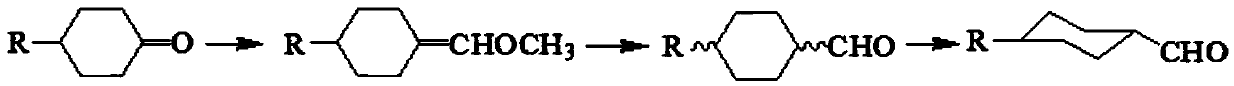

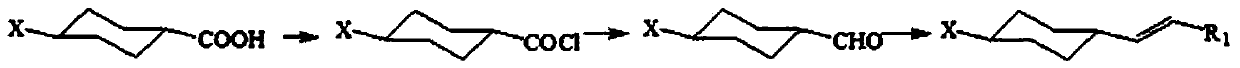

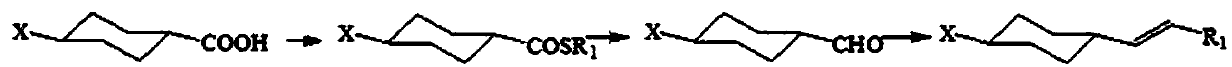

Preparation method of trans-4-substituted cyclohexyl formaldehyde

A technology of cyclohexyl formic acid and cyclohexyl carboxylic acid chloride, which is applied in the field of chemical synthesis and preparation, can solve the problems of increasing costs, hidden dangers of pollution, and inability to use precious metals, and achieve the effects of increased efficiency, reduced costs, and low costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Taking the preparation of trans-4-(trans-4-propylcyclohexyl)cyclohexyl formaldehyde (I-1) as an example, the preparation method of alkyl biscyclohexyl formaldehyde compounds is described in detail:

[0065] Step a. Preparation of trans-4-(trans-4-propylcyclohexyl)cyclohexylcarbonyl chloride (Ⅲ-1):

[0066] a 1 .Add dry toluene 18L to the reactor, and install an inert gas protection device, a dropping device, a heating and cooling device, a vacuum device and a tail gas absorption device on the reactor, and then pass nitrogen into it to empty the air in the reactor to keep Slight positive pressure, sequentially add 5.04 kg of raw materials trans-4-(trans-4-propylcyclohexyl)cyclohexyl formic acid (II-1) and 10 g of pyridine, and start to drop 2.79 g of oxalyl chloride when the temperature drops to 20 °C kg, dropping temperature 20°C-25°C;

[0067] a 2 . After the dropwise addition, keep warm at 20°C-25°C for reaction, react for 2 hours and take a sample test. After pass...

Embodiment 2

[0080] Taking the preparation of trans, trans-4-methylphenylbicyclohexylcarbaldehyde (I-2) as an example, the preparation method of trans, trans-4-alkylphenylbicyclohexylcarbaldehyde compounds is described in detail:

[0081] Step a. trans, the preparation of trans-4-methylphenylbicyclohexylcarbonyl chloride (Ⅲ-2):

[0082] a 1 .Add dry toluene 10L in the reactor, and install inert gas protection device, dripping device, heating and cooling device, vacuum device and tail gas absorption device on the reactor, then pass nitrogen into it to evacuate the air in the kettle to keep Slightly positive pressure, add raw materials in sequence: trans,trans-4-methylphenylbicyclohexylcarboxylate (II-2) 3.00kg, pyridine 8g, when the temperature is lowered to 20°C, start to drop 1.90kg of oxalyl chloride, drop The heating temperature is maintained at 20°C-25°C;

[0083] a 2 . After the dropwise addition, keep warm at 20°C-25°C for reaction, react for 2 hours and take a sample test. After ...

Embodiment 3

[0096] Taking the preparation of trans-4-(trans-4-(3,4-difluorophenyl)cyclohexyl)cyclohexylcarbaldehyde (I-3) as an example, the trans-4-(trans-4- The preparation method of fluorophenyl cyclohexyl) cyclohexyl formaldehyde compound:

[0097] Step a. Preparation of trans-4-(trans-4-(3,4-difluorophenyl)cyclohexyl)cyclohexylcarbonyl chloride (Ⅲ-3):

[0098] a 1. Add 5L of dry toluene to the reaction kettle, and install an inert gas protection device, a dropping device, a heating and cooling device, a vacuum device and a tail gas absorption device on the reaction kettle, and then pass nitrogen into it to evacuate the air in the kettle to keep a slight Under positive pressure, 1.61 kg of trans-4-(trans-4-(3,4-difluorophenyl)cyclohexyl)cyclohexyl formic acid (II-3) and 5 g of pyridine were sequentially added, and when the temperature was lowered to 20°C, Start to add 0.95 kg of oxalyl chloride dropwise, and keep the dropping temperature at 20°C-25°C;

[0099] a 2. After the dropw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| isotropization temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com