Method for synthesizing vitamin C crude product by adopting L-gulonic acid

A vitamin and gulonic acid technology, applied in the direction of organic chemistry, can solve the problems of high labor intensity, long centrifugation time, and long process flow, and achieve the effects of improving the production environment, environmental protection of the production process, and simple process production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

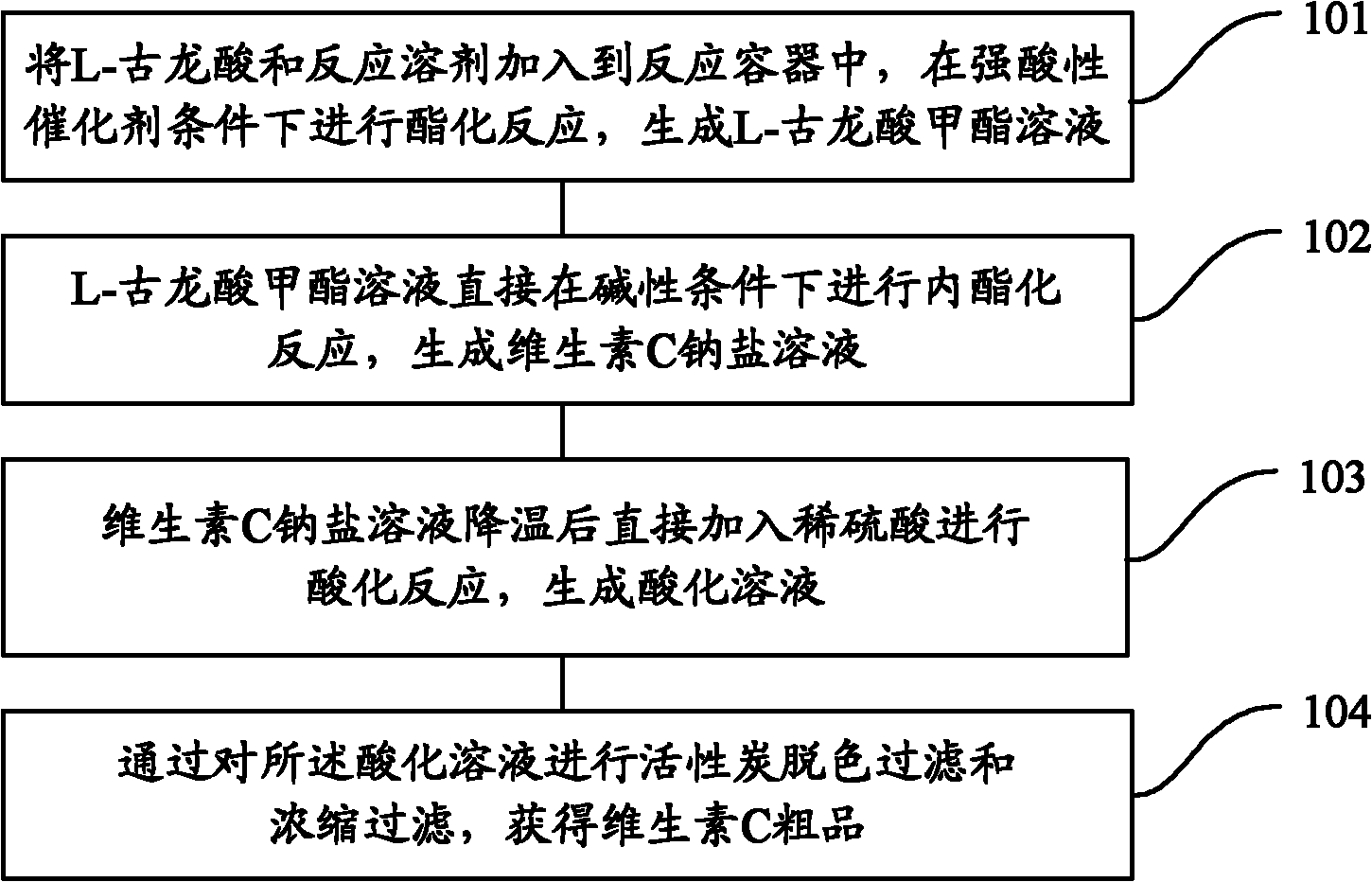

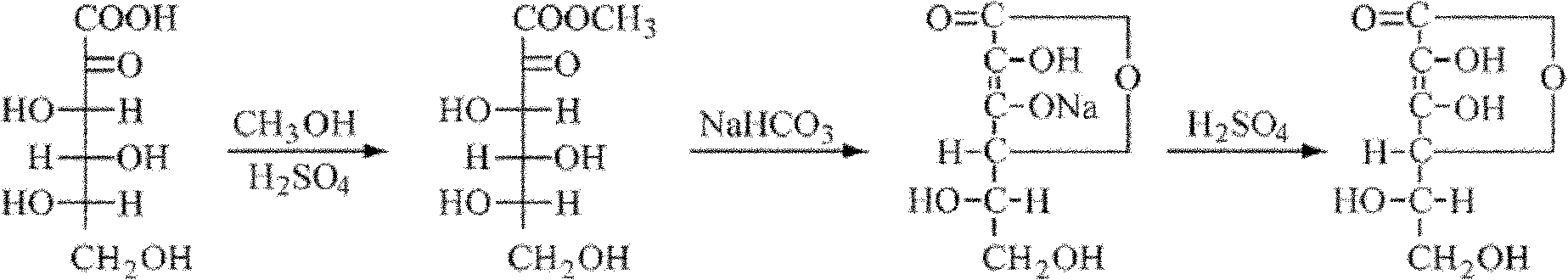

Method used

Image

Examples

Embodiment 1

[0057] Add 1.0mol of L-gulonic acid and 850ml of industrial methanol into a 2000ml reaction flask, add 4.85g of concentrated sulfuric acid at room temperature, raise the temperature to 66°C, and perform esterification for 2 hours. After the esterification reaction, the temperature was lowered to 55° C., an appropriate amount of baking soda (sodium bicarbonate) was added to adjust the pH value of the reaction solution to 9.0, the temperature was raised to 68° C., and the lactonization reaction was carried out for 3 hours. After the lactonization reaction, the temperature of the solution was lowered to 40° C., 55% dilute sulfuric acid was added until the pH of the reaction solution was 1.95, and the acidification reaction was carried out by keeping warm for 2 hours. Finally, the acidified solution is decolorized and filtered with activated carbon, and the filtrate is concentrated and crystallized, and the filtered white crystal is the crude vitamin C product. In Example 1, the p...

Embodiment 2

