Special coating process of cargo tank of product tanker/chemical tanker

A technology for chemical tankers and product oil tankers, which is applied in the direction of liquid coating devices, coatings, and pre-treated surfaces, etc., which can solve the surface pollution of paint films, increase the cost of special coating for washing water in the whole tank, and the construction period of special coating Lengthen and other issues, to avoid the whole tank washing, considerable economic and social benefits, scientific and reasonable construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

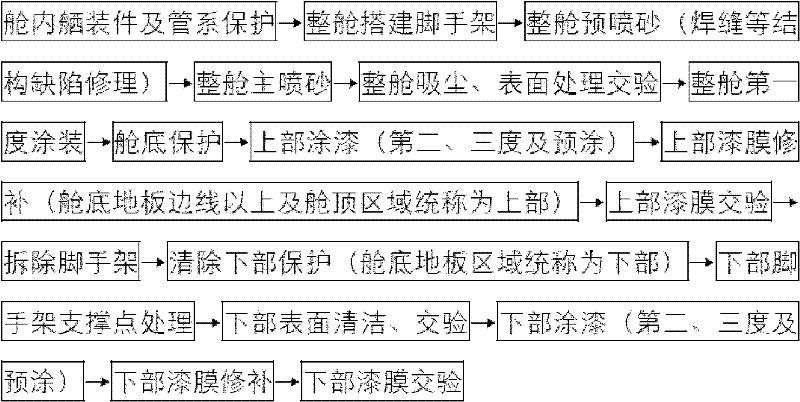

[0035] The present invention is an optimization technology for the construction process of the special coating cabin of the special coating ship. The "integral method" is used to replace the "upper and lower part method" of the prior art, so as to meet the construction requirements of the special coating, shorten the special coating cycle, and improve the special coating efficiency. , reduce the cost of special coating, and ensure the smooth progress of special coating construction.

[0036] "Integral method" means that in the special coating construction process of liquid cargo tanks of product oil tankers or chemical tankers, the whole tank is carried out from the main sandblasting to the spraying of the first paint, and from the second coat of paint to the inspection of the paint film. Do it separately for the upper and lower parts. Its main construction procedures, such as figure 2 Shown:

[0037] 1. Protection of outfitting and piping in the cabin; 2. Scaffolding of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com