Method for separating solution rich in gulonic acid and vitamin C by ion exclusion chromatography

A technology of ion exclusion chromatography and gulonic acid, which is applied in the field of separation by ion exclusion chromatography, can solve the problems of high resin synthesis requirements, unfavorable industrial production, and difficulty in continuing crystallization, and achieve the effects of reducing production costs and increasing yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

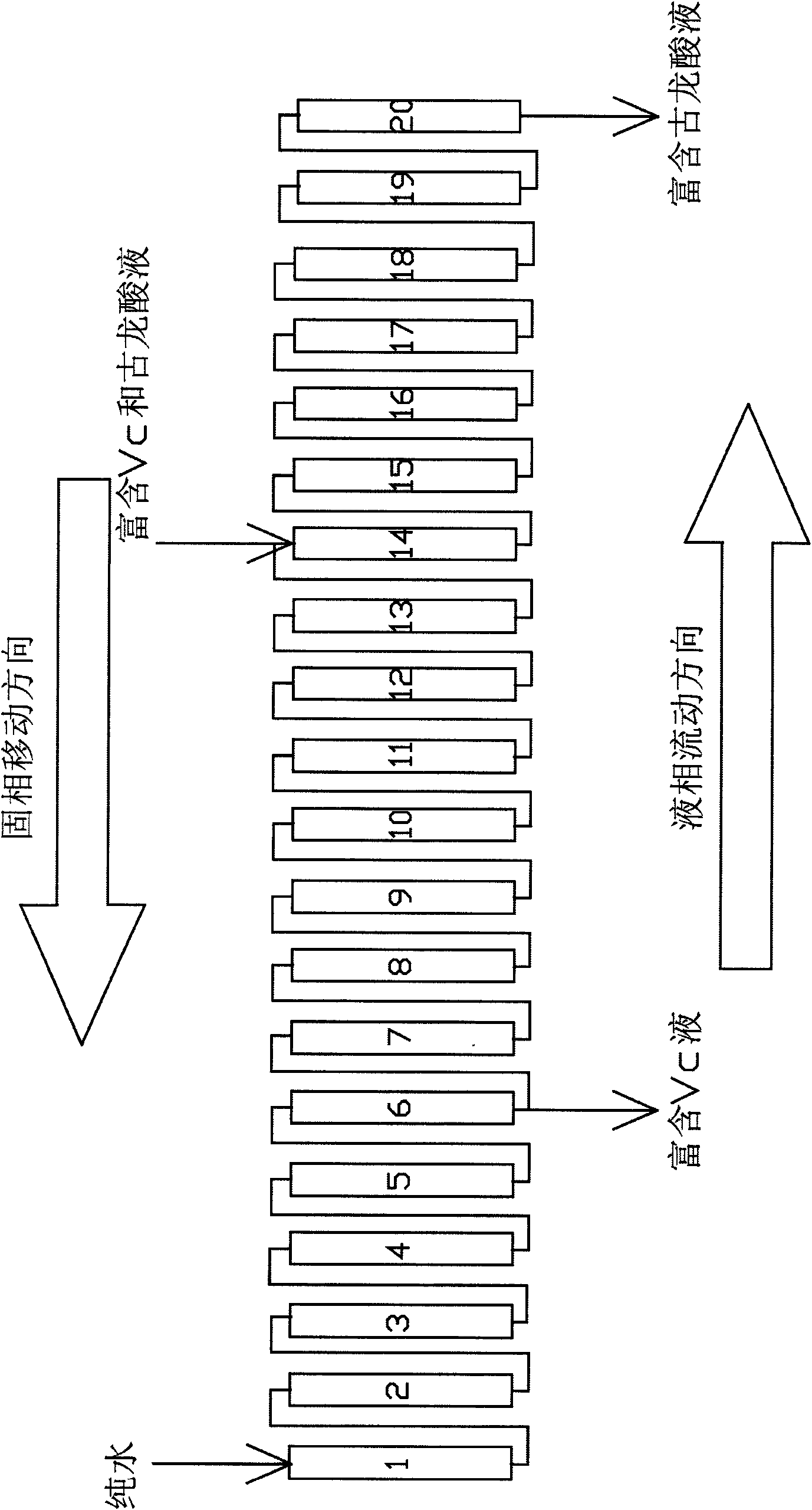

[0021] In the moving bed chromatographic system (produced by L100-139 U.S. CALGON company) with 20 resin columns, its resin column volume is 900ml / root, pack 800ml macroporous strong acid cation chromatographic separation resin by every resin column, resin grain Diameter 0.45mm. For column layout, see figure 1 shown.

