A kind of polyconjugated diene/sbs composite rubber particle and its preparation method and the application of composite rubber particle in modified asphalt

A technology of polyconjugated diene and composite rubber, which is applied to the field of modified asphalt in the field of composite rubber particles composed of SBS rubber, which can solve the problems of unreported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

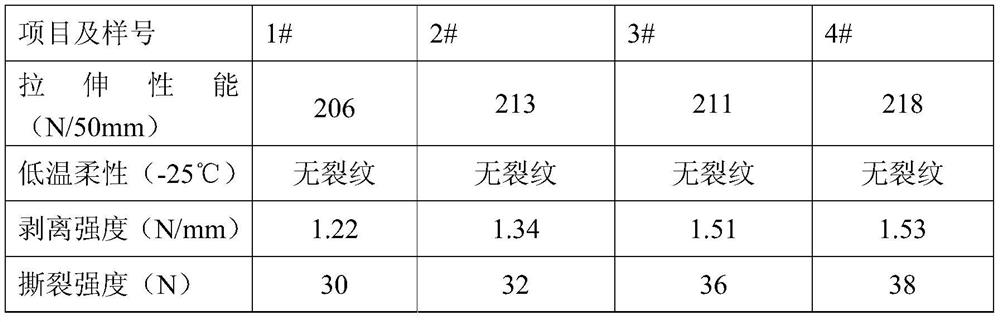

Examples

Embodiment 1

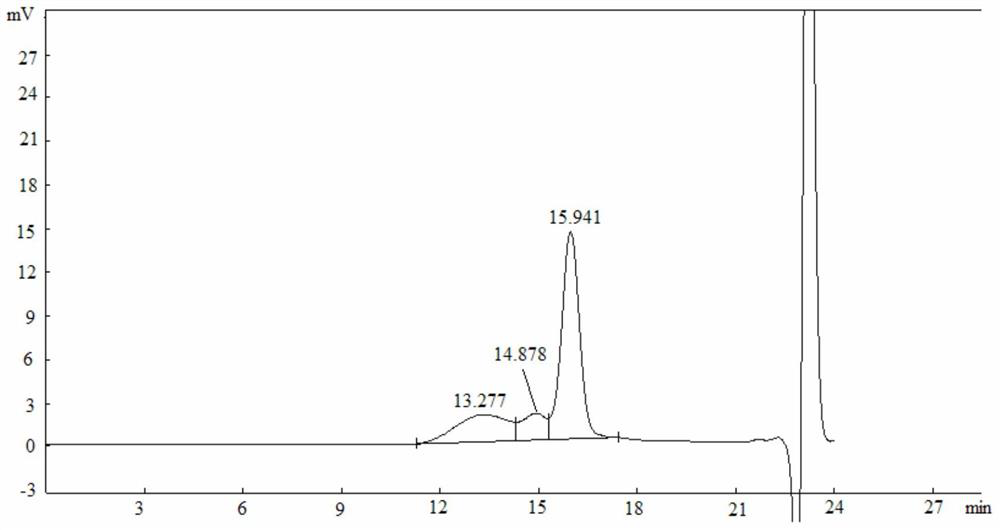

[0059] Add 3500mL of anhydrous cyclohexane and 0.04mL of anisole into a 5-liter polymerization kettle, stir and when the temperature rises to 50-60°C, add 50g of styrene, and then add 7.5mL of 0.66mol / L sec-butyllithium with a syringe Initiate styrene, react for 20min to 25min, then inject 483mL (300g) of butadiene into the second stage of reaction with nitrogen pressure, control the temperature below 95°C and react for 25min to 30min, then add 50g of styrene for the third stage After 20 minutes to 25 minutes of polymerization reaction, the SBS glue with a mass concentration of 12.8wt% cyclohexane solution was obtained, and Mn=86000 and MFR=8.43g / 10min were measured.

Embodiment 2

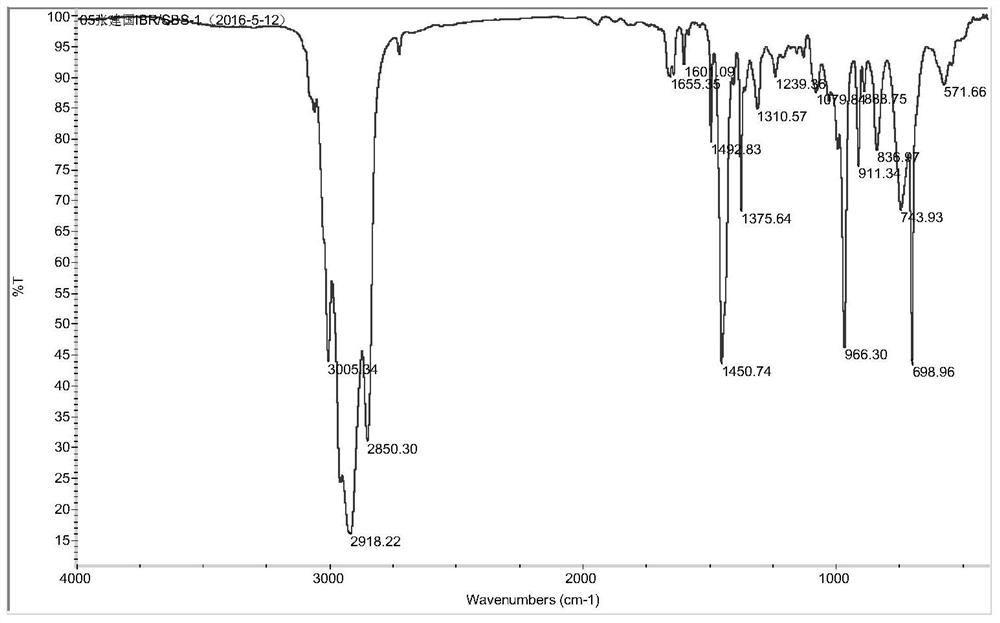

[0061] Add 3500 mL of anhydrous cyclohexane in a 5-liter polymerization kettle, then add 0.03 mL of divinylbenzene and 0.04 mL of anisole with a syringe, and simultaneously inject 485 mL of butadiene monomer into the polymerization kettle with nitrogen pressure, Add 6.5mL of 0.66mol / L sec-butyllithium into the polymerization kettle with a syringe at a temperature of 50-60°C, keep the polymerization temperature <90°C, and obtain a mass concentration of 9.90wt% polybutadiene cyclohexane after the polymerization time is 30min solution. The average Mn of polybutadiene (BDR) is 235000, the 1,4-addition content is 94.7%, the raw rubber Tg=-98.6°C, the Mooney viscosity is ML=66.4, and the raw rubber strength is 0.41MPa.

Embodiment 3

[0063] Add 3500mL of anhydrous cyclohexane into a 5-liter polymerization kettle, then add 0.06mL of divinylbenzene and 0.05mL of anisole with a syringe, and simultaneously inject 440mL of isoprene monomer into the polymerization kettle with nitrogen pressure Add 4.5mL of 0.66mol / L sec-butyllithium into the polymerization kettle with a syringe at a temperature of 50-60°C, keep the polymerization temperature <90°C, and obtain a mass concentration of 9.8wt% polyisoprene rings after the polymerization time is 35min. Hexane solution. The average Mn of polyisoprene (IDR) was measured to be 364000, the 1,4-addition content was 88.3%, the raw rubber Tg=-61.3°C, the Mooney viscosity was ML=68.4, and the raw rubber strength was 0.84MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com