Production method of gulonic acid in production of vitamin C

A production method and technology of gulonic acid, which are applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems of serious environmental pollution, affecting the quality of resin exchange equivalent gulonic acid, consumption of large tap water, etc., to simplify the process, The effect of avoiding waste liquid recovery and treatment problems and saving the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Describe in detail below in conjunction with accompanying drawing and embodiment:

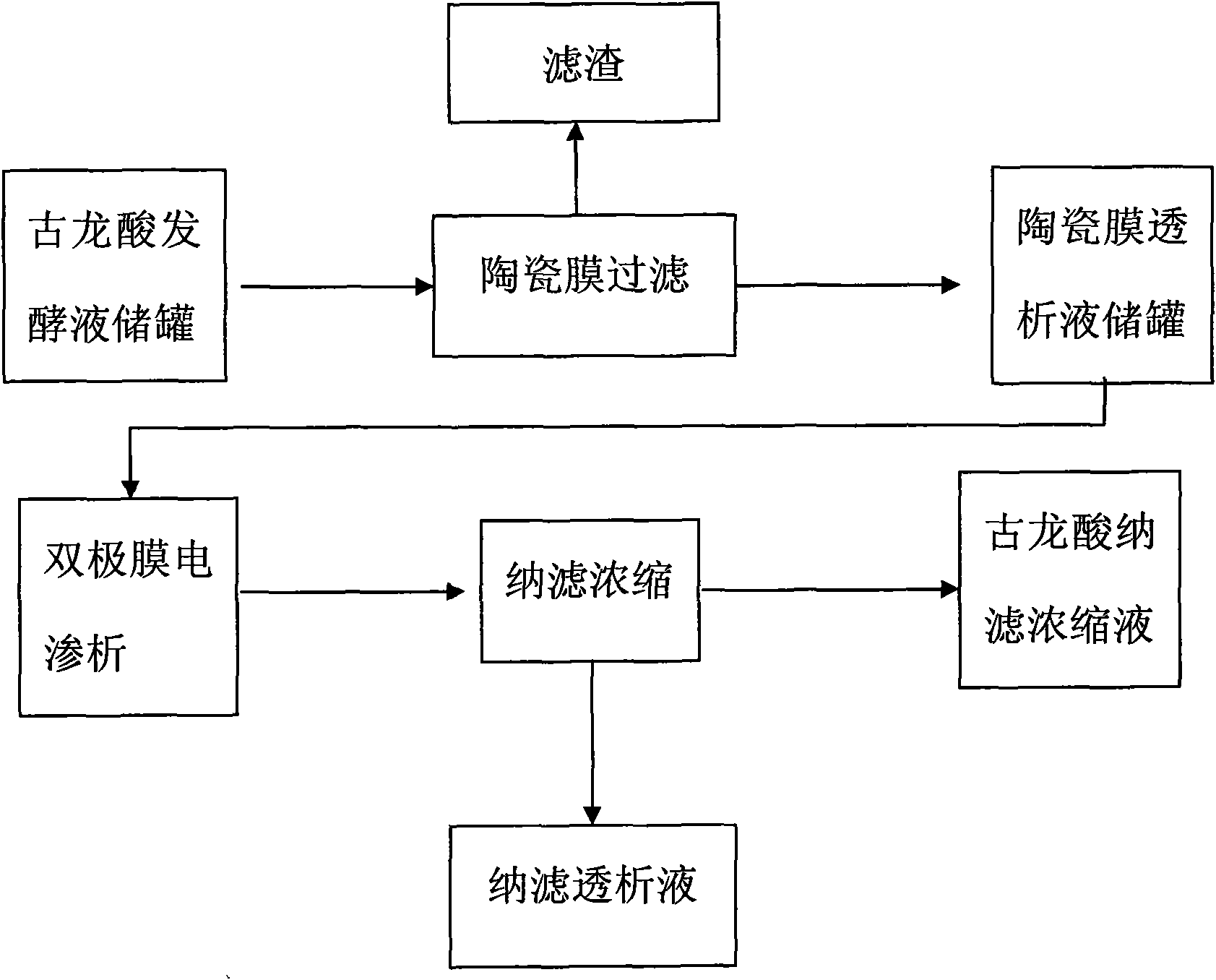

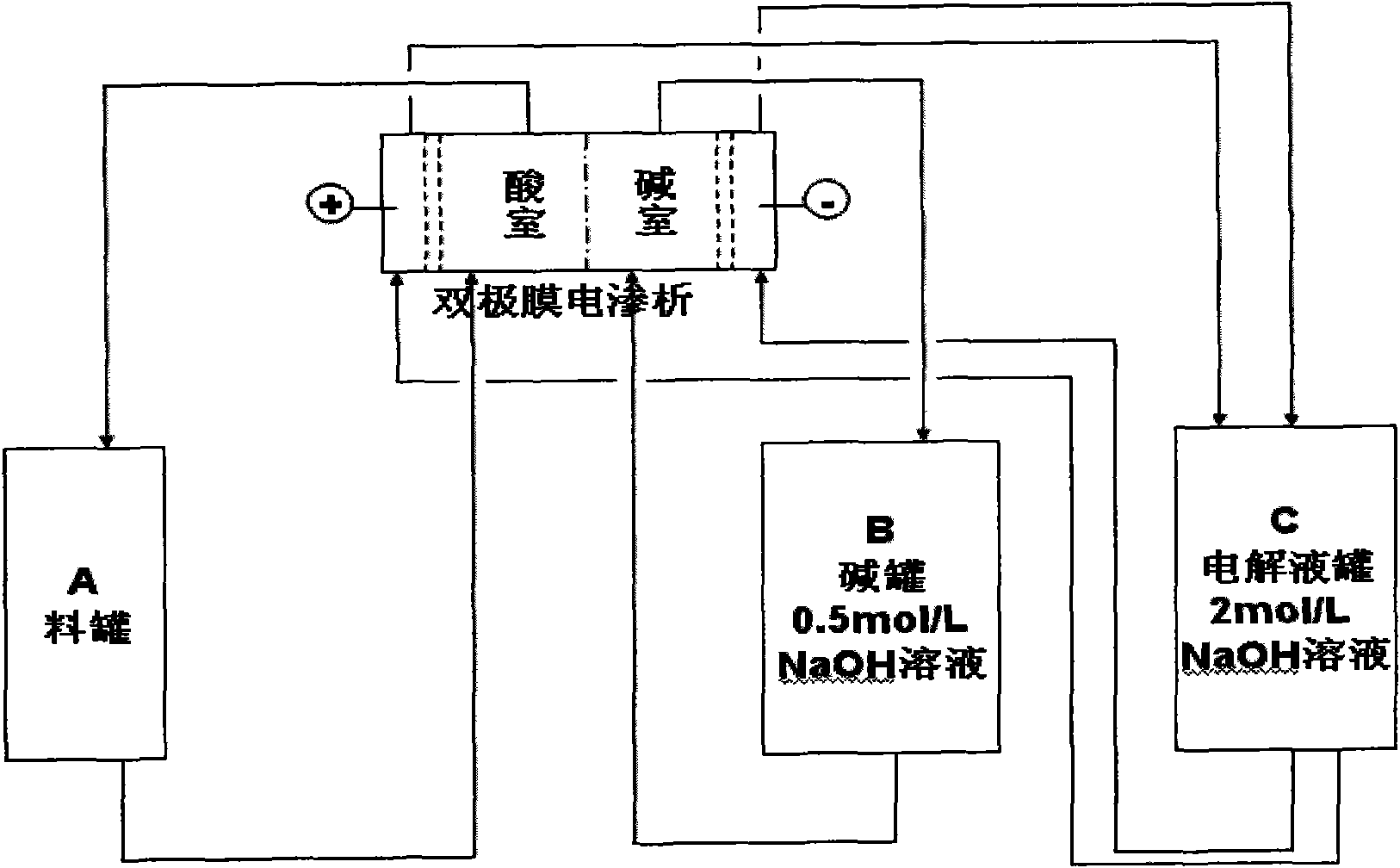

[0034] figure 1 For the purpose of the present invention, the fermented liquid containing gulon acid sodium salt is first filtered through a ceramic membrane with a pore size of 20 to 50 nm, and the filtrate is converted into a guron acid solution through a bipolar membrane electrodialysis system, and the guron acid solution is concentrated by nanofiltration to obtain a nanofiltration concentrate . The concentrated solution can be used for crystallization to make gulong acid crystals.

[0035] The specific operation process is as follows:

[0036] 1. Ceramic membrane filtration experiment

[0037] The feed liquid used is gulong acid fermentation liquid, the ceramic membrane pore size is 20-50nm, the temperature is 30-38°C, and the pressure is 0.15-0.5Mpa. A total of 3 batches of experiments have been carried out.

[0038] The specific results are shown in Table 1:

[0039] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com