[0022] The pH of the material rich in gulonic acid and vitamin C solution in the raw material is 4.0, and the components are 23.3% of gulonic acid radical, 16.5% of Vc and 8.6% of sorbose. Under the condition that the operating temperature of the moving bed is 45°C and the walking time is 900S, the chromatographic separation parameters are as follows:

[0023] Material name

Pure water (L / h)

Raw material(L / h)

Gulonic acid-rich components (L / h)

Vc-rich component (L / h)

flow

2.2

0.48

1.6

0.6

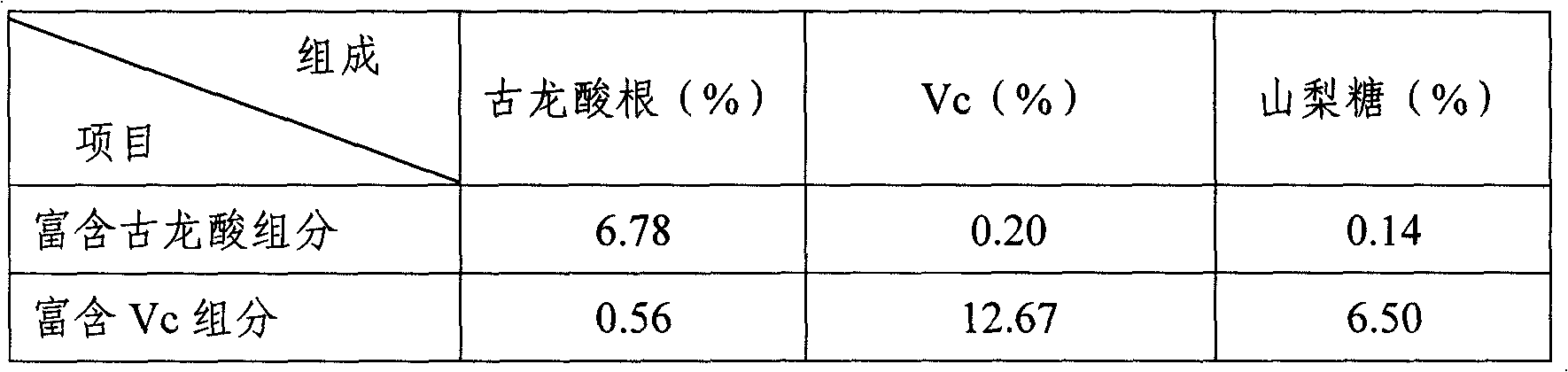

[0024] After three cycles, collection of the separated fractions was started. Its composition is as follows...

