Energy-converting photocatalysis nanophase material and preparation method thereof

A technology of nanomaterials and energy conversion, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as difficult washing, difficult promotion, and reduced natural light photocatalytic efficiency, so as to avoid particle agglomeration , the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

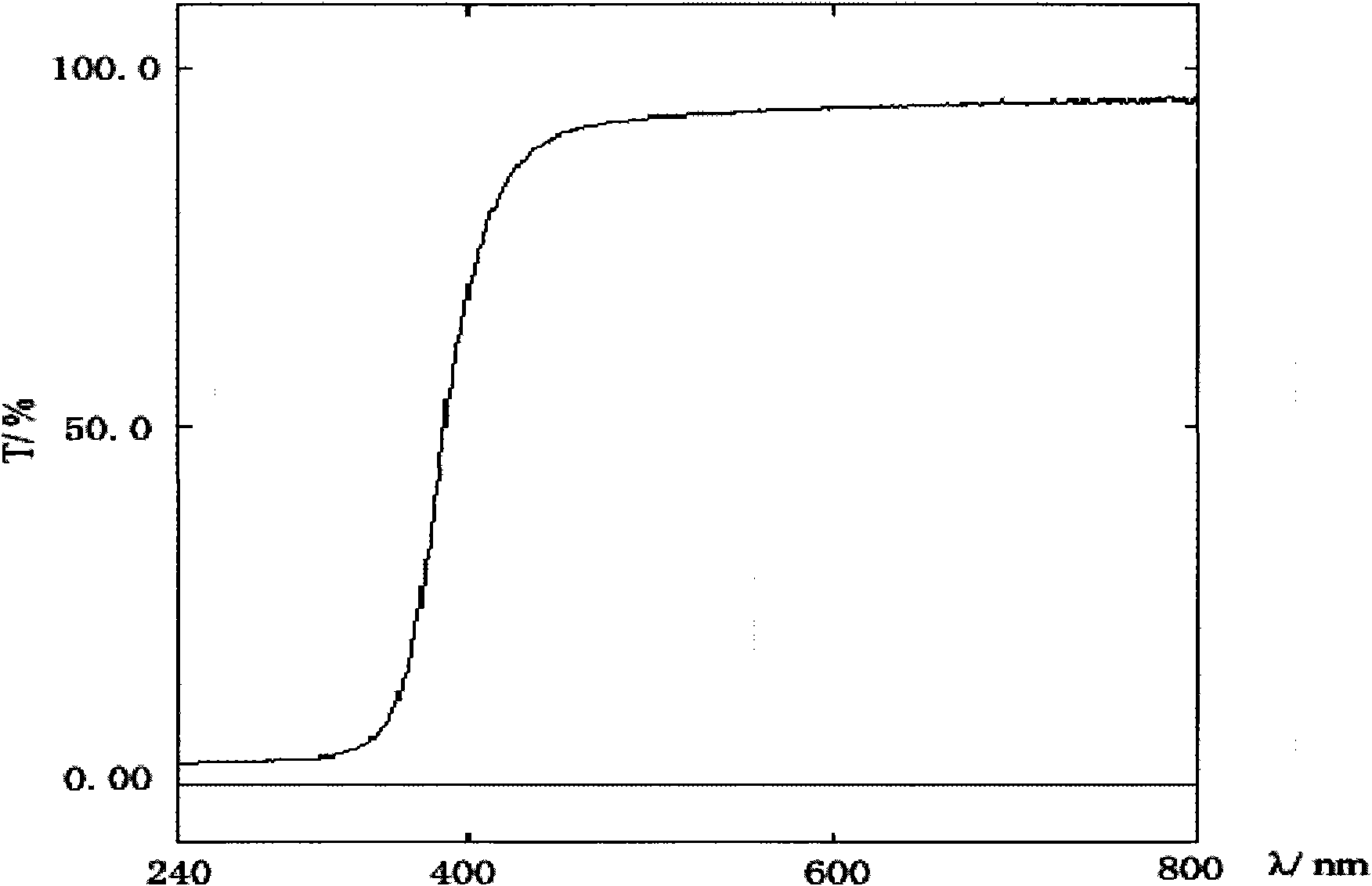

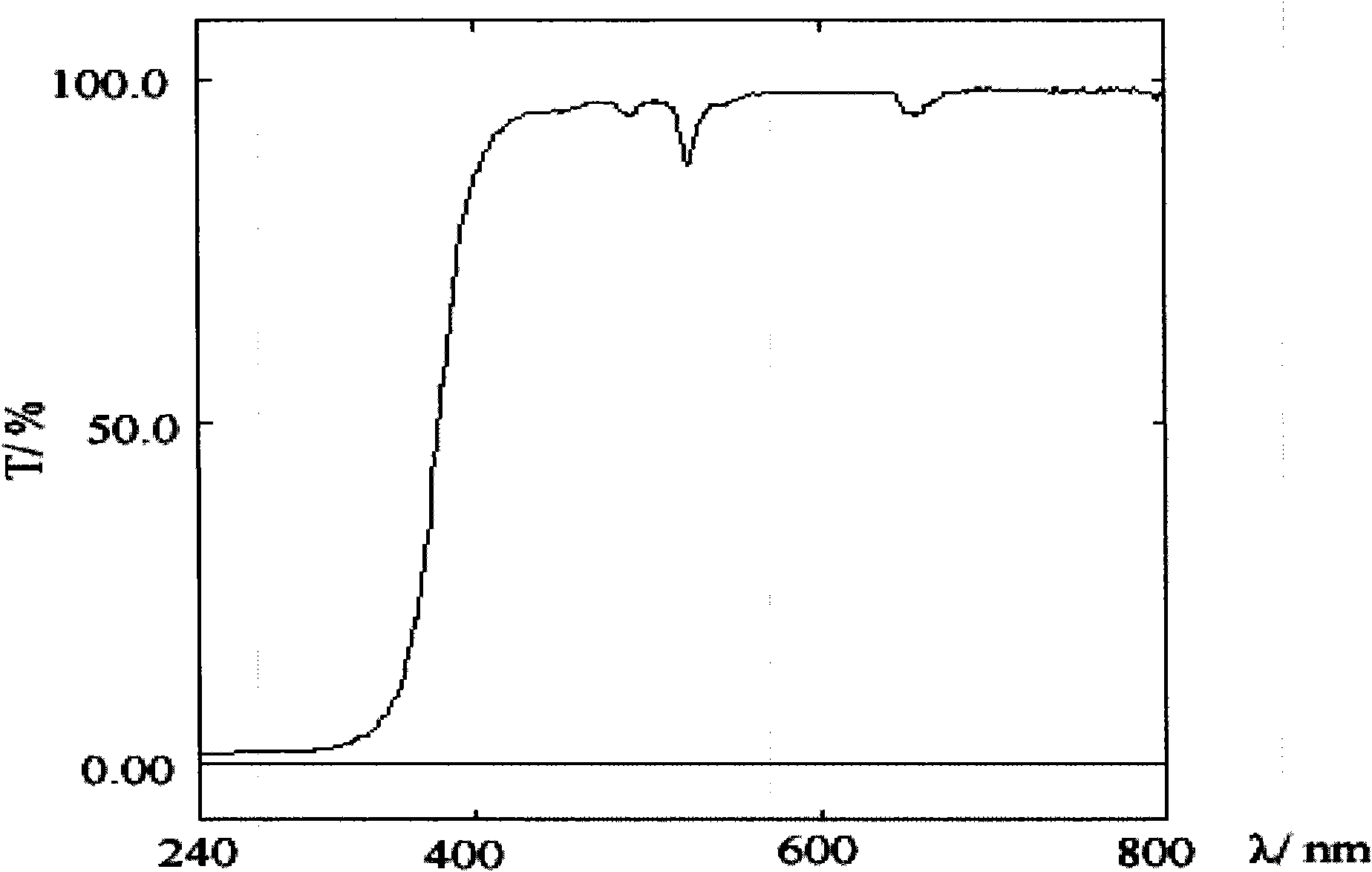

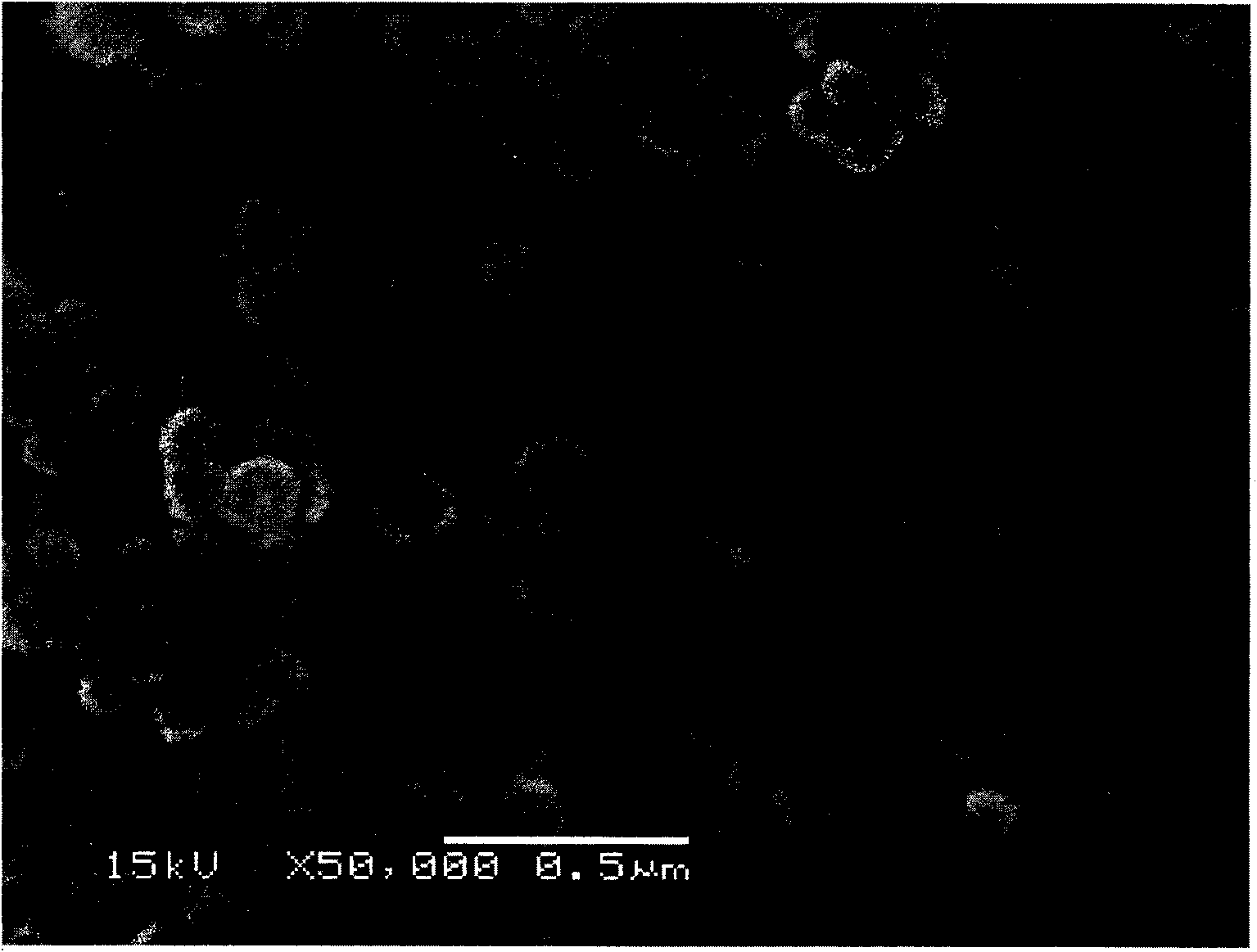

[0020] Put 112mL of analytically pure titanium tetrachloride solution into a three-neck flask, add 388mL of distilled water dropwise in an ice bath, and the temperature does not exceed 20°C. A stock solution of titanium dioxide (solution I) with a concentration of about 2 mol / L was obtained. Get solution I 20mL, weigh 0.0652 grams of ytterbium oxide, 0.0652 grams of erbium oxide, after stirring and dissolving, add 100ml distilled water. It was hydrolyzed at 50°C for 4 hours to obtain a transparent solution. Toluene and trioctylamine (volume ratio: 2:1) were used as the extractant to shake and extract the above hydrolyzed transparent solution for 15 minutes at room