A through sls with scfco 2 Combined method for preparing polymer-based piezoelectric foam parts

A technology of polymer and polymer powder, which is applied in processing and manufacturing, manufacturing tools, additive manufacturing, etc., can solve the problems that restrict the promotion and development of piezoelectric foam products with complex structures, time-consuming design, high preparation cost, etc., and achieve the best market promotion Value, increase production efficiency, reduce the effect of holding pressure time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] The present embodiment comprises the following steps in parts by weight:

[0095] (1) The polyvinylidene fluoride raw material is pulverized into polyvinylidene fluoride powder with a particle size of 60-250 μm, and dried for later use;

[0096] (2) 100 parts of the spare polyvinylidene fluoride powder of step (1) and flow aid nano-SiO 2 Mix 0.1 parts evenly, and pass through the selective laser sintering process to obtain the laser sintered part; among them, the process parameters of selective laser sintering are: preheating temperature 155 ℃, laser scanning speed 9600mm / s, laser scanning power 40W , the number of laser scans is 1 time, the laser scanning interval is 0.1-0.3mm, and the thickness of the powder layer is 0.1mm;

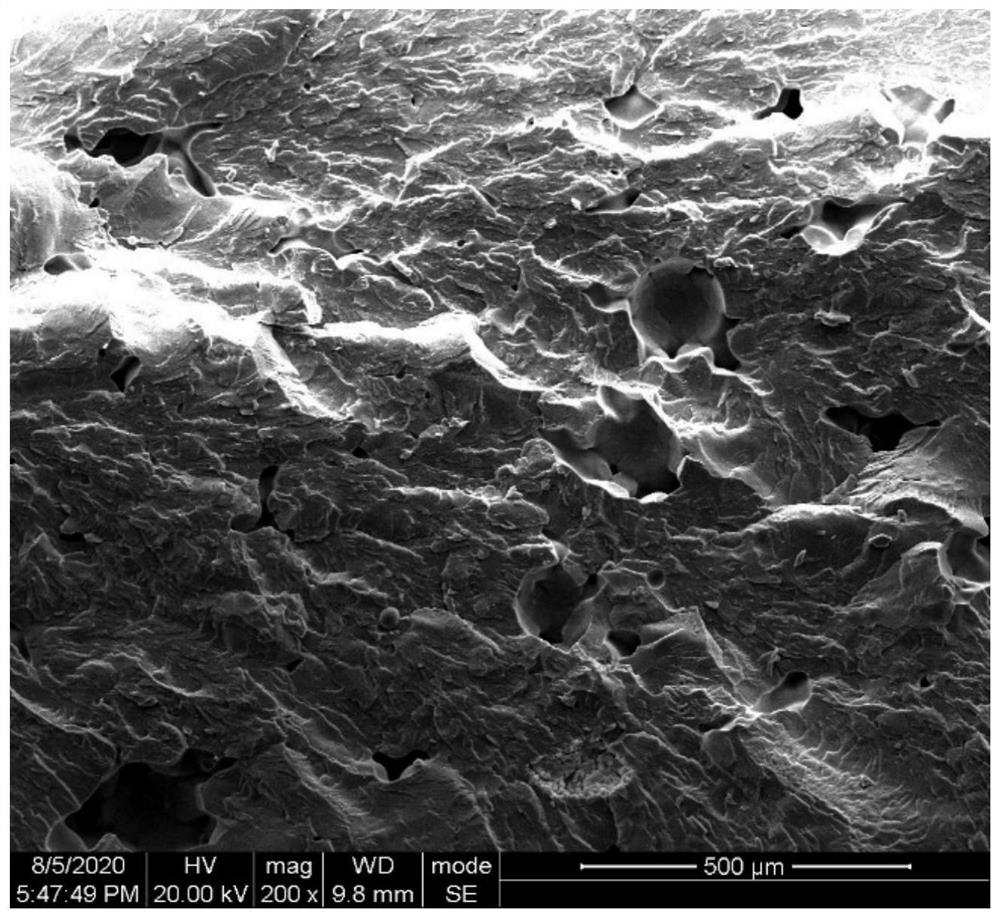

[0097] (3) The laser sintered part obtained in step (2) is prepared by a supercritical carbon dioxide autoclave pressure foaming method to obtain a PVDF foam part; wherein, the process parameters of the supercritical carbon dioxide autoclave pr...

Embodiment 2

[0101] Present embodiment except step (3) all the other are consistent with embodiment 1:

[0102] (3) The laser sintered parts obtained in step (2) are prepared by supercritical carbon dioxide autoclave pressure foaming method to obtain PVDF foam parts; wherein, the process parameters of supercritical carbon dioxide autoclave pressure foaming method are: the foaming process pressure is 14MPa , the foaming temperature is 161°C, the holding time is 30min, and the holding temperature is 45°C;