Embodiment 2

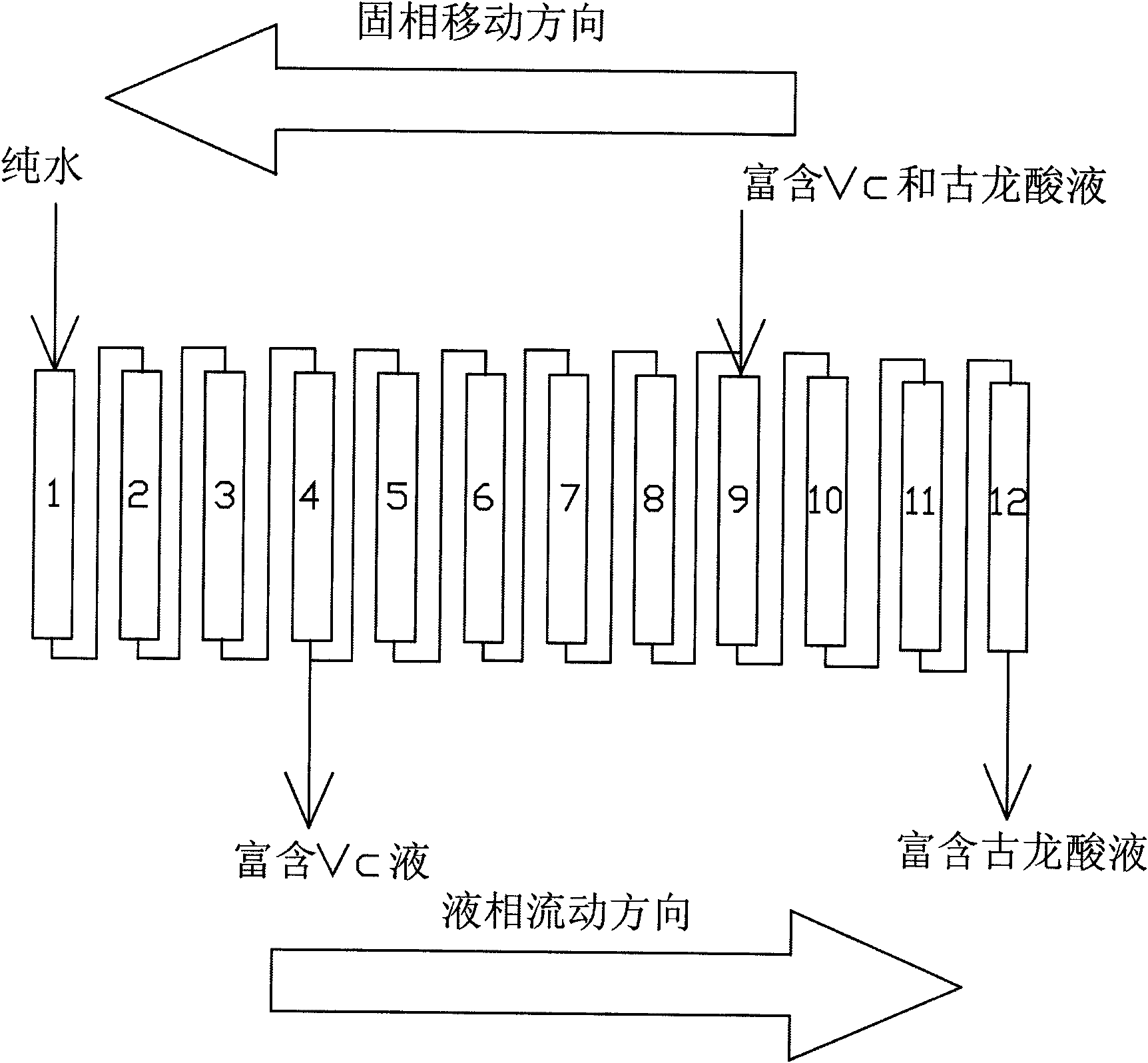

[0030] In the simulated moving bed chromatographic system with 12 resin columns, the volume of the resin column is 1000ml / piece, and the volume of each resin column is 900ml, and the gel-type strong acid cation chromatography separation resin is loaded, and the particle size of the resin is 0.30±0.05mm. For column layout, see figure 2 shown.

[0031] The pH of the material rich in gulonic acid and vitamin C solution is 1.0, and the components are 23.3% of gulonic acid, 16.5% of Vc and 8.6% of sorbose. Under the condition that the operating temperature of the moving bed is 30°C and the walking time is 1500S, the chromatographic separation parameters are as follows:

[0032] Material name

Pure water (L / h)

Raw material(L / h)

Gulonic acid-rich components (L / h)

Vc-rich component (L / h)

flow

2.76

0.36

1.68

0.72

[0033] After three cycles, start to collect the separated components, the composition of which is as follow...

Embodiment 3

[0039] In the simulated moving bed chromatographic system with 12 resin columns, the volume of the resin column is 1000ml / piece, and the volume of each resin column is 900ml, and the gel-type strong acid cation chromatography separation resin is loaded, and the resin particle size is 0.40±0.10mm. For column layout, see figure 2 shown.

[0040] The pH of the material rich in gulonic acid and vitamin C solution is 3.0, and the components are 23.3% of gulonic acid, 16.5% of Vc and 8.6% of sorbose. Under the condition that the operating temperature of the moving bed is 50°C and the walking time is 1200S, the chromatographic separation parameters are as follows:

[0041] Material name

Pure water (L / h)

Raw material(L / h)

Gulonic acid-rich components (L / h)

Vc-rich component (L / h)

flow

3.45

0.45

2.1

0.9

[0042] After three cycles, start to collect the separated components, the composition of which is as follows:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com