Patents

Literature

92results about How to "Avoid washing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

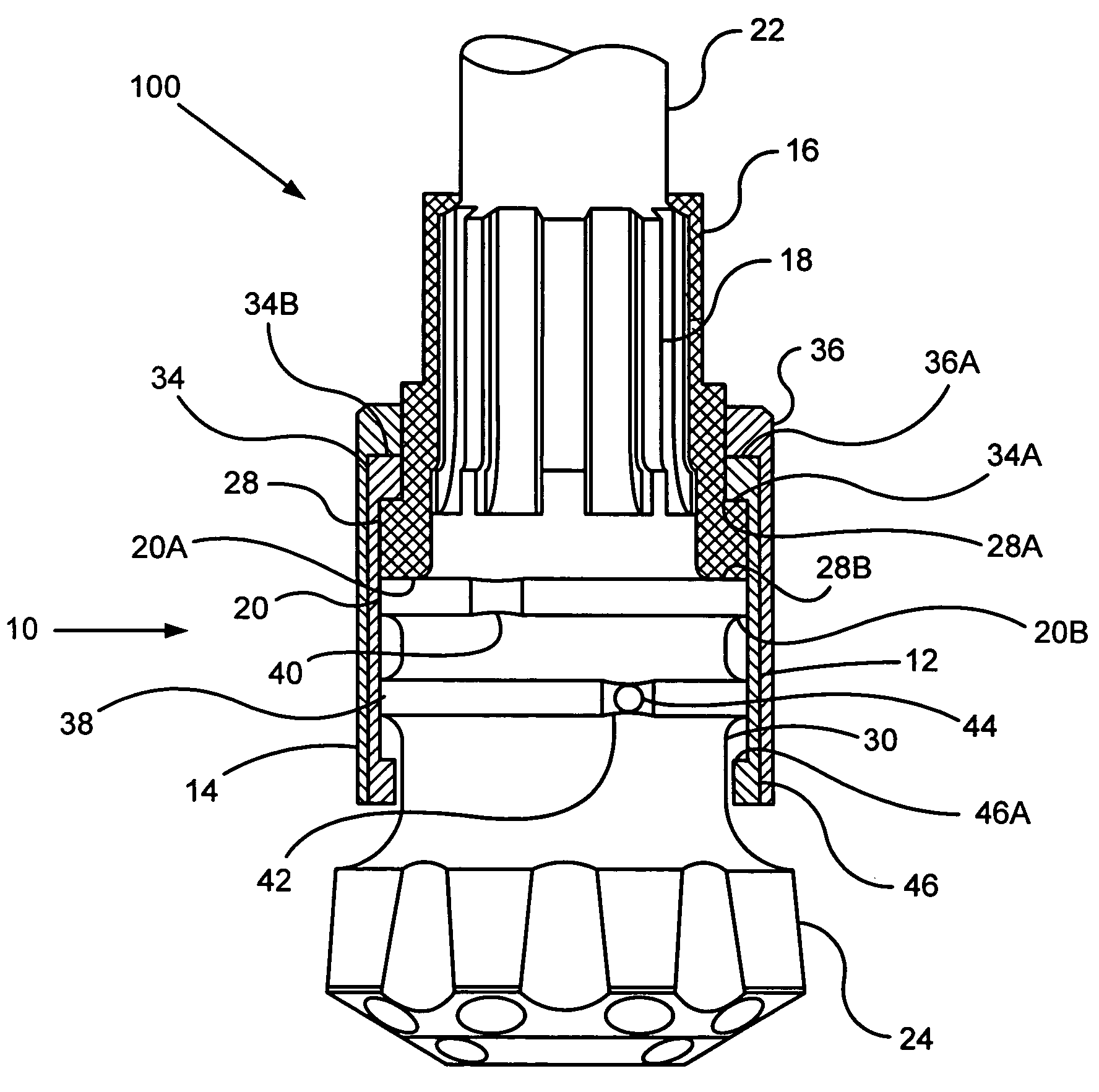

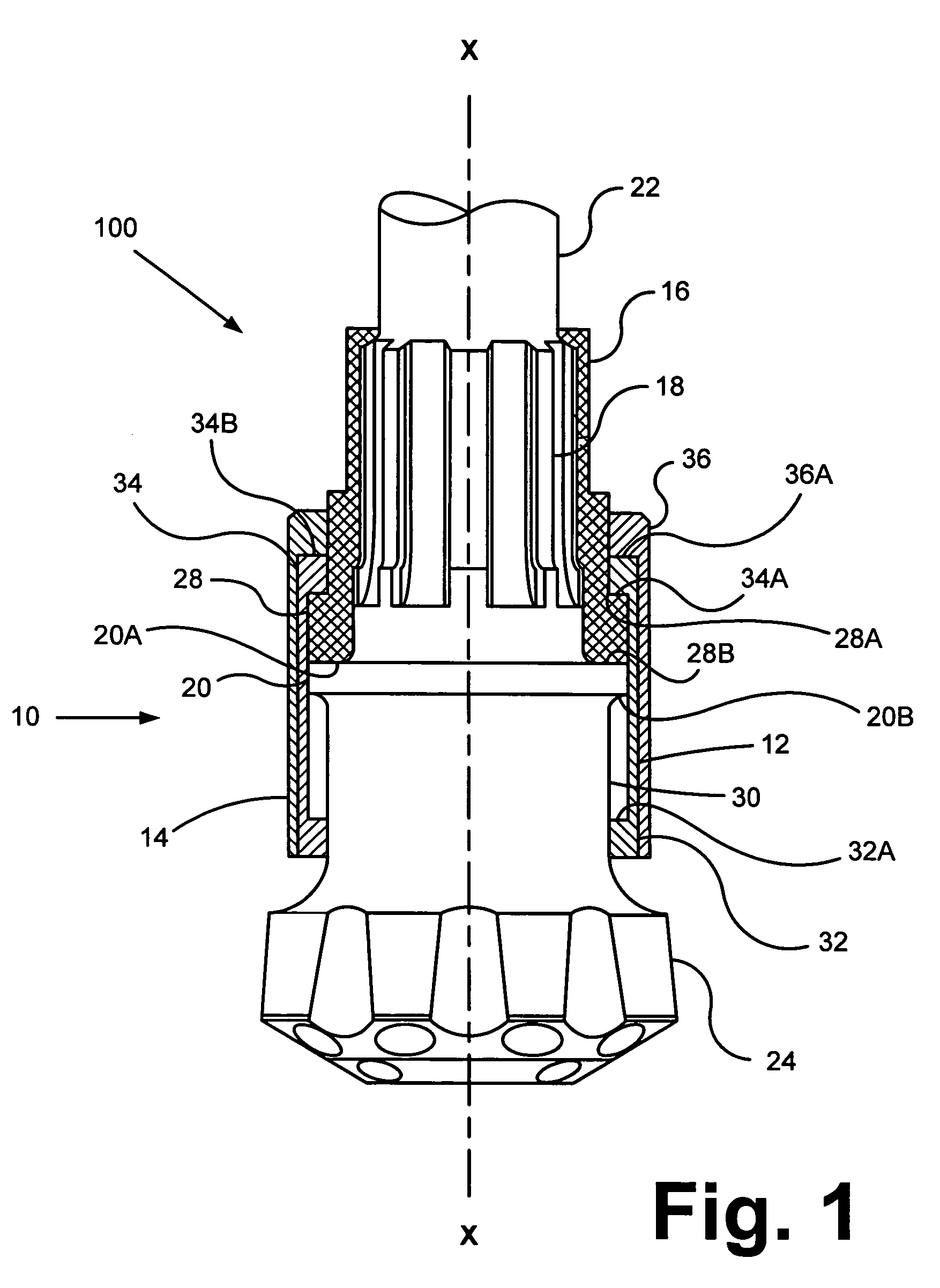

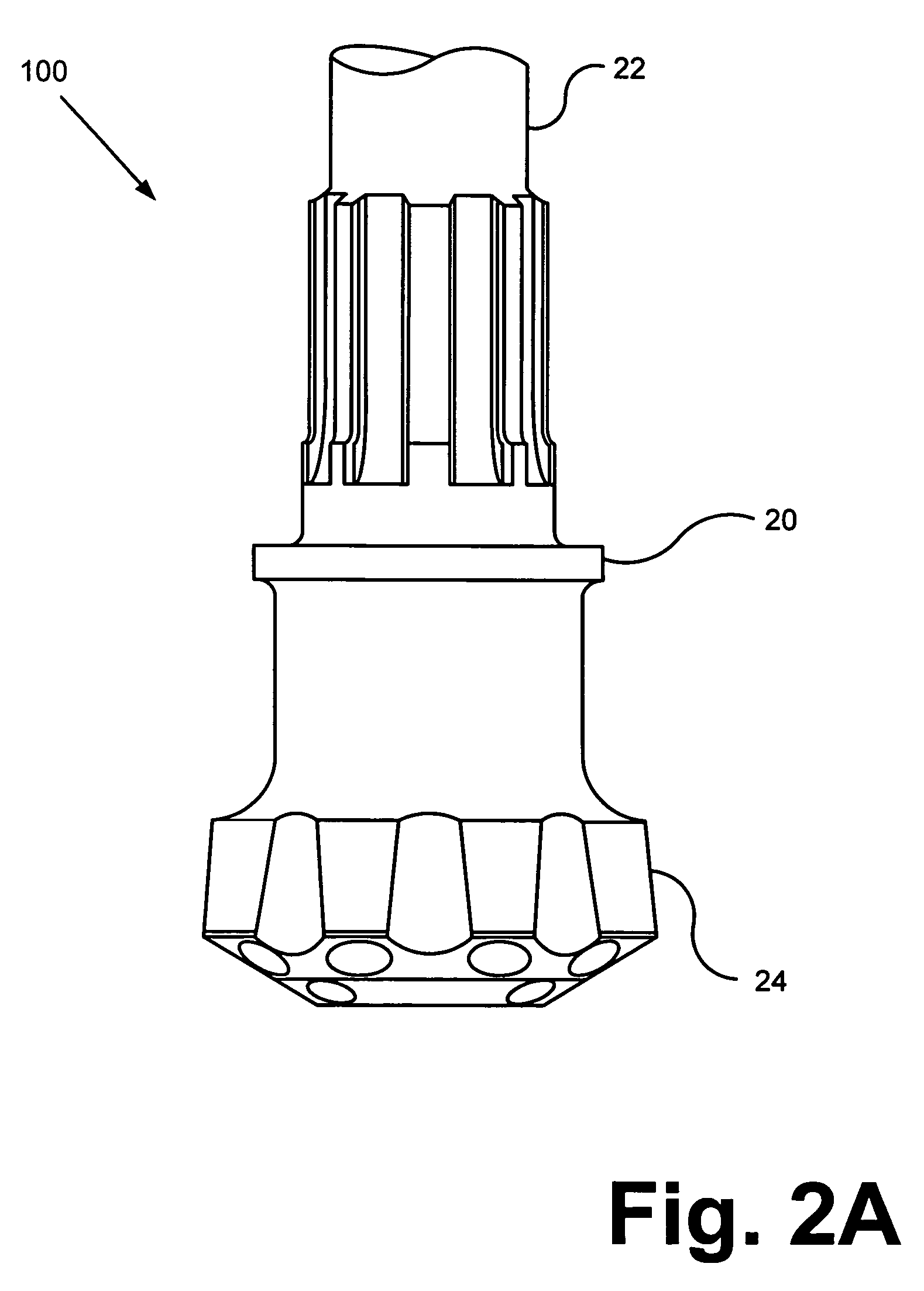

Percussion hammer bit retainer apparatus

ActiveUS7117939B1Avoid washingExtreme over-pull and unthreading of broken bit is greatly reducedDrill bitsDrilling rodsDrill bitEngineering

Owner:ATLAS COPCO CONSTR MINING TECHN USA +1

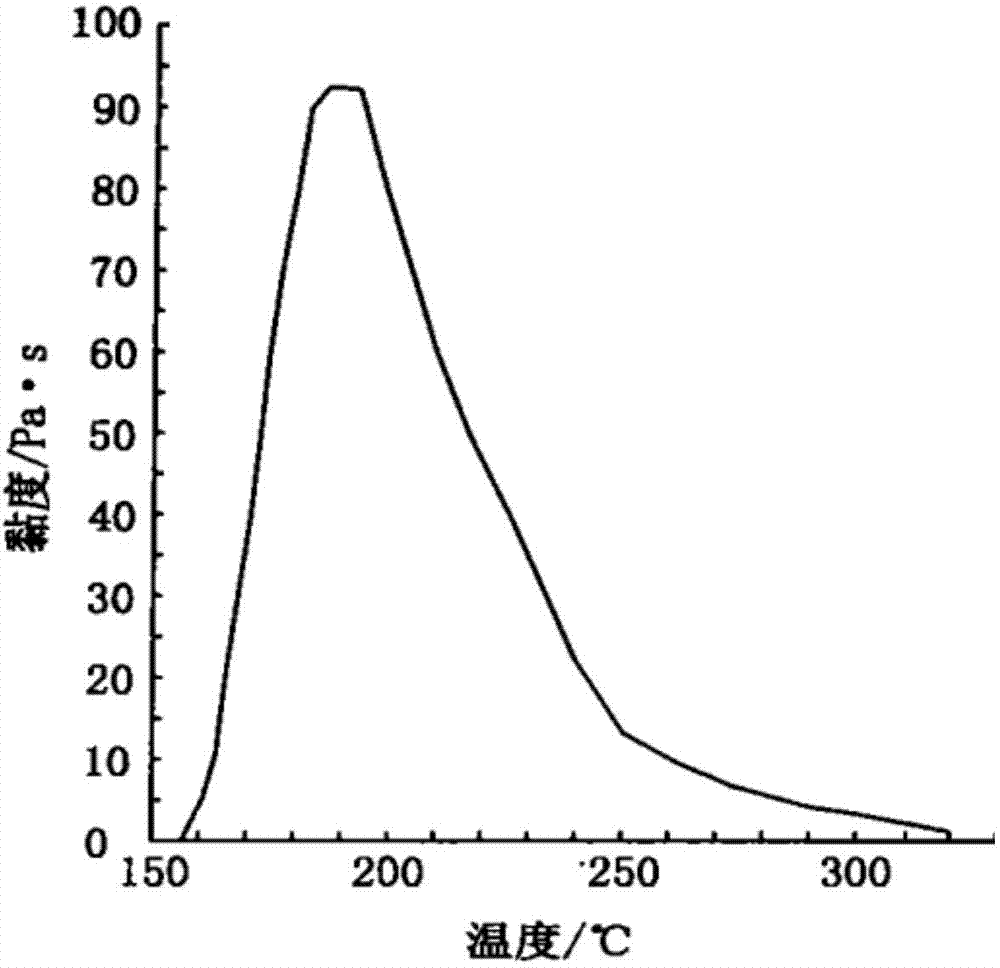

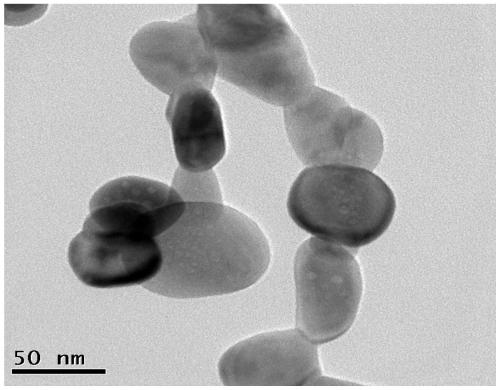

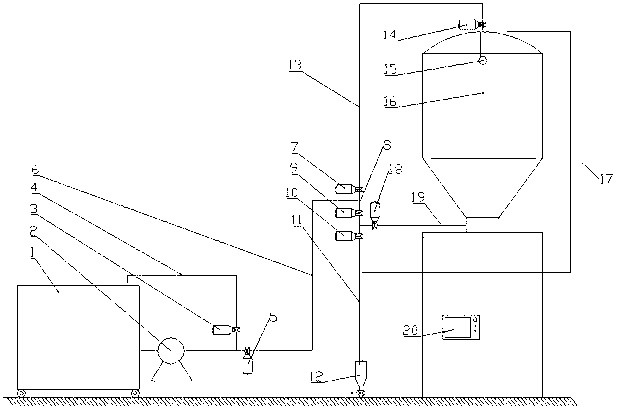

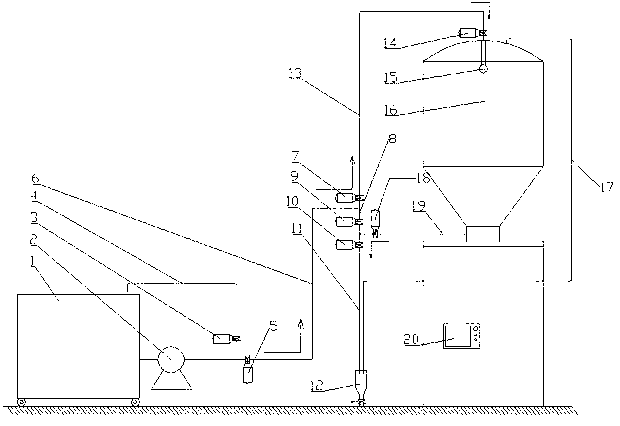

Method for preparation of insoluble sulfur

ActiveCN103539078AIncrease contentSmall particle sizeSulfur preparation/purificationSulfur productDirect effects

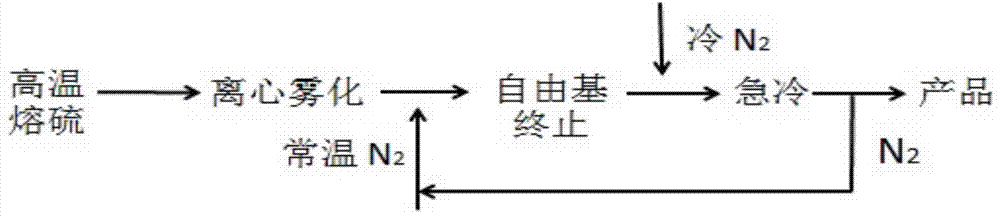

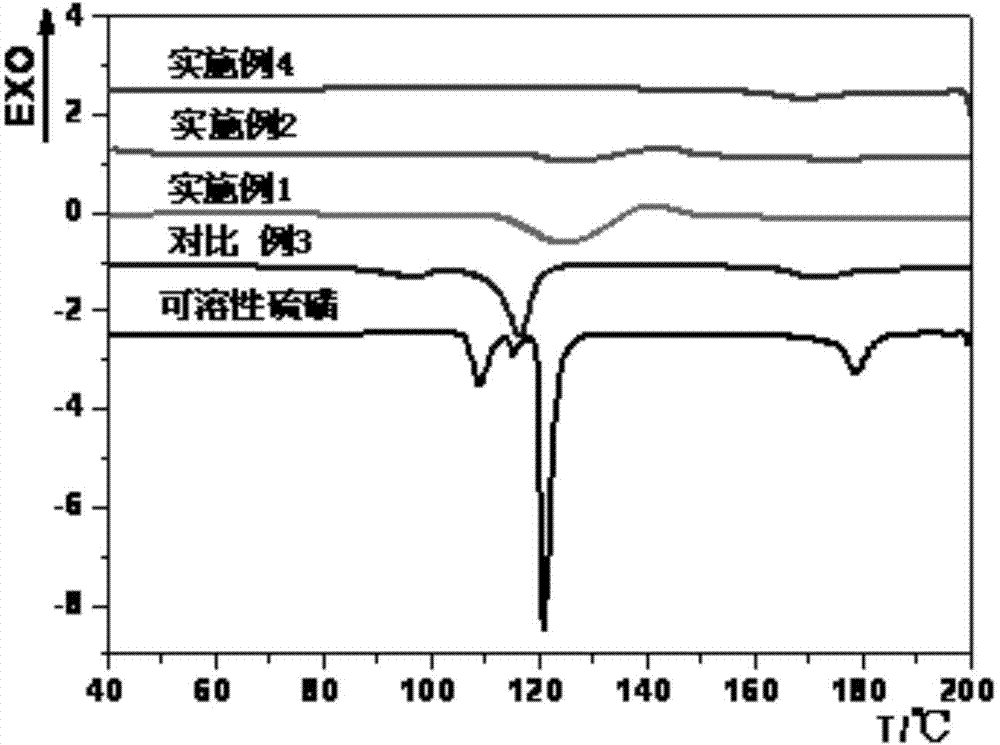

The invention relates to a method for preparation of insoluble sulfur. In a production process of insoluble sulfur, rapid cooling is one of very key process steps, realizes an effect of instantly stopping a reversible reaction and further directly affects the content of insoluble sulfur in a product. The method provided by the invention comprises the following steps of directly heating raw material sulfur to 280-400 DEG C, forming a large number of sulfur liquid droplets by centrifugal atomization through an atomizer, and increasing the specific surface area of sulfur; then cooling to 180-240 DEG C by circulating nitrogen at room temperature and keeping for 2-25 seconds; further cooling by circulating cold nitrogen to below 60 DEG C within 2-20 seconds; performing cyclone separation, collecting and packaging to obtain the insoluble sulfur product, wherein the average particle size of the product is 10 mu m-50 mu m; recycling the separated nitrogen. The method provided by the invention has the advantages of high safety in operation, low toxicity, high production efficiency, easiness in industrialization and high stability of prepared insoluble sulfur.

Owner:BEIJING UNIV OF CHEM TECH

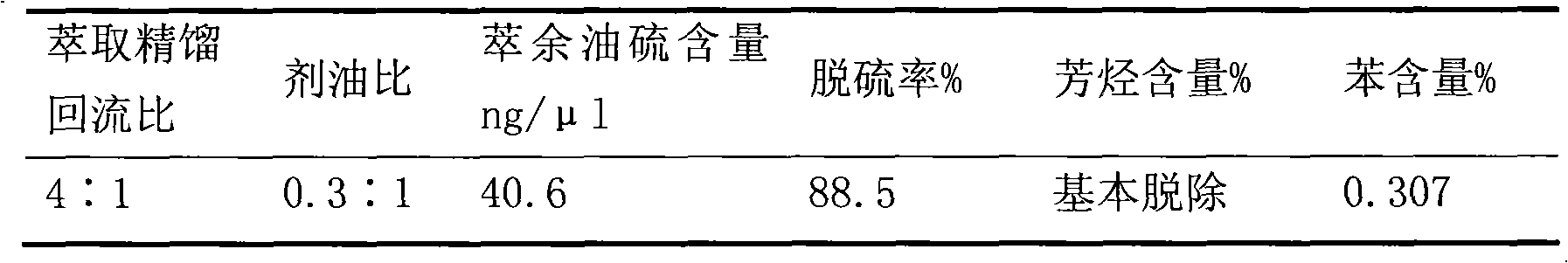

Method for producing reforming feedstock by light and medium gasoline distillates

ActiveCN101649221ASolve protection problemsRelieve pressureCatalytic naphtha reformingHydrocarbon oils refiningCatalytic reformingFractionation

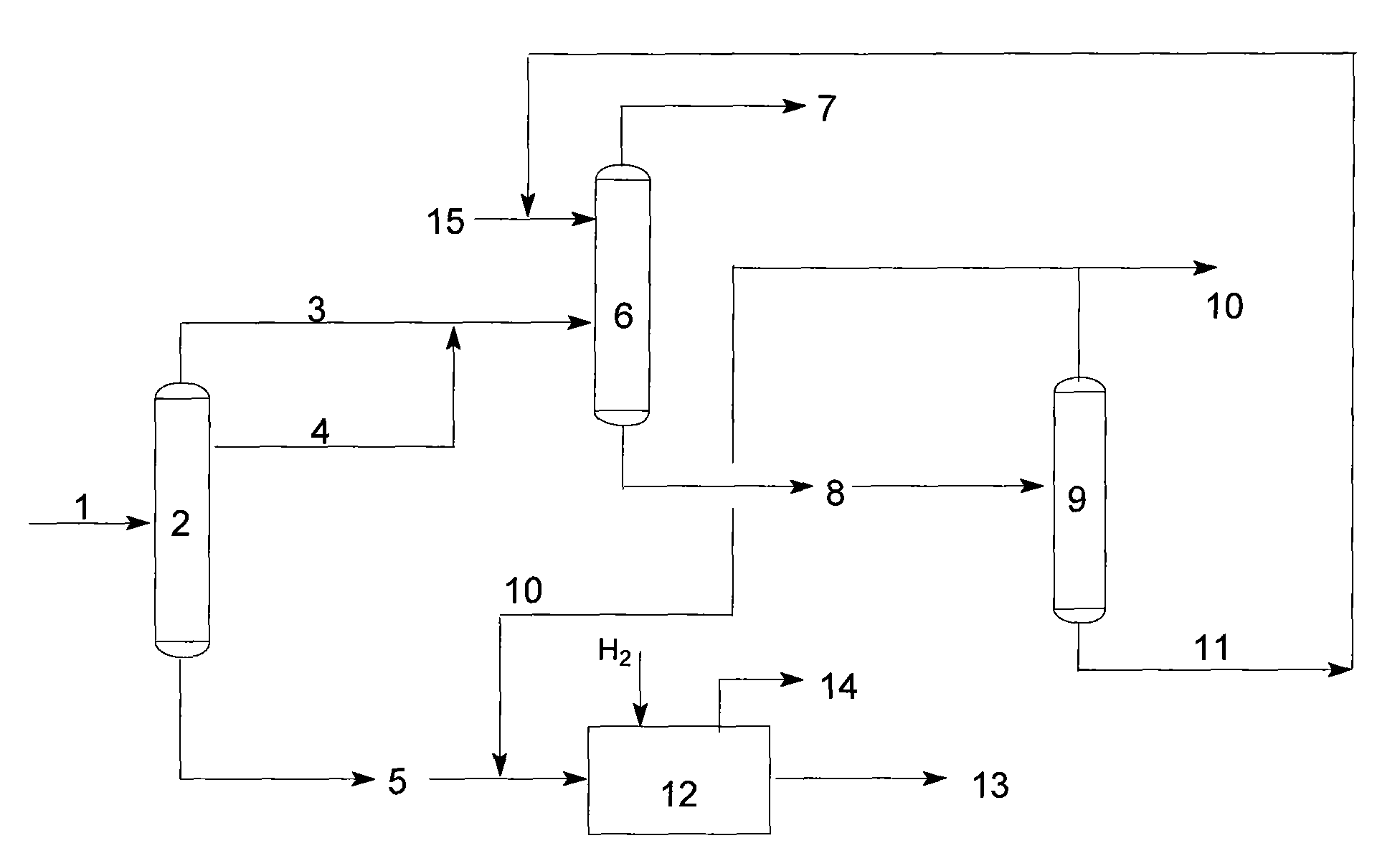

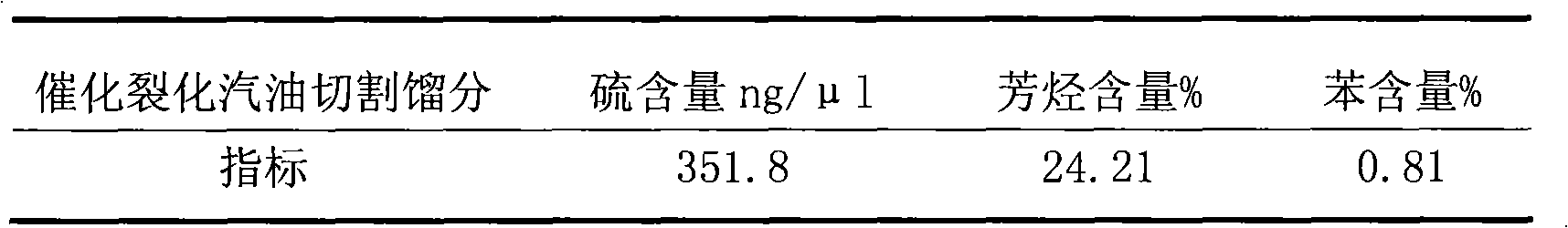

The invention relates to a method for producing catalytic reformed feedstock by taking light and medium gasoline distillates as raw materials and extracting selective solvent to extract and rectify catalytically cracked gasoline in the absence of hydrogen. The method comprises the following steps: 1, fractionation prefabrication of light and medium distillate raw materials of catalytically cracked gasoline; and 2, extraction, rectification, desulfuration and dearomatization of light and medium distillates of catalytically cracked gasoline, wherein light and medium distillates of catalyticallycracked gasoline obtained in step 1 are fed into the middle-lower part of an extraction-rectification tower, while fresh extraction agent or recycled extraction agent is added from the upper part of the extraction-rectification tower; thus, the light and medium distillates contact the extraction agent inside the tower to generate desulfurized and dearomatized light-component raffinate phase (i.e.catalytic reformed feedstock product) rich in olefin hydrocarbon at the top of the tower after extraction, rectification, desulfuration and dearomatization. The method carries out desulfuration and dearomatization of catalytically cracked gasoline at the same time and reclaims solvent, thereby having the advantages of simple process, moderate operation conditions, hydrogen source saving and low production cost.

