Method for synthesizing vitamin C sodium salt

A synthetic method and vitamin technology, applied in the direction of organic chemistry, can solve problems such as low esterification rate, unsatisfactory product color and quality, and long reaction time, so as to increase yield, shorten conversion reaction time, and prolong equipment service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

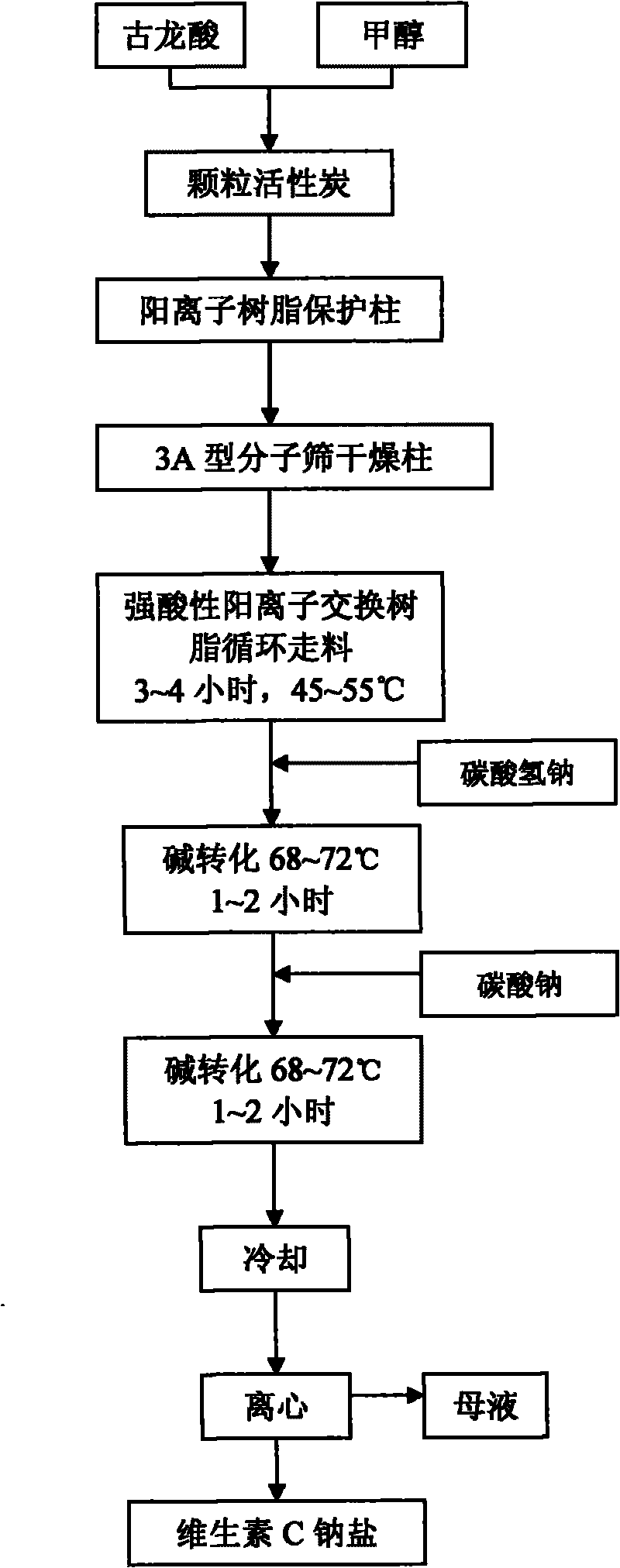

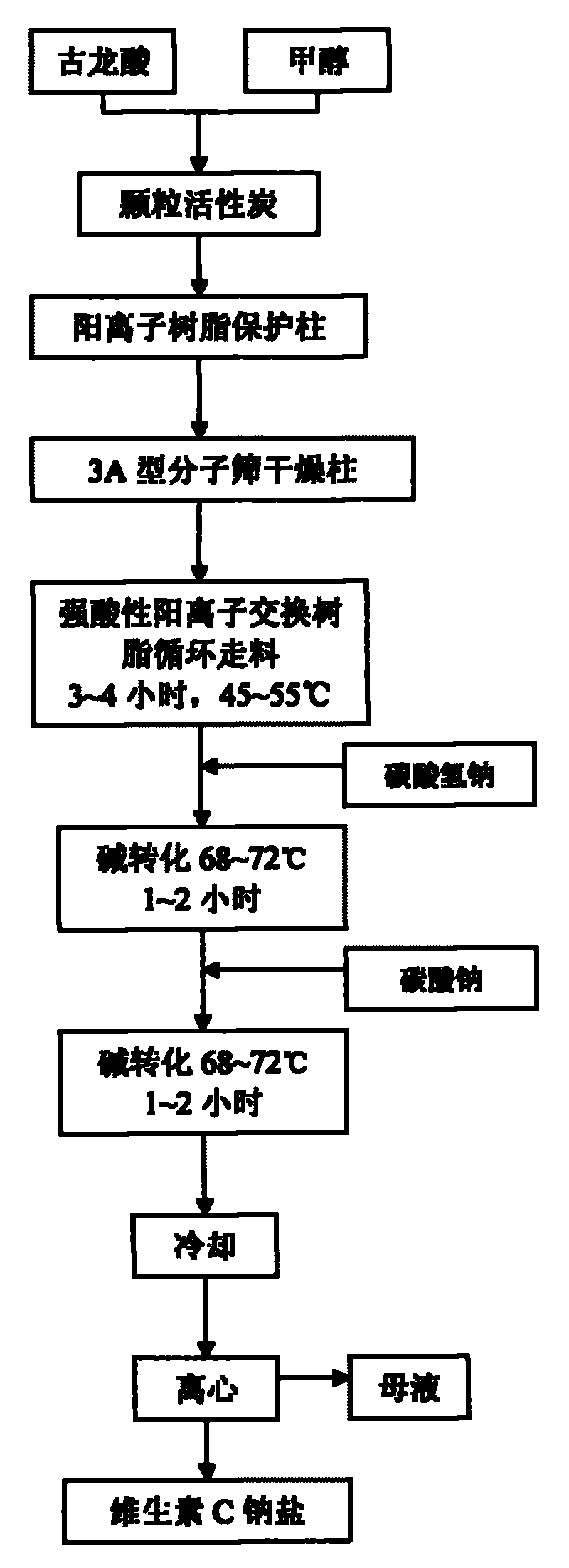

[0021] according to figure 1 As shown in the flow process, (1) take 300g of pure gulong acid with a content of 90.82% and place it in a reaction flask, add 900ml of 99.50% industrial methanol to dissolve the material, and then pass through the granular activated carbon column decolorization and SQD- 67 cation-exchange resin columns to remove metal impurities; (2) the treated methanol solution of guronic acid was filtered through a drying column filled with erionite (commercially available) with an adsorption critical diameter of 3A. (3) Preheating the strongly acidic styrene-based cation-exchange resin column to 50° C. to keep it at a constant temperature, passing the methanol solution of guronic acid through the resin column to circulate the material, and performing an esterification reaction for 3 hours to obtain an esterification reaction solution; (4) The esterification reaction solution was injected into the normal pressure reactor, and 110.4 grams of sodium bicarbonate w...

Embodiment 2

[0023] The technical process is the same as in Example 1, (1) get 91.51% gulong acid pure 300g and place it in a reaction flask, add 99.50% industrial methanol 1200ml to dissolve the material, then pass through the granular activated carbon column at 1 times speed at normal temperature