[0059] Add 1.0mol of L-gulonic acid and 870ml of industrial methanol into a 2000ml reaction flask, add 5.00g of concentrated sulfuric acid at room temperature, raise the temperature to 66°C, and perform esterification for 2 hours. After the esterification reaction, the temperature was lowered to 55° C., an appropriate amount of sodium bicarbonate was added to adjust the pH value of the reaction solution to 8.3, the temperature was raised to 68° C., and the lactonization reaction was carried out for 3 hours. After the lactonization reaction, the temperature of the solution was lowered to 40° C., 55% dilute sulfuric acid was added until the pH of the reaction solution was 1.90, and the acidification reaction was carried out by keeping warm for 2 hours. Finally, the acidified solution is decolorized and filtered with activated carbon, and the filtrate is concentrated and crystallized, and the filtered white crystal is crude vitamin C. In Example 2, the purity detected by HPLC was...

Embodiment 3

[0061] Add 1.0mol of L-gulonic acid and 890ml of industrial methanol into a 2000ml reaction flask, add 5.5g of concentrated sulfuric acid at room temperature, raise the temperature to 65°C, and perform esterification for 2 hours. After the esterification reaction, the temperature was lowered to 53° C., an appropriate amount of sodium bicarbonate was added to adjust the pH value of the reaction solution to 9.3, the temperature was raised to 69° C., and the lactonization reaction was carried out for 3 hours. After the lactonization reaction, the temperature of the solution was lowered to 40° C., 55% dilute sulfuric acid was added until the pH of the reaction material was 1.98, and the acidification reaction was carried out by keeping warm for 2 hours. The acidified solution is decolorized and filtered with activated carbon, the filtrate is concentrated and crystallized, and the filtered white crystal is crude vitamin C. In Example 3, the purity detected by HPLC was 99.5%, the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com