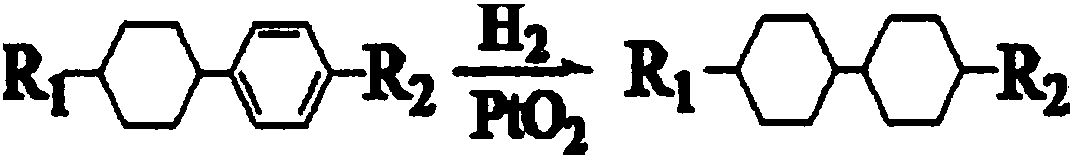

New preparation method of trans-trans dicyclohexyl alkane liquid crystal compounds

A liquid crystal compound and cyclohexylane technology, which is applied in the preparation of carbon-based compounds, the preparation of organic compounds, and the production of hydrocarbons from oxygen-containing organic compounds, etc., can solve the problems of high raw material costs and high product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

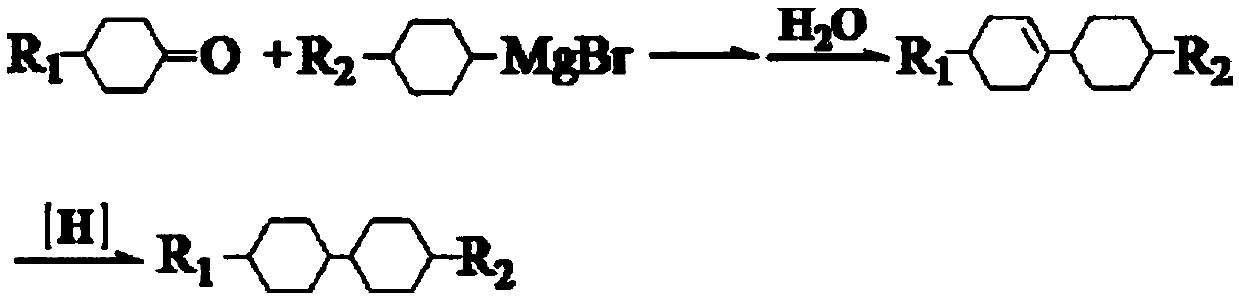

Method used

Image

Examples

Embodiment 1

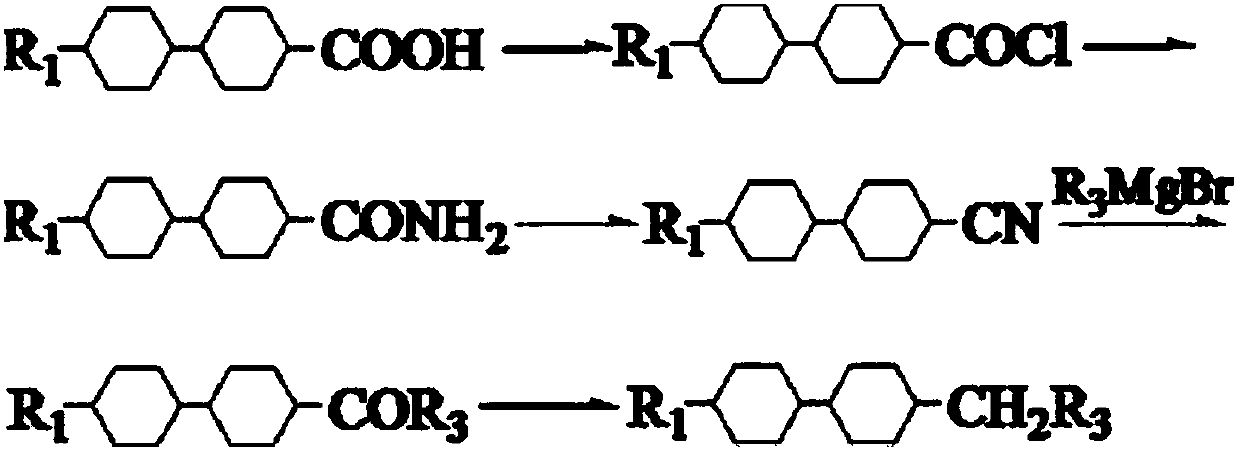

[0094] Taking the preparation of trans, trans-4-propyl-4'-ethyl-1,1'-bicyclohexyl (I-1) liquid crystal compound as an example, the trans-trans bicyclohexyl dialkyl liquid crystal compound is described in detail The preparation method:

[0095] Step a: Preparation of 1-(4-(4-propylcyclohexyl)cyclohexyl)ethyl-1-ol (Ⅲ-1):

[0096] a 1 .Add 200ml of cyclohexane to the hydrogenation kettle, and install an inert gas protection device, a heating and cooling device, a vacuum device and a water separator on the reaction kettle, and then pass nitrogen into it to empty the air in the kettle to maintain a pressure of 0.11MPa. Add 8.5g of 5% Ru / C, turn on the vacuum device, raise the temperature to 90°C and reflux for 5h, separate the water through the water separator until the water is completely evaporated.

[0097] a 2 .Stop heating and stirring, repressurize with nitrogen, after cooling, add 1-(4-(4-propylcyclohexyl)phenyl)ethyl-1-one 122g (0.5mol) and potassium carbonate 69g into t...

Embodiment 2

[0106] The preparation method of trans, trans-4-pentyl-4'-propyl-1,1'-bicyclohexyl liquid crystal compound (I-2):

[0107]The preparation process is the same as in Example 1, except that the raw material of 1-(4-(4-propylcyclohexyl)phenyl)ethyl-1-one in step a is replaced by 1-(4-(4-pentane Cyclohexyl) phenyl) propyl-1-ketone, the catalyst Ru / C is replaced by Pd / C, other steps are similar, and the prepared gas chromatography purity is ≥99.98%, resistivity ≥10 14 Ω.cm target product (I-2).

[0108] The experimental results are as follows: phase change of the liquid crystal compound: C22.0°CN 56.1°CI.

Embodiment 3

[0110] The preparation method of trans, trans-4-pentyl-4'-ethyl-1,1'-bicyclohexyl liquid crystal compound (I-3):

[0111] The preparation process is the same as in Example 1, except that the raw material of 1-(4-(4-propylcyclohexyl)phenyl)ethyl-1-one in step a is replaced by 1-(4-(4-pentane Cyclohexyl) phenyl) ethyl-1-ketone, catalyst Ru / C is replaced by Pd / C, other steps are similar, and the prepared gas chromatography purity is ≥99.98%, resistivity ≥10 14 Ω.cm target product (I-3).

[0112] The experimental results are as follows: phase change of liquid crystal compound: C16.1°CN 77.1°CI.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com