Owner:PETROCHINA CO LTD +1

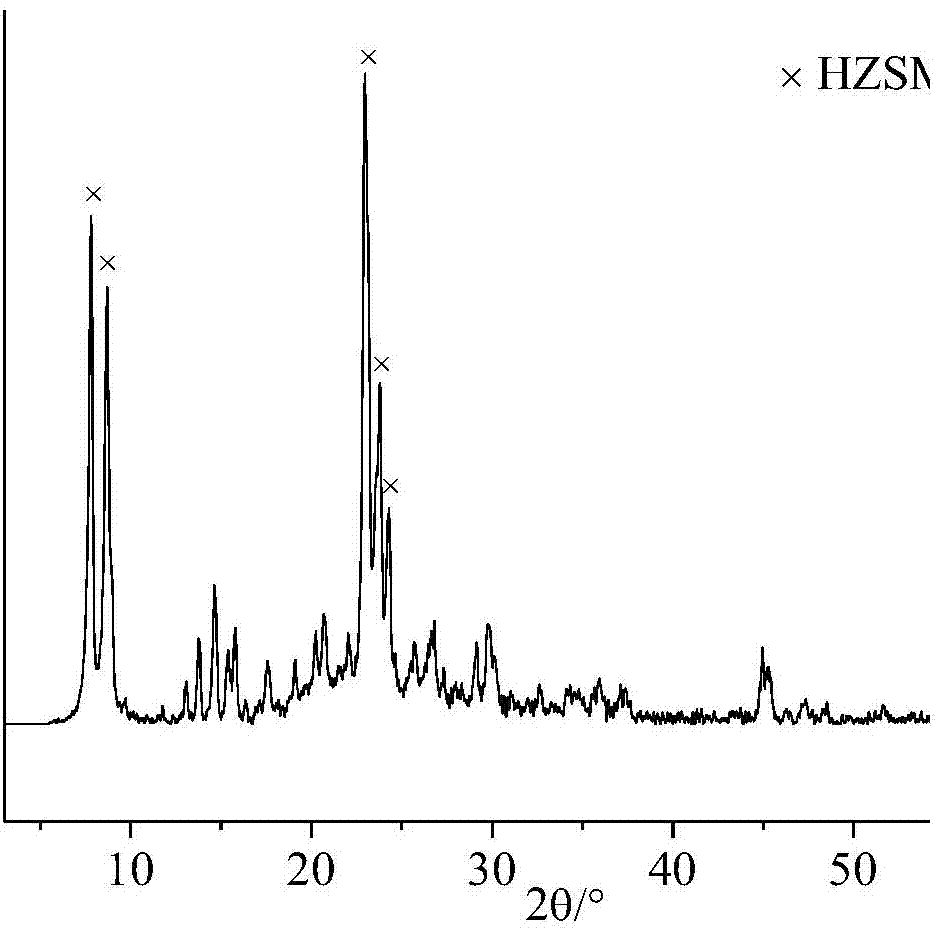

Synthesis method of HZSM-5 molecular sieve

InactiveCN104724720AAvoid swappingAvoid washingCrystalline aluminosilicate zeolitesIonMolecular sieve

The invention relates to a synthesis method of an HZSM-5 molecular sieve, which comprises the following steps: (1) mixing an aluminum source, a silicon source, a template, ammonia water, ethanol and water, and stirring uniformly until dry glue powder forms a gel; drying the gel, and pulverizing into powder; (2) putting the dry glue powder in a water-containing reaction kettle, and crystallizing in a static state; and (3) washing the crystallization product, drying and roasting to obtain the product. The method does not use any sodium-ion-containing raw material, thereby avoiding the traditional ammonium exchange, washing and roasting process. The method avoids the separation between the product and mother solution in the traditional crystallization technique, and has the characteristics of low template consumption, low waste liquid amount, high yield, low cost, low pollution and the like.

Owner:NINGXIA UNIVERSITY

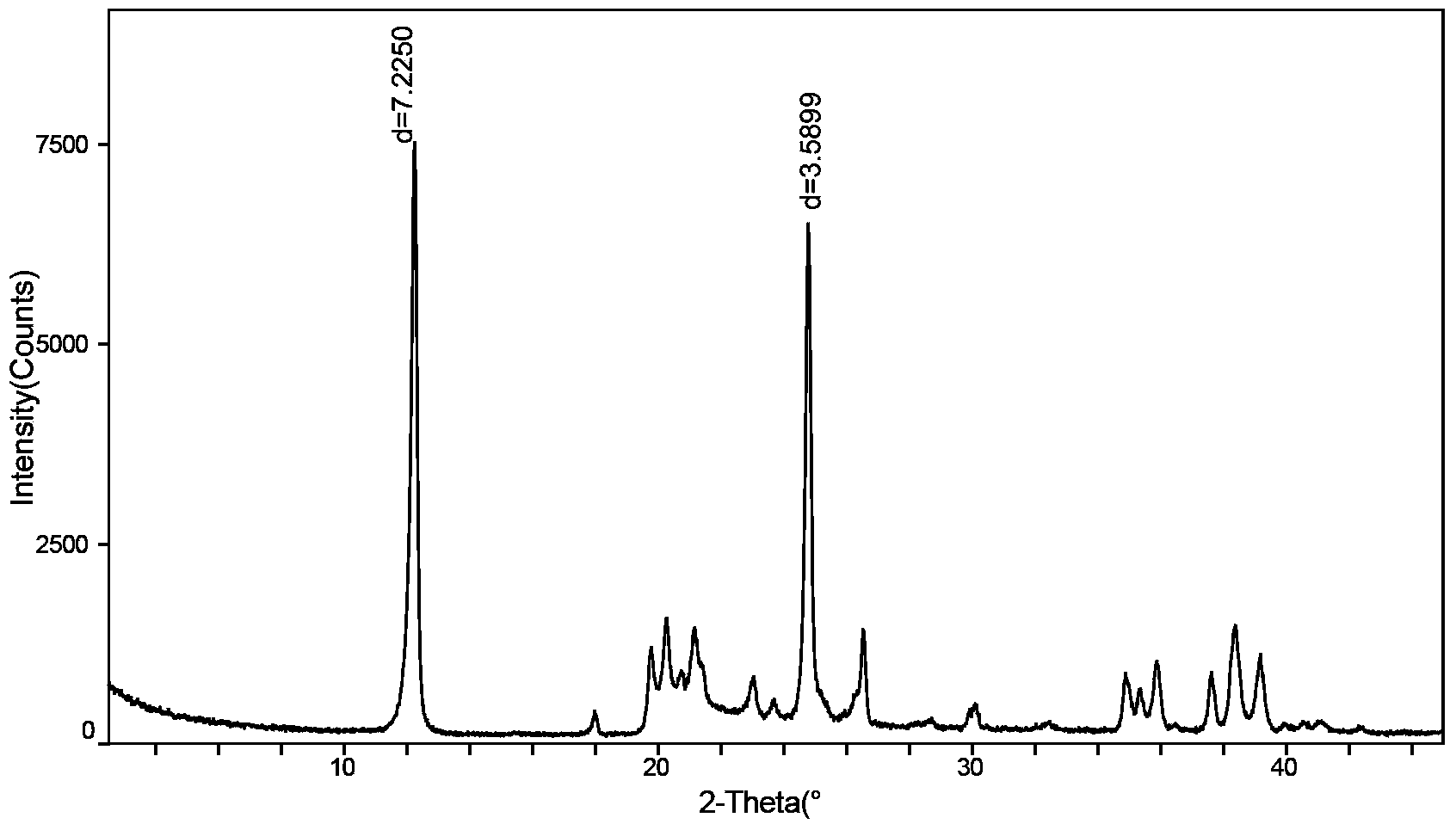

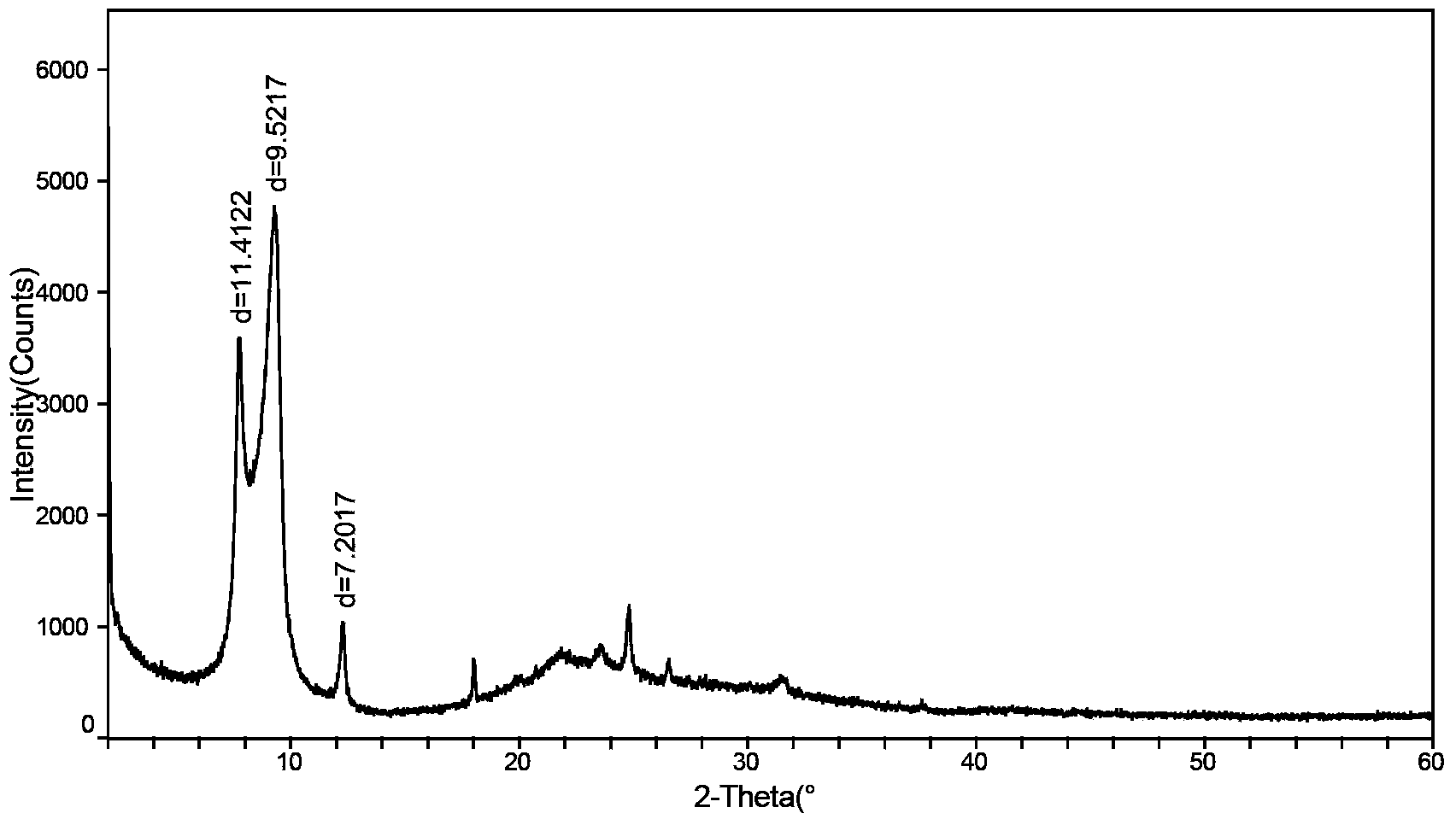

Preparation method of kaolin-amine grafted complex

The invention discloses a preparation method of kaolin-amine grafted complex. The preparation method comprises the following synthesis steps of: selecting 200-325 meshes of kaolin, and purifying to remove impurities; mixing the kaolin and an intercalator with a prepared intercalator solution in a mass ratio of 1:2, and directly intercalating the kaolin under a liquid condition, wherein the intercalator is selected from one or more of hydrazine hydrate, formamide, acetamide, methyl formamide, acrylamide, potassium acetate, dimethyl sulfoxide, urea and potassium chloride; repeatedly leaching the directly intercalated kaolin for ten times by liquid alcohol to prepare a kaolin-alcohol composite, wherein each leaching lasts for 10-48 hours; adding the kaolin-alcohol grated body into an amine solution under a wet condition and magnetically stirring for 40 times; and centrifuging to obtain precipitates, drying the precipitates to separate out excessive amine to obtain the kaolin-amine grafted body, wherein the interlayer distance of the kaolin-amine grafted body can be changed with the difference of intercalated amine molecule size to reach nearly 6.0nm. And the complex is of significance to nanometer research of the kaolin.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

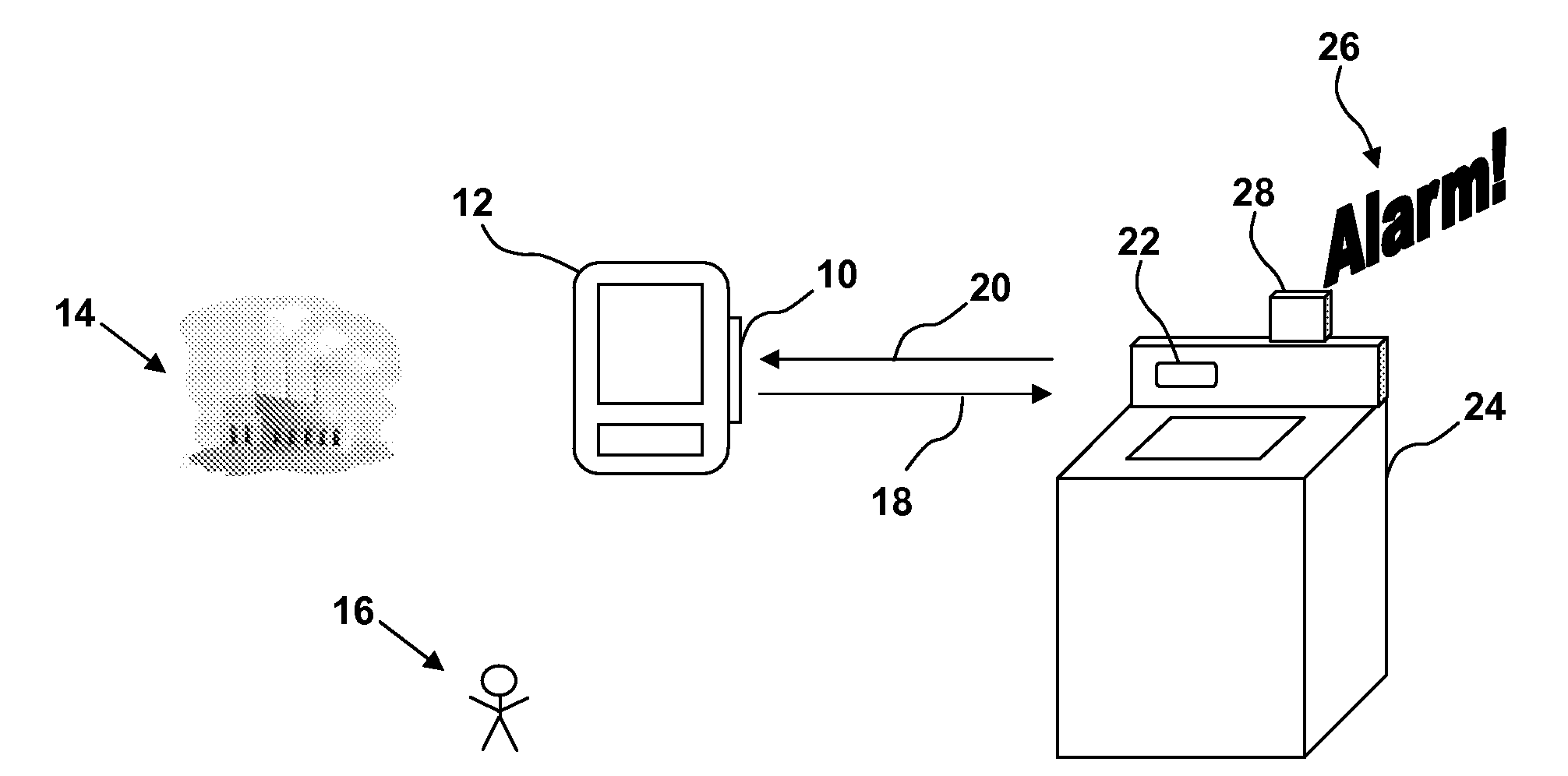

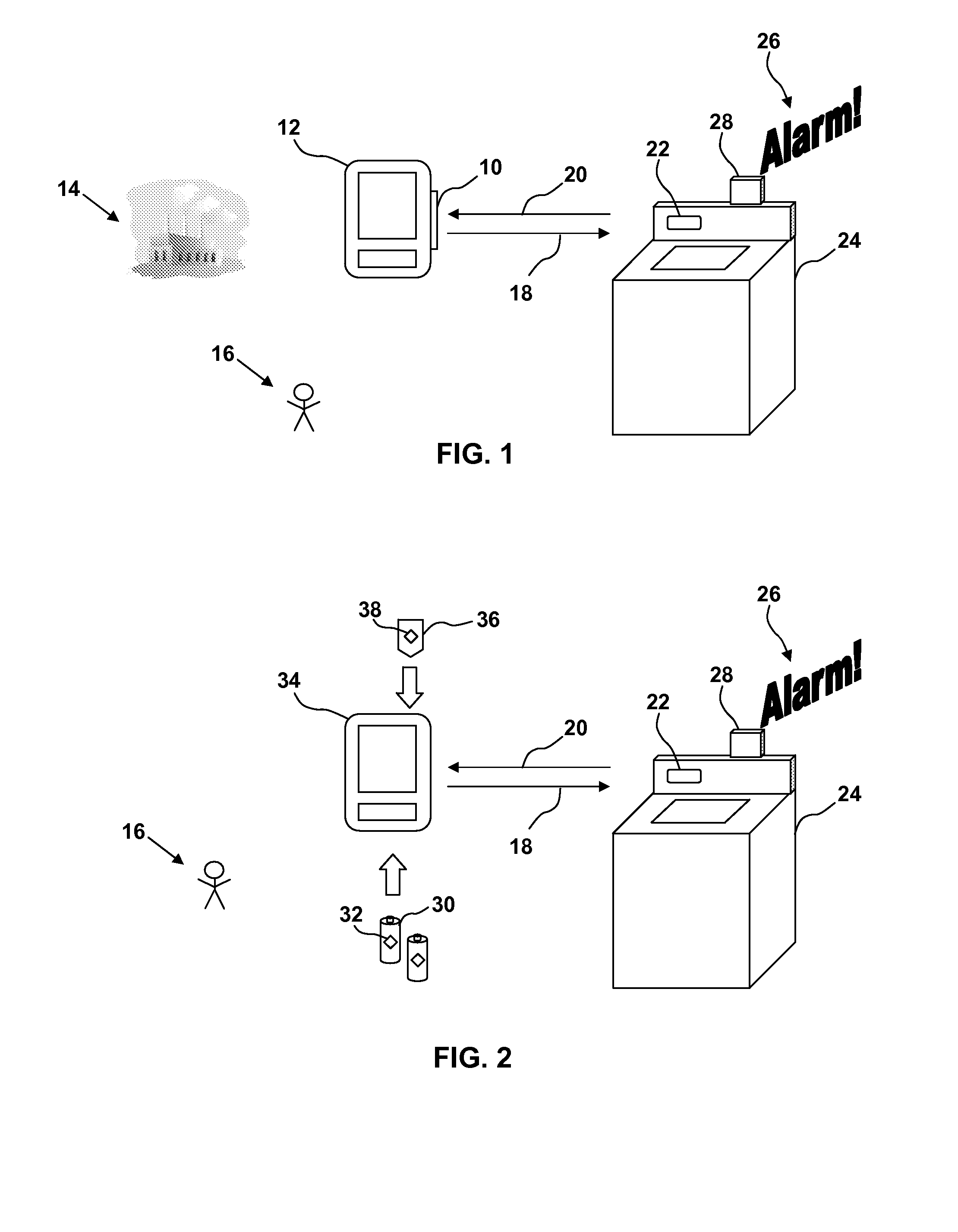

Method and apparatus for preventing water damage to articles

InactiveUS20090146811A1Avoid water damageAvoid washingOther washing machinesControl devices for washing apparatusRadio frequencyRadio-frequency identification

The present invention is directed to a method and apparatus for preventing water damage to non-washable articles in a washing machine. A method in accordance with an embodiment of the present invention includes: providing an article with a radio frequency identification (RFID) tag identifying the article as being non-washable; preventing the article from being washed in a washing machine by: scanning the washing machine using an RFID reader; and generating an alarm upon detection of a predetermined code emitted by the RFID tag.