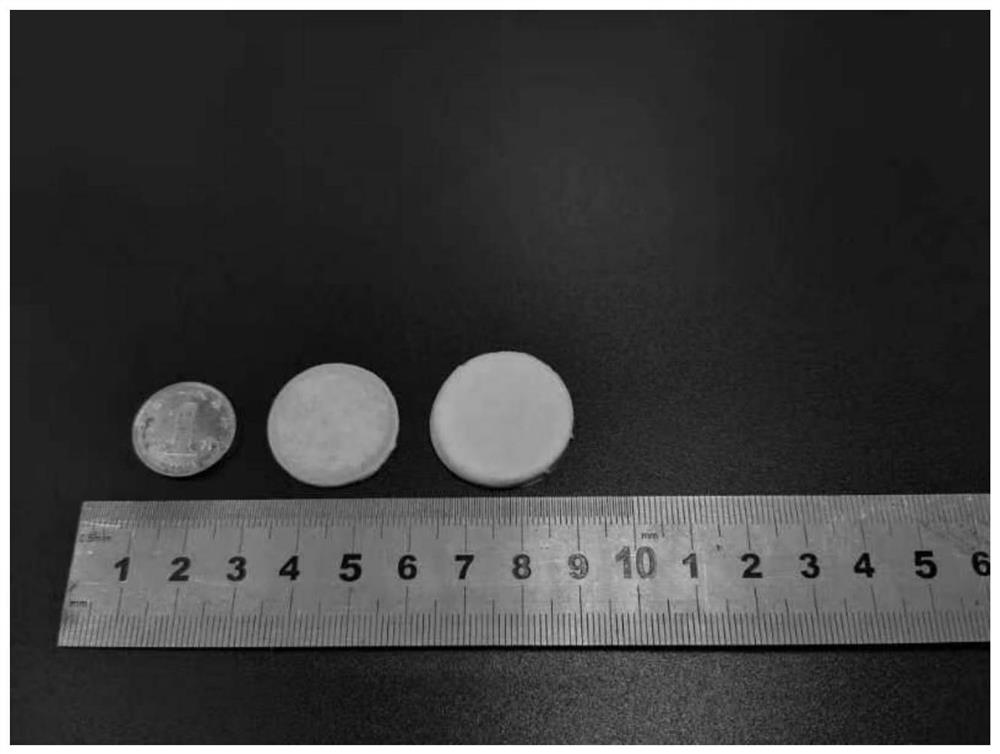

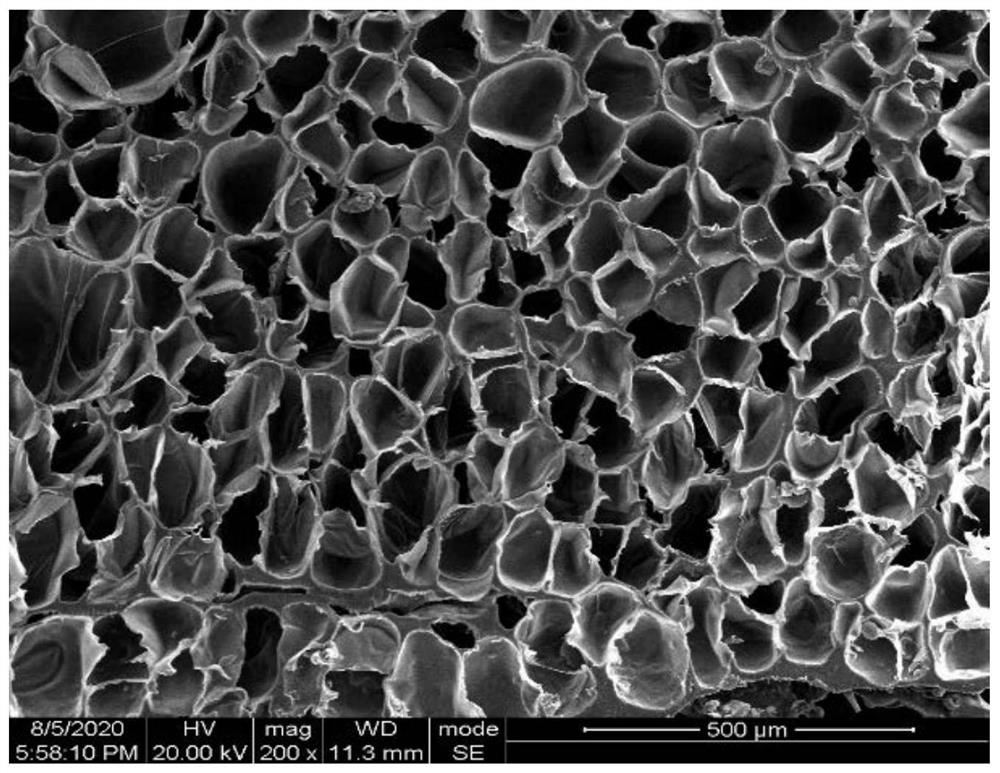

[0103] The final PVDF piezoelectric foam product is a test sample with a thickness of 3 mm. After testing, the average cell diameter is 61.70 μm, the cell wall thickness is 40.41 μm, the compression modulus is 8.85 MPa, the β crystal content is 59.4%, and the crystallinity is 40.6%. , The open circuit voltage can reach up to 2.1V, and the short circuit current can reach up to 42nA. After polarization, the open circuit voltage can reach up to 3.3V, and the short circuit current can reach ...

Embodiment 3

[0105] Present embodiment except step (3) all the other are consistent with embodiment 1:

[0106] (3) The laser sintered parts obtained in step (2) are prepared by supercritical carbon dioxide autoclave pressure foaming method to obtain PVDF foam parts; wherein, the process parameters of supercritical carbon dioxide autoclave pressure foaming method are: the foaming process pressure is 14MPa , the foaming temperature is 163°C, the holding time is 30min, and the holding temperature is 45°C;

[0107] The final PVDF piezoelectric foam product is a test sample with a thickness of 3 mm. After testing, the average cell diameter is 67.64 μm, the cell wall thickness is 32.32 μm, the compression modulus is 6.13 MPa, the β crystal content is 61.1%, and the crystallinity is 43.8%. , The open circuit voltage can reach up to 3.5V, and the short circuit current can reach up to 51nA. After polarization, the open circuit voltage can reach up to 4.4V, and the short circuit current can reach ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com