Method for separating and purifying oligosaccharide in high purity

A technology for separation and purification of oligosaccharides, applied in oligosaccharides, chemical instruments and methods, sugar derivatives, etc., can solve problems such as difficult sugar separation and purification, high cost, and non-recyclable activated carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Conventional resin separation and purification soybean oligosaccharides of embodiment 1 special treatment

[0046] Resin pretreatment:

[0047] After the HZ001 resin is fully swollen with no salt water, it is soaked with 1-2mol / L HCl for 2 hours, and washed with water until neutral;

[0048] After soaking in 1-2mol / L NaOH for 2 hours, wash with water until neutral;

[0049] Use 1~2mol / LCaCl 2 After soaking for 2 hours, wash with water until neutral.

[0050] The glass column used for the separation medium: the ratio of diameter to height is 1:30,

[0051] The loading volume is 120ml, and the column is packed by wet method.

[0052] Resin regeneration:

[0053] After soaking with 1-2mol / L HCl for 2 hours, wash with water until neutral;

[0054] After soaking in 1-2mol / L NaOH for 2 hours, wash with water until neutral;

[0055] Use 1~2mol / LCaCl 2 After soaking for 2 hours, wash with water until neutral and set aside.

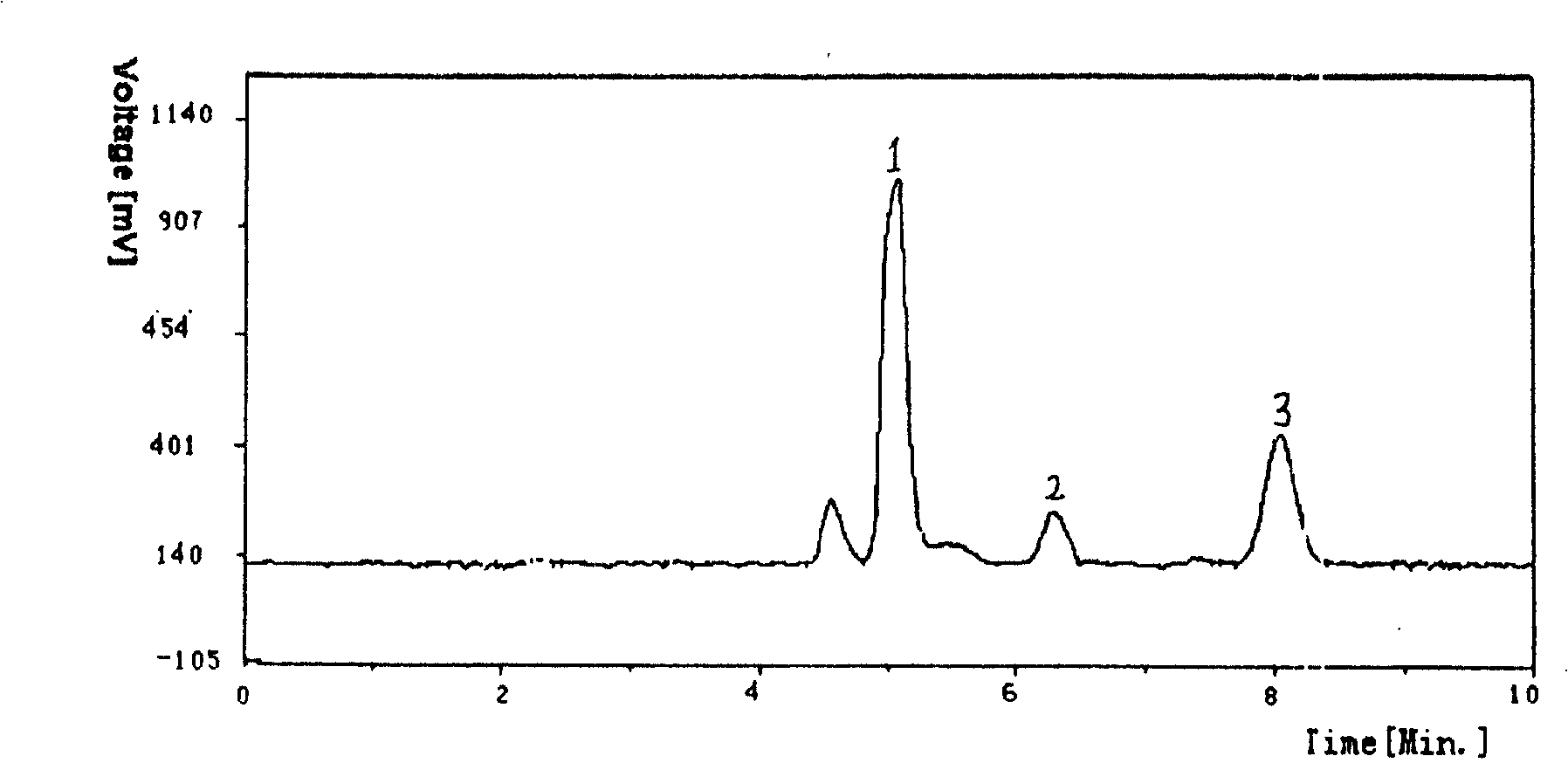

[0056] Commercially available soybean oligos...