temperature. The aqueous phase and the organic phase were separated, and the organic phase was back-extracted with 10% NaOH 20mL at room temperature, and the obtained organic phase could be used repeatedly. Until the pH value of the aqueous phase is 6.5-7. Aging for 24 hours to obtain a transparent anatase-type na...

Embodiment 2

[0023] Take 20 mL of solution I in Example 1, weigh 0.0652 g of ytterbium oxide and 0.0652 g of holmium oxide, stir and dissolve, and then add 80 ml of distilled water. It was hydrolyzed at constant temperature at 60°C for 3 hours to obtain a transparent solution. Toluene and trioctylamine (volume ratio: 2:1) were used as the extractant to shake and extract the above hydrolyzed transparent solution for 15 minutes at room temperature. The aqueous phase and the organic phase were separated, and the organic phase was back-extracted with 10% NaOH 20mL at room temperature, and the obtained organic phase could be used repeatedly. Until the pH value of the aqueous phase is 6.5-7. Aging for 24 hours to obtain a transparent anatase-type nano-titanium dioxide gel, take about 50 grams of the titanium dioxide gel, add it to a hydrothermal reaction kettle, add distilled water to 70% of the reaction kettle, and conduct a hydrothermal reaction at 200°C After 6 hours, cool to room temperatu...

Embodiment 3

[0026]Take 20 mL of solution I in Example 1, weigh 0.0652 g of ytterbium oxide and 0.0652 g of thulium oxide, stir and dissolve, then add 80 ml of distilled water. It was hydrolyzed at 50°C for 4 hours to obtain a transparent solution. Toluene and trioctylamine (volume ratio: 2:1) were used as the extractant to shake and extract the above hydrolyzed transparent solution for 15 minutes at room temperature. The aqueous phase and the organic phase were separated, and the organic phase was back-extracted with 10% NaOH 20mL at room temperature, and the obtained organic phase could be used repeatedly. Until the pH value of the aqueous phase is 6.5-7. After aging for 24 hours, a transparent anatase-type nano-titanium dioxide gel was obtained. Take about 50 grams of the titanium dioxide gel, add it to a hydrothermal reaction kettle, add distilled water to 70% of the reaction kettle, and conduct a hydrothermal reaction After 3 hours, cool to room temperature, open the kettle, separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com