Gulonic acid adsorption separation method utilizing hyper-crosslinked resin

An ultra-high cross-linked resin, adsorption and separation technology, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of many unit operations, pollution, and large consumption of ion exchange resins, etc., to achieve Effects of avoiding environmental pollution, large adsorption capacity, and reducing waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: Obtaining of gulonic acid feed solution.

[0047] The percentage content of gulonic acid in the fermented liquid obtained by Bacillus megaterium and Ketogulonicigenium vulgare fermentation is 35% (w / w), and its fermentation process is as follows: Prepare plate culture medium: 8.0% L-sorbose, 1.0% corn steep liquor, 0.2 % urea, 0.1% KH 2 PO 4 , 0.01% MgSO 4 ·7H 2 O, 0.5% NaCl, 1.5% agar was sterilized at 121°C for 15min. The pH of the fermentation broth was adjusted to about 7.0. Add half of the nutrients initially, and then gradually add them later. Cultivate in a Bugbox anaerobic tank at 37° C. for 72 h with a stirring speed of 300 rpm. Gulong acid ~ 35g / L in the obtained fermentation broth, residual L-sorbose<1g / L.

[0048] The above-mentioned Bacillus megaterium and Ketogulonicigenium vulgare can be replaced by other bacillus to realize the fermented liquid containing gulonic acid prepared by fermentation of different strains.

[0049] The ferme...

