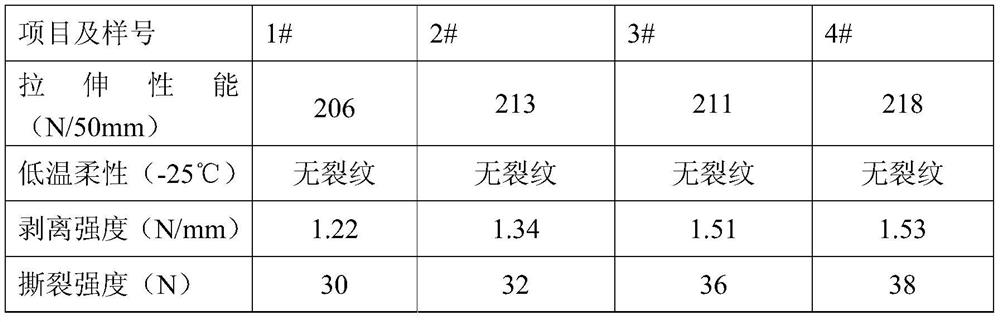

A kind of polyconjugated diene/sbs composite rubber particle and its preparation method and the application of composite rubber particle in modified asphalt

ActiveCN107474464BLower glass transition temperatureImprove low temperature resistanceBuilding insulationsPolymer scienceAsphalt

The invention discloses a polyconjugated diene / SBS composite rubber particle and a preparation method thereof and application of the composite rubber particle in modified asphalt. The preparation method of the polyconjugated diene / SBS composite rubber particle comprises the following steps: uniformly mixing a polyconjugated dieneglue solution and a SBS glue solution, and carrying out coagulation, expansion drying and granulation to obtain the composite rubber particle. The composite rubber particle will not cold-flow and is non-sticky at room temperature, shows good autohension under the action of rubber oil, is used for modified asphalt materials, and shows low low-temperature performance, excellent processability and good physical properties. In addition, the preparation method of the composite rubber particle is simple, cost is low, process conditions are mature, especially there is no dust pollution, and the method is beneficial to industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing D-xylose and L-arabinose by recycling phosphoric acid

ActiveCN103074454BAchieve recyclingReduce pollutionSugar derivativesSugar derivatives preparationHydrolysatePhosphoric acid

Owner:广西轻工业科学技术研究院有限公司

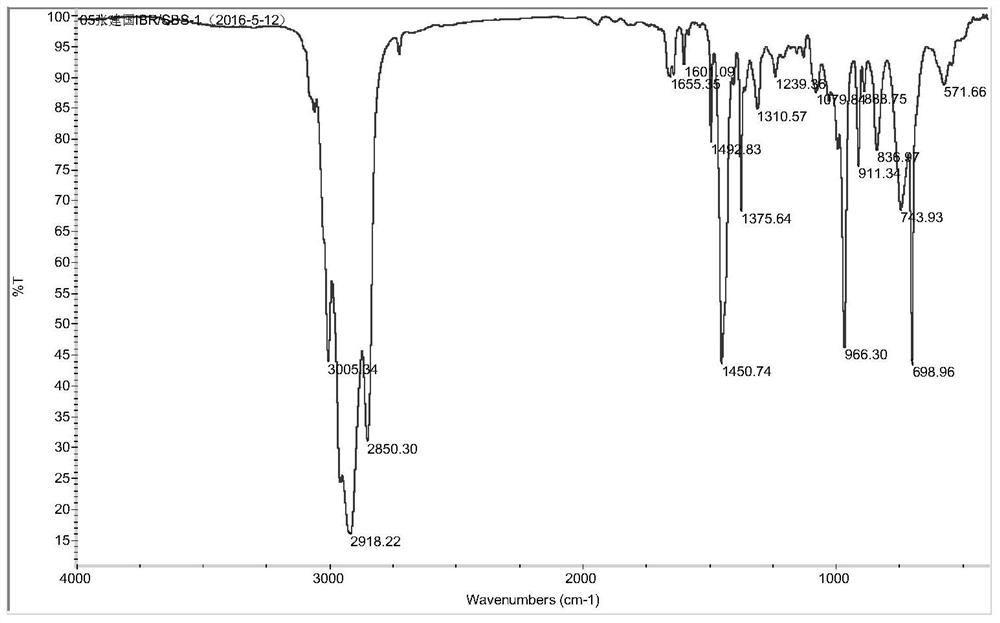

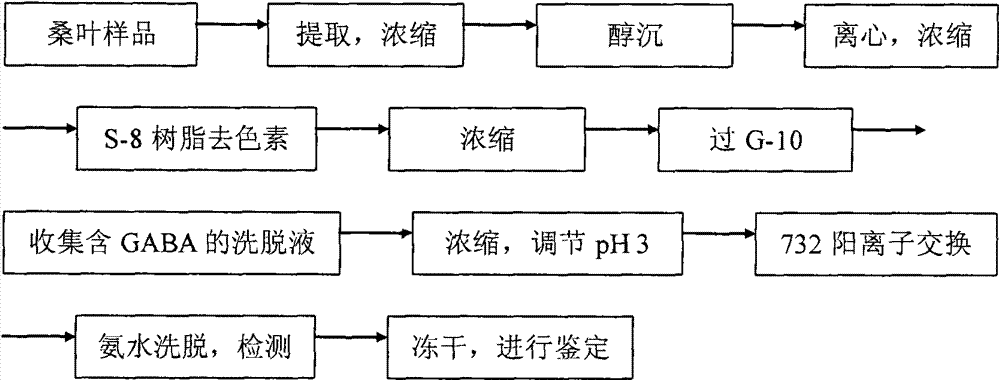

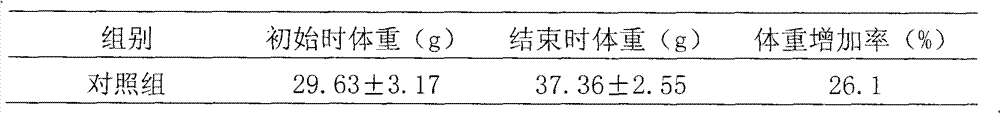

Method for extracting mulberry leaf gamma-aminobutyric acid and application thereof

InactiveCN101633623BEasy extractionReduce manufacturing costOrganic active ingredientsMetabolism disorderLivestock breedingOrganic chemistry

The invention discloses a method for extracting mulberry leaf gamma-aminobutyric acid and an application thereof. In the invention, mulberry leaves are utilized as a raw material, a coarse extract is prepared by mulberry leaf drying, pulverization, water leaching and ultrasonic wave-microwave synergistic extraction, and then a gamma-aminobutyric acid white crystal with high purity is prepared by three-stage separation and purification after parts of doped proteins and polysaccharide substances of the coarse extract are removed. The invention provides the active functions of the mulberry leaf gamma-aminobutyric acid for promoting the growth and development of animals and reinforcing the anti-fatigue capability. The invention has simple method and mature technological conditions, is suitable for industrialized production, provides a technical base for further developing a novel application of the mulberry leaves in the non-silk industry and puts forward a way of applying the mulberry leaves GABA to the fields of the medicine, health-care foods, the livestock industry and the like so as to enable the mulberry leaves GABA to become a novel luminous point for extending and developing the silk road.

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com