A construction method of surface contact pipe curtain structure

A construction method and surface contact technology, which is applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of uneven force and difficult control of construction accuracy, and achieve uniform force, good advance support effect, and construction. Process scientific and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

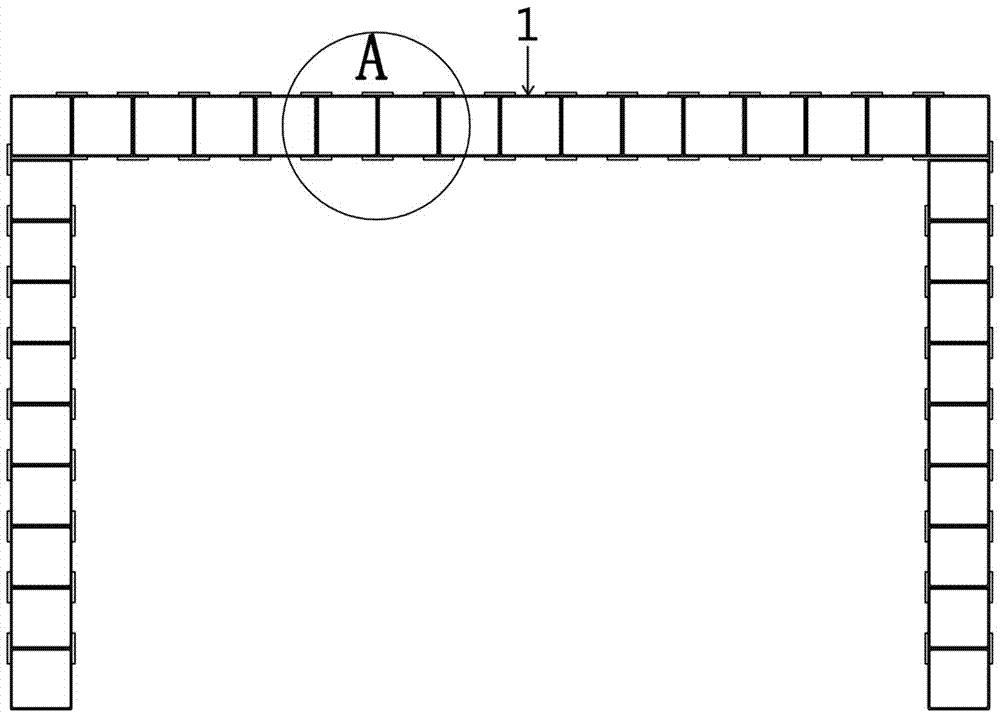

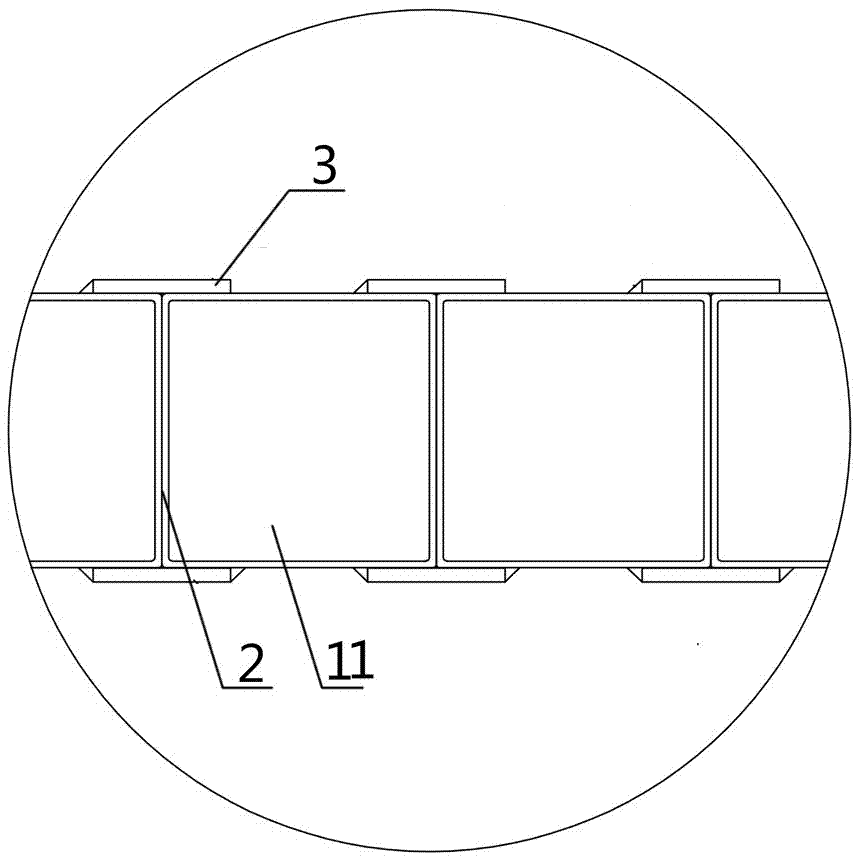

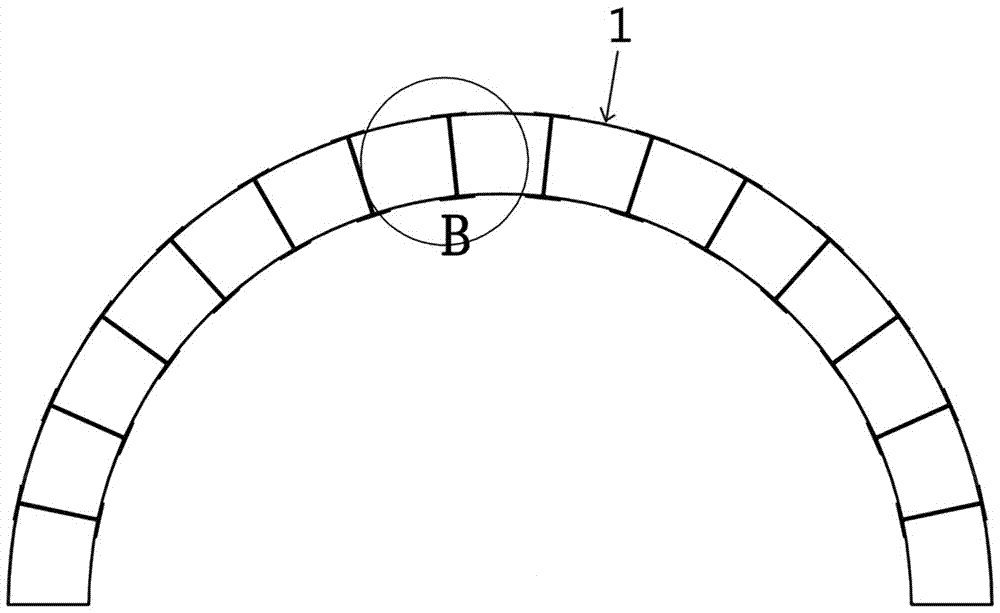

[0047] see Figure 1-10 , the present invention relates to a surface contact pipe curtain structure, used in tunnel construction, as the advance support structure of the tunnel, composed of a row of steel pipes 1 horizontally laid in the soil body along the axis of the tunnel, the steel pipes 1 are connected to each other The connection is characterized in that: the steel pipe 1 is in surface contact with the adjacent steel pipe; the steel pipe 1 includes at least two contact planes 2, which respectively fit seamlessly with the contact planes 2 of the adjacent steel pipes; The sizes of the two contact planes 2 are adapted to each other; on the outer wall of the steel pipe 1, a slideway 3 is respectively welded along the two long edges of a contact plane 2, and two adjacent steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com