Well Stimulation and Cleaning Tool

a technology for cleaning tools and wells, applied in the direction of fluid removal, drilling accessories, borehole/well accessories, etc., can solve the problem that the switch will stop working, and achieve the effect of smooth inside the tool body, reducing the stoppage of pulsating fluid flow, and exceeding the magnitude of for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

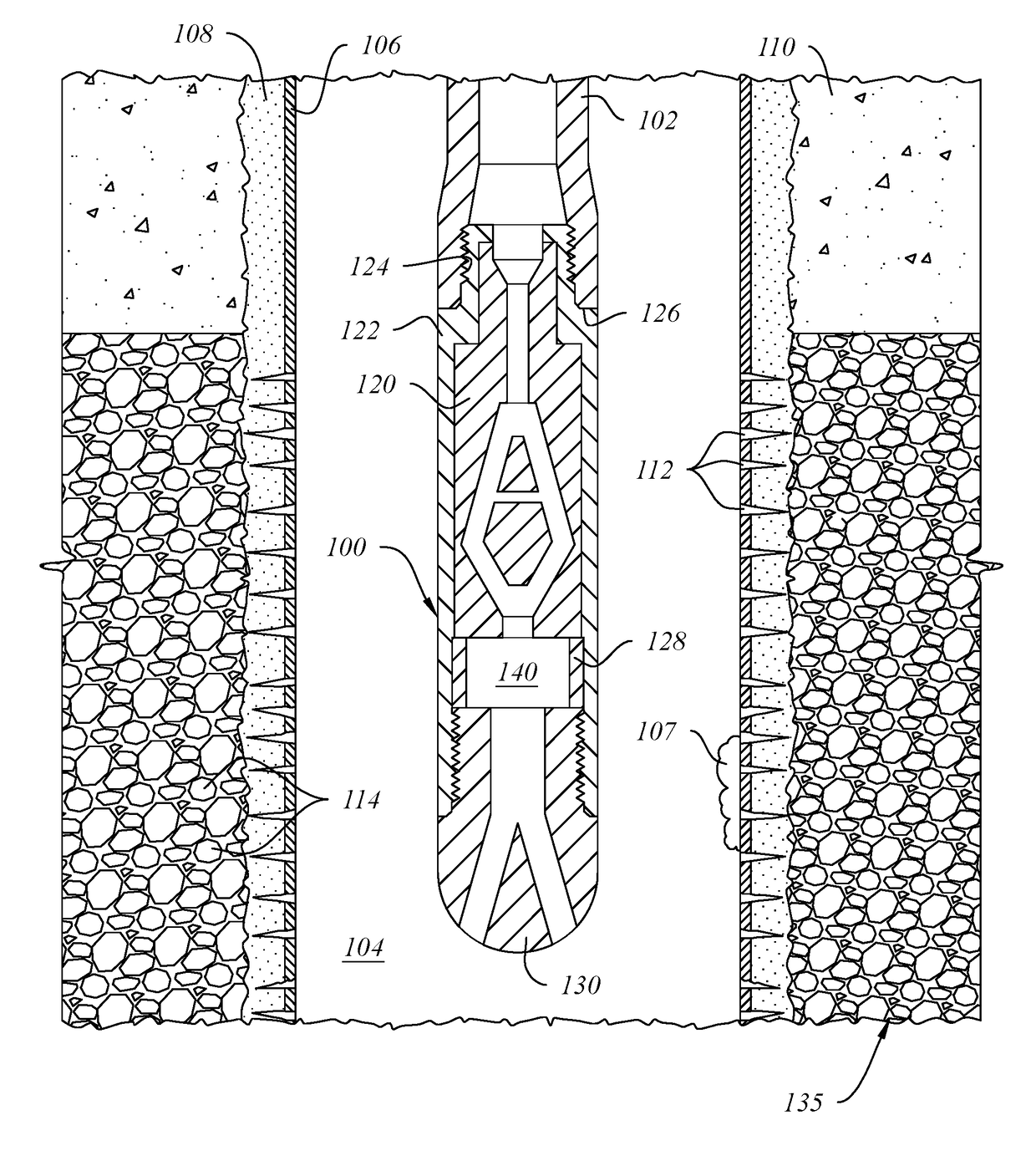

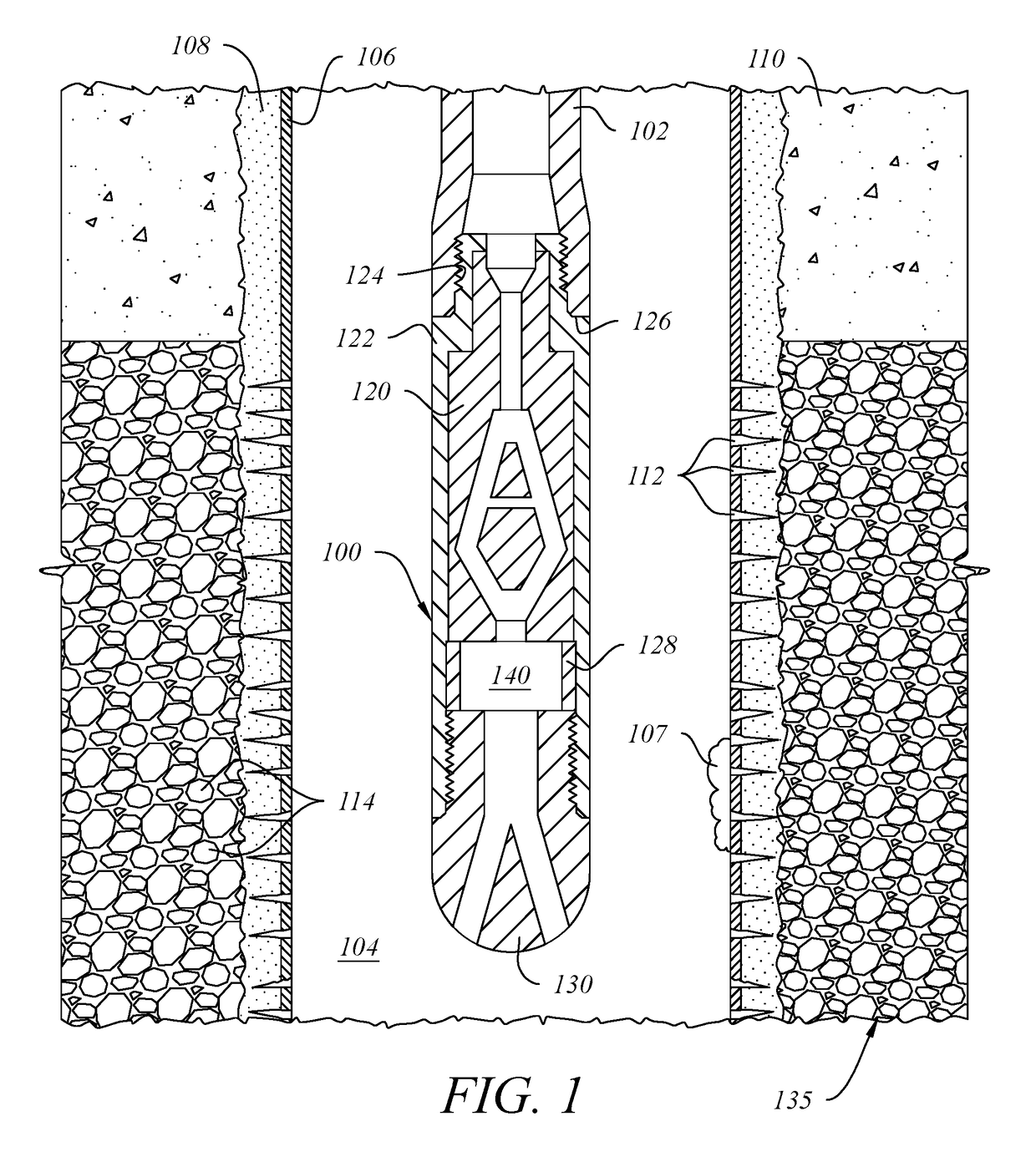

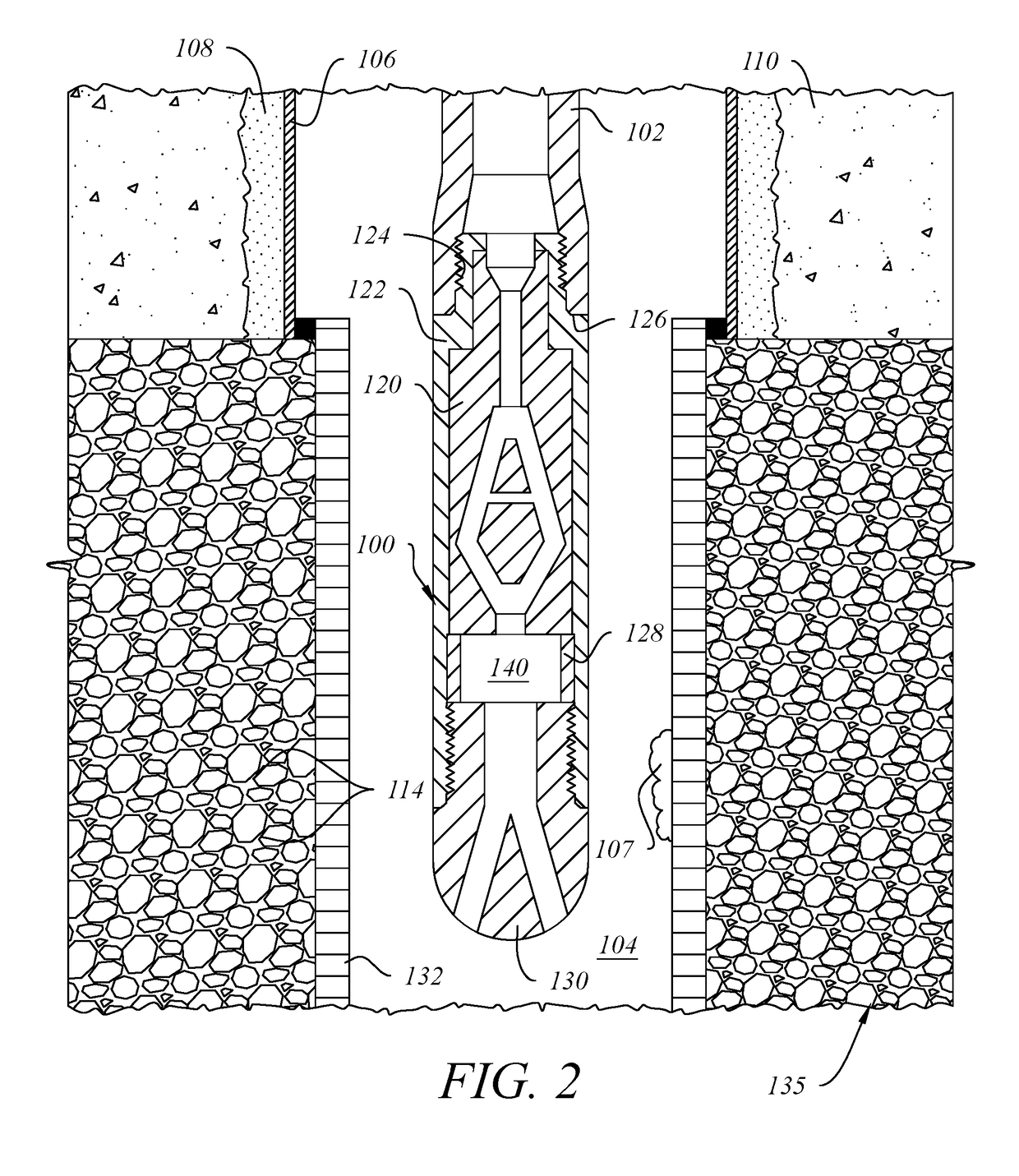

[0030]Referring to FIG. 1, tool 100 is depicted as being suspended from tubing 102 inside bore 104 of a subterranean well in which casing 106 is held in place by cement 108. Casing 106 further comprises a plurality of perforations 112 through which the surrounding formation 110 (as depicted above perforations 112) has been fractured into smaller particles 114 to increase its permeability. At one location inside casing 106, mineral scale 107 has formed on the inside of the casing and has blocked some of perforations 112, thereby reducing the ability to inject fluids or proppants into or recover fluids from formation 135. Tool 100 further comprises tool body 122 having an externally threaded pin end 124 that engages the internally threaded box end of tubing 102, with downwardly facing shoulder 126 of tubing 102 shown in abutting contact with an upwardly facing annular collar of tool body 122. Tool internal 120 (one of two opposed halves) is disposed in sliding engagement with tool bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com