Owner:IBM CORP

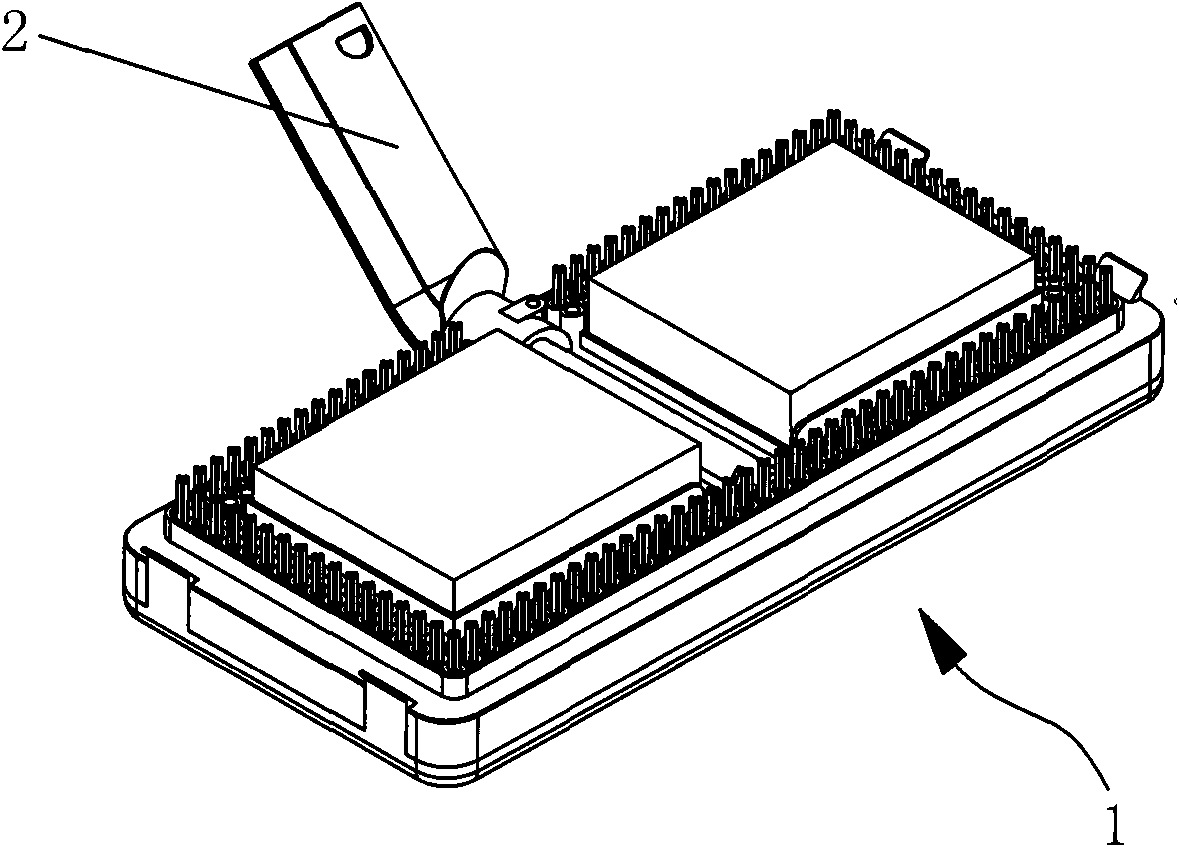

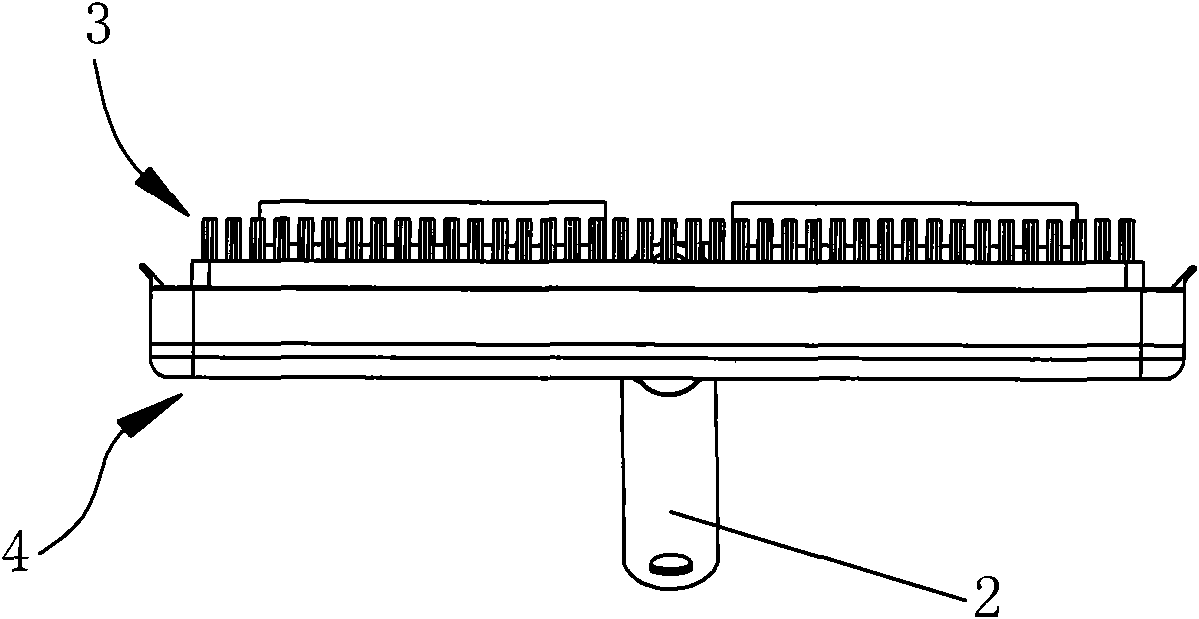

Steam brush head

ActiveCN101803894AAvoid washingAchieve cleaningFloor-scrubbing machinesCleaning using liquidsEngineeringMechanical engineering

The invention relates to a steam brush head which is used to be connected on steam cleaning equipment, and comprises a brush head body and a connecting pipe used for transporting steam to the brush head body; one end of the connecting pipe is connected with the brush head body, and the other end thereof is connected with the steam cleaning equipment; the brush head body is provided with an upper working surface and a lower working surface which are respectively arranged at the upper part and the lower part of the brush head body; the connecting pipe is connected with the brush head body in a rotating way; and the brush head body can at least rotate for 180 degrees relative to the connecting pipe, and the brush head body switches the upper working surface and the lower working surface by rotating for 180 degrees around the connecting pipe. The invention can switch two surfaces by one steam brush head, thereby preventing the brush head from being detached and cleaned when the ground or the wall are cleaned for many times; and in addition, the steam brush head can also clean a plurality of cleaning surfaces, thereby not only saving time and being convenient, but also having diversified functions.

Owner:SUZHOU EUP ELECTRIC CO LTD

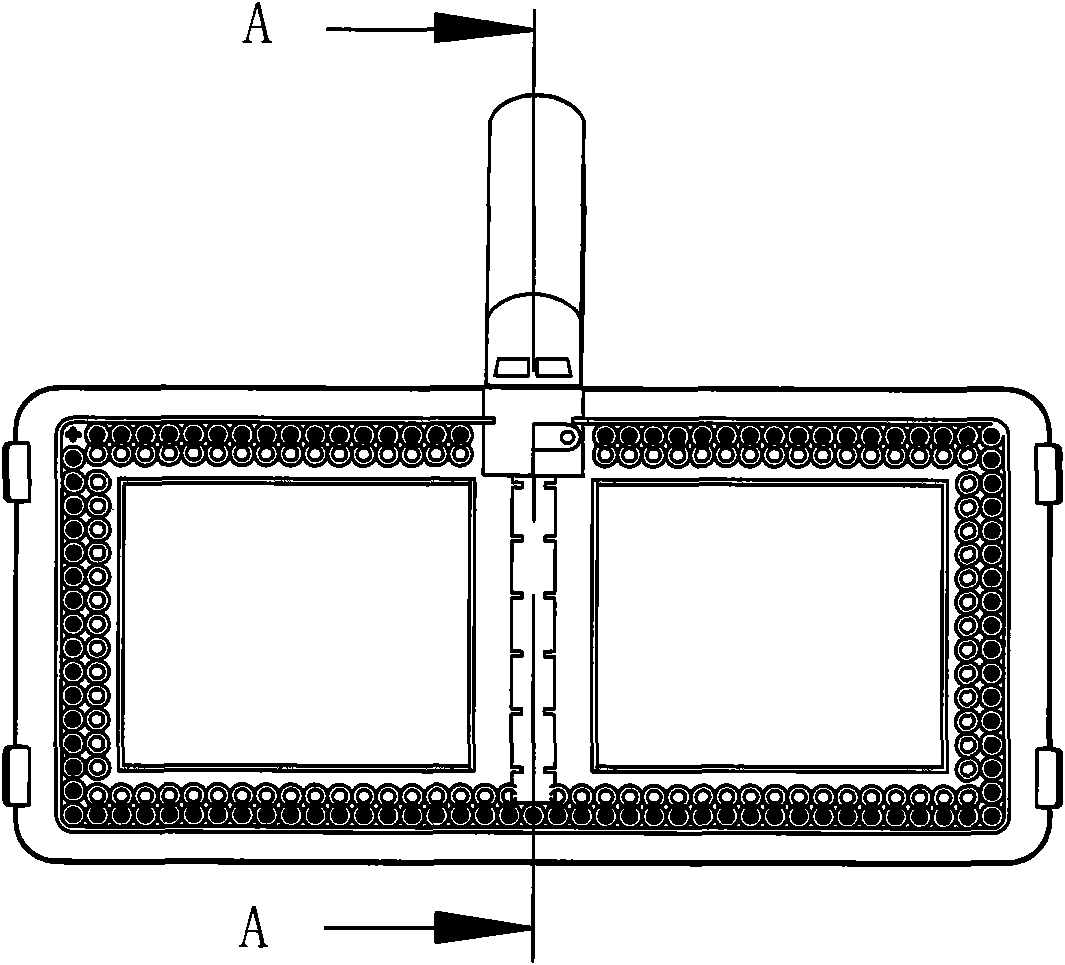

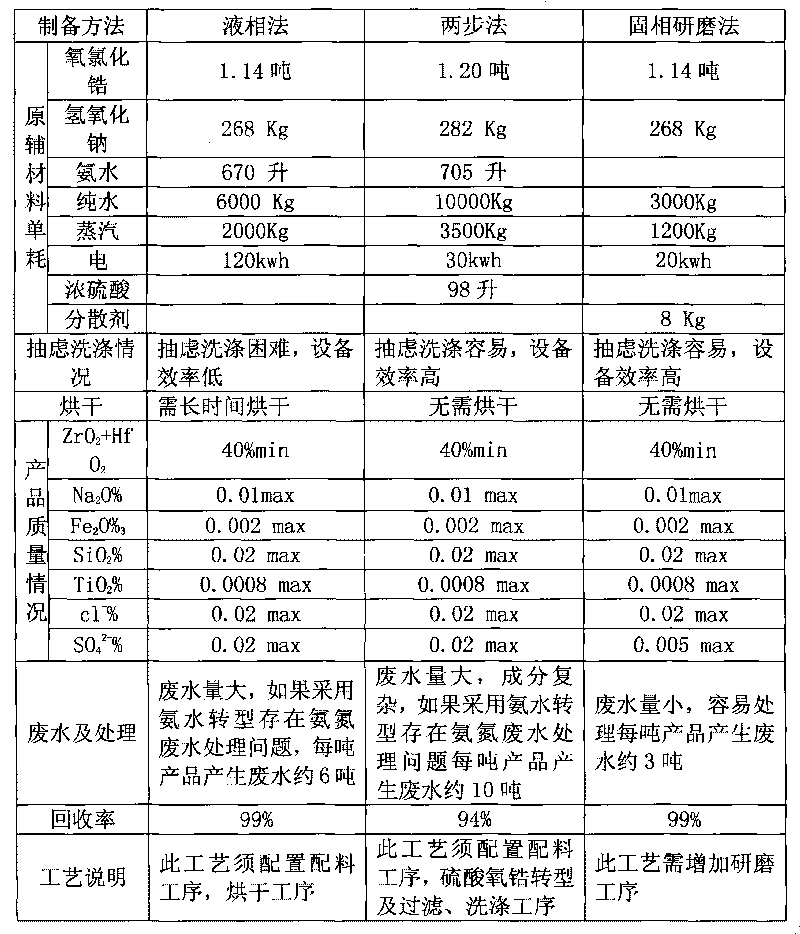

Zirconium hydroxide solid-phase grinding synthesis method

The invention discloses a zirconium hydroxide solid-phase grinding synthesis method. The method of high purity zirconium hydroxide comprises the following steps: adding zirconium hydroxide in a mixing machine, adding dispersant of which weight ratio to zirconium hydroxide is 0.005-0.02; adding solid sodium hydroxide in the mixing machine; starting the mixing machine for mixing and aging, pouring materials in a grinder, transferring the grinded materials into a vacuum suction filtration tank; pumping 40-90 DEG C of pure water of which weight ratio to the materials is 1-10:1 in a suction filtration tank, draw off water after soaking, adding 40-90 DEG C of pure water of which weight ratio to the materials is 1-10:1 again; and rinsing 2-8 times with pure water, transferring the product to a centrifuge to centrifuge for 10-30 minutes, and packaging to obtain the finished product. The method of the invention reduces the flow, simplified devices and reduces the water consumption; in addition, the devices are easy to operate and the production cost is reduced.

Owner:JIANGXI KINGAN HI TECH

Method for solvent recovery in polyphenylene sulfide synthesis process

The invention provides a method for solvent recovery in a polyphenylene sulfide synthesis process. The method includes: subjecting a synthesis reaction generated product to solid-liquid separation by a centrifugal machine or filter press at 40-80DEG C; drying the solid product by a vacuum double-cone rotary dryer or a vacuum rake dryer at 100-150DEG C and under an operation pressure of not greater than -0.096MPa, using condensed water to conduct condensation at normal temperature to recover a solvent; and sending the recovered solvent and the filtrate obtained from solid-liquid separation directly to a rectifying tower to undergo rectification treatment. The method provided in the invention adopts vacuum drying equipment to dry the separated reaction product, and directly recovers the solvent, thus avoiding other solvent washing and water washing in commonly used solvent recovery methods, greatly reducing energy consumption and material consumption, and improving the solvent recovery rate.

Owner:CHINA PETROLEUM & CHEM CORP

Copper foil anti-oxidation treating fluid, preparation method of copper foil anti-oxidation treating fluid and copper foil anti-oxidation treating equipment

ActiveCN106399996AIncrease concentrationRaise the ratioMetallic material coating processesEnvironmental resistancePhosphoric acid

The invention discloses a copper foil anti-oxidation treating fluid, a preparation method of the copper foil anti-oxidation treating fluid and copper foil anti-oxidation treating equipment. The copper foil anti-oxidation treating fluid comprises the following raw material ingredients by weight: 0.05-0.1 g / L hydroxybenzotrizole (HBTA), 0.02-0.05 g / L 2-mercaptobenzothiazole (MBT), 0.1-0.5 g / L of silver nitrate, 0.1-0.5 g / L sodium molybdate, 0.05-0.1 g / L phosphoric acid, 0.5-3 g / L boric acid and the balance of pure water. The copper foil anti-oxidation treating fluid can prevent water washing, reduces the water treatment cost, does not contain such harmful substances to the environment as hexavalent chromium, and meets the demand for environmental protection; an anti-oxidation and anti-passivation film is stable under the high-temperature condition and does not contain zinc metal; and such unstable problems as resistance reduction of a copper foil are solved. A liquid inlet of an anti-oxidation treatment groove of the copper foil anti-oxidation treating equipment is positioned above one end of the feeding side of a copper foil roller, so that two surfaces of the copper foil can be subjected to full anti-oxidation treatment.

Owner:佛冈建滔实业有限公司

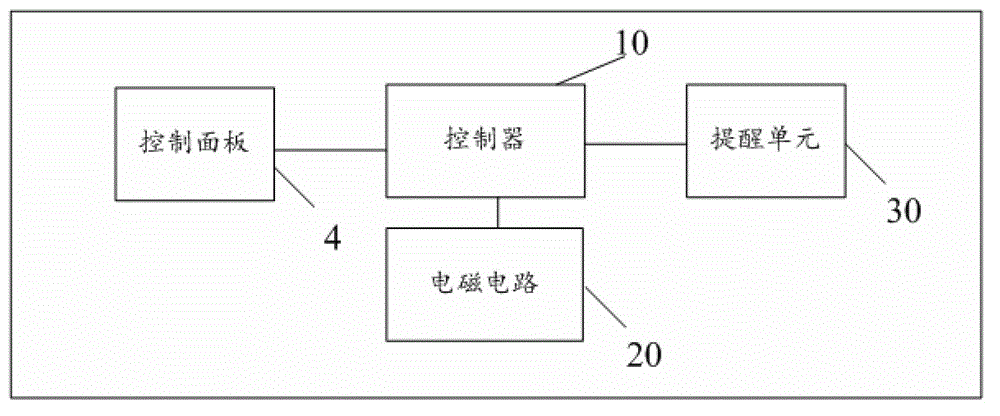

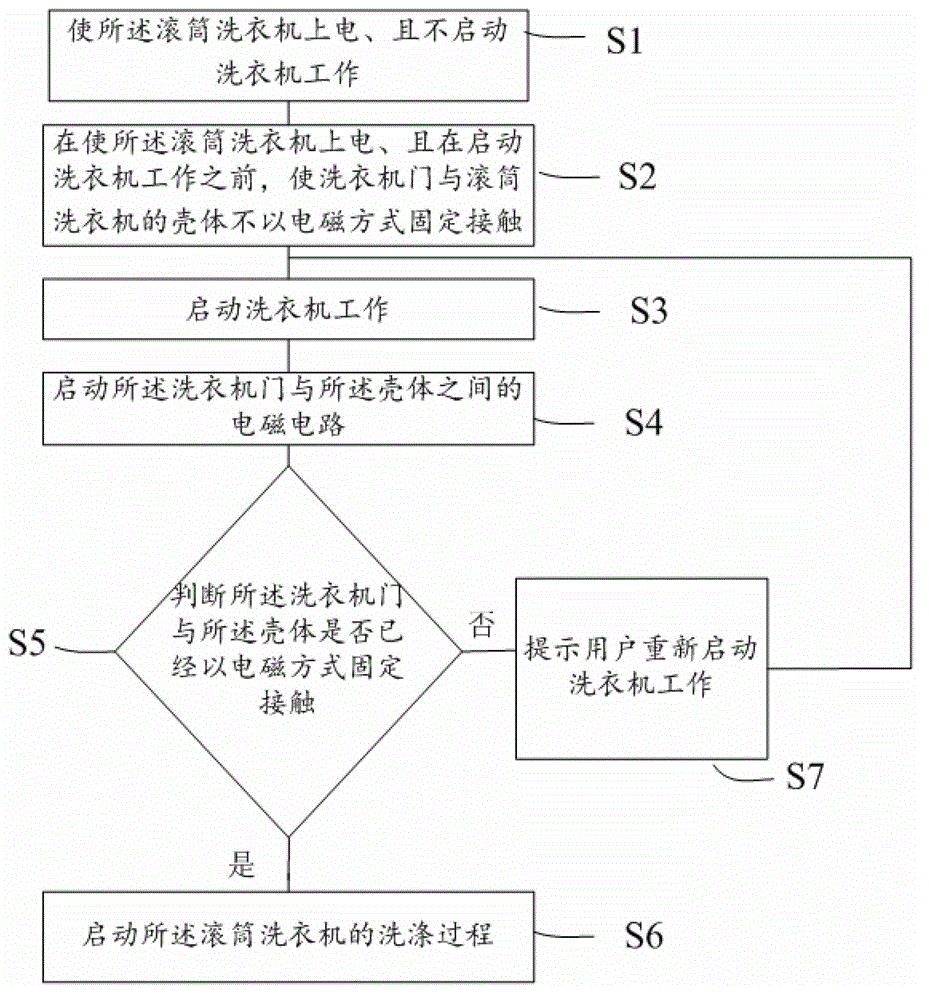

Drum washing machine and control method thereof

InactiveCN102978869AEasy to climb outAvoid personal injuryOther washing machinesControl devices for washing apparatusMechanical engineeringFull Term Infant

The invention provides a drum washing machine and a control method thereof. The control method comprises the following steps that the drum washing machine is energized, and is not started to work; a door of the washing machine is not in electromagnetic fixed contact with a casing of the drum washing machine, so the door of the washing machine is not closed; the washing machine is started to work; an electromagnetic circuit between the door and the casing of the washing machine is started; and whether the electromagnetic fixed contact exists between the door and the casing of the washing machine or not is judged, wherein if the door and the casing of the washing machine are in the electromagnetic fixed contact, the washing process of the drum washing machine is started, and if the door and the casing of the washing machine are not in the electromagnetic fixed contact, a user is prompted to restart the washing machine to work, so as to restart the electromagnetic circuit between the door and the casing of the washing machine. The drum washing machine has the advantage that the injury to infants who can climb is avoided.

Owner:YUYAO HUIDIAN ELECTRONICS TECH DEV

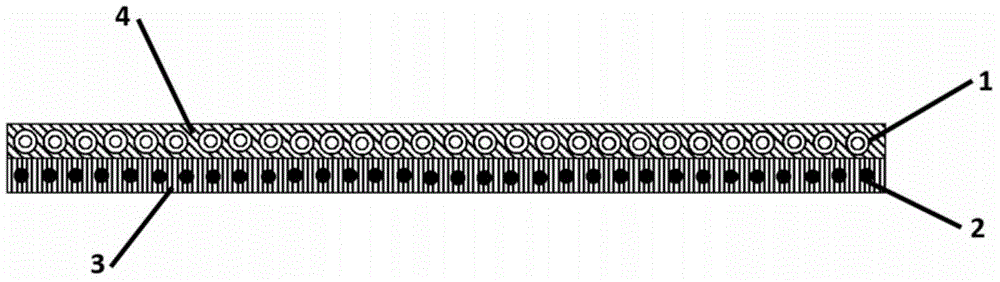

Thermal-insulation and temperature-adjustment lining

InactiveCN104943310AReduce lossReduce the impactLamination ancillary operationsSynthetic resin layered productsThermal insulationMicrosphere

The invention relates to a thermal-insulation and temperature-adjustment lining which comprises one or more thermal insulation layers and a temperature adjustment layer, wherein phenolic resin hollow microspheres are adopted as the thermal insulation layers; a phase change material is adopted as a temperature adjustment material; the phase change material is covered by a macromolecule thin film by adopting a coating technology instead of being exposed out of the surface of the thin film, so as to be protected. Through the adoption of the structure of the lining and the utilization of the good thermal insulation function of the phenolic resin hollow microspheres, the utilization efficiency of the phase change material is improved, the fact that the temperature adjustment function plays a role in a relatively closed local area, and the lining is good in hand feeling, and can realize lightening and thinning under the same warm keeping effect when being used as a garment lining. The lining provided by the invention can be used for temperature adjustment garments, and can also be applied to the fields of industry, agriculture, construction, electronic components, special protection and the like.

