A piezoelectric ceramic super-filled silicon rubber composite ink material for ink direct writing printing and its preparation method and application

A piezoelectric ceramic and silicone rubber technology, applied in the field of 3D printing polymer materials, can solve the problems of difficult control of printing ink viscosity, poor ink support, restricting research and development, etc. effect of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

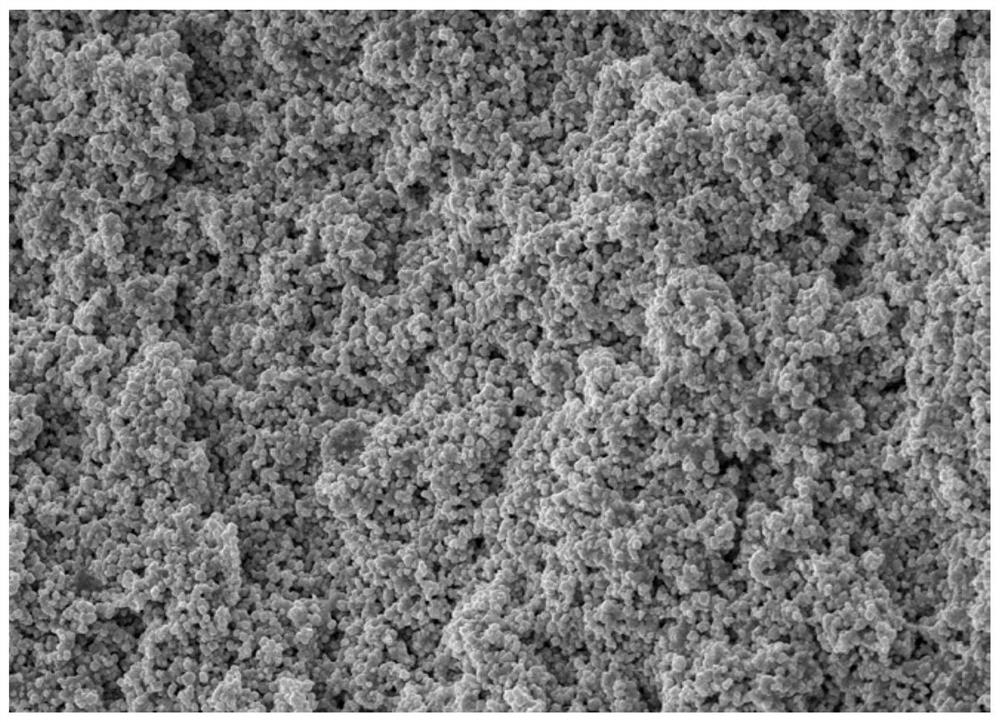

[0069] In this embodiment, a piezoelectric ceramic ultra-high-filled silicone rubber composite ink material for ink direct writing printing, in terms of parts by weight, the raw materials mainly include the following components:

[0070] 200 parts of silicone rubber resin,

[0071] Piezoelectric ceramic filler 800 parts,

[0072] 400 parts of solvent;

[0073] Wherein, the silicone rubber resin is selected as polydimethyl silicone rubber,

[0074] The piezoelectric ceramic filler is selected as barium titanate,

[0075] Described solvent is selected as ethyl acetate;

