Enhancing method of production strength of 2-keto-L-gulonic acid

A technology for producing strength and gulonic acid, applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as inability to use L-sorbose, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

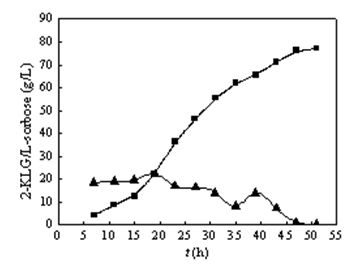

[0048] at 1 m 3 Carried out in a fermenter, the initial concentration of L-sorbose in the fermentation medium was 16.15 g L -1 , fermented for 6 h, began to feed L-sorbose (i.e. sterile one-step fermentation broth), and controlled the L-sorbose concentration to 15~30 g L during the feeding process -1 After 39 hours of fermentation, the feeding of L-sorbose ended, the dissolved oxygen was controlled at 40% during the fermentation process, and the concentration of 2-KLG at the end of the fermentation was 77.09 g·L -1 , the fermentation period was 51 h, and the acid production rate was 1.51 g·(L·h) -1 ( figure 1 ).

Embodiment 2

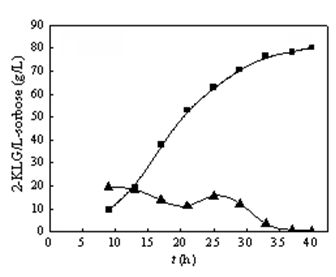

[0050] at 1 m 3 Carried out in a fermenter, the initial concentration of L-sorbose in the fermentation medium was 10.15 g L -1 , add 0.21 g·L -1 L-glycine and 0.24 g L -1 L-proline, fermented for 4 h, began to feed L-sorbose (i.e. sterile one-step fermentation broth), and controlled the concentration of L-sorbose to 15-30 g L during the feeding process -1 After 29 hours of fermentation, the feeding of L-sorbose ended, the dissolved oxygen was controlled at 40% during the fermentation process, and the concentration of 2-KLG at the end of the fermentation was 80.29 g·L -1 , the fermentation period was 40 h, and the acid production rate was 2.00 g·(L·h) -1 ( figure 2 ).

Embodiment 3

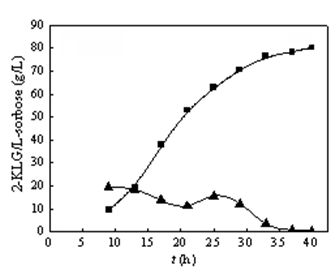

[0052] at 1 m 3 Carried out in a fermenter, the initial concentration of L-sorbose in the fermentation medium was 10.15 g L -1 , add 0.1 g·L -1 L-glycine and 0.8 g L -1 L-proline, fermented for 4 h, began to feed L-sorbose (i.e. sterile one-step fermentation broth), and controlled the concentration of L-sorbose to 15-30 g L during the feeding process -1 After 29 hours of fermentation, the feeding of L-sorbose ended, the dissolved oxygen was controlled at 40% during the fermentation process, and the concentration of 2-KLG at the end of the fermentation was 78.34 g·L -1 , the fermentation period was 43 h, and the acid production rate was 1.88 g·(L·h) -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com