Owner:YUTIAN ENERGY CO LTD

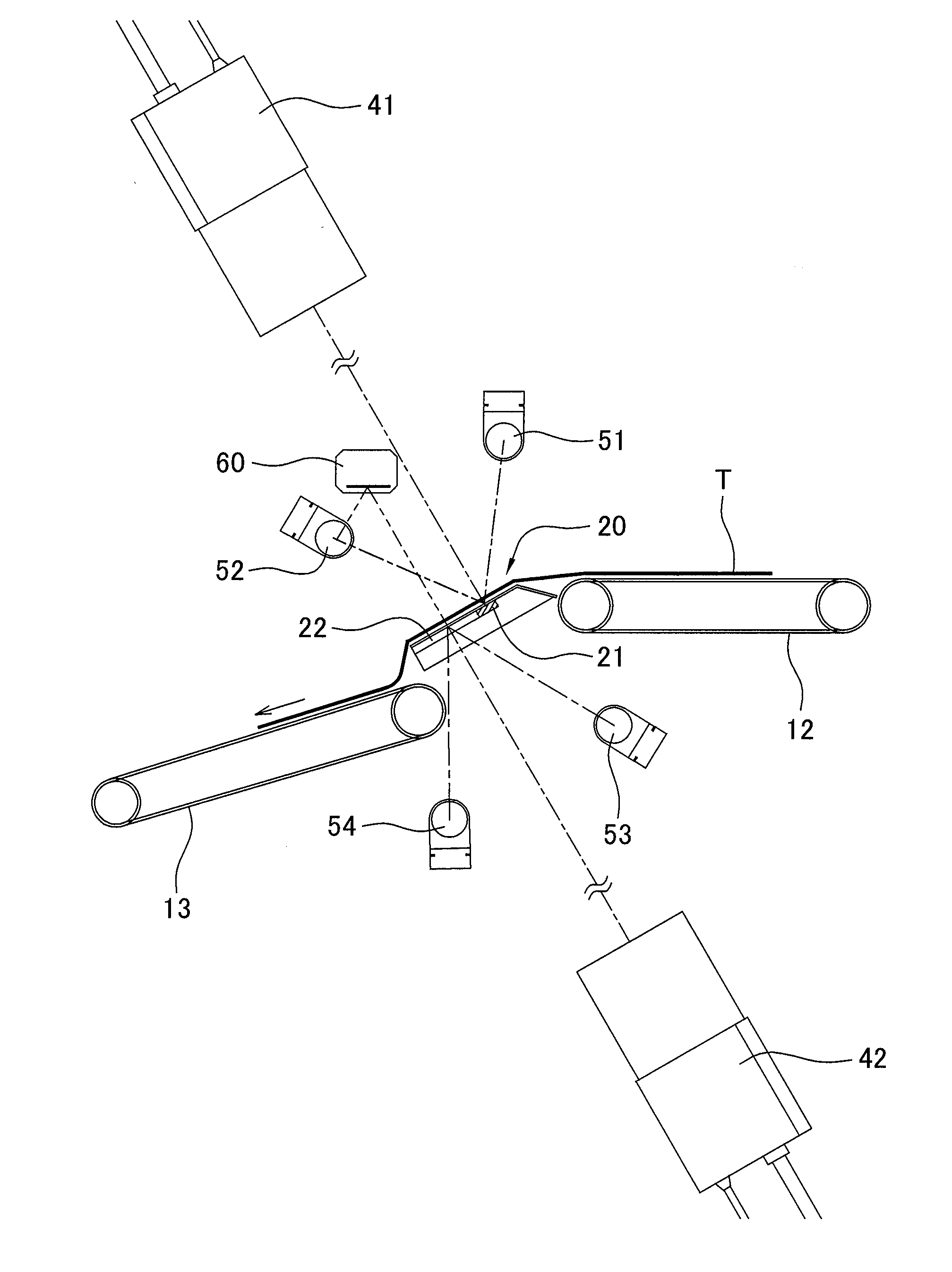

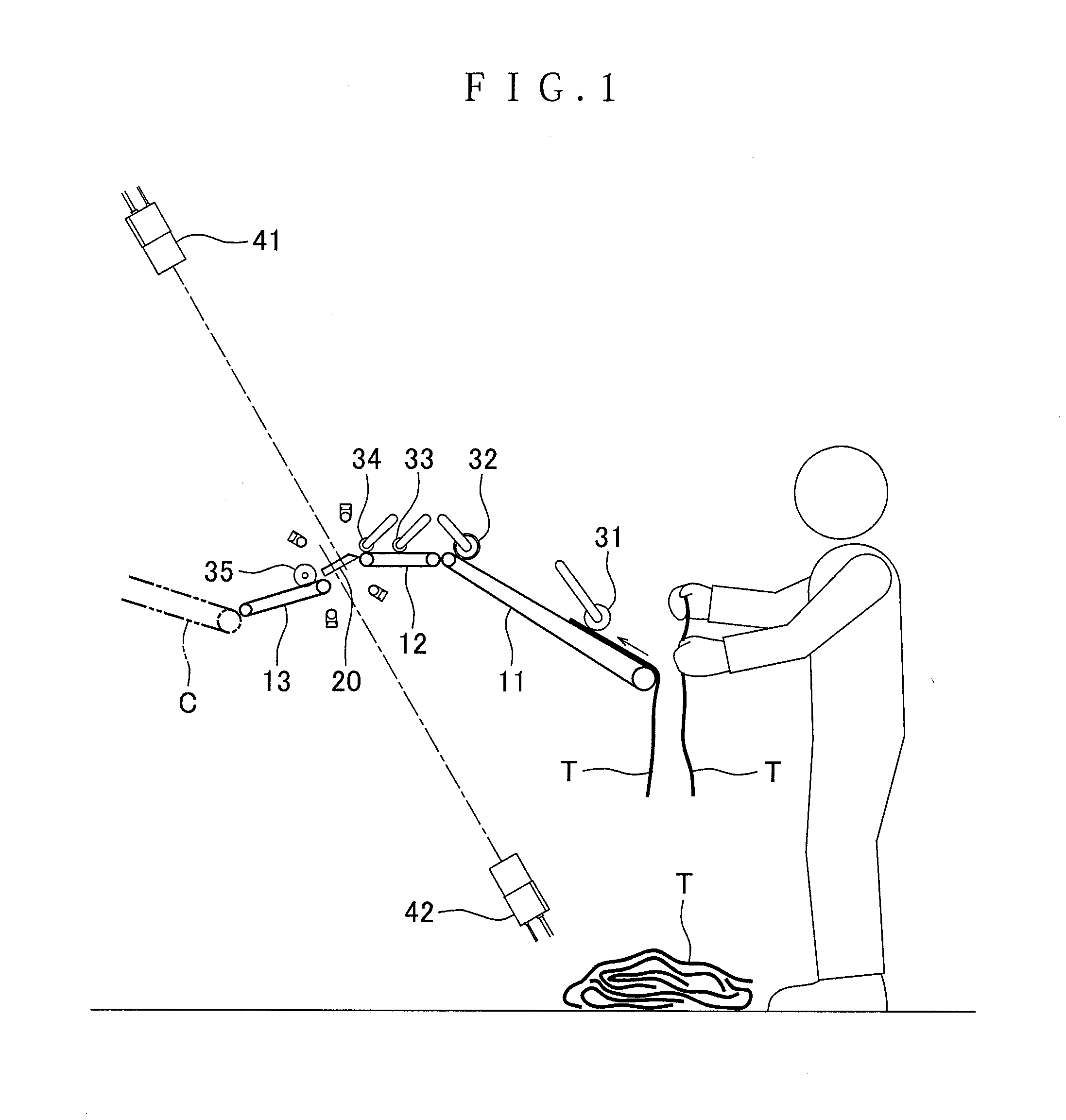

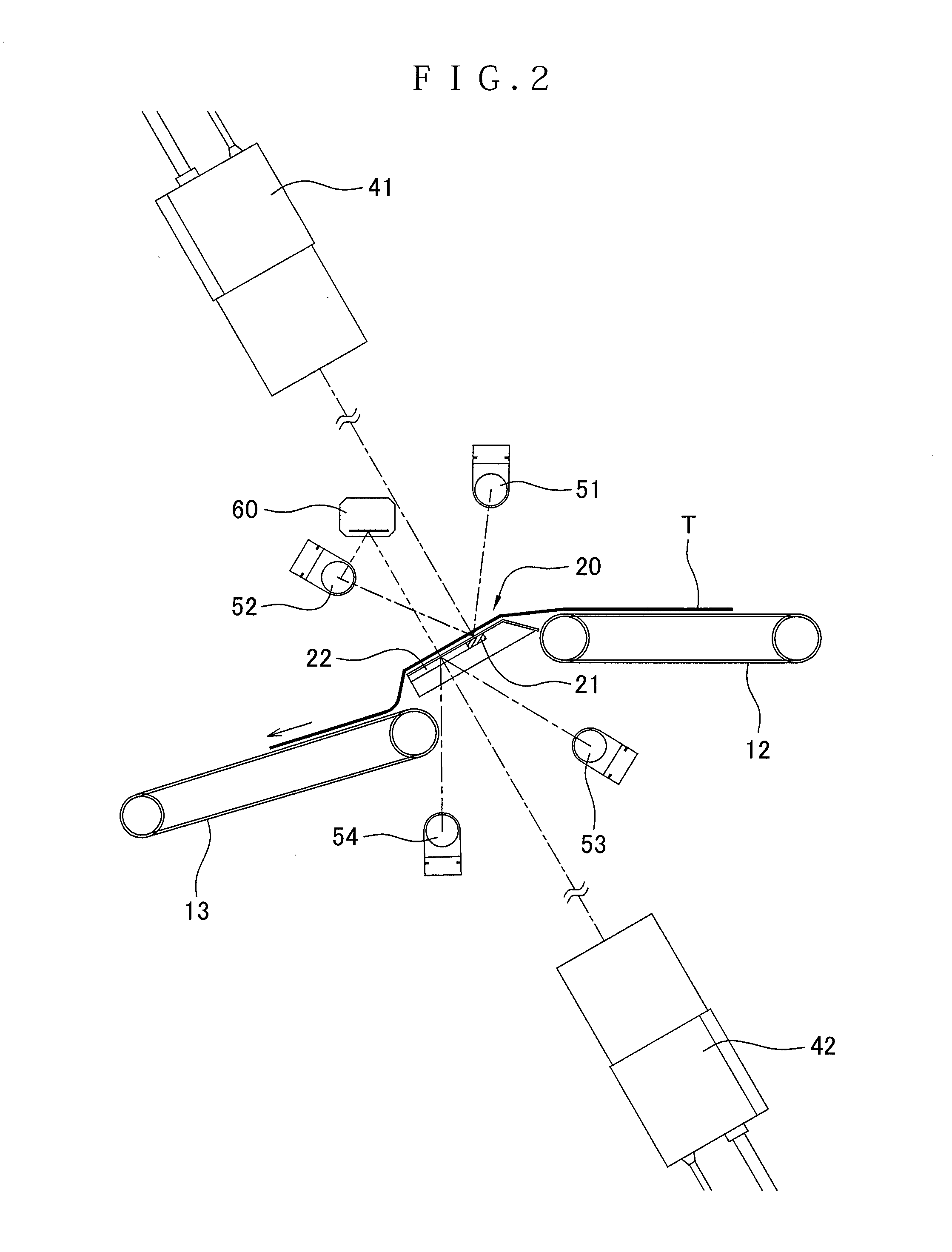

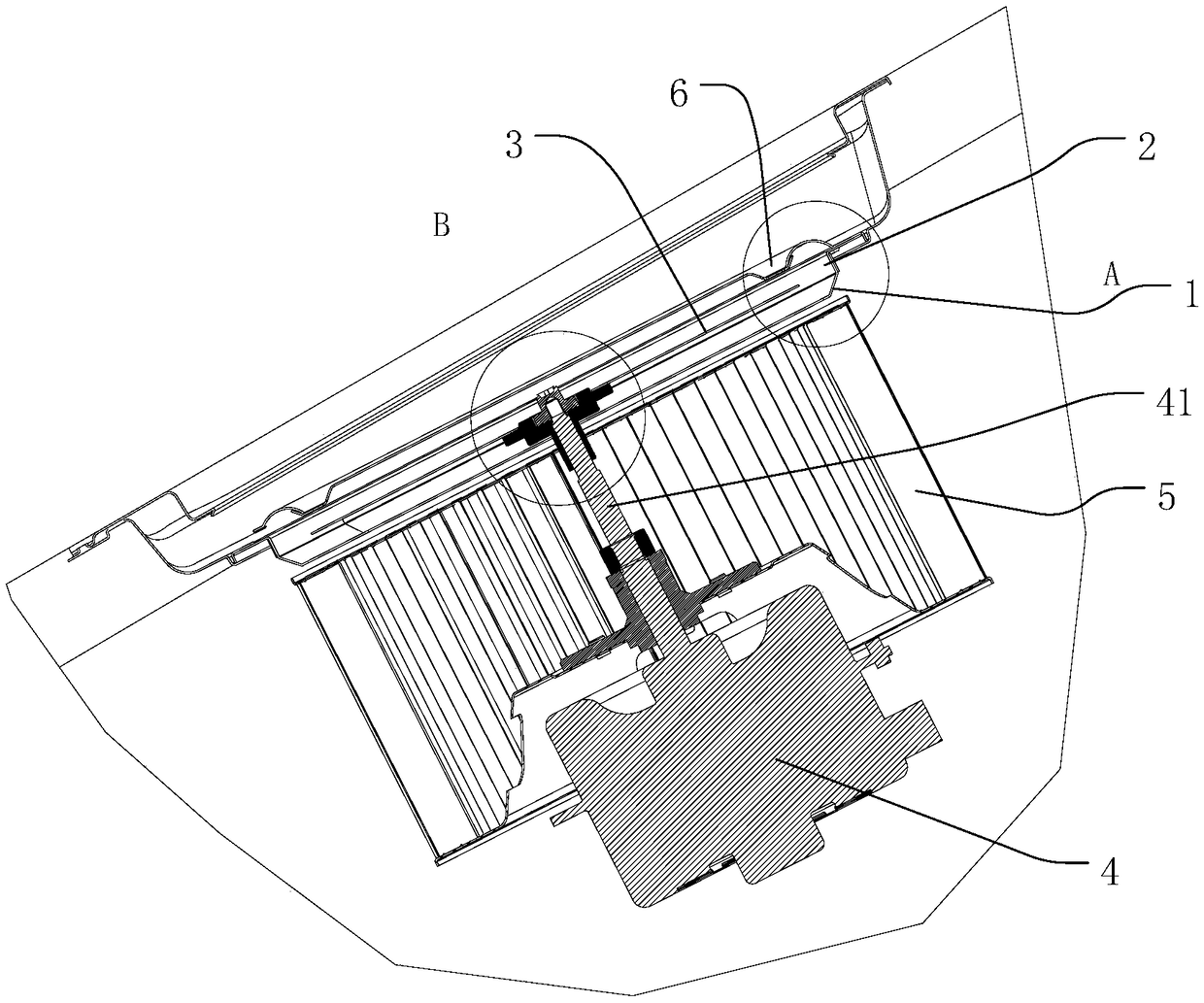

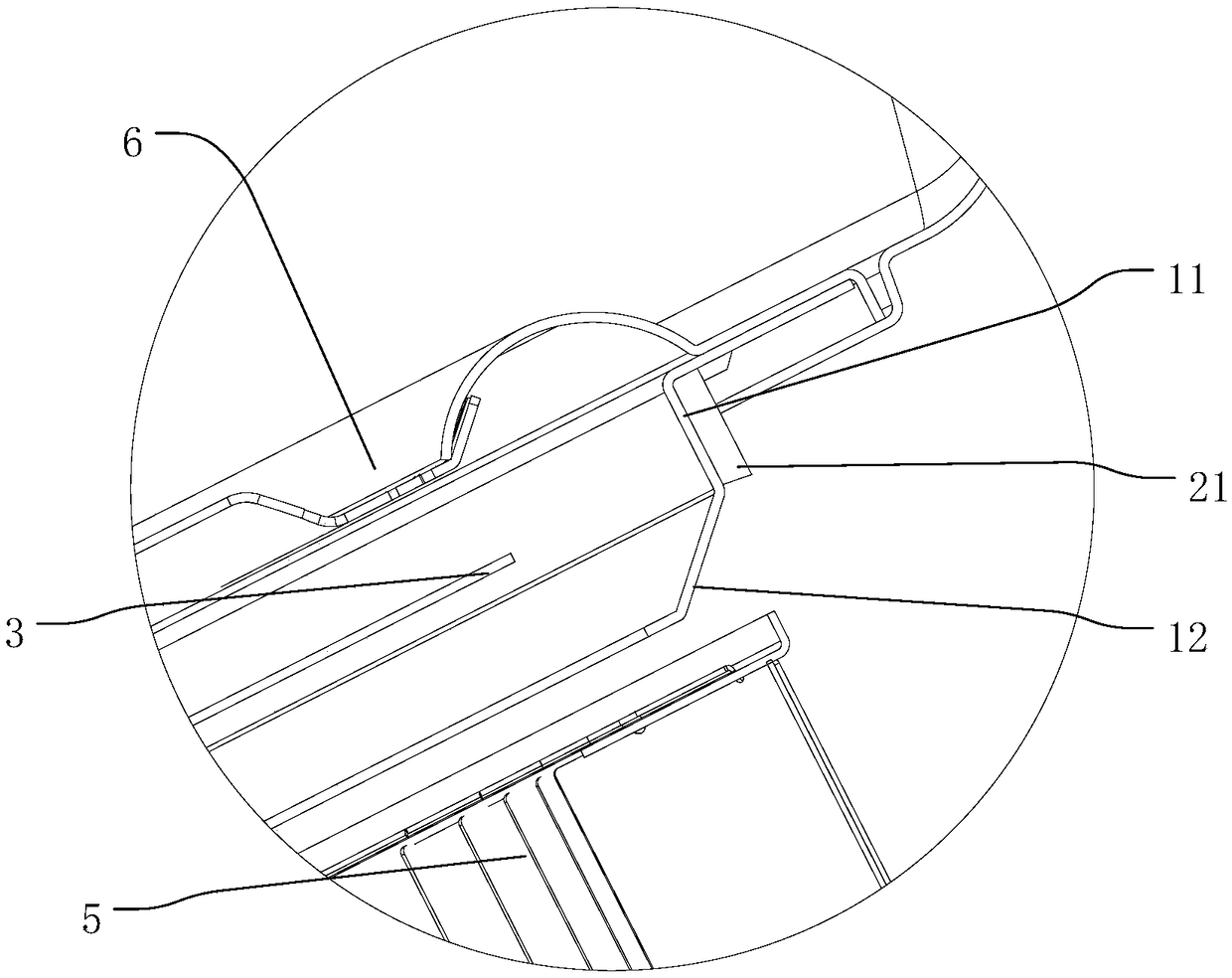

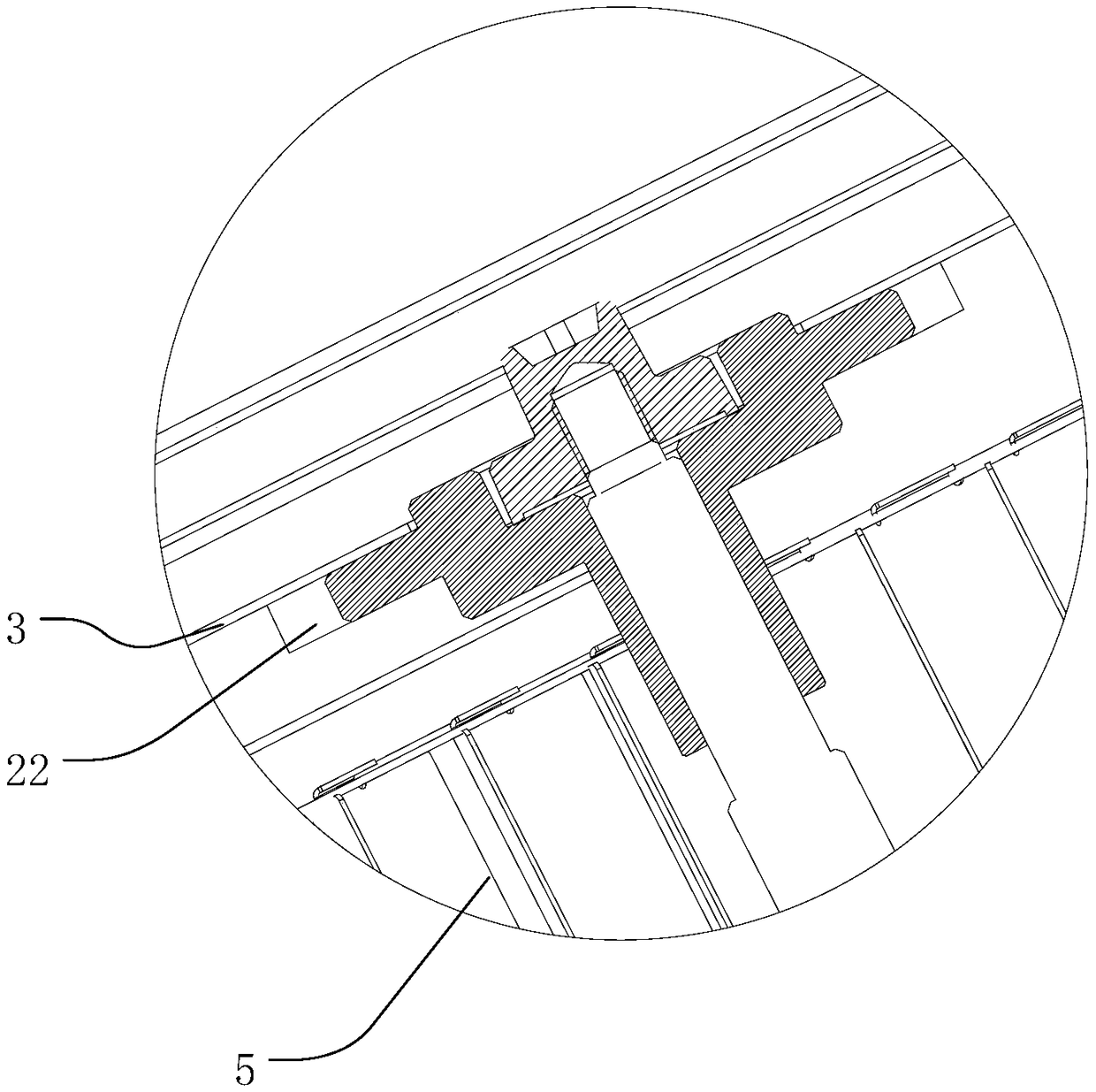

Apparatus and method for inspecting cloth piece

ActiveUS20130077093A1Reliable distinctionHigh accuracy to detectInspecting textilesTextile testingDark colorComputer science

Provided is an apparatus and a method for inspecting a cloth piece, by which dirt and a tear can be reliably distinguished, and which have high accuracy to detect the dirt. The apparatus for inspecting a cloth piece includes: an inspection table 20 having a dark color section 21 and a light transmitting section 22; a first inspection camera 41 for picking up an image of reflected light from a cloth piece T passing through the dark color section 21; and a second inspection camera 42 for picking up an image of transmitted light through the cloth piece T passing through the transparent section 22. The dirt and the tear can be reliably distinguished by determining an area where the reflected light and transmitted light are both darker than a surrounding area to be dirt and by determining an area where the reflected light is darker than the surrounding area and the transmitted light is brighter than the surrounding area to be the tear. The dirt inside the cloth piece is emphasized, thereby providing high detection accuracy to detect the dirt.

Owner:PUREX

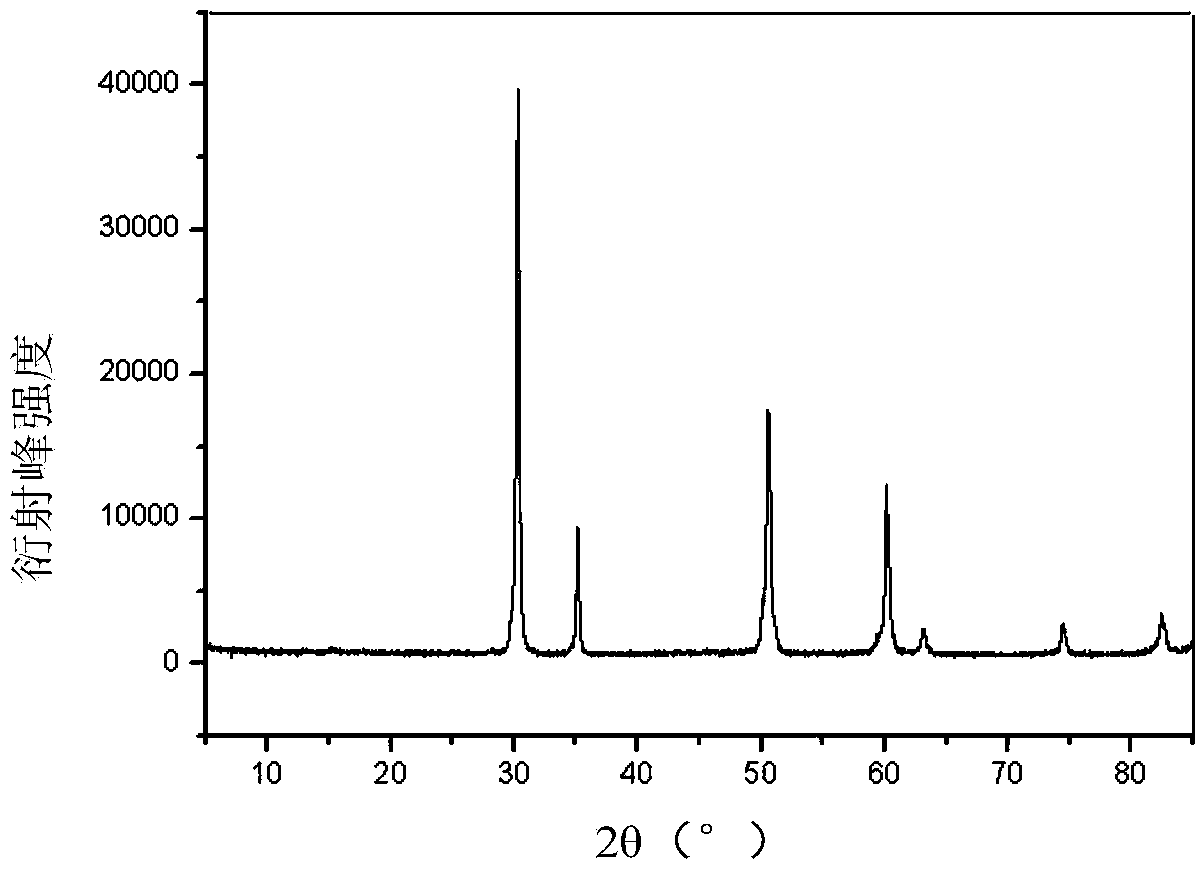

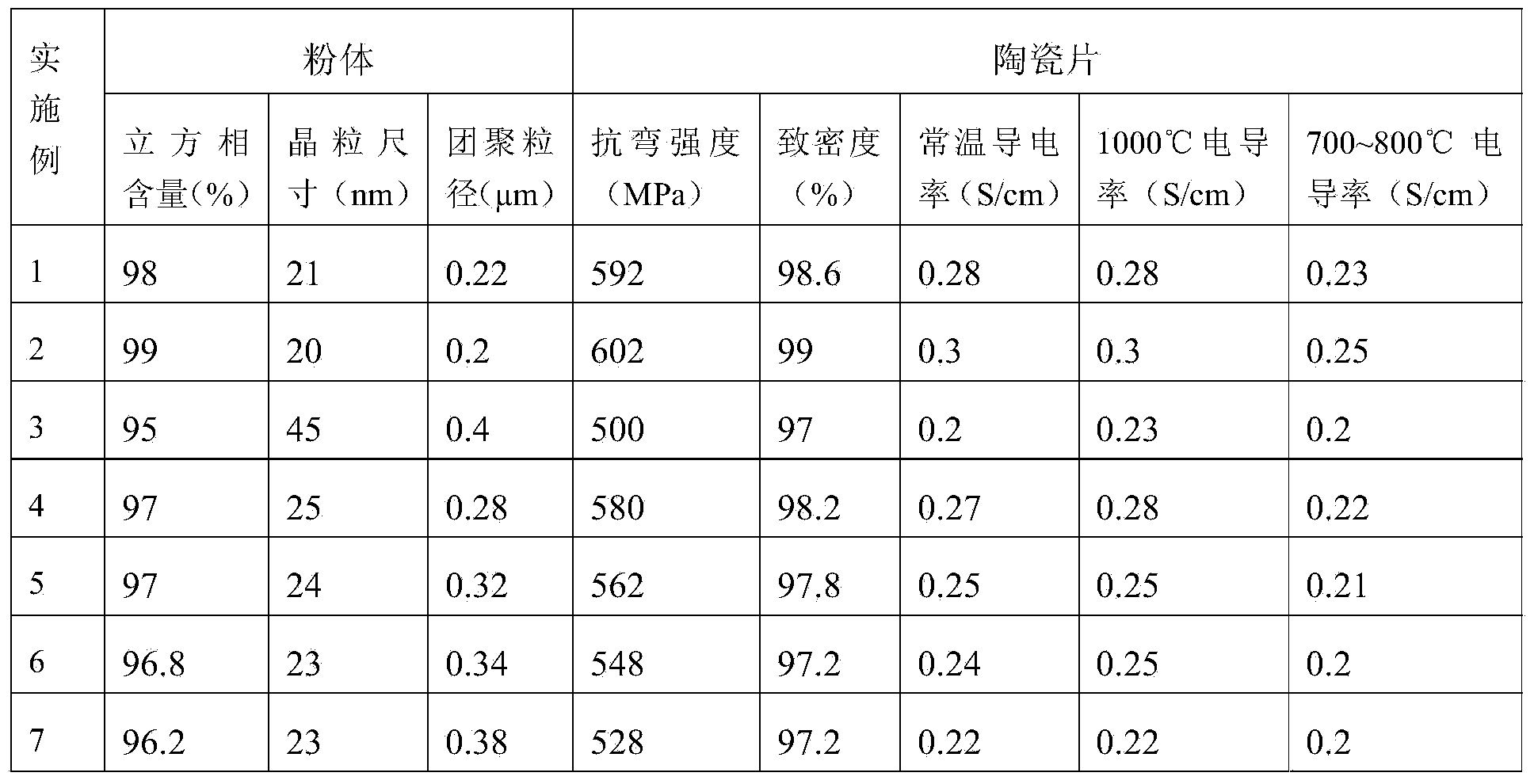

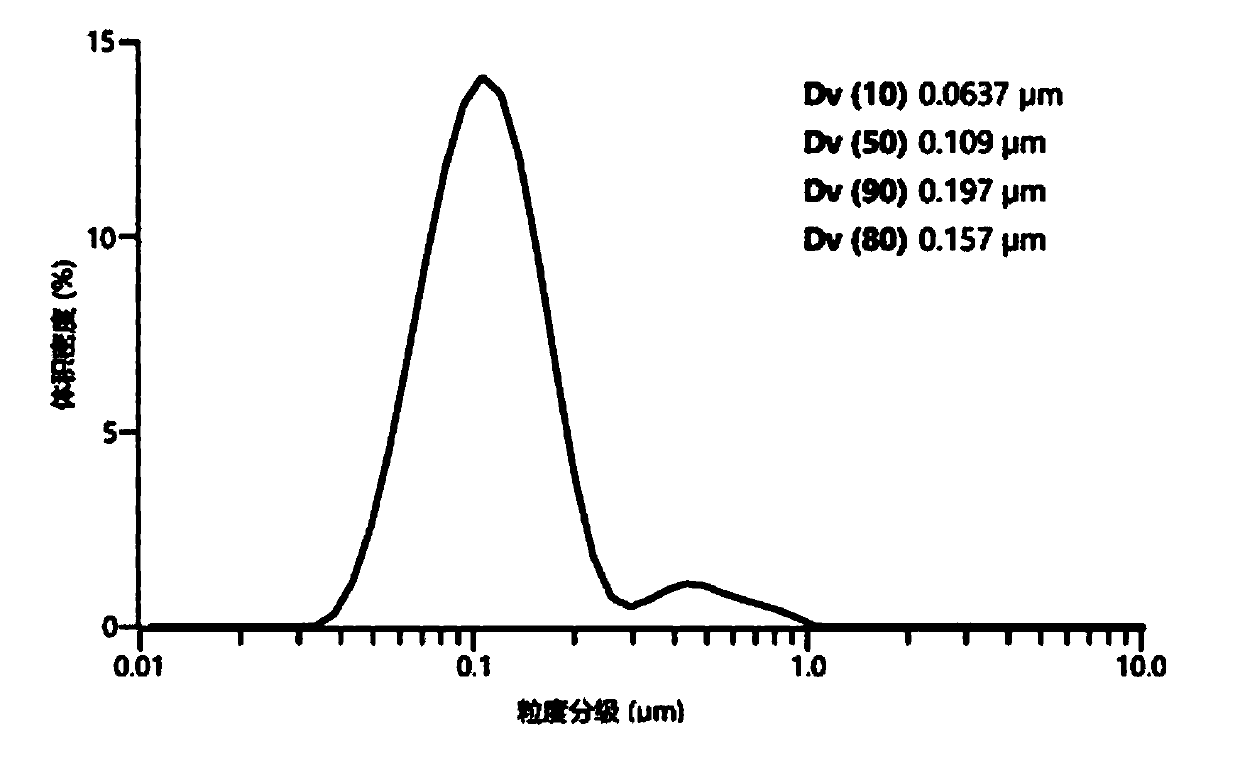

Sc2O3-stabilized ZrO2-based electrolyte powder and preparation method thereof, and Sc2O3-stabilized ZrO2 electrolyte ceramic wafer prepared from powder

