Method for separating and purifying oligosaccharide in high purity

A technology for separation and purification of oligosaccharides, applied in the fields of oligosaccharides, chemical instruments and methods, sugar derivatives, etc., can solve the problems of high cost, non-recyclable activated carbon, and difficulty in sugar separation and purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Conventional resin separation and purification soybean oligosaccharides of embodiment 1 special treatment

[0046] Resin pretreatment:

[0047] After the HZ001 resin is fully swollen with no salt water, it is soaked in 1-2mol / L HCL for 2 hours, and washed with water until neutral;

[0048] After soaking in 1-2mol / L NaOH for 2 hours, wash with water until neutral;

[0049] Use 1~2mol / LCaCl 2 After soaking for 2 hours, wash with water until neutral.

[0050] The glass column used for the separation medium: the ratio of diameter to height is 1:30,

[0051] The loading volume is 120ml, and the column is packed by wet method.

[0052] Resin regeneration:

[0053] After soaking in 1-2mol / L HCL for 2 hours, wash with water until neutral;

[0054] After soaking in 1-2mol / L NaOH for 2 hours, wash with water until neutral;

[0055] Use 1~2mol / LCaCl 2 After soaking for 2 hours, wash with water until neutral and set aside.

[0056] Commercially available soybean oli...

Embodiment 2

[0057] Conventional resin separation and purification soybean oligosaccharides of embodiment 2 special treatment

