Process for refining gulonic acid

A technology of gulonic acid and sodium gulonic acid, which is applied in the refining process of the precursor, that is, gulong acid, can solve the problems of difficult and complex components, complex components, and poor technical applicability, so as to save usage, improve removal rate, and absorb good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

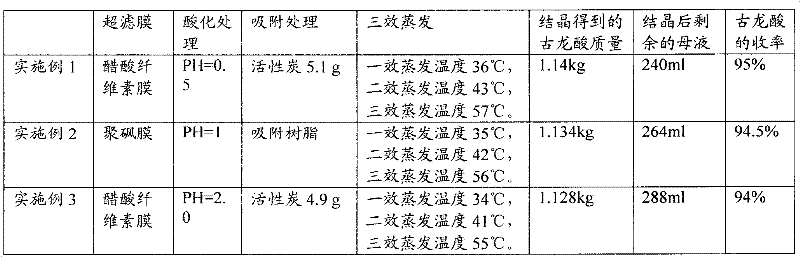

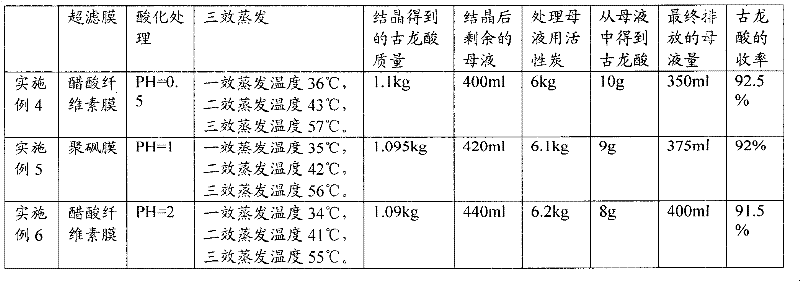

[0020] Below in conjunction with embodiment the present invention is described in further detail:

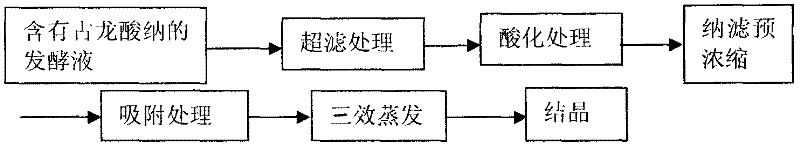

[0021] A kind of gulong acid extraction process, this process comprises the following steps:

[0022] A. fermented by L-sorbose to prepare the fermented liquid containing sodium guronate, and carry out ultrafiltration to the fermented liquid; the ultrafiltration membrane used in the ultrafiltration process is a cellulose acetate membrane or a cellulose acetate membrane with a molecular weight cut-off of 10,000 to 30,000 Polysulfone membrane.

[0023] B. adopt ion exchange device to carry out acidification treatment to the fermented liquid after ultrafiltration treatment, make more than 98% sodium guronate in the fermented liquid be converted into gulonic acid, the pH of the fermented liquid in the ion exchange device is below 2.0.

[0024] C. Perform nanofiltration pre-concentration on the fermented liquid after the acidification treatment to obtain a pre-concentrated liquid, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com