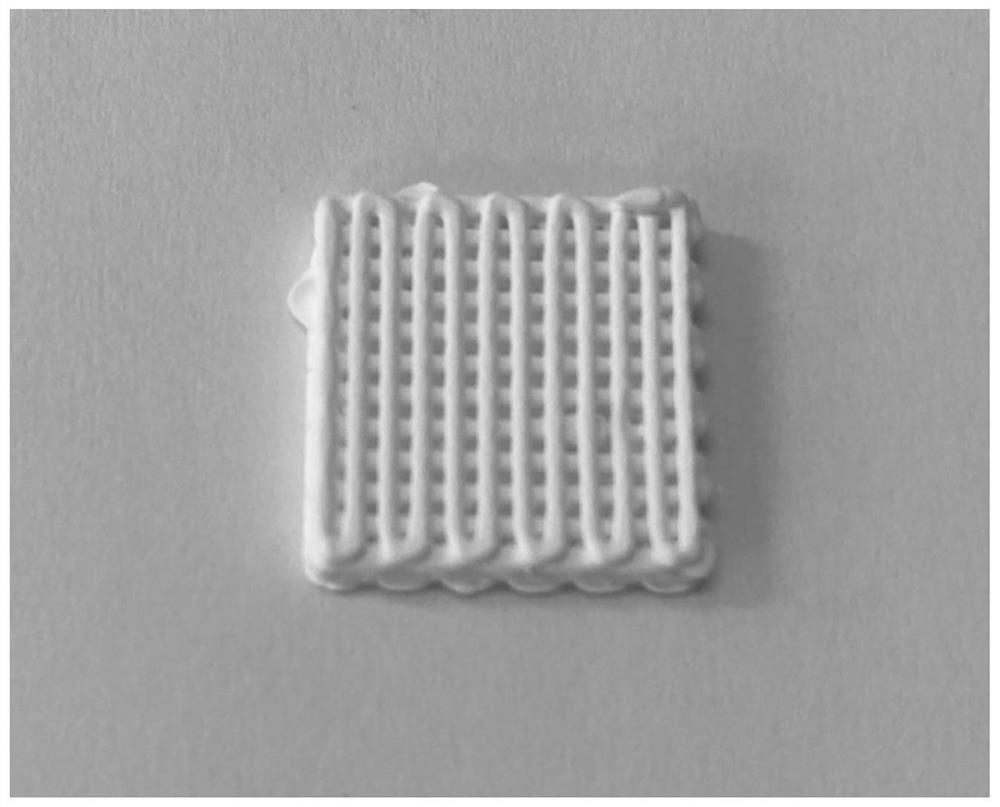

[0076] The above-mentioned preparation method of the piezoelectric ceramic ultra-high-filled silicone rubber composite ink material for ink direct writing printing includes the following steps:

[0077] (1) Under normal temperature conditions, add piezoelectric ceramic fillers in the solvent and mix them fully, then use them as mixed liquids for use;

[0078] (2) after adding silicone rubber resin to the mi...

Embodiment 2

[0086] In this embodiment, a piezoelectric ceramic high-filled silicone rubber composite ink material for direct ink writing, in terms of parts by weight, the raw materials mainly include the following components:

[0087] 100 parts of silicone rubber resin,

[0088] Piezoelectric ceramic filler 900 parts,

[0089] 500 parts of solvent;

[0090] Wherein, the silicone rubber resin is selected as polydimethyl silicone rubber,

[0091] The piezoelectric ceramic filler is selected as barium titanate,

[0092] Described solvent is selected as ethyl acetate;

[0093] The above-mentioned preparation method of piezoelectric ceramic high-filled silicone rubber composite ink material for direct ink writing comprises the following steps:

[0094] (1) Under normal temperature conditions, add piezoelectric ceramic fillers in the solvent and mix them fully, then use them as mixed liquids for use;

[0095] (2) after adding silicone rubber resin to the mixed solution obtained in step (1) a...

Embodiment 3

[0102] In this embodiment, a piezoelectric ceramic high-filled silicone rubber composite ink material for direct ink writing, in terms of parts by weight, the raw materials mainly include the following components:

[0103] 300 parts of silicone rubber resin,

[0104] Piezoelectric ceramic filler 700 parts,

[0105] 350 parts of solvent;

[0106] Wherein, the silicone rubber resin is selected as polydimethyl silicone rubber,

[0107] The piezoelectric ceramic filler is selected as barium titanate,

[0108] Described solvent is selected as ethyl acetate;

[0109] The above-mentioned preparation method of piezoelectric ceramic high-filled silicone rubber composite ink material for direct ink writing comprises the following steps:

[0110] (1) Under normal temperature conditions, add piezoelectric ceramic fillers in the solvent and mix them fully, then use them as mixed liquids for use;

[0111] (2) after adding silicone rubber resin to the mixed solution obtained in step (1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com