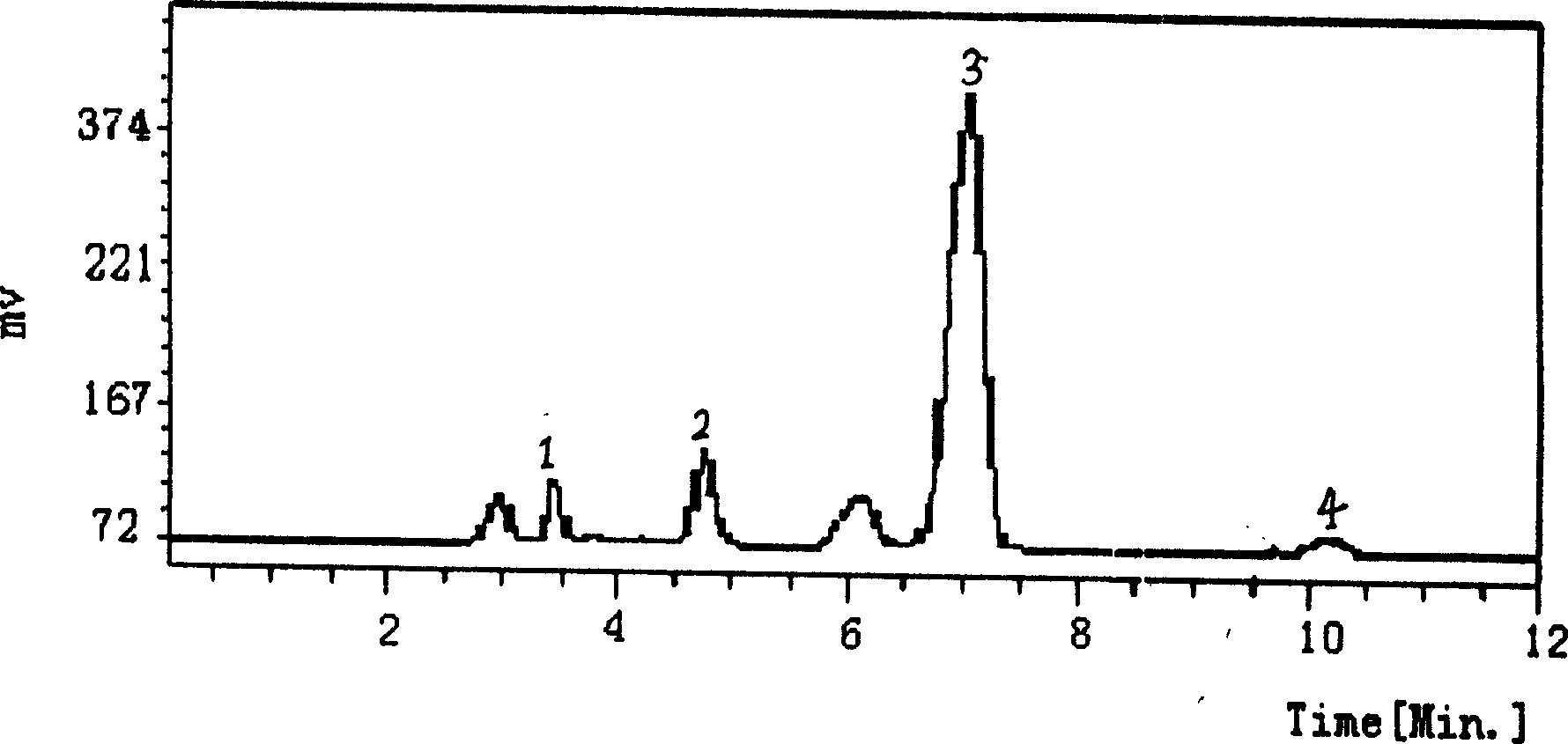

[0058]Same as Example 1, except that 0.5-1mol / L sulfuric acid is used instead of 1-2mol / LHCL, and 5-8% ammonia water is used instead of 1-2mol / LNaOH to obtain a finished product of oligosaccharides with a stachyose content of 89%, with a primary recovery rate of 65%. %. The finished product map is attached figure 2 .

Embodiment 3

[0059] Example 3 Sephadex G-10 separation and purification of soybean oligosaccharides

[0060] Sephadex G-10 Resin Resin Pretreatment:

[0061] After the resin is fully swollen with water, the column is wet-packed.

[0062] The glass column used for Sephadex G-10 resin: diameter to height ratio is 1:25

