Method for extracting mulberry leaf gamma-aminobutyric acid and application thereof

An aminobutyric acid and extraction method technology, applied in the field of chemistry, can solve problems such as unfavorable large-scale application production, destruction of γ-aminobutyric acid, cumbersome extraction process, etc., and achieve the effects of low production cost, easy extraction, and mature process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

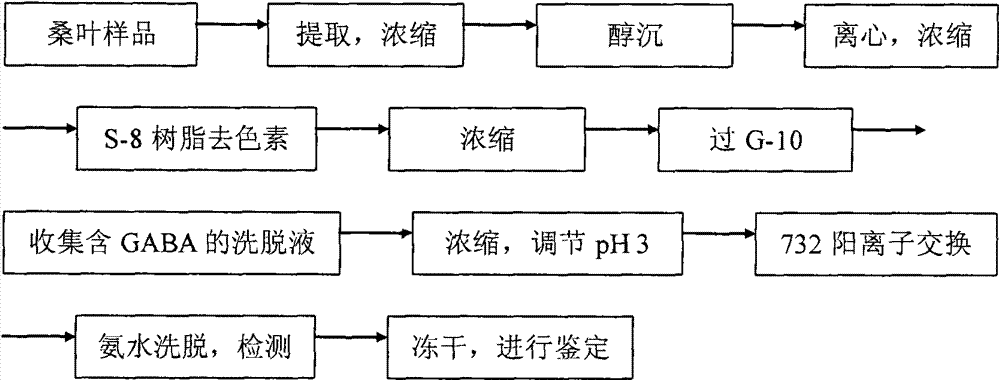

[0055] Extraction and preparation of γ-aminobutyric acid

[0056] 1. The specific operation steps are as follows:

[0057] (1) mulberry leaves are dried and pulverized;

[0058] Mature leaves of the mulberry variety Kangqing 10 were picked, rinsed with clean water to remove the dust attached to the surface of the mulberry leaves, dried in the air, baked in an oven at 85°C for 30 minutes, and then cooled to 65°C for 4.2 hours.

[0059] The dried samples were pulverized, sealed in bags and stored at low temperature (5-0°C) for later use.

[0060] (2) prepare the crude extract of gamma-aminobutyric acid

[0061] Add water to dry mulberry leaf powder according to the ratio of mulberry leaf powder weight (g): water volume (mL) of 1:30, soak for 15min, then carry out ultrasonic-microwave synergistic extraction under the conditions of microwave 144W and ultrasonic wave 50W, time After 160s, the extract was centrifuged to remove the precipitate, and the supernatant was collected an...

Embodiment 2

[0074] Extraction and preparation of γ-aminobutyric acid

[0075] (1) mulberry leaves are dried and pulverized;

[0076] Mature leaves of the mulberry variety Kangqing 10 were picked, rinsed with clean water to remove the dust attached to the surface of the mulberry leaves, dried in the air, baked in an oven at 83°C for 32 minutes, and then cooled to 67°C for 4 hours.

[0077] The dried samples were pulverized, sealed in bags and stored at low temperature (5-0°C) for later use.

[0078] (2) prepare the crude extract of gamma-aminobutyric acid

[0079] Add water to the dry mulberry leaf powder according to the ratio of mulberry leaf powder weight (g): water volume (mL) of 1:35, soak for 13 minutes, and then carry out ultrasonic-microwave cooperative extraction under the conditions of microwave 144W and ultrasonic wave 50W. After 170 s, the extract was centrifuged to remove the precipitate, and the supernatant was collected and concentrated by rotary evaporation.

[0080] (3)...

Embodiment 3

[0089] Example 3 Extraction and preparation of γ-aminobutyric acid

[0090] (1) mulberry leaves are dried and pulverized;

[0091] Mature leaves of the mulberry variety Kangqing 10 were picked, rinsed with clean water to remove the dust attached to the surface of the mulberry leaves, dried in the air, baked in an oven at 87°C for 28 minutes, and then cooled to 63°C for 4.5 hours. The dried samples were pulverized, sealed in bags and stored at low temperature (5-0°C) for future use.

[0092] (2) prepare the crude extract of gamma-aminobutyric acid

[0093] Add water to the dry mulberry leaf powder according to the ratio of mulberry leaf powder weight (g): water volume (mL) of 1:32, soak for 17 minutes, and then carry out ultrasonic-microwave synergistic extraction under the conditions of microwave 144W and ultrasonic wave 50W. After 165 s, the extract was centrifuged to remove the precipitate, and the supernatant was collected and concentrated by rotary evaporation.

[0094]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com