Treatment method for gulonic acid mother liquor in VC production

A cologne mother and treatment method technology, applied in water/sewage treatment, natural water treatment, chemical instruments and methods, etc., can solve the problems of high operating cost, harsh conditions, low ozone utilization rate, etc., to increase water potential gradient, The effect of accelerating fruit ripening and improving drought resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

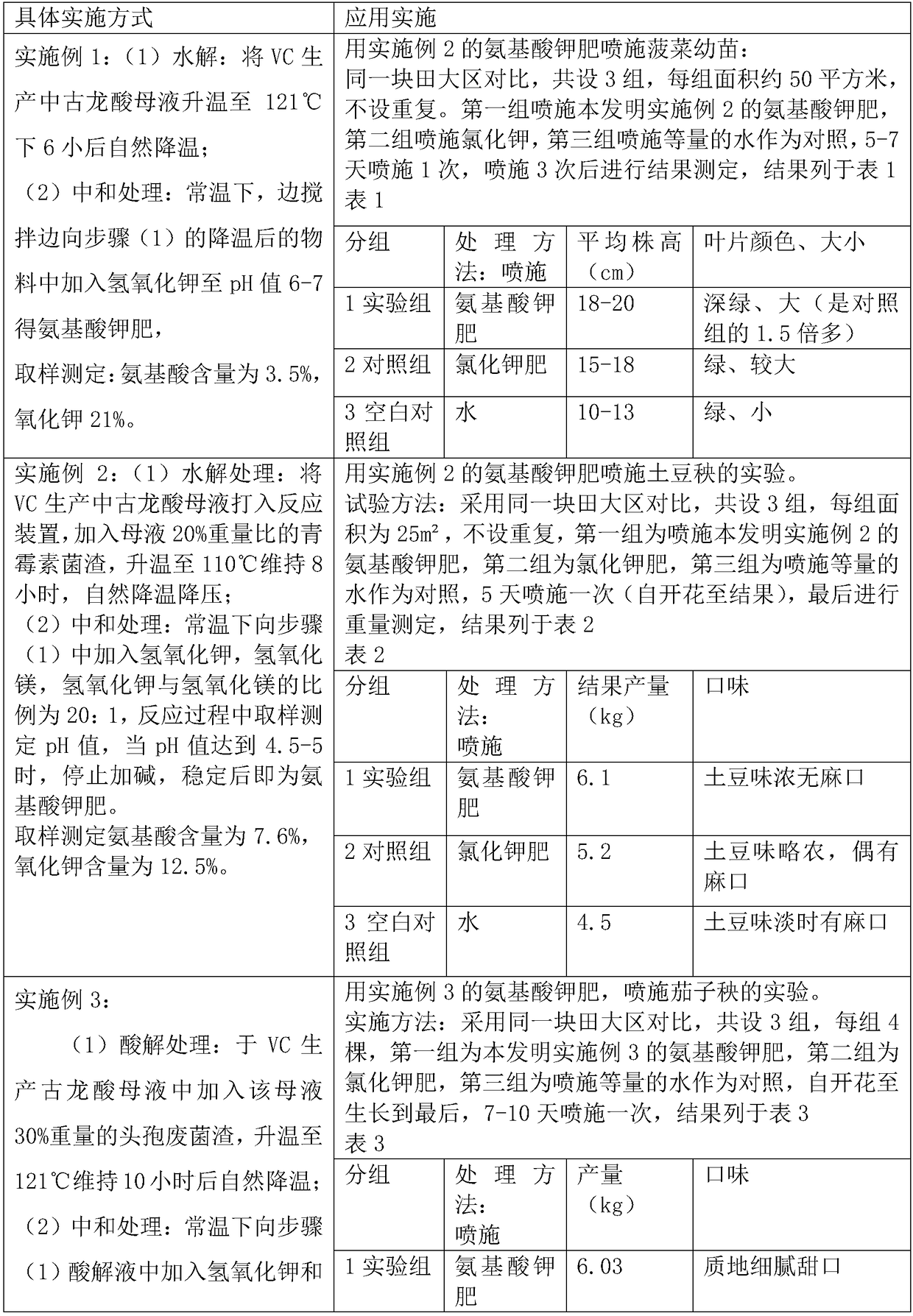

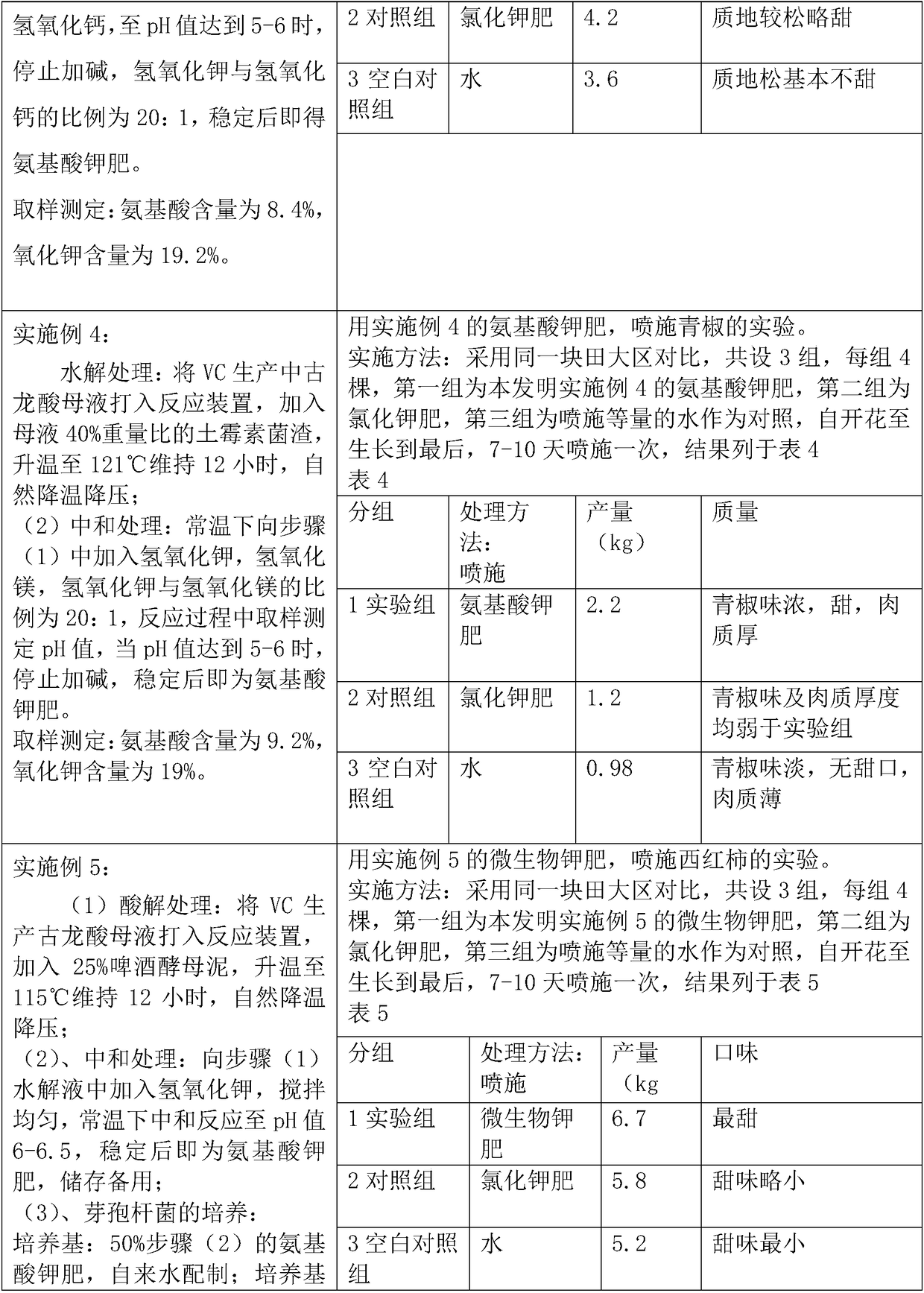

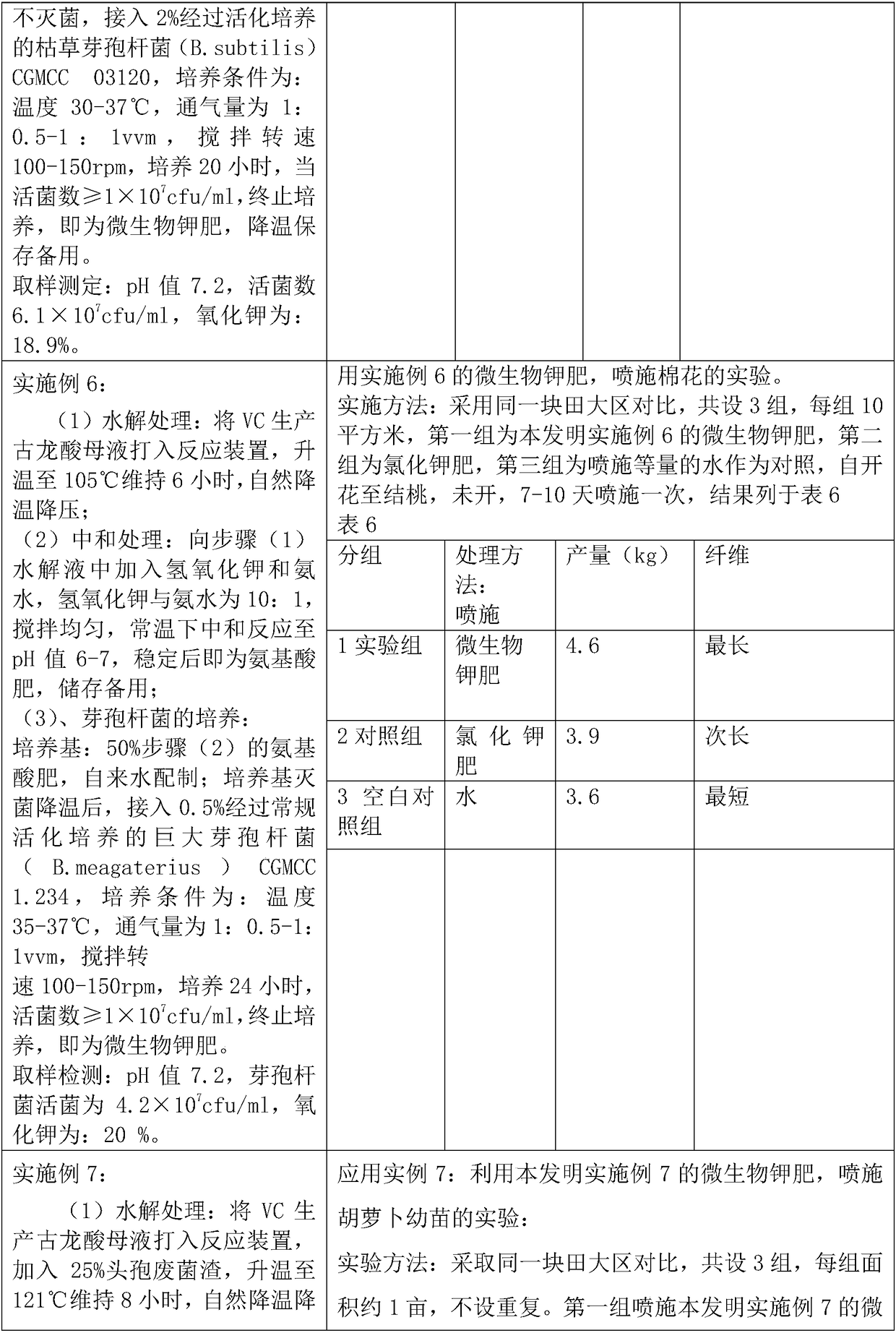

Examples

manufacture Embodiment 1

[0030] Manufacture Example 1, processing gulongic acid mother liquor in the production of VC:

[0031] Hydrolysis treatment: Put the gulong acid mother liquor in VC production into the reaction device, raise the temperature to 121°C for 6 hours, and naturally cool down the temperature and pressure.

Embodiment 2

[0032] Embodiment 2, prepare fertilizer with the mother liquor of gulong acid in the production of VC by processing:

[0033] Neutralization treatment: Add potassium hydroxide to the cooled hydrolyzate in Example 1, stir evenly, neutralize at room temperature to pH 6-7, and become amino acid potassium fertilizer after stabilization. The amino acid content was determined by sampling to be 3.5%, and the potassium oxide content was 21%.

manufacture Embodiment 3

[0034] Manufacture Example 3, prepare amino acid potassium fertilizer:

[0035] (1) Hydrolysis treatment: put the gulong acid mother liquor in VC production into the reaction device, add penicillin slag with 20% by weight of the mother liquor, raise the temperature to 110°C for 8 hours, and naturally cool down the temperature and pressure;

[0036] (2) Neutralization treatment: add potassium hydroxide and magnesium hydroxide to step (1) at normal temperature. The ratio of potassium hydroxide to magnesium hydroxide is 20:1. During the reaction, take samples to measure the pH value. When the pH value reaches 4.5-5, stop adding alkali. After stabilization, it becomes amino acid potassium fertilizer. The amino acid content is 7.6% by sampling. Potassium oxide content is 12.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com