for decolorization and SQD-67 cation exchange resin column removes metal impurities; (2) Guronic acid methanol solution after treatment is filtered through a drying column filled with 3A molecular sieve adsorbent (available from the market); (3) (732) 001× 7 Preheat the strongly acidic cation exchange resin column to 55°C, keep it at a constant temperature, pass the treated guaronic acid methanol solution through the resin column, and circulate the material, and perform esterification reaction for 3.5 hours to obtain an esterification reaction solution; (4) esterification The reaction solution was injected into the normal pressure reactor, and 103.9 g of sodium bicarbonate was added for conversio...

Embodiment 3

[0025] (1) Take 92.28% gulong acid pure 300g and place it in a reaction flask, add 99.50% industrial methanol 1500ml to dissolve the material, and then pass through the granular activated carbon column decolorization and SQD-67 cation exchange resin column at room temperature with a flow rate of 1 times speed Remove metal impurities; (2) the treated gulong acid methanol solution is passed through a drying column filled with 3A molecular sieve adsorbent; (3) the strongly acidic cation exchange resin column is preheated to 60°C to keep it at a constant temperature, and the treated cologne The acid methanol solution was circulated through the resin column to feed, and the esterification reaction was carried out for 4 hours to obtain the esterification reaction solution; (4) the esterification reaction solution was injected into the normal pressure reactor, and 90.9 grams of sodium bicarbonate was added for conversion reaction for 1 hour, and then added 28.7 grams of sodium carbona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com