Method for preparation of insoluble sulfur

A sulfur and soluble technology, which is applied in the field of preparing insoluble sulfur, can solve the problems of low conversion rate and poor quenching effect, and achieve the effects of increased insoluble sulfur content, high production efficiency, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

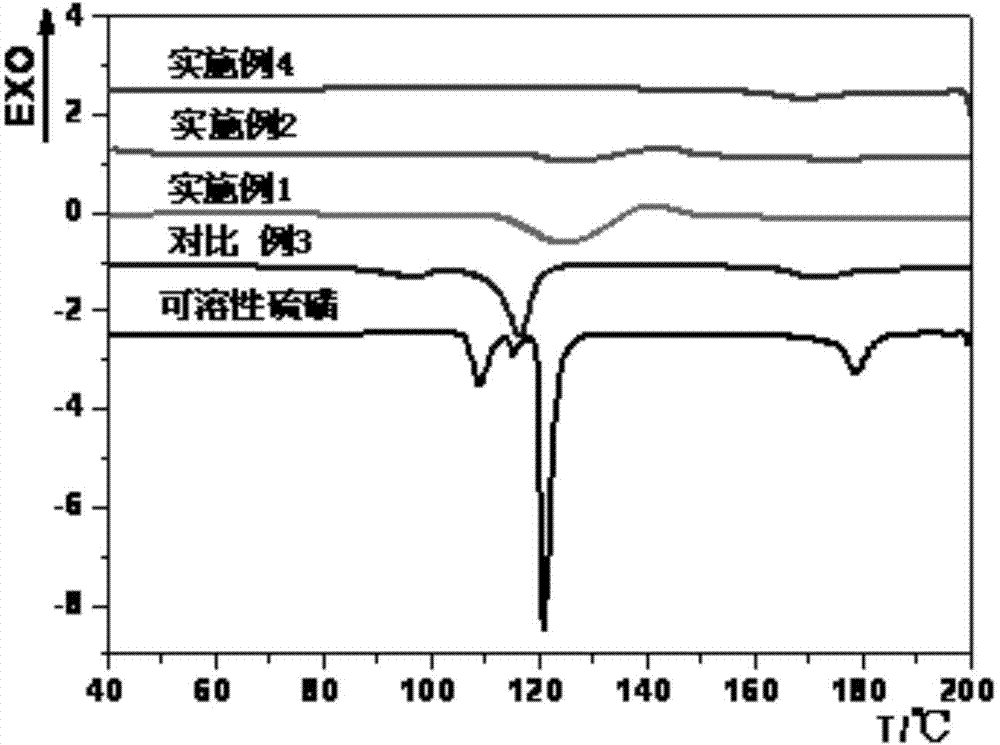

Embodiment 1

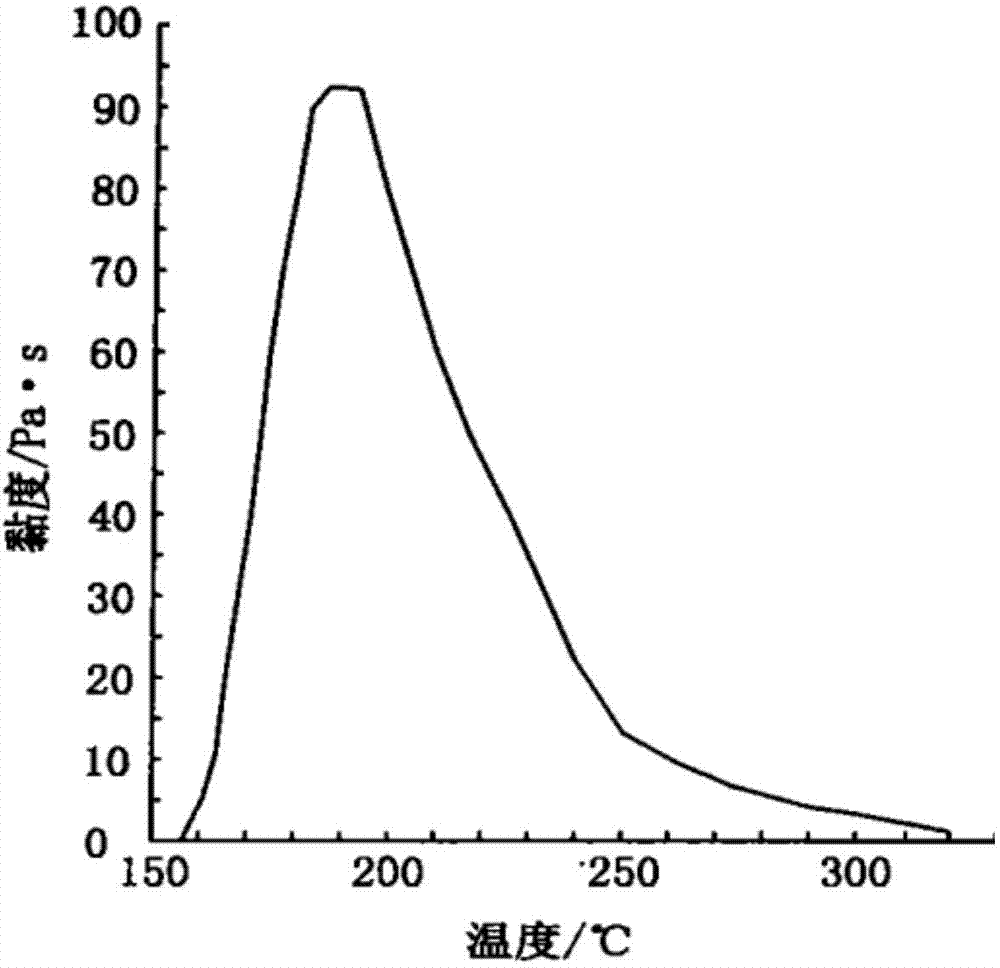

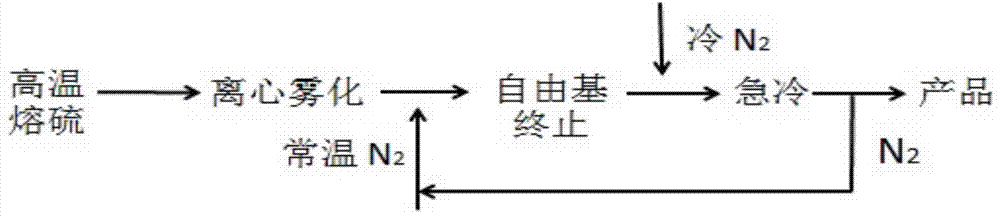

[0025] The raw material sulfur is directly heated to 280°C to make it melt; the molten sulfur liquid is centrifugally atomized into sulfur droplets with an average particle size of 10 μm through the atomizer; the circulating nitrogen at room temperature is distributed by the gas distributor and mixed with the sulfur droplets; nitrogen The outlet temperature is controlled at 180°C; the sulfur droplets stay on the upper part of the tower for 25 seconds. The polymerized sulfur is mixed with nitrogen cooled to 0°C by the cooling device and distributed by the gas distributor, enters the lower part of the tower body, and is cooled to below 60°C in 2 seconds; cyclone separation, collection, and packaging to obtain insoluble sulfur products; The nitrogen discharged from the tower body is recycled by being separated from the residual sulfur particles.

Embodiment 2