Embodiment 2

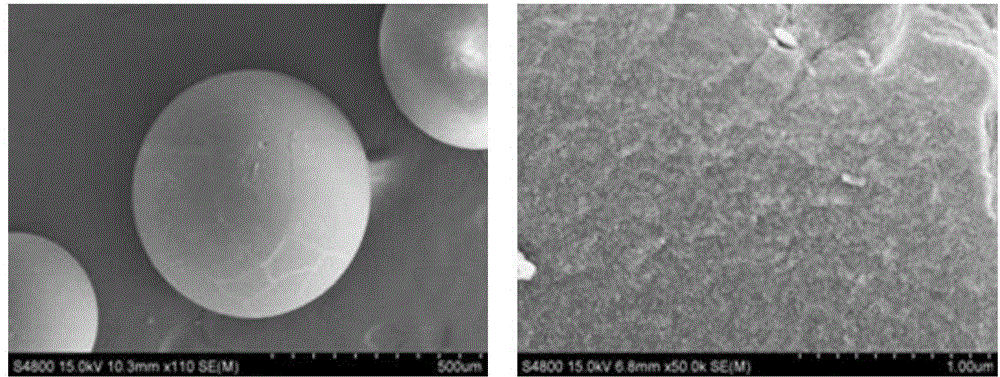

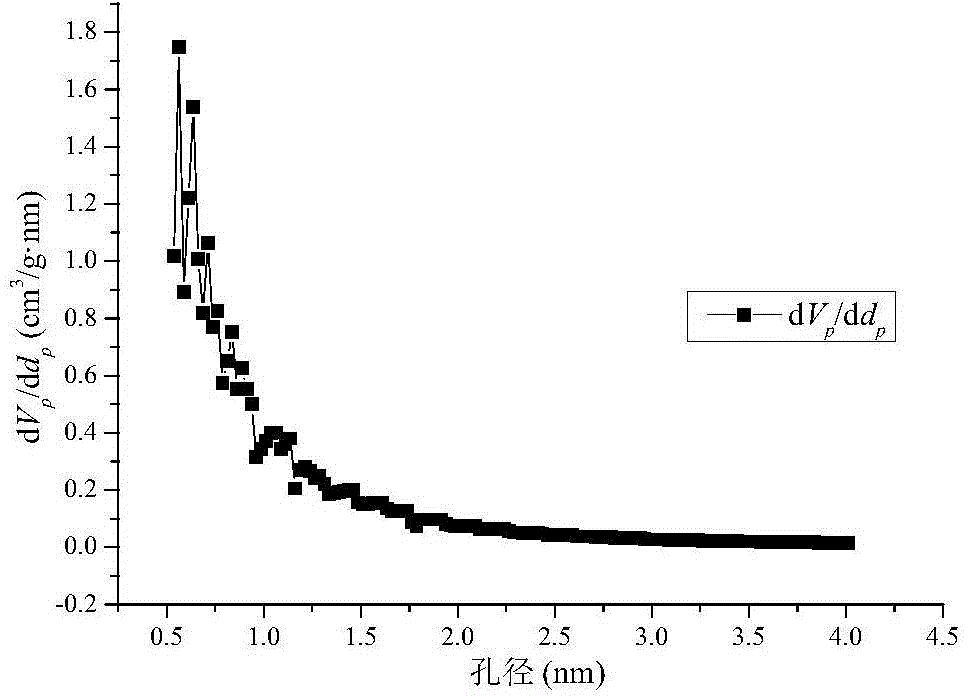

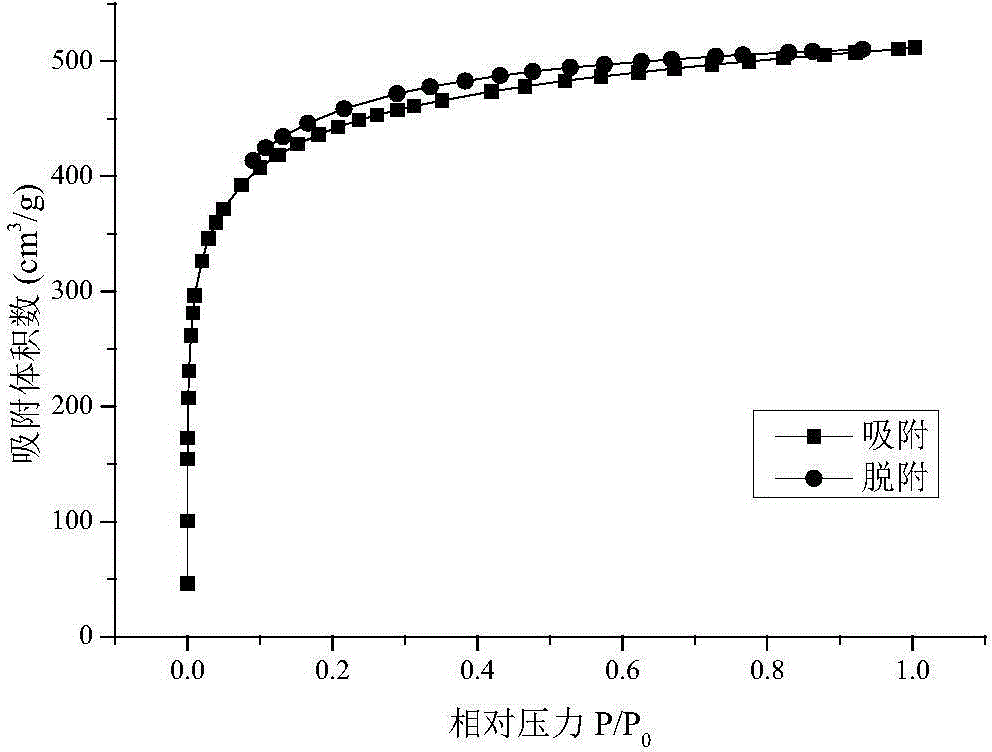

[0050] Example 2: Preparation of ultra-high cross-linked resin HD-01.

[0051] In a 2000mL three-necked flask, add 200g of dry chloromethylated polystyrene resin, add 1500g of nitrobenzene, stir and mix well and fully swell at room temperature for 2 hours, add 12g of aluminum trichloride and 40g of divinylbenzene, and stir at room temperature After reacting for 1 hour, the temperature was raised to 95° C. at a rate of 1° C. / min to carry out the cross-linking reaction. After reacting for 8 h, 300 mL of ethanol was added to stop the reaction, and cooled to room temperature. Suction filtration, wash off the residual solvent and catalyst with ethanol, and vacuum dry to obtain the weak polar ultra-high cross-linked resin HD-01. The obtained product is in the shape of dark brown round particles, with an average particle size of 0.42-0.56mm, a water content of 43wt%, a pore size of 1.92nm, a porosity of 30-40%, and a wet density of 1.09g / cm 3 , the average specific surface area is ...

Embodiment 3

[0052] Embodiment 3: Pretreatment of ultra-high cross-linking resin HD-01.

[0053] Rinse the resin with 2BV 1mol / L HCl solution at a flow rate of 1BV / h, and then wash with water until neutral; wash the resin with 2BV 1mol / L NaOH solution at a flow rate of 1BV / h, and then wash with water until neutral; finally use 2BV Rinse the resin with ethanol at a flow rate of 2BV / h, wash away the ethanol with deionized water, and set aside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Wet density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com