ActiveCN103647097ALow priceHigh strengthFinal product manufactureSolid electrolyte fuel cellsNitrateHigh intensity

The invention discloses Sc2O3-stabilized ZrO2-based electrolyte powder and a preparation method thereof, and a Sc2O3-stabilized ZrO2 electrolyte ceramic wafer prepared from the powder. The Sc2O3-stabilized ZrO2-based electrolyte powder is characterized in that zirconyl nitrate, Sc2O3, optional CeO2, nitric acid, and optional auxiliary materials are used as the raw materials, an ammonium bicarbonate-ammonia buffer system is used as a precipitant, and the coprecipitation, mist spray and heat treating method is carried out to prepare the powder of which a bulk phase is a cubic phase. Such Sc2O3-stabilized ZrO2-based electrolyte powder has the advantage that the raw materials are low in price and nontoxic; the Sc2O3-stabilized ZrO2-based electrolyte powder can be prepared into a high-strength dense electrolyte ceramic wafer which has relatively high ionic conductivity stability and the like. Simultaneously, according to the preparation method of the Sc2O3-stabilized ZrO2-based electrolyte powder, follow-up complex processes such as filtering, washing and drying in the coprecipitation method are avoided, the agglomeration is reduced, the product purity is ensured, the process is simple, the process is continuous and efficient in process, and large industrial production is facilitated.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

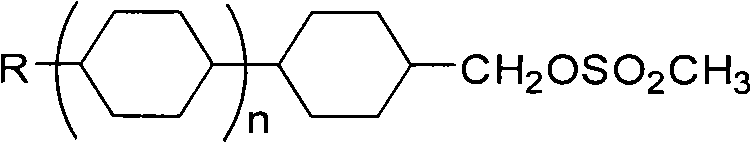

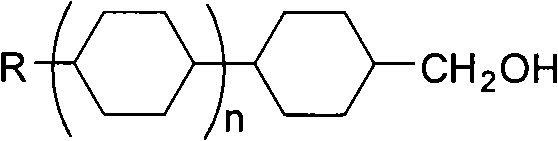

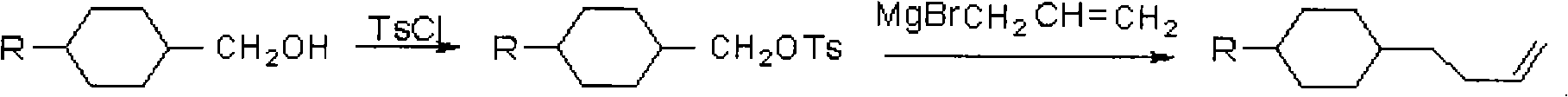

Intermediate for synthesizing butene liquid crystal and synthetic method thereof

ActiveCN101407482AThorough responseHigh puritySulfonic acid esters preparationMethanesulfonyl chlorideSolvent

The invention relates to an intermediate for synthesizing butene liquid crystal and a synthesizing method thereof. The intermediate for synthesizing butene liquid crystal has a general formula structure as the right, which is shown in a right formula (I) or alkyl of C1-C7 or alkoxy of C1-C7; when in a right formula (II), X is H or F, Z is H or F, Y=F or alkyl of C1-C7 or alkoxy of C1-C7 or -OCHF2 or -OCF3 or -CF3 or CHF2; and n=0 or 1. The synthesizing method lies in that corresponded raw material alcohol is reacted with methyl sulfonic acid chloride in solvent with the presence of catalyst. The synthesizing method has a fast reaction without other side products, the post treatment process is simple and handy and the obtained product has high yield coefficient and purity.

Owner:HEBEI MAIERSTON ELECTRONICS MATERIAL

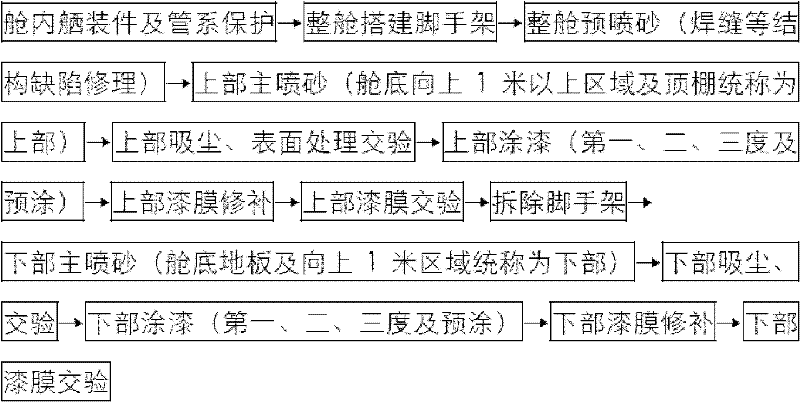

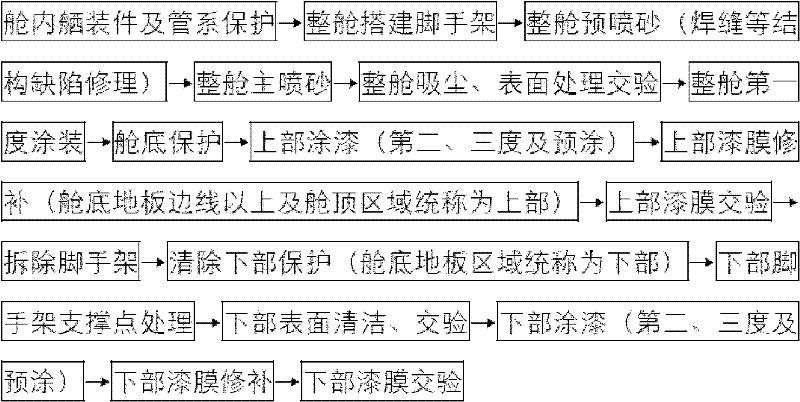

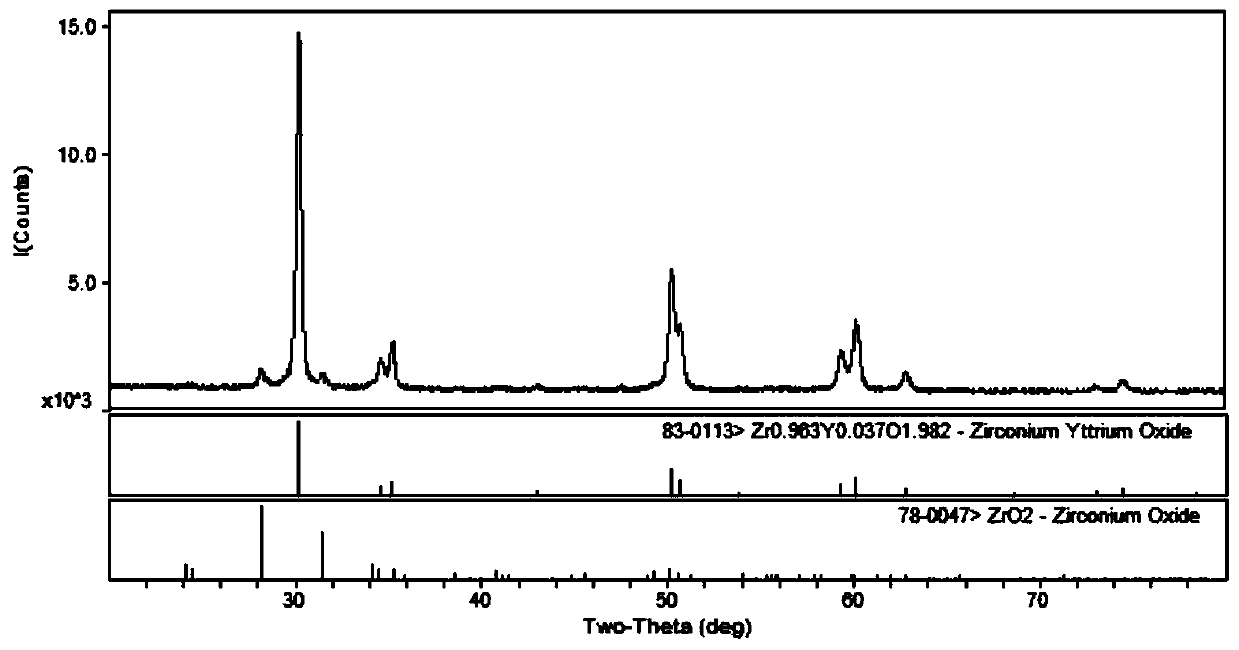

Special coating process of cargo tank of product tanker/chemical tanker

InactiveCN102476094AThe construction process is scientific and reasonableShorten special coating cyclePretreated surfacesCoatingsSocial benefitsSurface cleaning

The invention discloses a special coating process of a cargo tank of a product tanker / chemical tanker. The process adopts an integral method instead of an upper and lower part method and has the effects of meeting the construction requirement of the special coating, shorting the special coating period, improving the special coating efficiency, lowering the special coating cost and ensuring smooth special coating construction. The process specifically comprises the concrete steps of protection of fittings and piping systems in a cabin, scaffold setting up in the whole cabin, advance sand blasting in the whole cabin, main sand blasting in the whole cabin, dust absorption and surface treatment inspection in the whole cabin, first coating of the whole cabin, cabin bottom protection, upper part painting, upper part film painting and repairing, upper part film painting inspection, scaffold dismantling, lower part protection removal, treatment of the support point of the lower scaffold; lower surface cleaning and inspection; and lower part painting, lower part film painting and repairing and lower part film painting inspection. The process has multiple considerable effects such as high efficiency, low cost, energy conservation and the like and has the effects of not only ensuring smooth completion of special coating of the 110,000-ton large product tanker but also creating considerable economic and social benefits.

Owner:DALIAN SHIPBUILDING IND

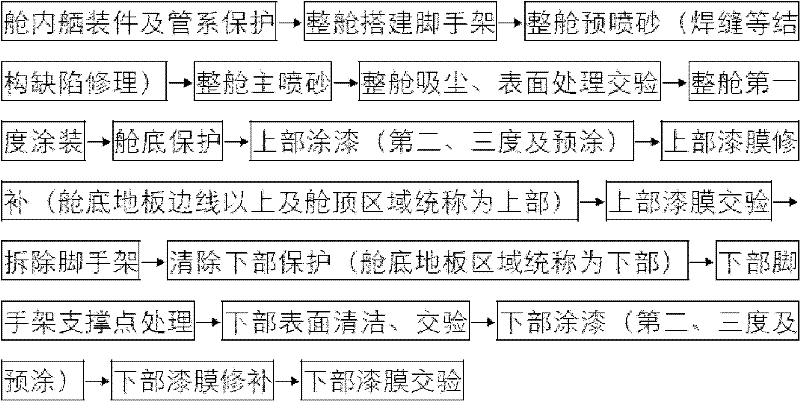

Preparation method of yttrium oxide stabilized zirconium oxide powder based on supercritical dispersion roasting

ActiveCN110078120APrevent the occurrenceAvoid conditionsBulk chemical productionZirconium oxidesCombustionSpherical morphology

The invention discloses a preparation method of yttrium oxide stabilized zirconium oxide powder based on supercritical dispersion roasting. The method comprises the following steps: first, weighing zirconium salt and yttrium salt, mixing the zirconium salt with the yttrium salt to prepare a precursor material of the yttrium oxide stabilized zirconium oxide powder, and drying the precursor material; mixing the dried precursor material with a grinding auxiliary agent and a dispersing agent, grinding the mixture into the d10 being less than 100 nm and d50 being greater than 150 nm in a nano-sandmill; continuously conveying the ground slurry into a high-pressure kettle with the temperature being greater than 250 DEG C and the pressure being greater than 6.5 MPa through a metering pump, and spraying the slurry into a calcining furnace for combustion from an outlet, wherein the precursor is dispersed by the grinding auxiliary agent and the dispersing agent which are in a supercritical stateand is decomposed into the yttrium oxide stabilized zirconium oxide powder in the calcining furnace. The yttrium oxide stabilized zirconium oxide powder prepared with the method has small particle size, uniform particle size and nearly spherical morphology, and can meet the requirement of high-end application.

Owner:SHENZHEN ZHONGJIN LINGNAN NONFEMET COMPANY +2

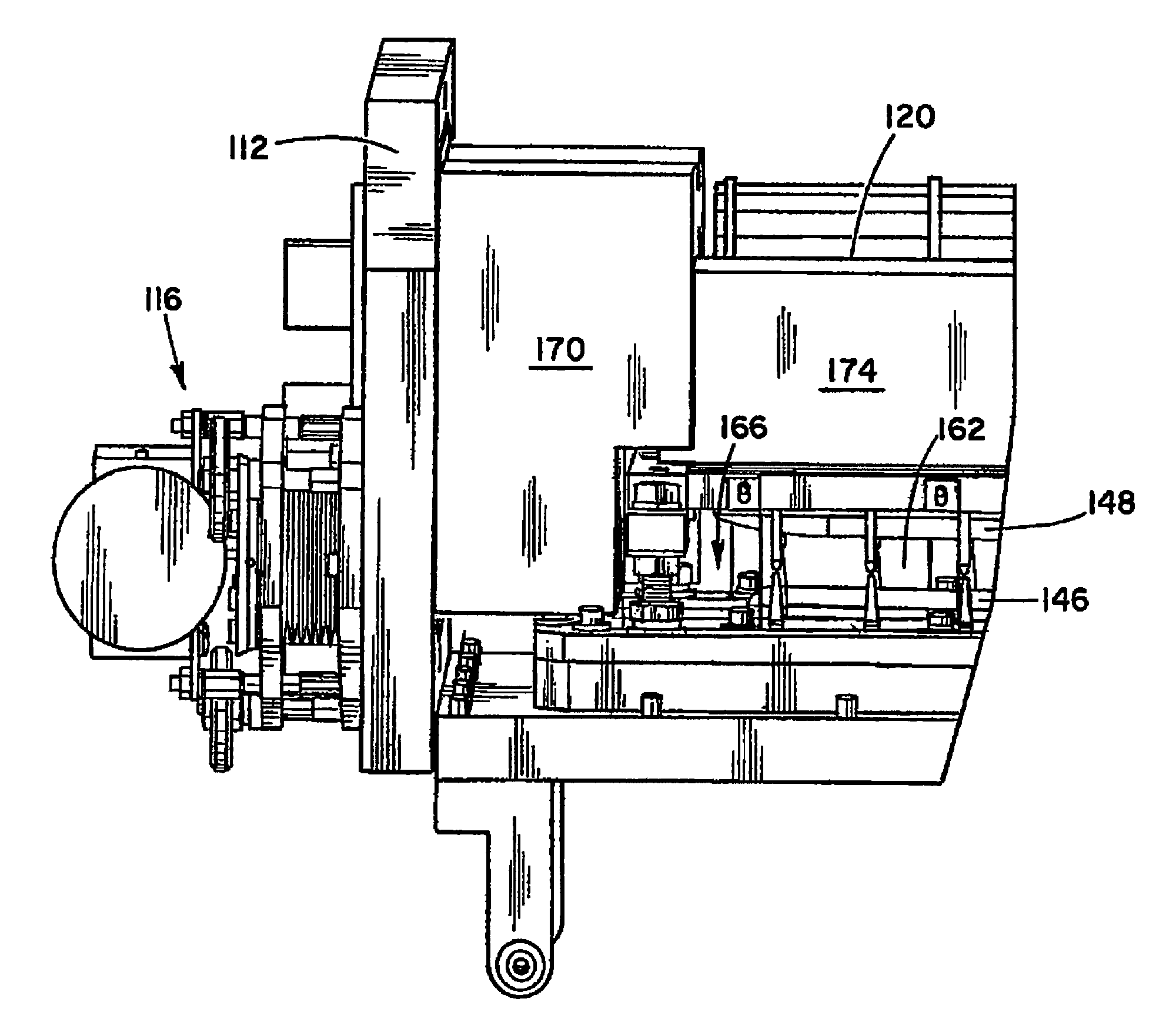

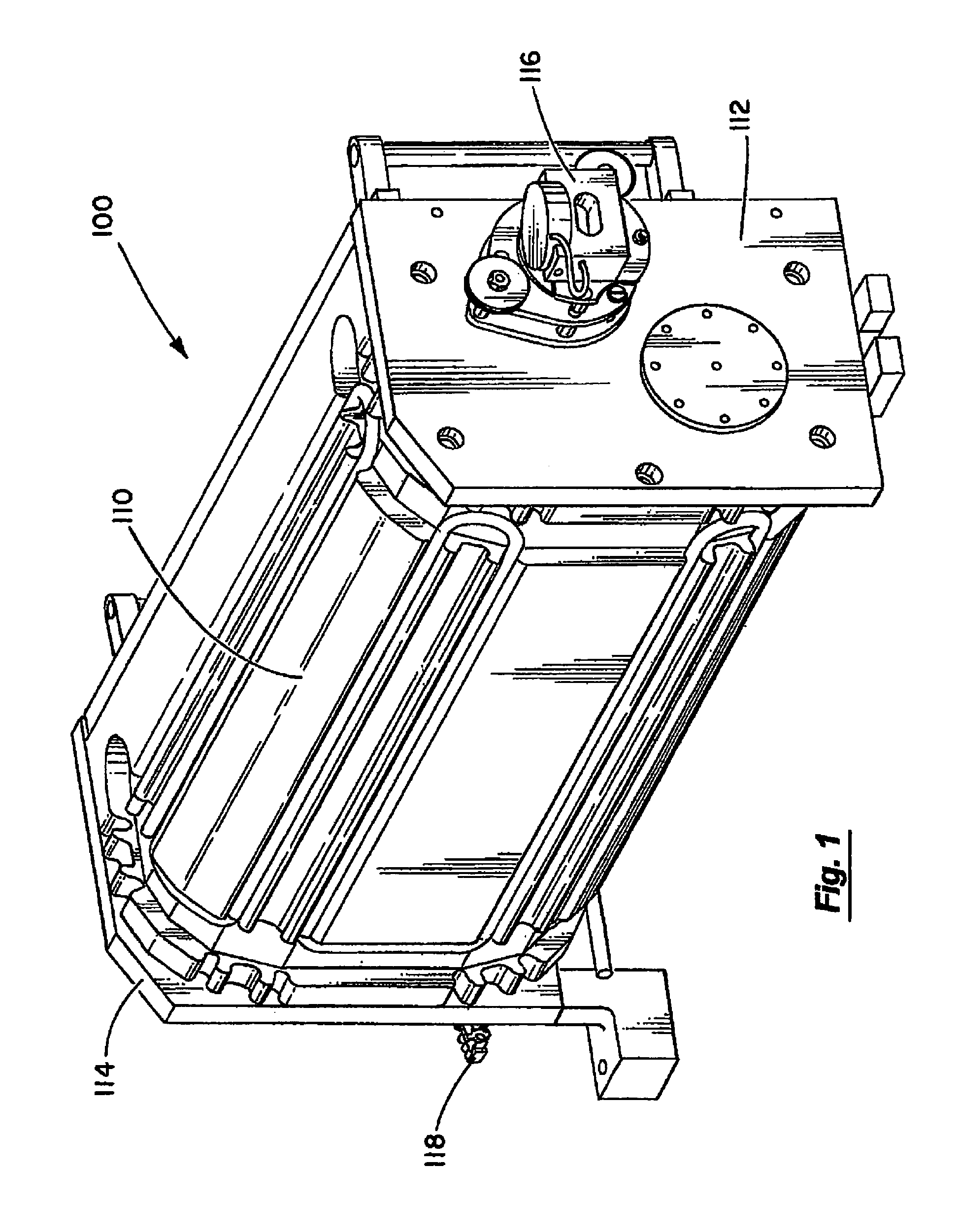

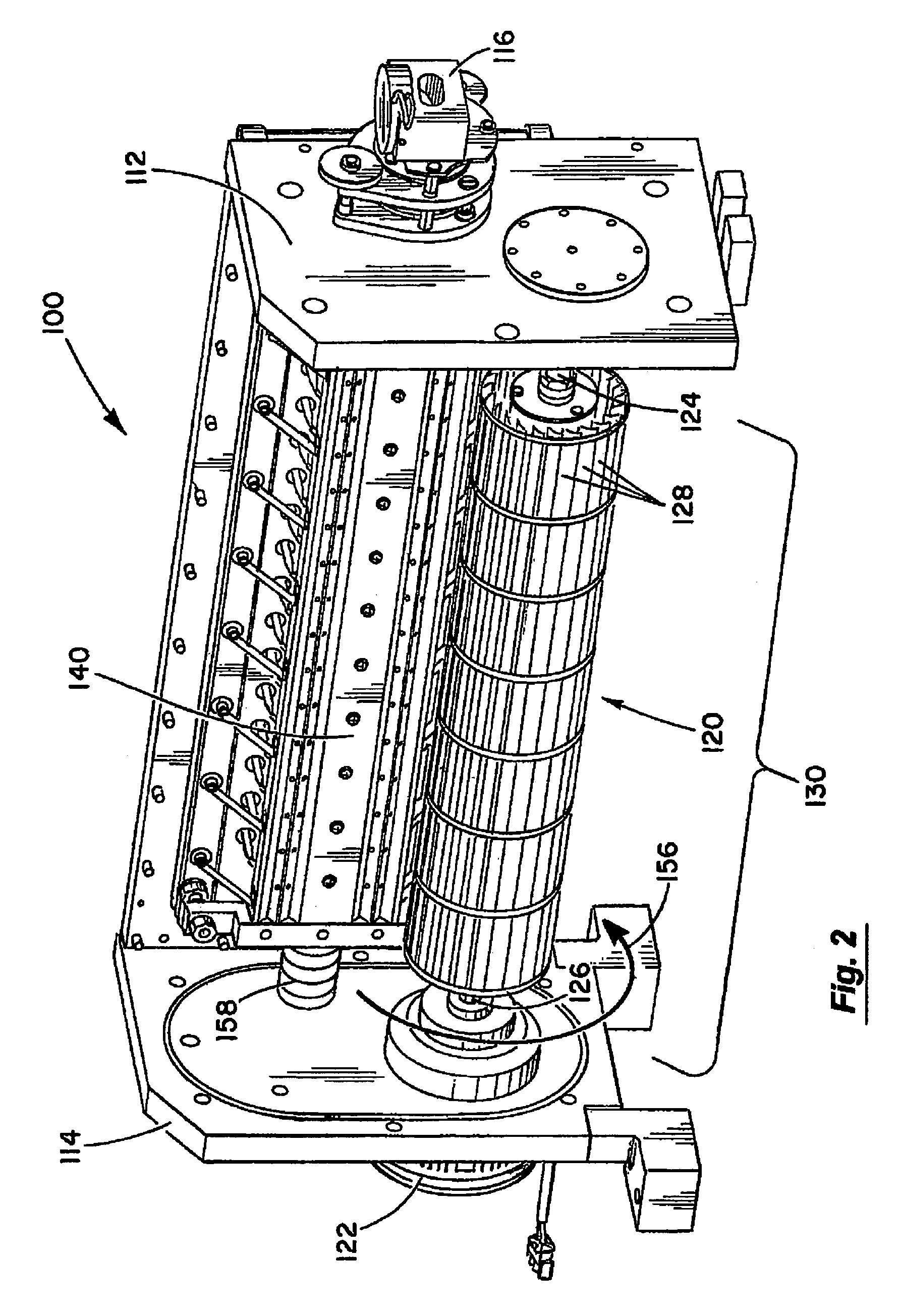

Passive gas flow management and filtration device for use in an excimer or transverse discharge laser

InactiveUS6973112B2Avoid washingOptical resonator shape and constructionActive medium materialFiltrationFilter system

The present invention provides systems and methods for filtering particles and assisting gas flow management within laser systems. In one embodiment, a laser apparatus (100) includes an elongate laser chamber defining a chamber cavity (130) and an electrode structure (140) disposed therein. The electrode structure includes an anode (148) spaced apart from a cathode (146). The laser includes an elongate baffle (174) disposed in the laser chamber. The baffle is adapted to arrest a plurality of particles generated within the chamber. In this manner, the baffle operates as a passive filtration system to help filter particles generated within the chamber during laser operation, and may further provide gas flow management capabilities.