Embodiment 2

[0057] Conventional resin separation and purification soybean oligosaccharides of embodiment 2 special treatment

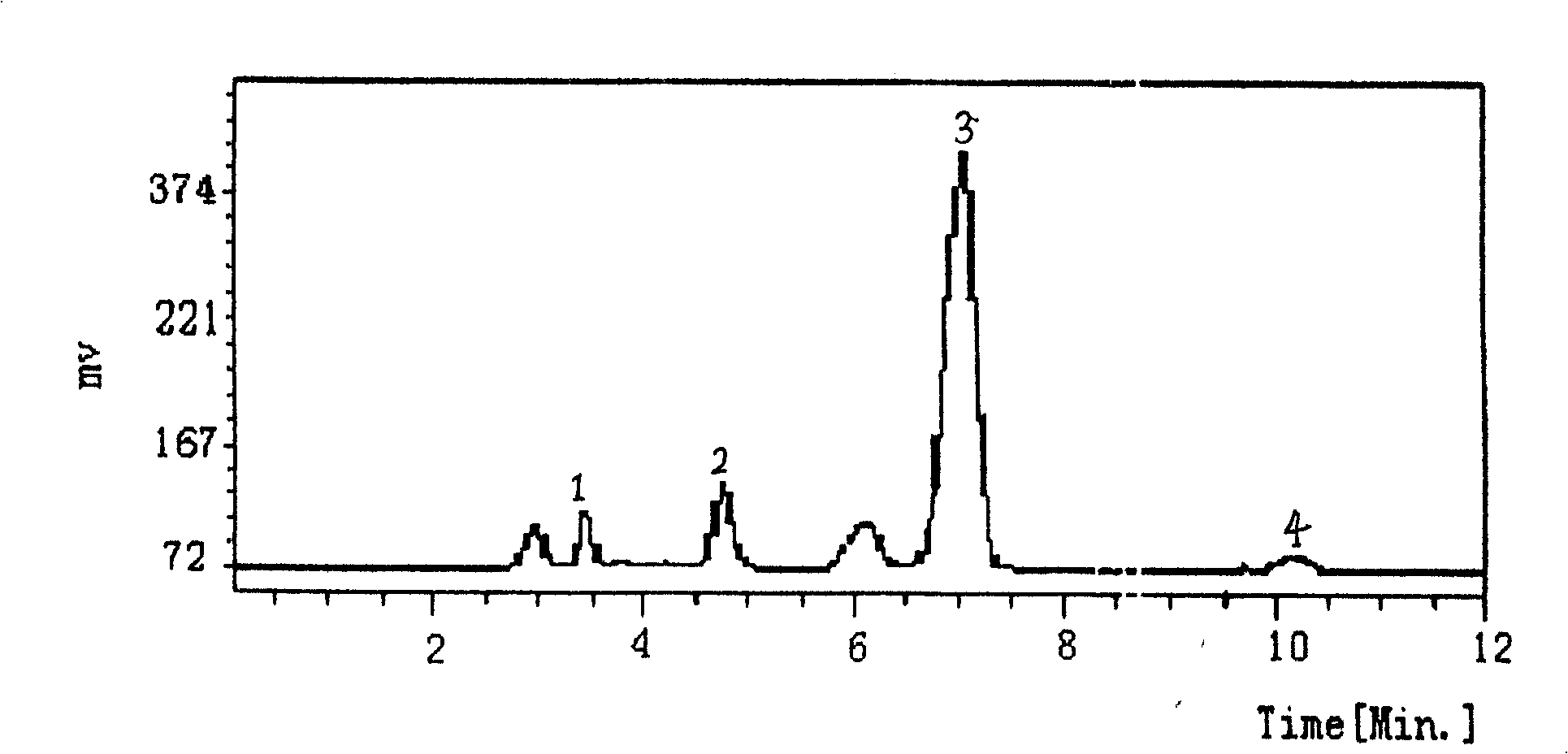

[0058] Same as Example 1, except that 0.5~1mol / L sulfuric acid is used to replace 1~2mol / LHCl, and 5~8% ammonia water is used to replace 1~2mol / LNaOH to obtain a finished product of oligosaccharides with a stachyose content of 89%, with a primary recovery rate of 65%. %. The finished product atlas is the same as attached drawing 2.