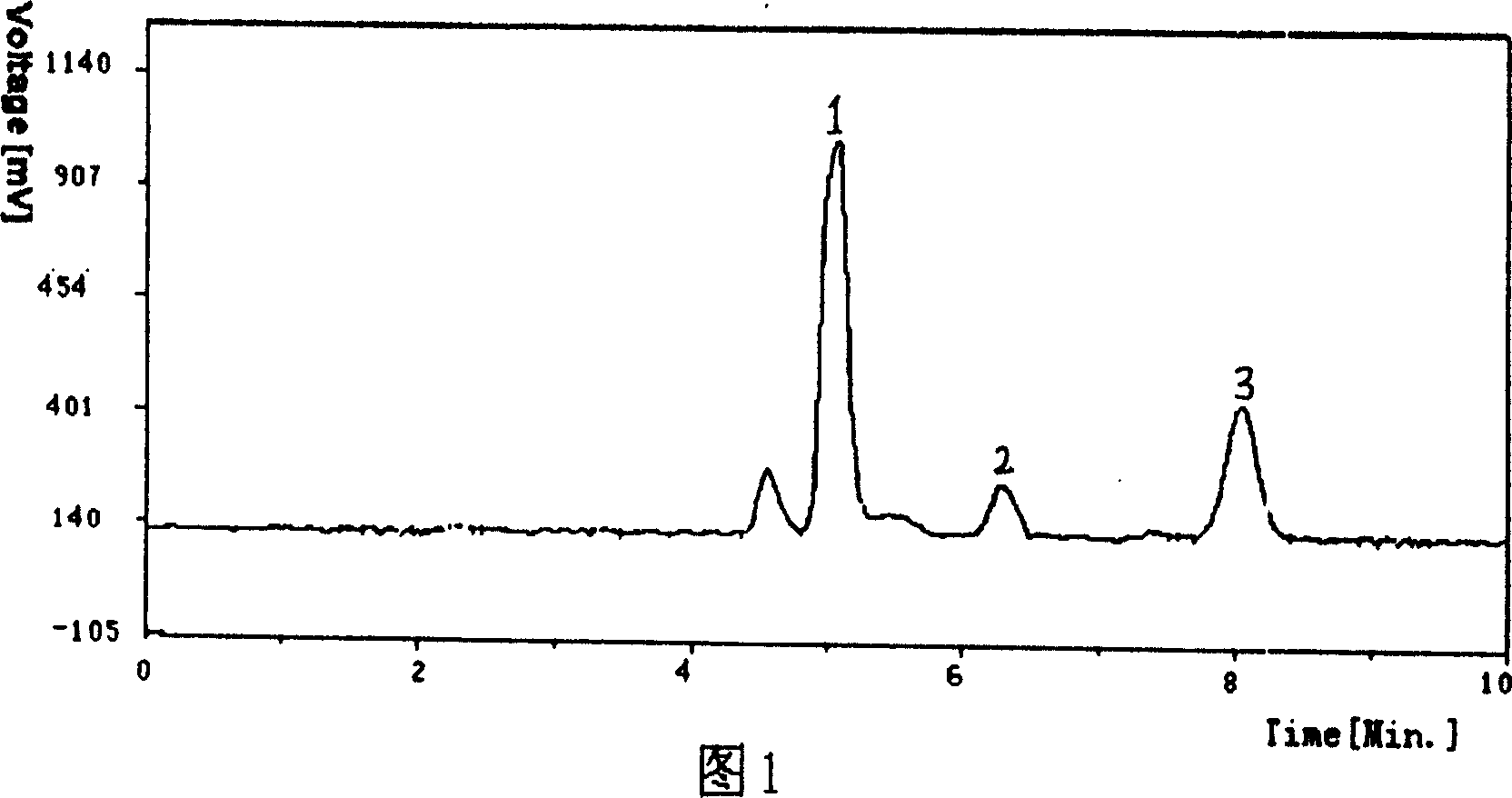

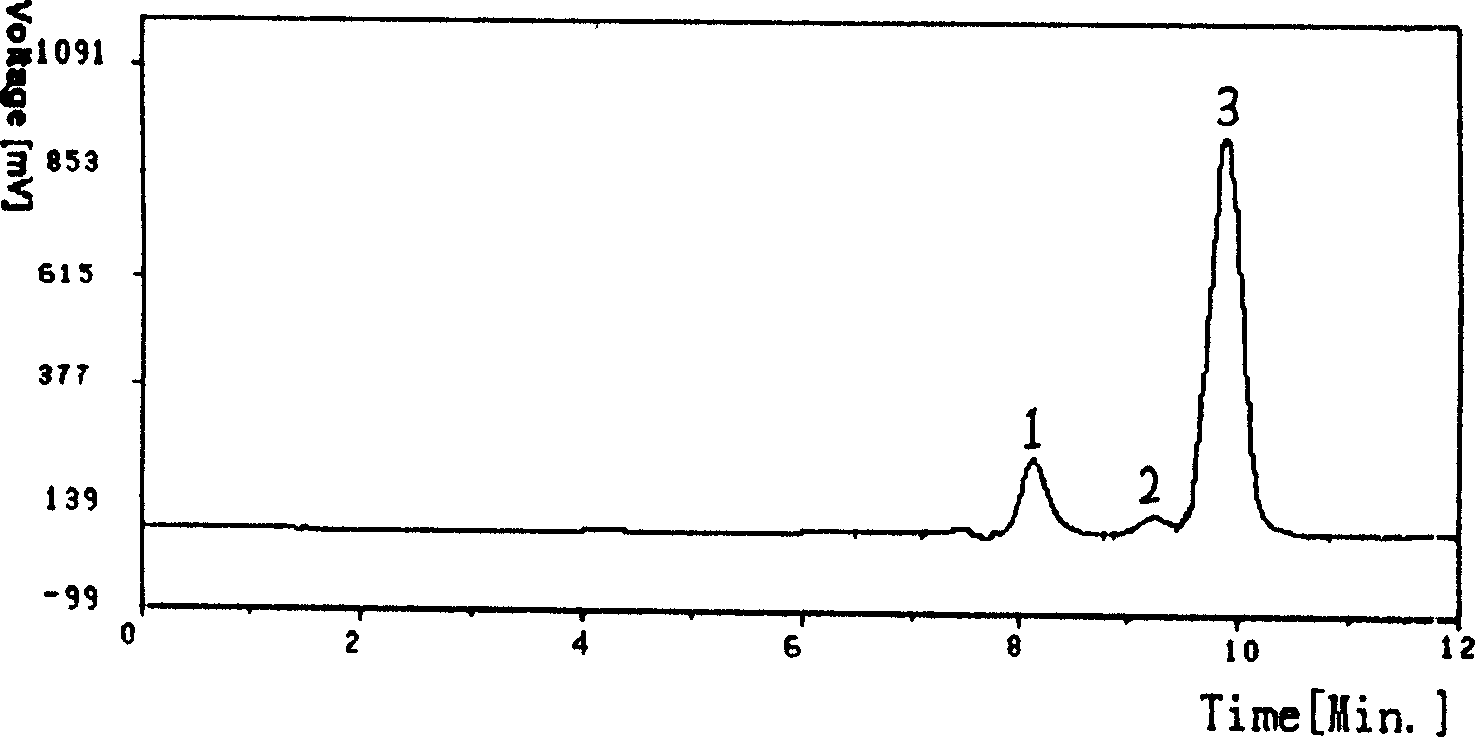

[0063] Commercially available soybean oligosaccharide syrup (stachyose content is 30%), see accompanying drawing 1, after diluting 5 times (stachyose unit: 24800ug / ml) take 1ml sample, flow rate is 1 / 10-1 / 15BV / hr, ELSD follow-up detection, collect the effective parts and concentrate under reduced pressure to obtain a finished oligosaccharide with a stachyose content of 90% and a recovery rate of 65%, which is suitable for diabetics and obese patients. The finished product diagram is attached image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com