Owner:AMO MFG USA INC

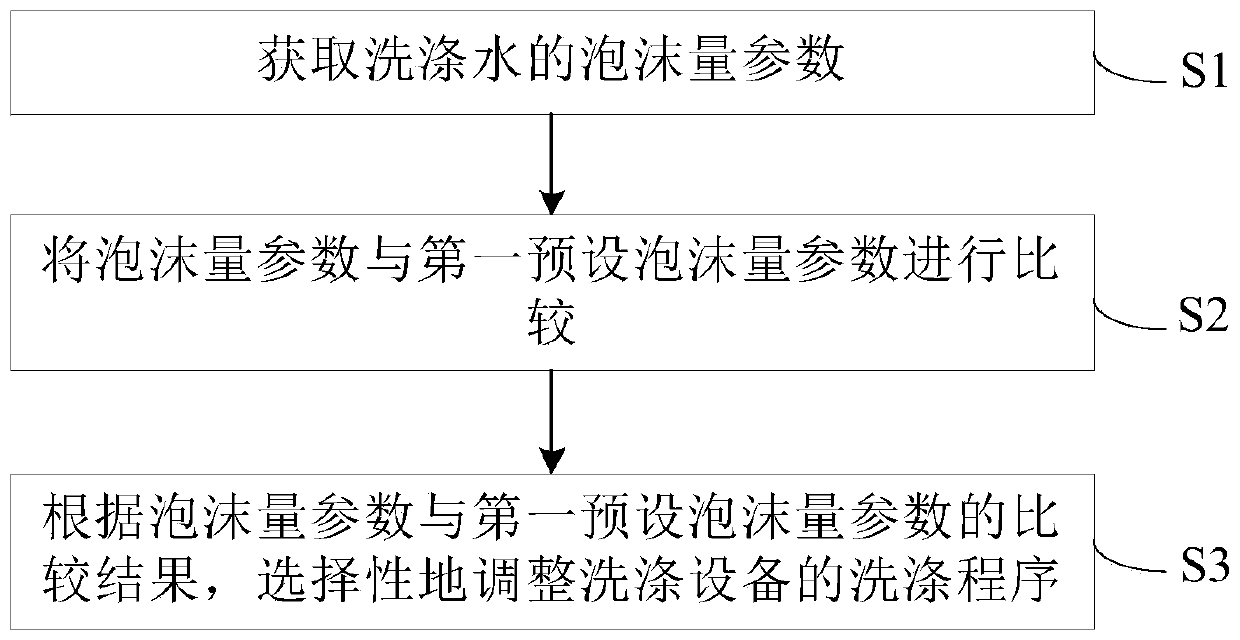

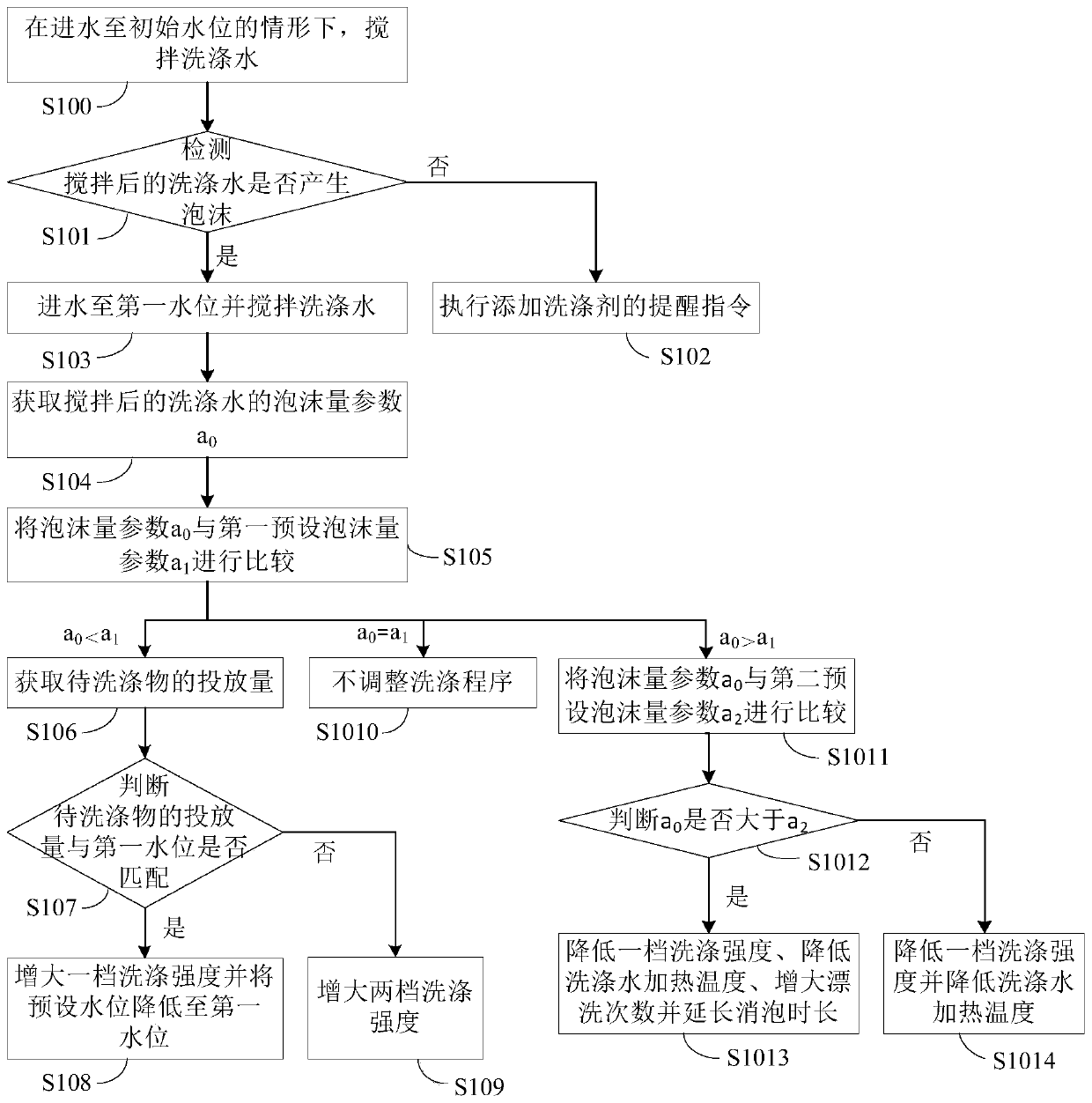

Washing device control method

PendingCN110205775AGuaranteed work performanceReduce difficultyControl devices for washing apparatusTextiles and paperWash waterProcess engineering

The invention belongs to the technical field of washing, particularly relates to a washing device control method, and aims to solve the problem that working effects of an existing washing machine arereduced as the feeding quantity of washing agents and washing water quantity are not matched. According to the washing device control method, washing procedures of a washing device can be selectivelyadjusted according to foam quantity parameters generated by washing water, and harmful influence caused by improper feeding or improper water intake quantity on working effects of the washing device is furthest reduced. The matching degree between the feeding quantity of the washing agents and the water intake quantity and the relational degree among the feeding quantity of the washing agents, thewater intake quantity and washing effects are reduced, and the difficulty of a user in using the washing device is reduced.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

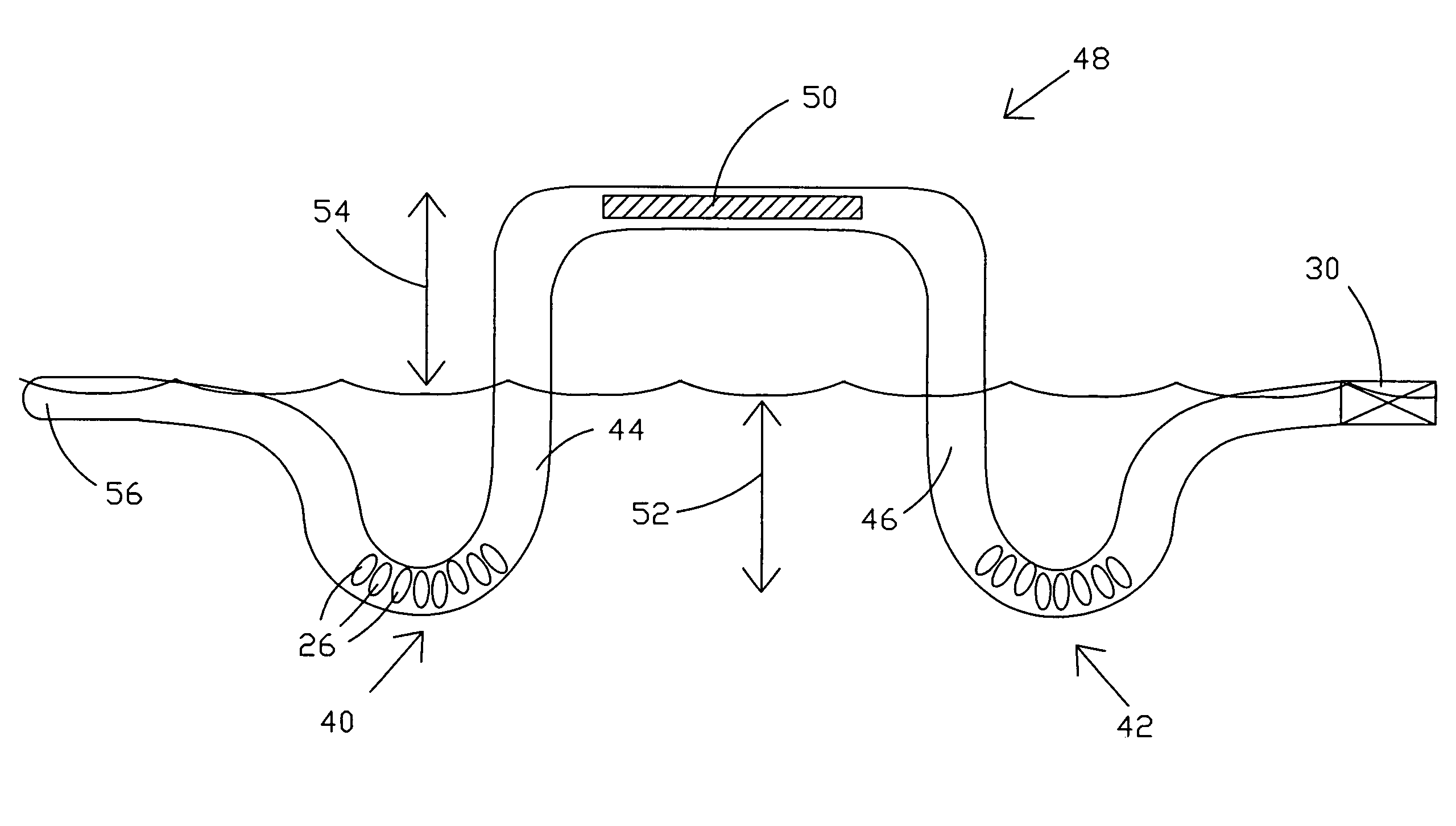

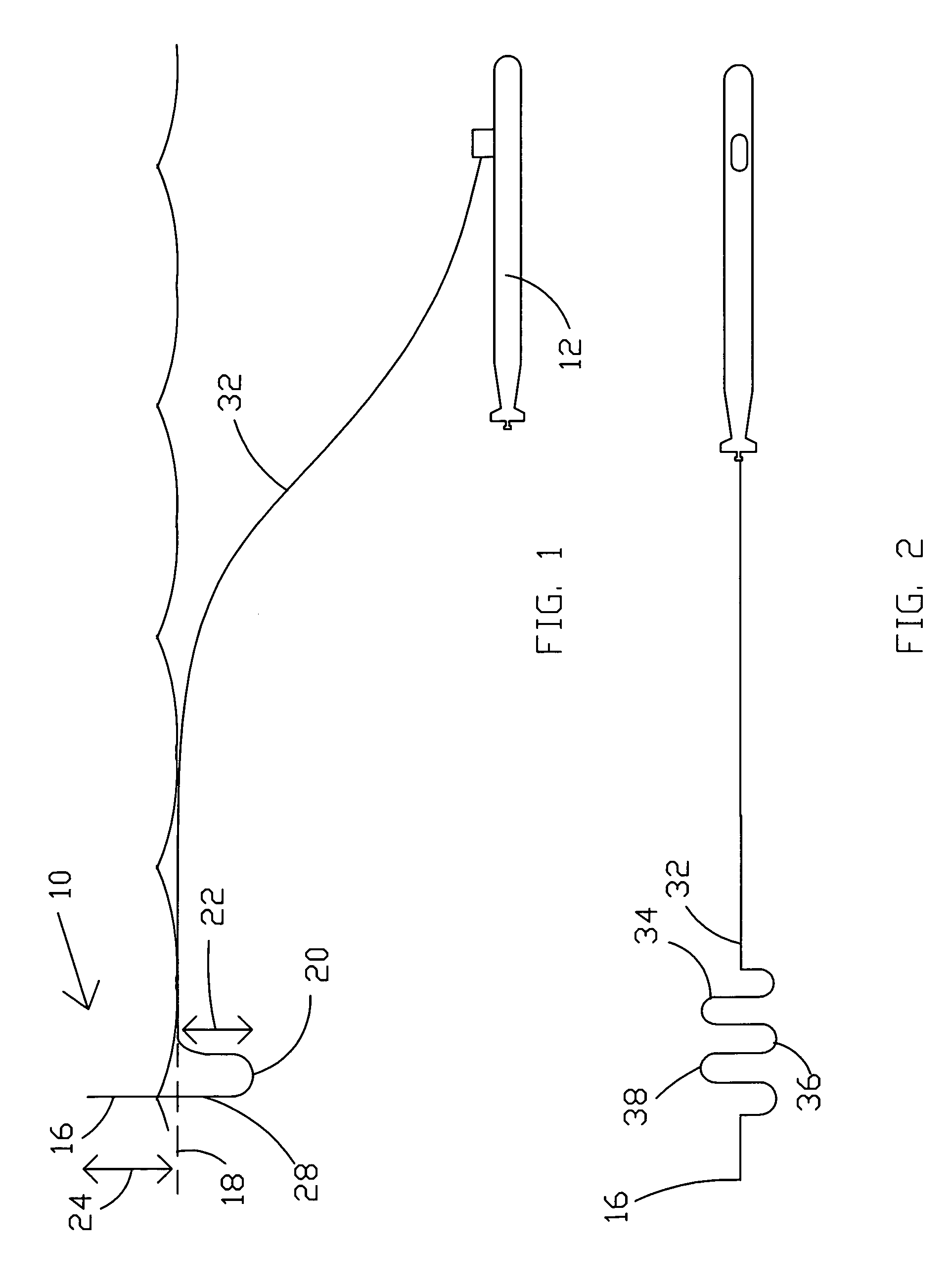

Buoyant cable antenna configuration and system

InactiveUS7411558B1Different typeAvoid washingAntenna adaptation in movable bodiesSubaqueous/subterranean adaptionKeelDirectional antenna

A buoyant cable system and method is provided with a towed transmission line and antenna platform that may be deployed into the water from a submerged submarine so that the antenna extends above the surface of the water. The cable system preferably utilizes a flexible weighted keel formed in a section of the transmission line. A buoyant section of transmission line extends upwardly from the depth of the weighted keel to support one or more antennas above the surface of the water. In another embodiment, a plurality of weighted keels may be formed in sections of the transmission line whereby an inverted U-shaped buoyant portion extends upwardly from the depth of weighted keel to act as the support for a horizontally oriented antenna.

Owner:UNITED STATES OF AMERICA

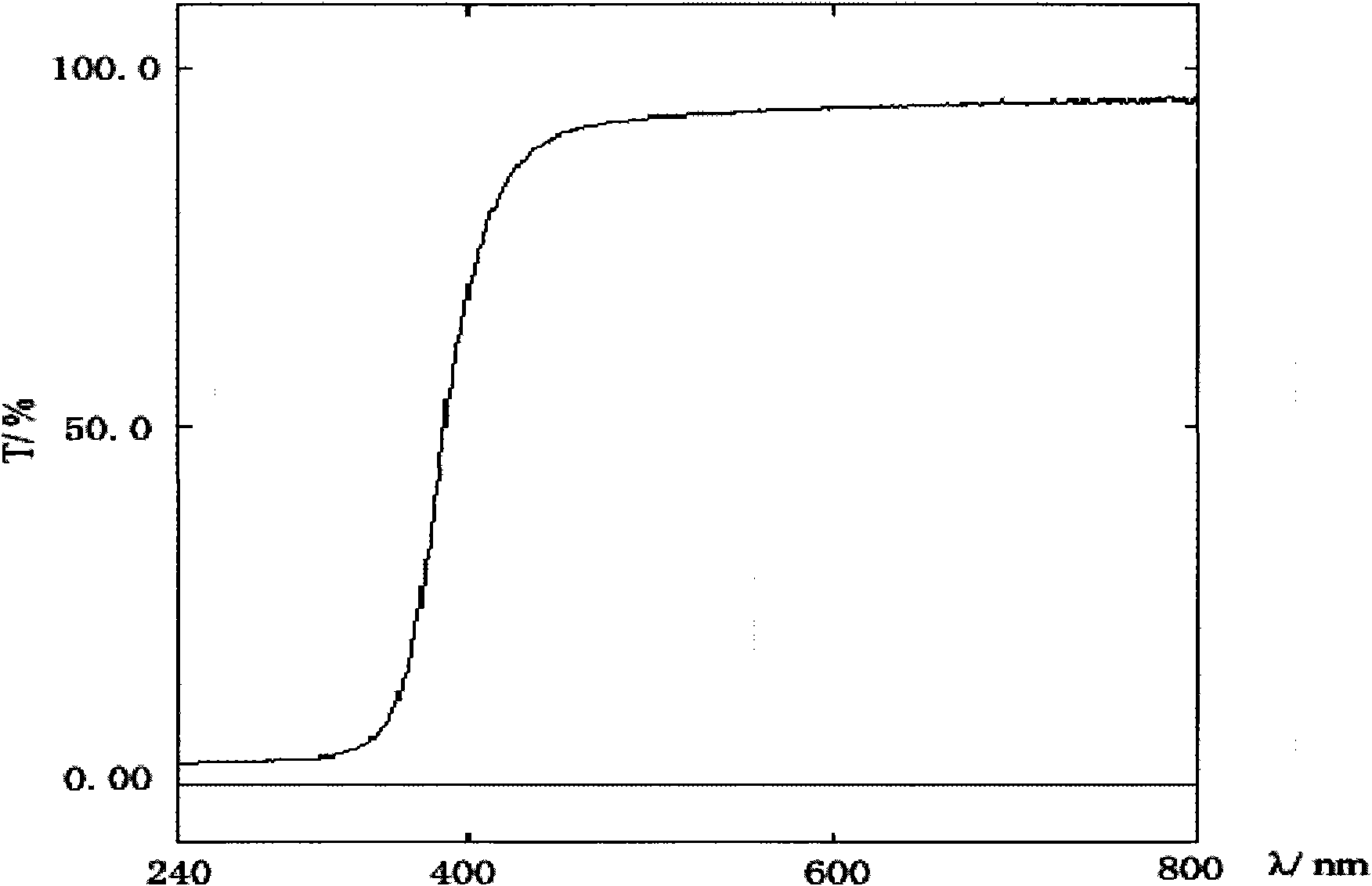

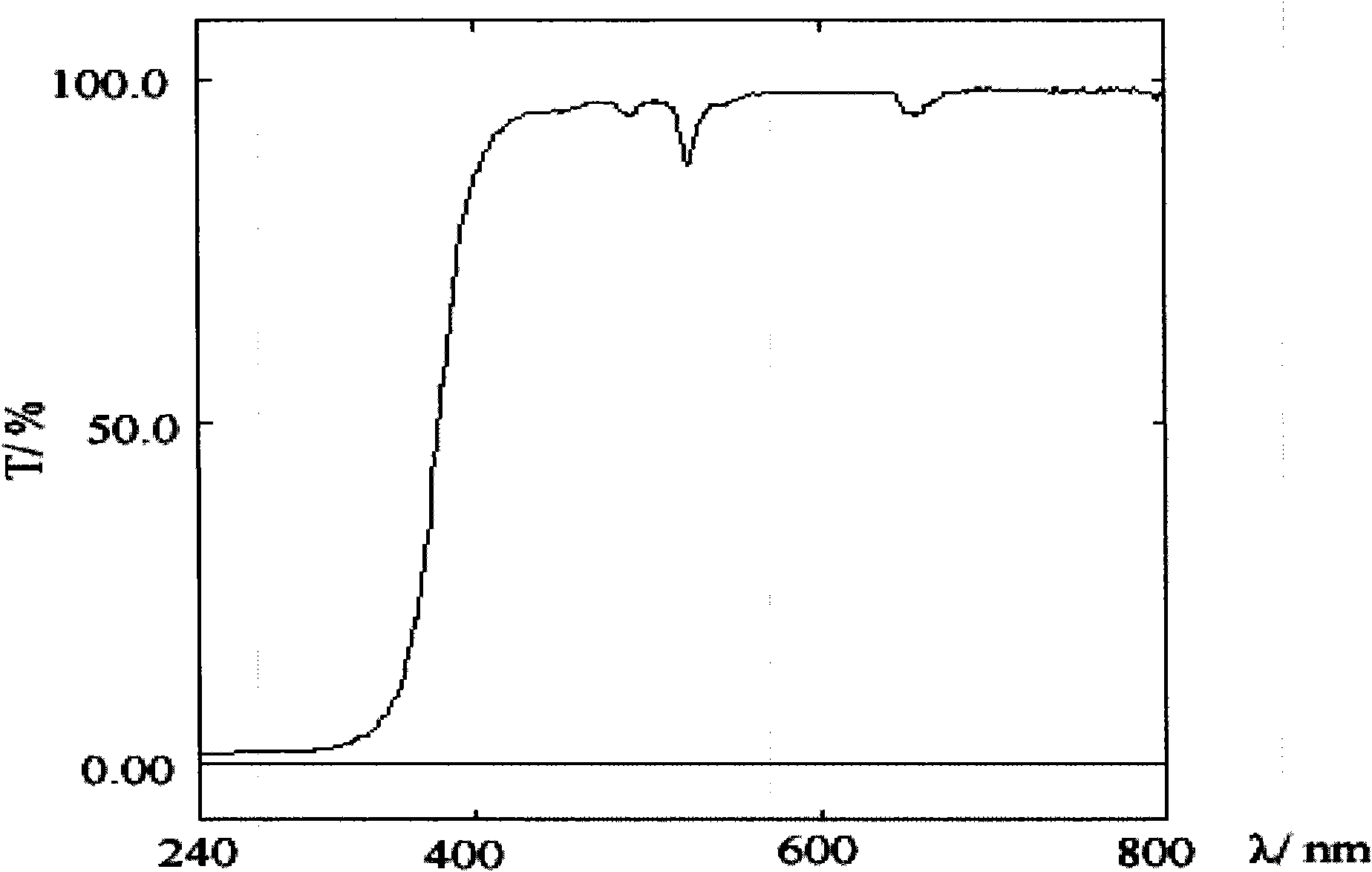

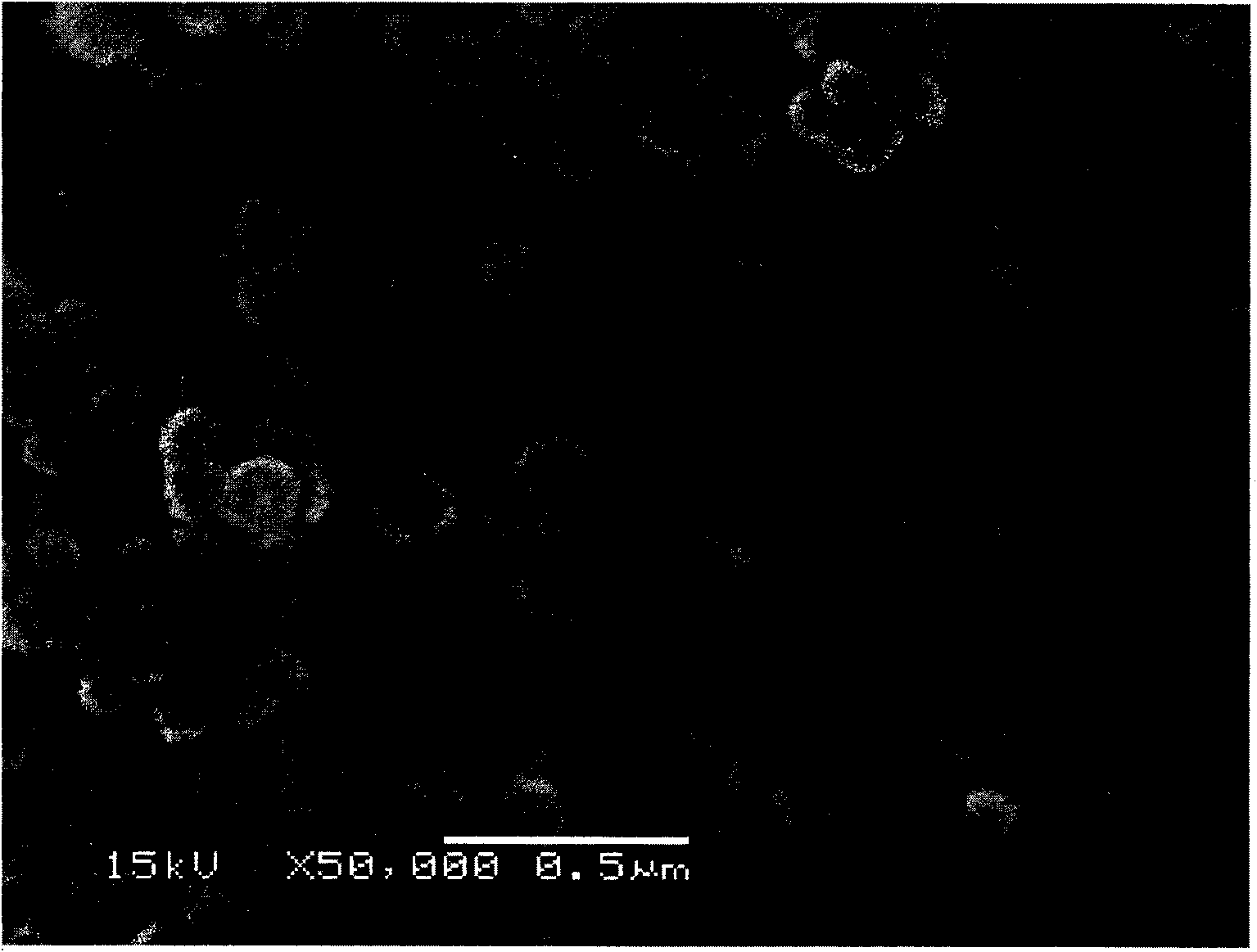

Energy-converting photocatalysis nanophase material and preparation method thereof

