Double-drill bit tunnel automatic drilling machine and method

A dual-bit and drilling machine technology, applied in drilling equipment and methods, automatic control systems for drilling, drilling equipment, etc., can solve the problems of high labor intensity, poor environmental conditions, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

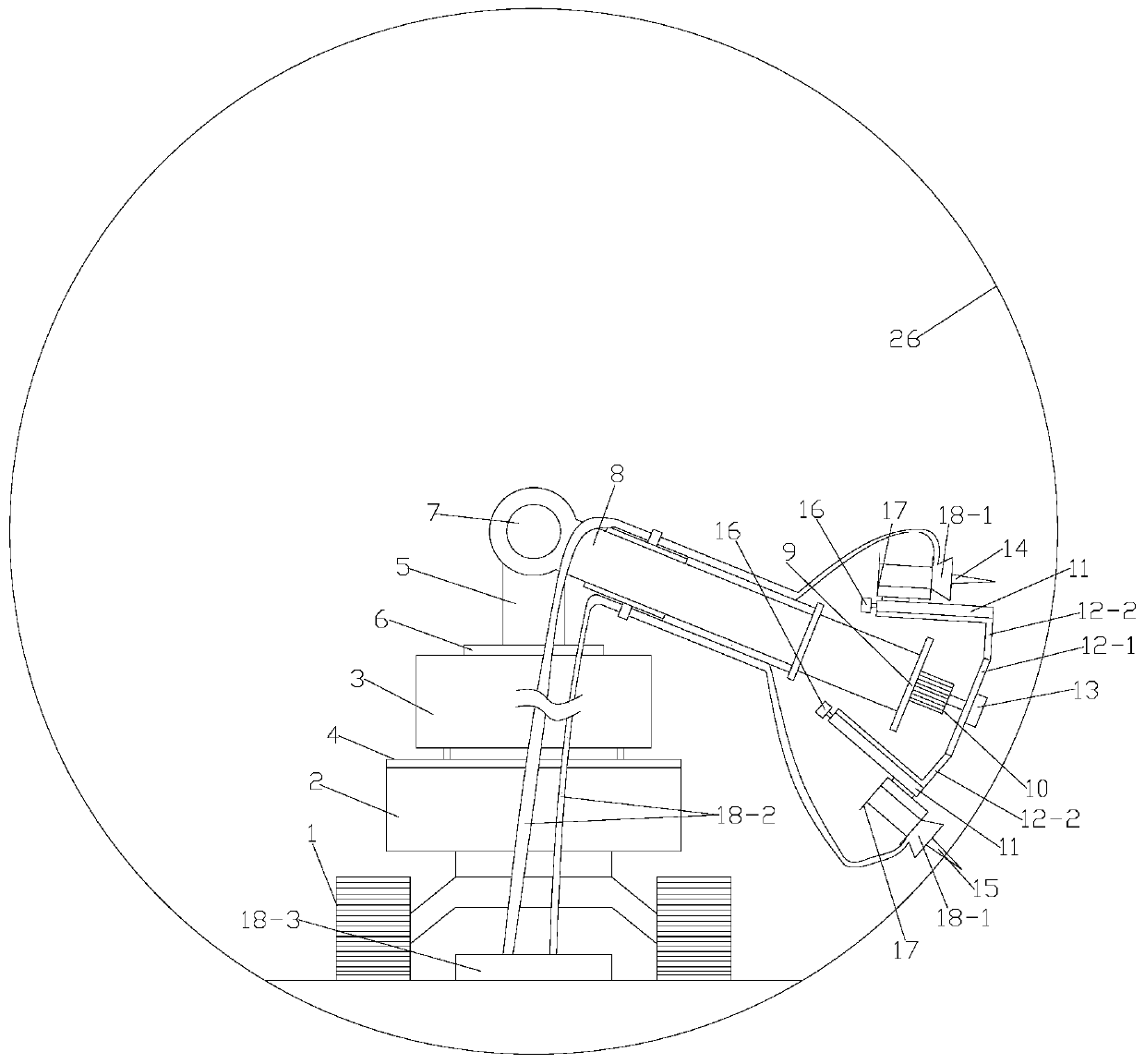

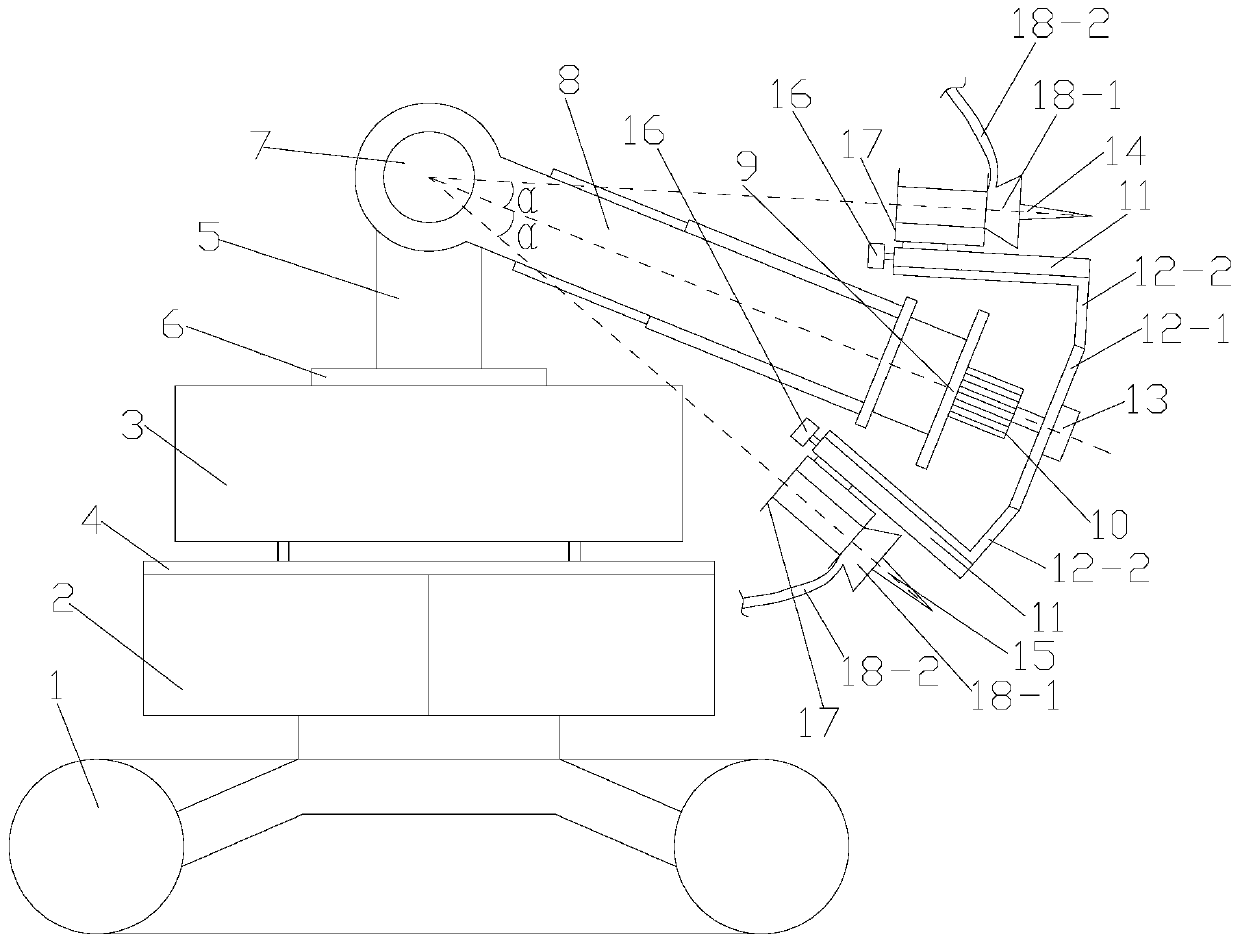

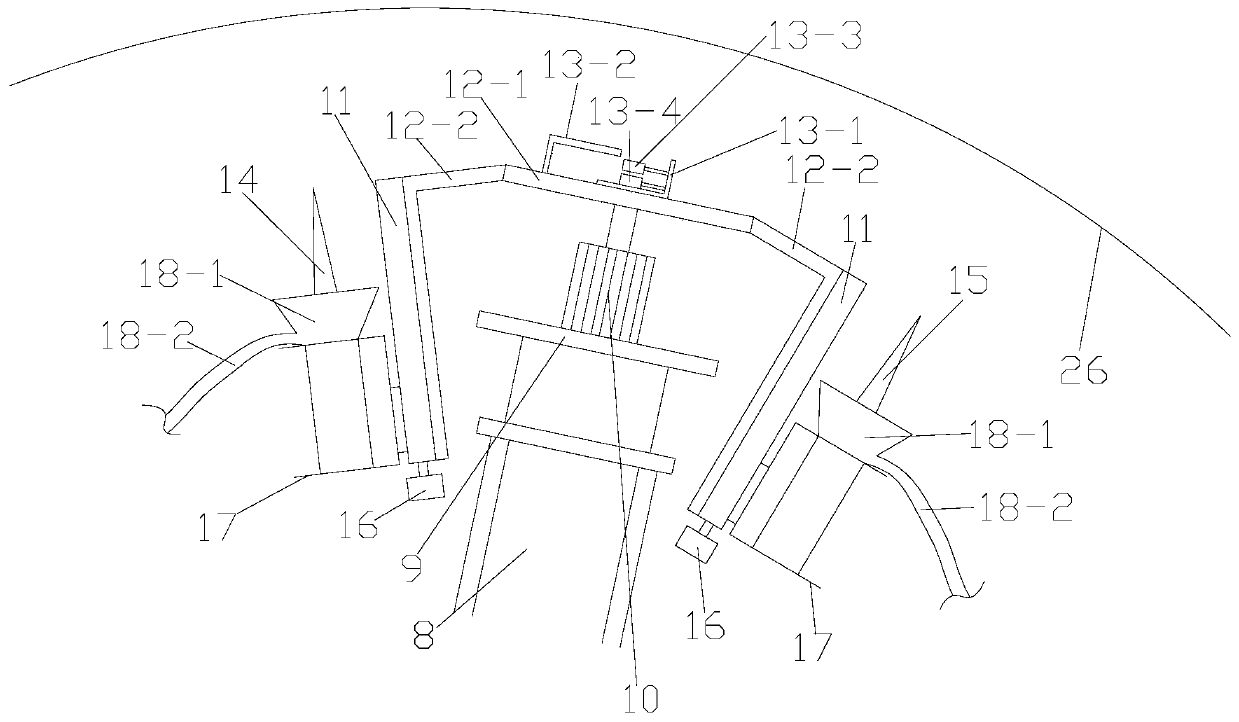

[0076] Such as figure 1 and figure 2 As shown, a kind of double-bit tunnel automatic drilling machine according to the present invention includes a crawler chassis 1, a control support box 2, a hydraulic control box 3 and a central support shaft 5 installed sequentially from bottom to top, and the hydraulic control box 3 passes through The plane moving mechanism 4 is installed on the control support box 2, the central support shaft 5 is installed on the hydraulic control box 3 through the rotating disk 6, the top of the central support shaft 5 is installed with a horizontal shaft 7, and the fixed end of the main oil cylinder 8 is installed on the horizontal shaft 7, the plunger end of the main oil cylinder 8 is provided with a mounting seat 9 for the installation of the double drill mechanism, and the mounting seat 9 is connected with the double drill mechanism through a motor 10, and the rotating shaft of the motor 10 is connected to the double drill mechanism. The mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com