[0027] The raw material sulfur is directly heated to 300°C to melt it; the melted sulfur liquid is centrifugally atomized into sulfur droplets with an average particle size of 20 μm through the atomizer; the circulating nitrogen at room temperature is distributed by the gas distributor and mixed with the sulfur droplets; nitrogen The outlet temperature is controlled at 200°C; the sulfur droplets stay on the upper part of the tower for 25 seconds. The polymerized sulfur is mixed with the nitrogen cooled to -10°C by the cooling device and distributed by the gas distributor, enters the lower part of the tower body, and is cooled to below 60°C within 5 seconds; cyclone separation, collection, and packaging to obtain insoluble sulfur products ; The nitrogen discharged from the tower body is recycled by being separated from the residual sulfur particles.

Embodiment 3

[0029] The raw sulfur is directly heated to 330°C to make it melt; the molten sulfur liquid is centrifugally atomized by the atomizer into sulfur droplets with an average particle size of 20 μm; the circulating nitrogen at room temperature is distributed by the gas distributor and mixed with the sulfur droplets; nitrogen The outlet temperature is controlled at 210°C; the sulfur droplets stay on the upper part of the tower for 20 seconds. The polymerized sulfur is mixed with the nitrogen cooled to -20°C by the cooling device and distributed by the gas distributor, enters the lower part of the tower body, and is cooled to below 60°C within 5 seconds; cyclone separation, collection, and packaging to obtain insoluble sulfur products ; The nitrogen discharged from the tower body is recycled by being separated from the residual sulfur particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com