InactiveCN101537348AImprove utilization efficiencyWithout reducing the band gapCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementHydrolysis

The invention discloses an energy-converting photocatalysis nano material and a preparation method thereof. Firstly, 0.02-3.5 mol.L<-1> titanium tetrachloride is used as the raw material, and one or two oxides of the rare earth elements of Yb, Er, Ho and Tm are mixed with the titanium tetrachloride. The mixed rare earth oxides account for 0.01-20 percent of the total weight. The mixed solution is subject to hydrolysis for 20-480 minutes at a temperature of 20-90 DEG C. Then, the mixed solution is extracted by means of an organic extraction method with organic amine so as to remove the Cl<-> in the solution and obtain anatase type nanometer titanium dioxide gel containing rare earth elements, and the titanium dioxide gel is aged for 2-48 hours. Finally, the titanium dioxide gel undergoes hydrothermal crystallization at a temperature of 120-240 DEG C so as to obtain the nano energy-converting photocatalysis material. In the invention, through energy conversion, part of the visible light, which is absorbed by the anatase type titanium dioxide, is converted into ultraviolet energy to be absorbed, without reducing forbidden gap, thereby improving the utilization rate of the visible light by a titanium dioxide photocatalyst, being capable of realizing the industrialization production of titanium tetrachloride hydrolysis and avoiding particle aggregation possibly generated by high-temperature calcining.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

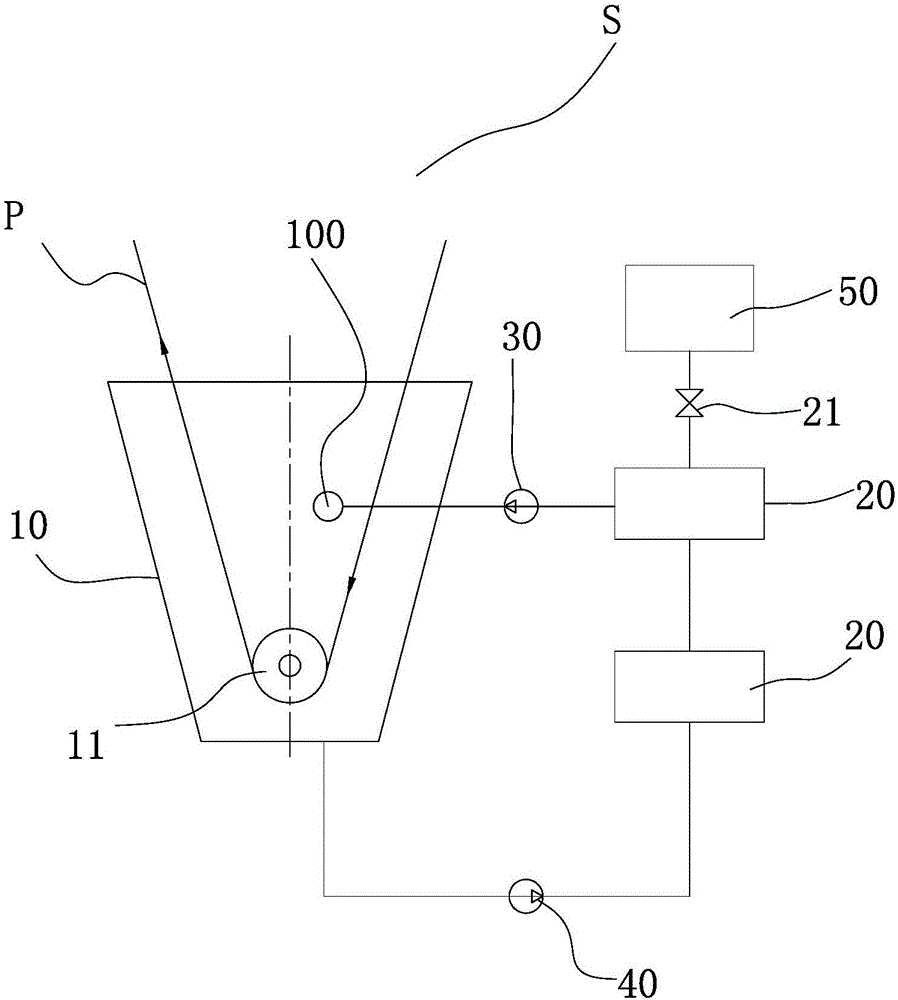

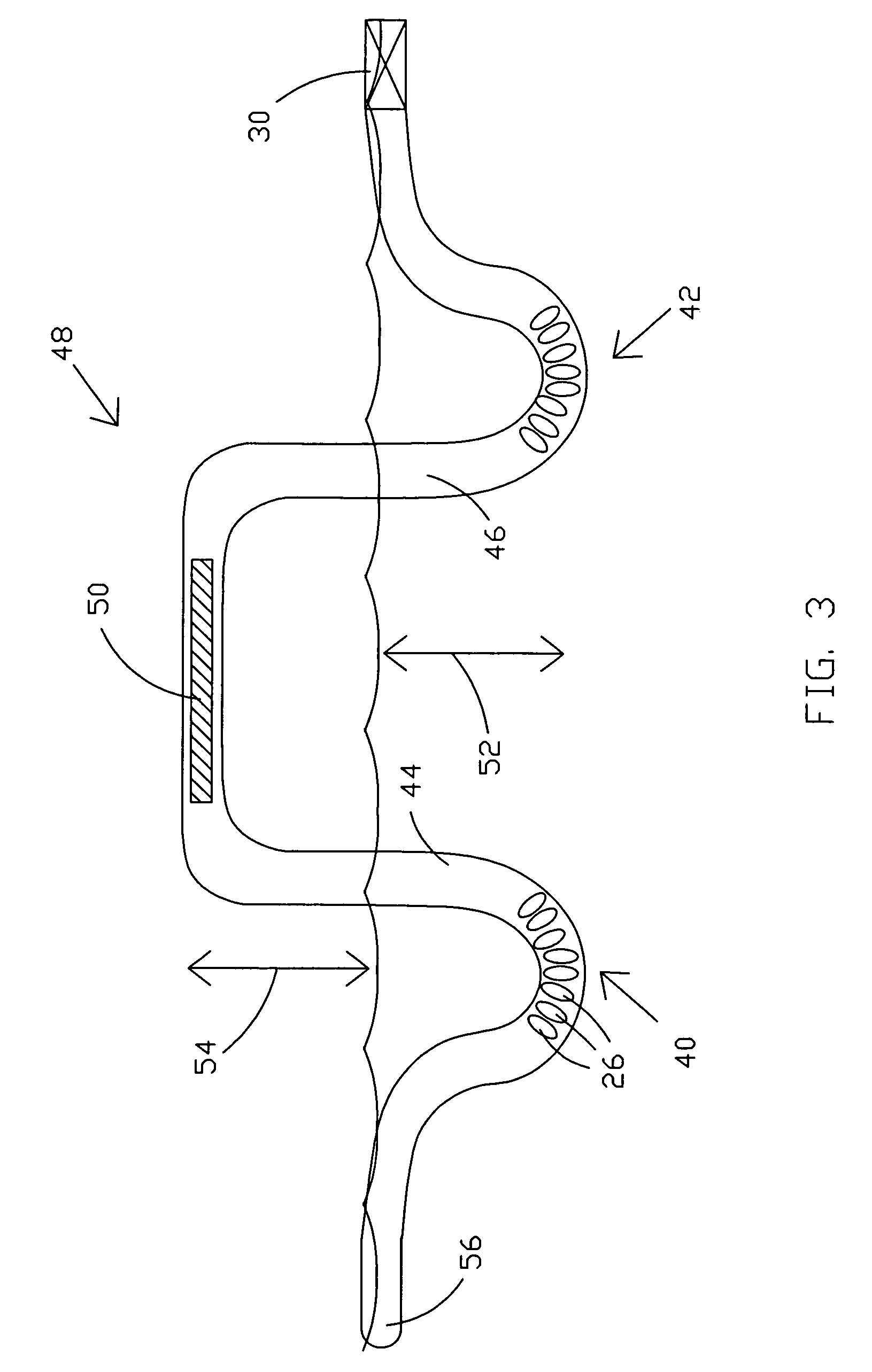

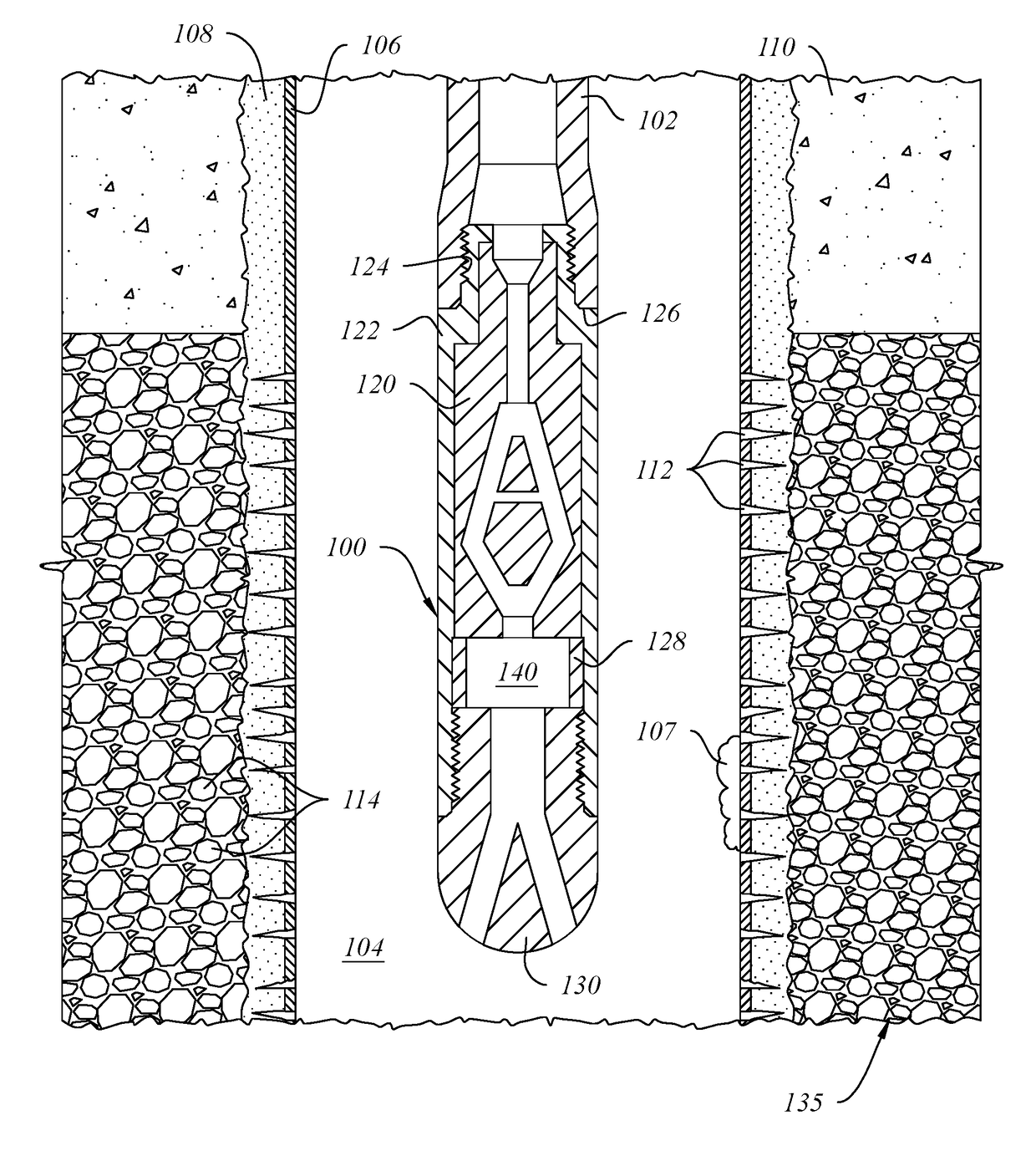

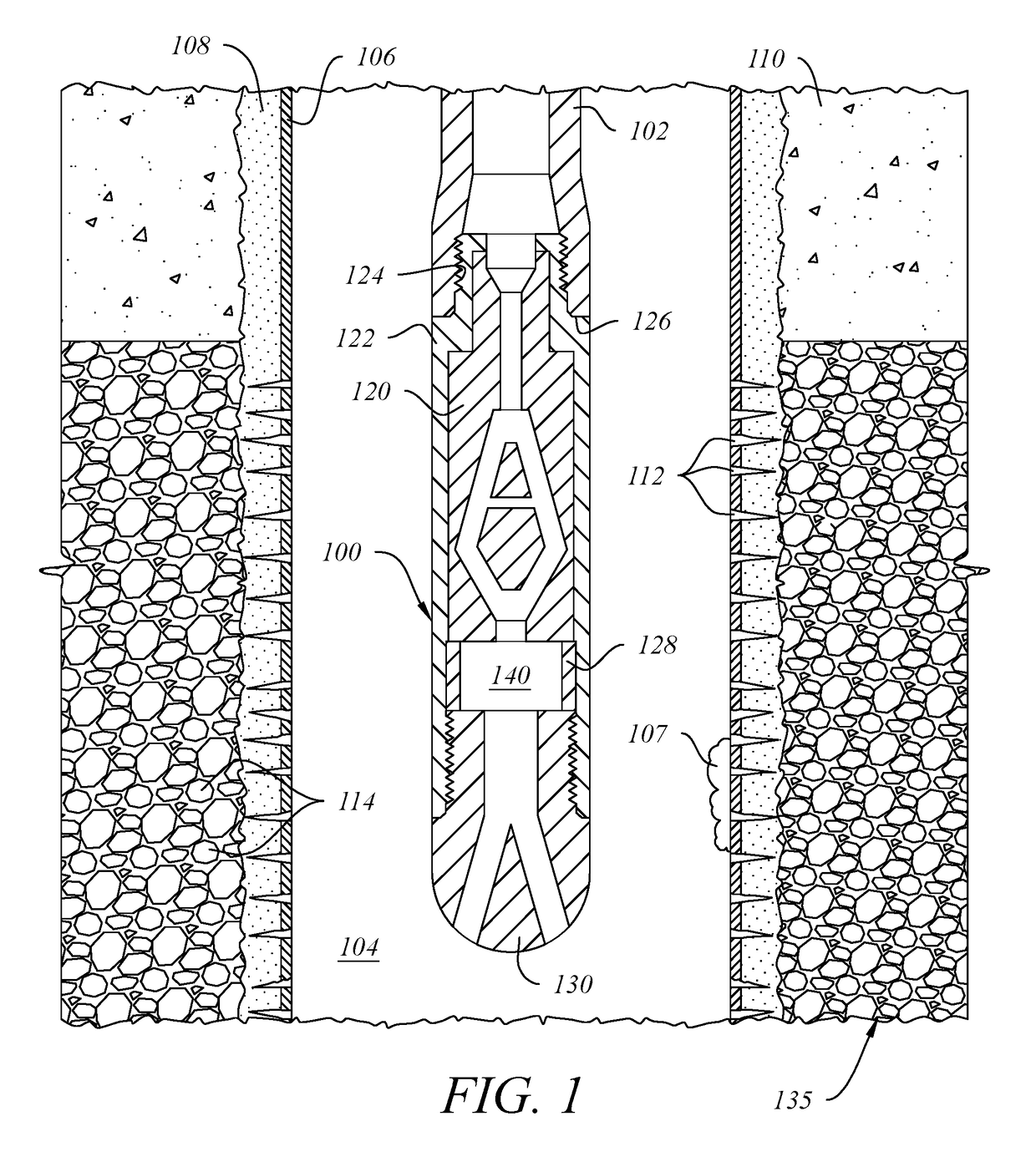

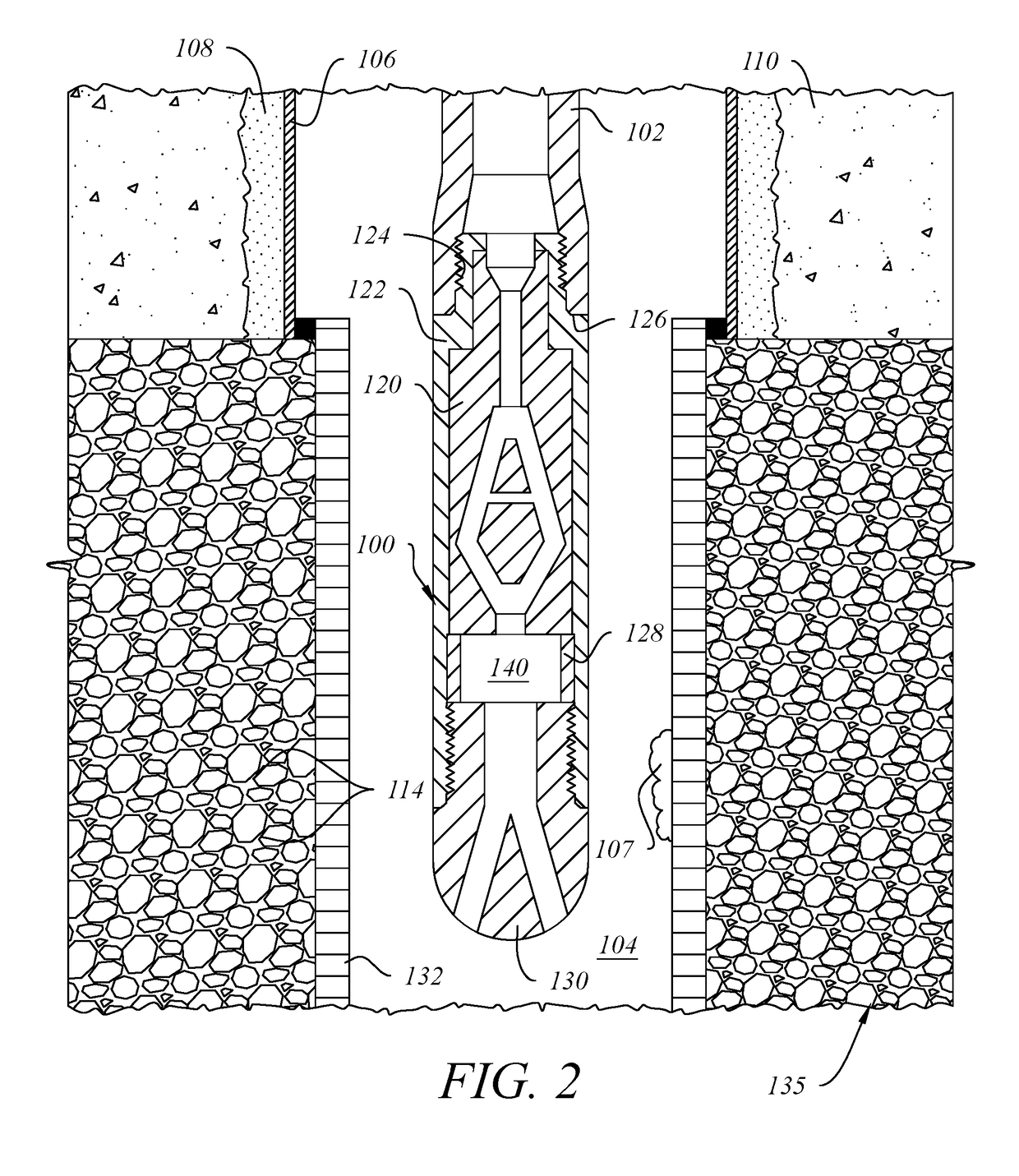

Well Stimulation and Cleaning Tool

ActiveUS20180195368A1Avoid drillingRestrict movementDrill bitsCleaning apparatusEngineeringWell stimulation

A subterranean well stimulation and cleaning tool comprising an upper chamber, a splitter, at least two diffuser legs having proximal ends in fluid communication with the upper chamber and distal ends in fluid communication with a lower chamber, and a laterally disposed crossover channel connecting the at least two diffuser legs between the proximal and distal ends, whereby fluid pulses are generated inside the upper chamber from a substantially constant fluid flow received into the tool from the well surface and are alternately directed through the at least two diffuser legs and into the lower chamber, where the fluid pulses are intensified prior to discharging them from the tool through a nose block or other device disposed downstream of the tool.

Owner:REX A DODD LLC

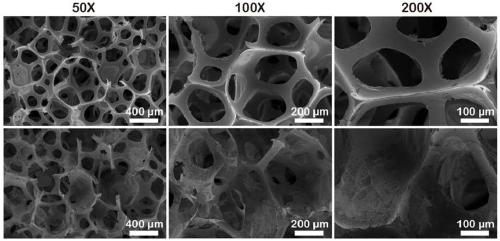

Flame retardant polyurethane sponge, preparation method and application thereof

The invention discloses a flame retardant polyurethane sponge, a preparation method and application thereof. The method includes the specific steps of: soaking polyurethane sponge in a halloysite nanotube aqueous dispersion, extruding the polyurethane sponge with effort, and conducting stirring or ultrasonic treatment to coat halloysite nanotubes uniformly on the polyurethane sponge; placing the polyurethane sponge in drying equipment, and turning over the sponge once at set intervals; after gradual evaporation of the liquid, removing the halloysite nanotubes that are not firmly combined, thusobtaining the halloysite nanotube coated modified flame retardant polyurethane sponge. The preparation method provided by the invention uses water as the dispersing medium, is free of environmental pollution, and has no need for a complicated layer-by-layer assembly process. The method is carried out at room temperature, has the characteristics of simple operation, good repeatability, no involvement of chemical process, low cost and no use of organic solvent, also can self-extinguishing flame retardance of polyurethane sponge, and the combustion process is free of smoke and dripping.