Embodiment 3

[0059] Example 3 Sephadex G-10 separation and purification of soybean oligosaccharides

[0060] Sephadex G-10 Resin Resin Pretreatment:

[0061] After the resin is fully swollen with water, the column is wet-packed.

[0062] Glass column used for Sephadex G-10 resin: diameter to height ratio is 1:25

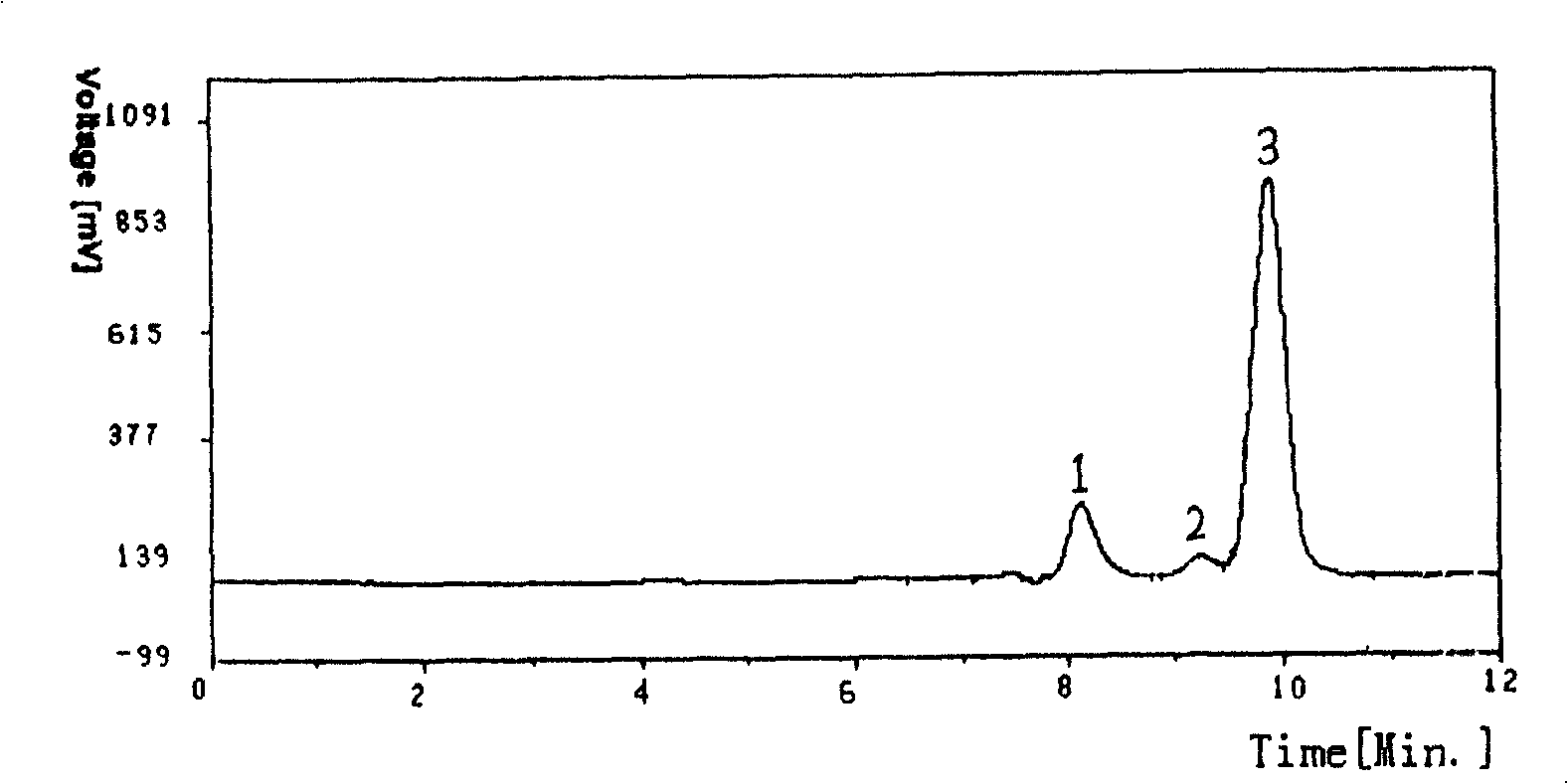

[0063] Commercially available soybean oligosaccharide syrup (stachyose content is 30%), see accompanying drawing 1, after diluting 5 times (stachyose unit: 24800ug / ml) take 1ml sample, flow rate is 1 / 10-1 / 15BV / hr, ELSD follow-up detection, collect the effective parts and concentrate under reduced pressure to obtain a finished oligosaccharide with a stachyose content of 90% and a recovery rate of 65%, which is suitable for diabetics and obese patients. See attached drawing 3 for the finished product map.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com