Owner:JINAN UNIVERSITY

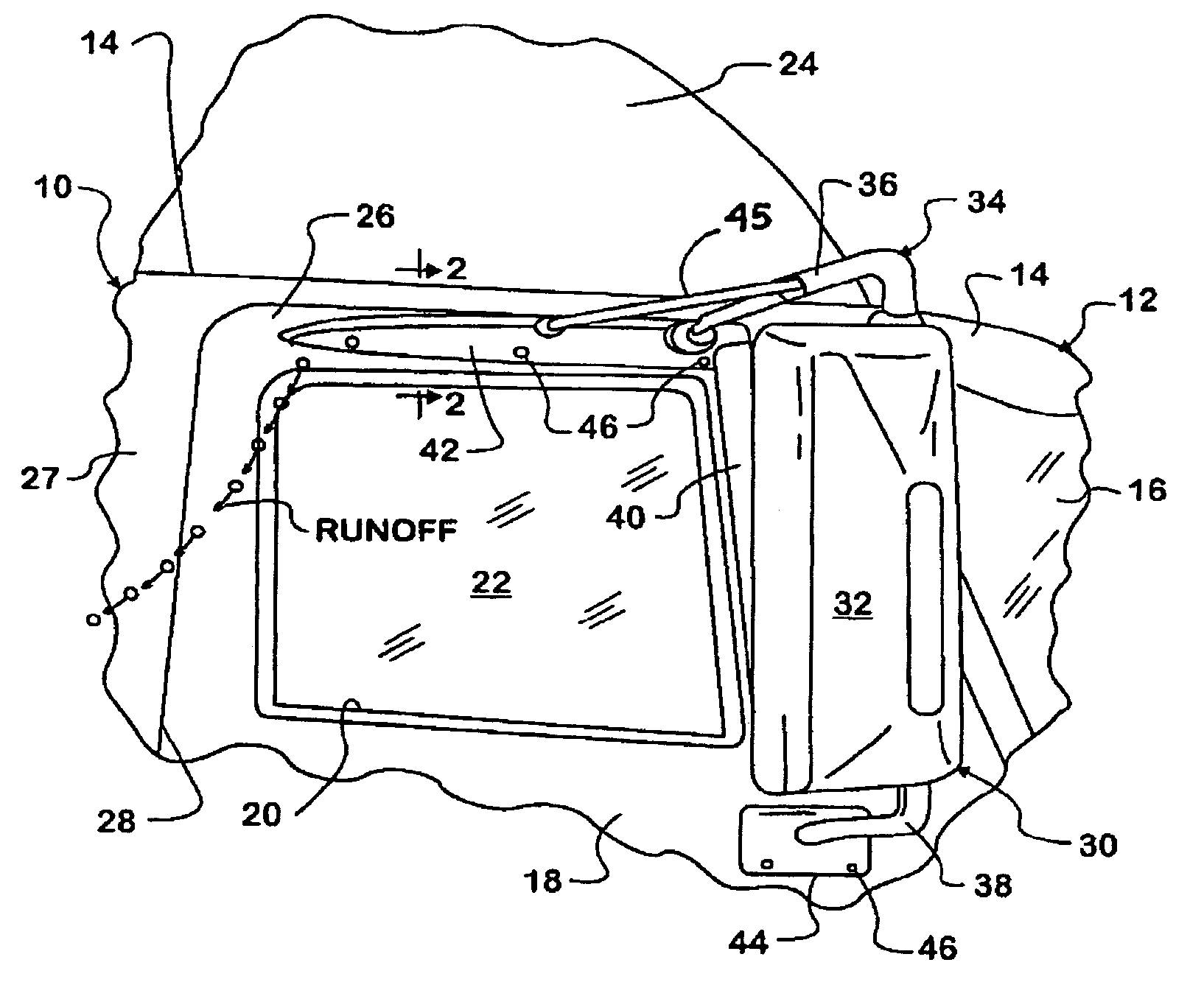

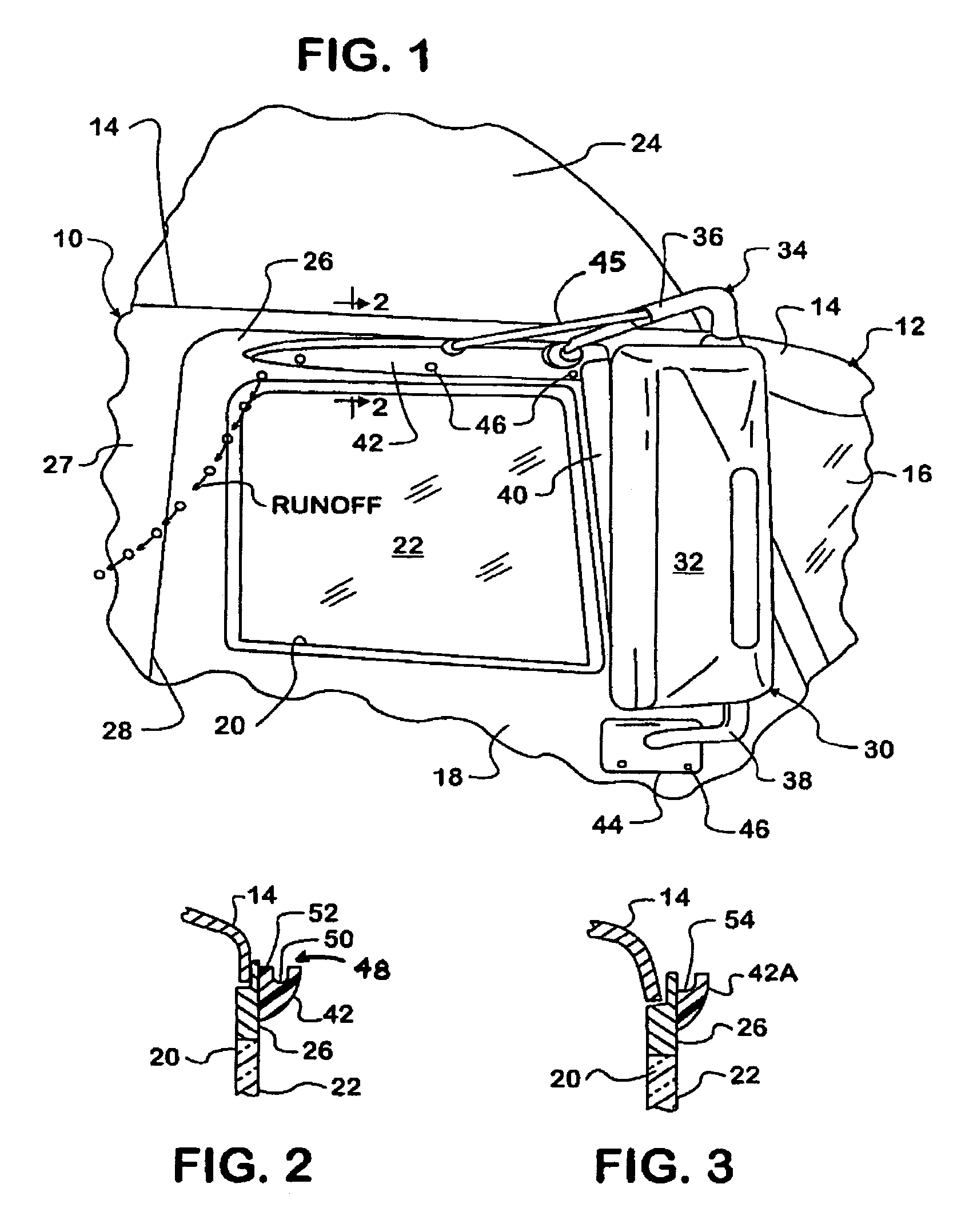

Mirror mounting with integral rain gutter

InactiveUS7648185B2Reduced Clarity RequirementsAvoid washingSuperstructure subunitsMonocoque constructionsWindow openingSpecular reflection

A mirror assembly (30) has a housing (32) that houses a mirrored reflecting surface (40) for enabling a person in a driver's compartment of a vehicle cab (10) to look through a side door window opening (20) and see a field of view toward the rear of the vehicle. The mirror assembly mounting (32) includes a mounting bar (42) that is attached to the side door, that has a length running along the top margin of the door, and that along at least a portion of that length comprises an upwardly open channel (50) for collecting rainwater runoff from the roof and carrying it rearward before the runoff can wash across the window opening.

Owner:INT TRUCK INTPROP LLC

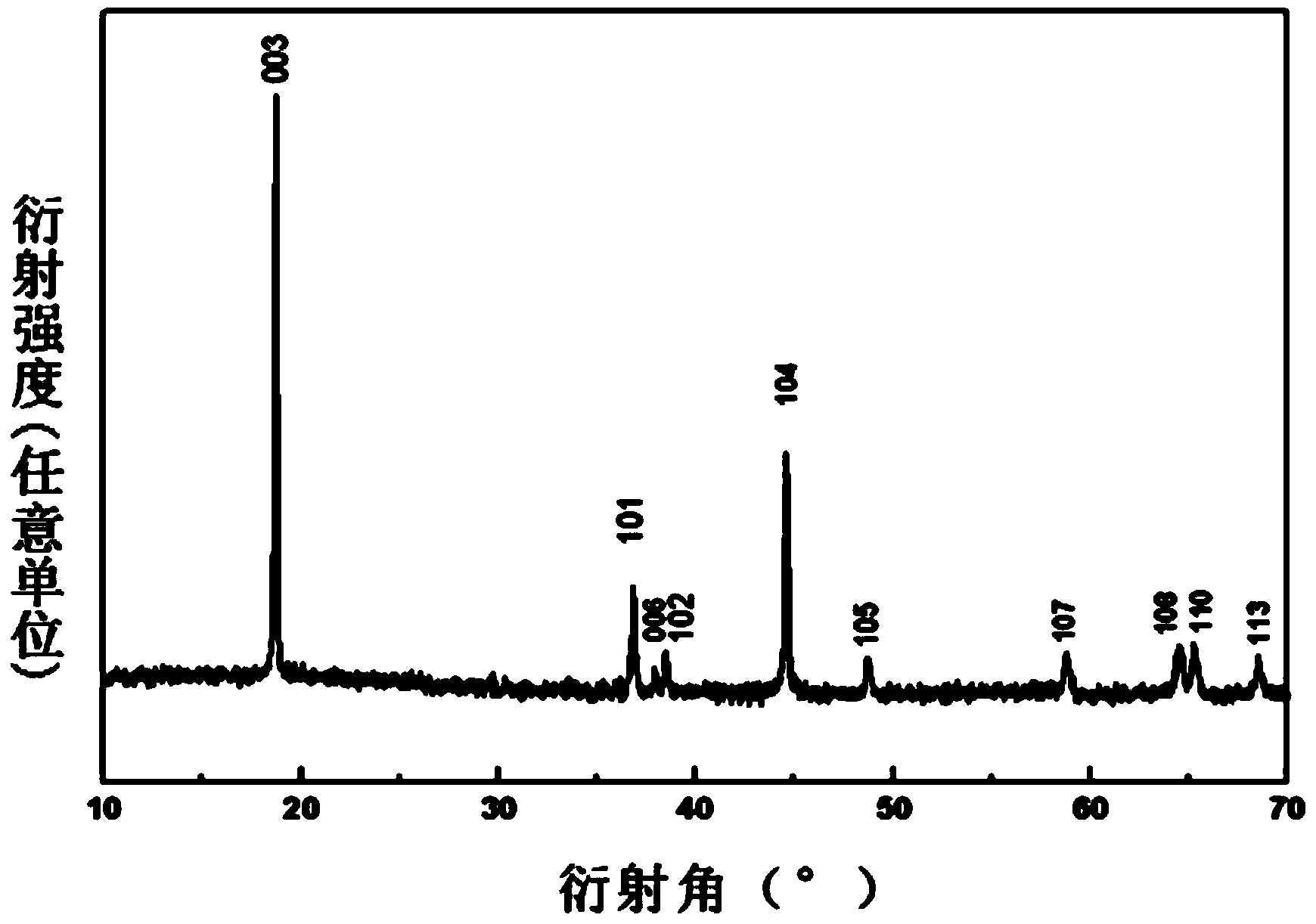

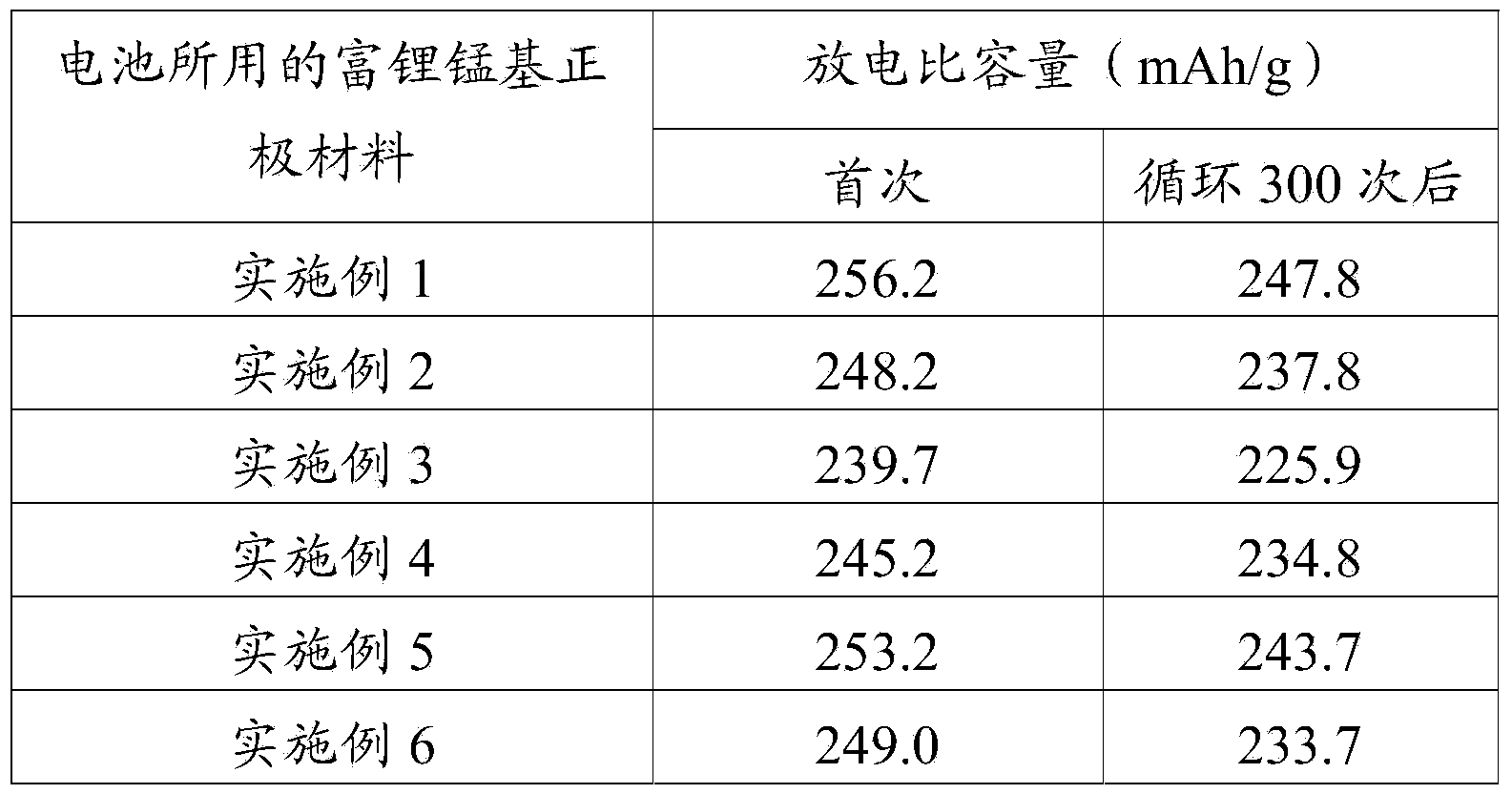

Preparation method for lithium-enriched manganese-based cathode material

ActiveCN104218238AImprove electrochemical performanceAvoid washingCell electrodesNickel saltEvaporation

The invention discloses a preparation method for a lithium-enriched manganese-based cathode material, belonging to the field of cathode materials for lithium ion batteries. The method comprises the following steps: preparing a water solution of a mixture of a lithium salt, a nickel salt, a manganese salt and an M salt according to a stoichiometric ratio of a chemical formula Li1.5Ni<0.25-x>Mn<0.75-x>M<2x>O2.5 (x is more than or equal to 0.003 and less than or equal to 0.02 and M is cobalt or chromium); adding a pre-set amount of urea to obtain a mixed solution; enabling the mixed solution to react in a sealed container at 70-90 DEG C under an agitating condition to obtain a reaction system containing first sediment; dropwise adding (NH4)2CO3 water solution into the system and reacting to obtain a reaction system containing second sediment; carrying out evaporation treatment on the reaction system containing the second sediment at 75-85 DEG C to remove water in the system to obtain a precursor containing Li, Ni, Mn and M; and carrying out two times of sintering treatment on the grinded precursor to obtain the lithium-enriched manganese-based cathode material. The method does not need to use clean water to wash so that wastewater is not generated and the loss of Li, Ni, Mn and other metal ions is avoided.

Owner:CHERY AUTOMOBILE CO LTD

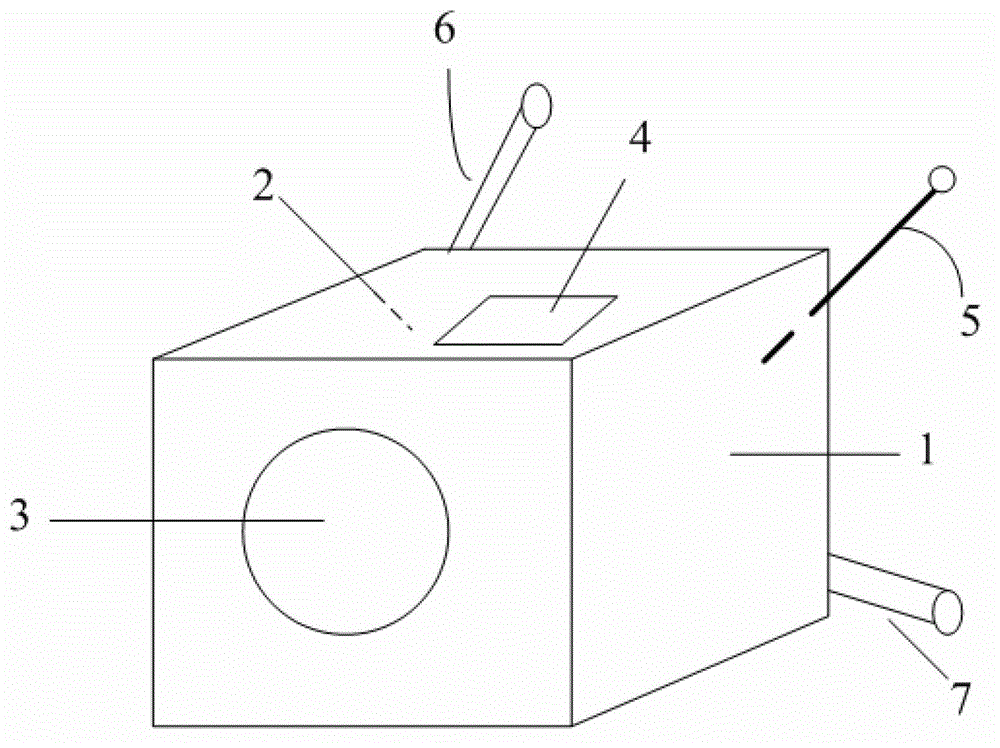

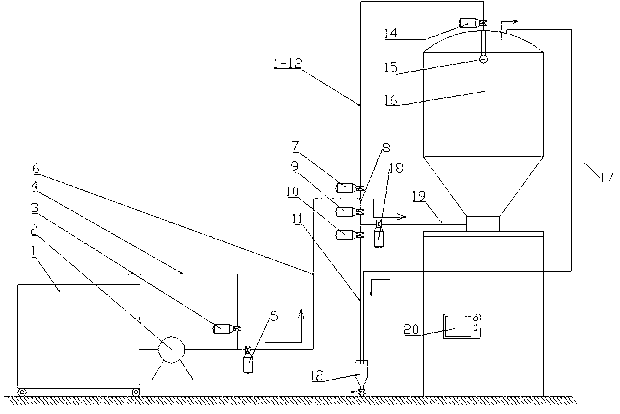

Automatic cleaning and disinfecting system of canning device

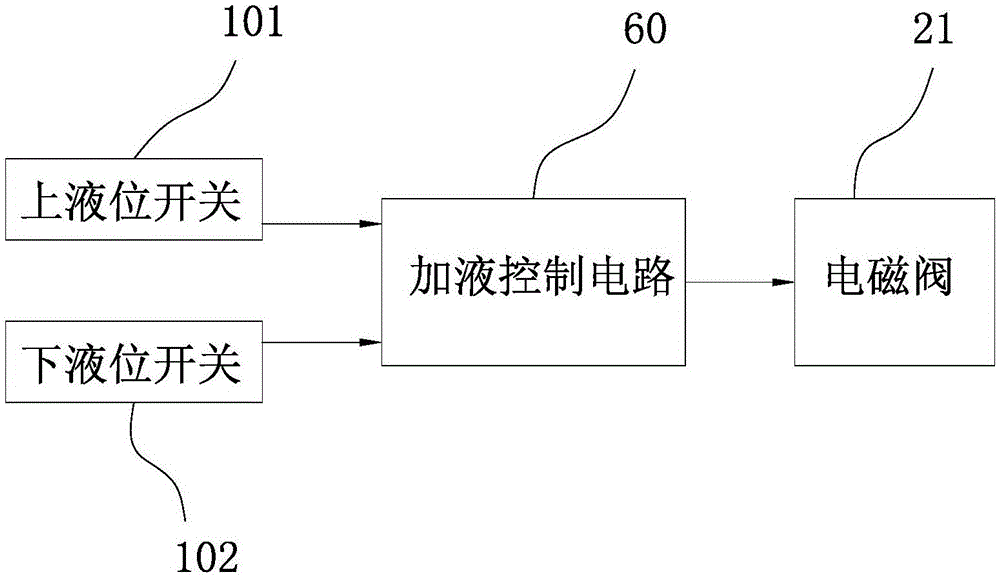

InactiveCN103212558ANo secondary pollutionAvoid washingHollow article cleaningHeatEngineeringHot water storage tank

The invention provides an automatic cleaning and disinfecting system of a canning device. The automatic cleaning and disinfecting system of the canning device is used for cleaning and disinfecting the canning device. The automatic cleaning and disinfecting system of the canning device comprises a hot water storage tank, a device material tank, a pipeline system and an electrical system, wherein a spraying ball is arranged in the device material tank. The pipeline system mainly comprises a cleaning pipeline, a disinfecting pipeline and a common pipeline. The electrical system mainly comprises a hot water conveying pump and a man-machine control system, wherein the man-machine control system controls work of the hot water conveying pump and opening and closing of valves arranged in the pipelines. The automatic cleaning and disinfecting system of the canning device can clean and disinfect the device automatically while the device does not need to be disassembled, and the automatic cleaning and disinfecting system of the canning device solves the problems of time consumption and labor consumption in the process of cleaning and disinfecting the canning device, saves time and labor and guarantees disinfection effects.

Owner:GUANGZHOU BEAUTY STAR CO LTD

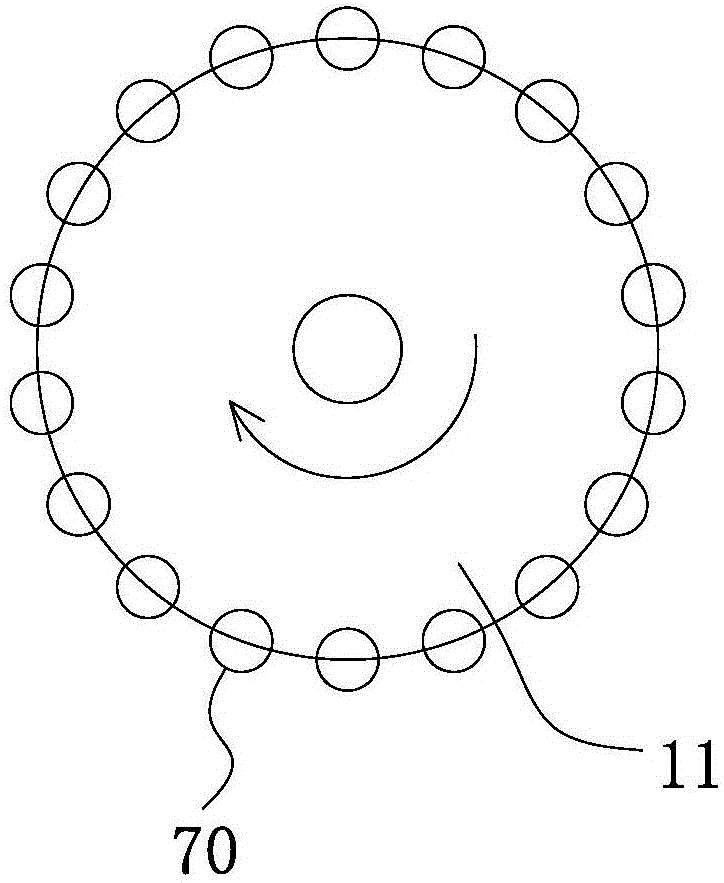

Oil smoke extraction system

PendingCN109237567AAvoid washingImprove experienceDomestic stoves or rangesLighting and heating apparatusEngineeringPetroleum engineering

The invention discloses an oil smoke extraction system. The oil smoke extraction system comprises an oil blocking part for blocking oil smoke, a heating device and a dynamic oil net capable of rotating, wherein the oil blocking part is arranged at the peripheral side of the dynamic oil net; at least one position of the dynamic oil net and the oil blocking part is provided with the heating device;and the heating device is used for heating the corresponding dynamic oil net and the oil blocking part. The oil smoke extraction system heats the dynamic oil net or the oil blocking part or heats thedynamic oil net and the oil blocking part through the heating device, so that greasy dirt on the dynamic oil net or the oil blocking part or on the hydraulic oil net and the oil blocking part is heated and is not condensed, and therefore, dismounting and cleaning for the dynamic oil net or the oil blocking part or the dynamic oil net and the oil blocking part are avoided, the oil smoke extractionsystem is free of dismounting and cleaning, and user experience is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Method for synthesizing epoxy-modified silicone resin

The invention provides a method for synthesizing an epoxy-modified silicone resin. With the adoption of the technical scheme, the method for synthesizing the epoxy-modified silicone resin comprises the following steps: dissolving one or several of trifunctional silicone monomers containing epoxy alkyl and trifunctional silicone monomers into an organic solvent, dropwise adding an aqueous solutionof sodium fluoride into the solution for carrying out a hydrolytic polycondensation reaction, heating and condensing to remove the lower composition, and filtering the sodium fluoride to obtain the epoxy-modified silicone resin. The filtered sodium fluoride is cleaned with a solvent and can be reutilized after drying.

Owner:RUNHE ORGANICSILICONE NEW MATERIAL

Method for reducing harmful materials in by-product hydrochloric acid in production process of chlorobenzene

The invention provides a method for reducing harmful materials in by-product hydrochloric acid in a production process of chlorobenzene. The method comprises the following steps: compressing normal-temperature hydrogen chloride gas separated by a chlorobenzene system to 0.08-0.12MPa through a Roots blower, condensing the hydrogen chloride gas through a primary condenser, condensing water and low-boiling-point materials, separating the hydrogen chloride gas through a gas-liquid separator, then continuously compressing the hydrogen chloride gas to 1-1.5MPa through a compressor, condensing the hydrogen chloride gas through a secondary condenser for further removing organic impurities, filling the hydrogen chloride gas into an adsorption tower from the bottom of the adsorption tower with adsorbent, removing other impurities to obtain qualified hydrogen chloride gas, absorbing the qualified hydrogen chloride gas through water and then obtaining industrial pure hydrochloric acid. The purityof hydrogen chloride obtained by the method is high; the quality of the by-product hydrochloric acid is high; the wastewater is not generated; the enterprise income is increased; meanwhile, the methodis simple in process and easy to operate; the benzene-series organic matters recycled from the by-product hydrochloric acid enter a benzene recycling tank and return to the chlorination process for recycling, so that the material loss is reduced, and the production cost is reduced.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

Novel chlorobenzene production process

InactiveCN109096042AHigh conversion selectivityReduce outputHalogenated hydrocarbon preparationGeneration rateChlorobenzene

The invention provides a novel chlorobenzene production process. Chlorobenzene used in the novel chlorobenzene production process comprises the following raw materials: anhydrous benzene, chlorine, acatalyst and a positioning agent. The novel production process comprises the following steps: preparing the anhydrous benzene; enabling the anhydrous benzene to flow out from the bottom of a benzene high-level tank, metering by using a flowmeter, and continuously putting into a chlorinator from the bottom of the chlorinator; buffering qualified chlorine made after gasification of liquid chlorine by using a chlorine buffer tank, introducing into the chlorinator from the bottom of the chlorinator to flow upwards together with the anhydrous benzene along flows in a same direction, carrying out areaction under the action of the catalyst and the positioning agent in the chlorinator so as to generate a chlorination liquid, and carrying out aftertreatment on the chlorination liquid, thereby obtaining chlorobenzene. By adopting the novel production process provided by the invention, the problem that a great deal of wastewater is generated from water washing and alkali washing in the conventional method can be avoided, no wastewater is generated, in addition, the catalyst is long in service life, the equipment is long in service life, the detection cycle can be prolonged, a product made byusing the process is high in purity, and due to adoption of an iron catalyst and chelate EDTA-Fe with iron as the center as the positioning agent, the process is low in wastewater generation rate andgreen, environmentally friendly and fee of pollution.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com