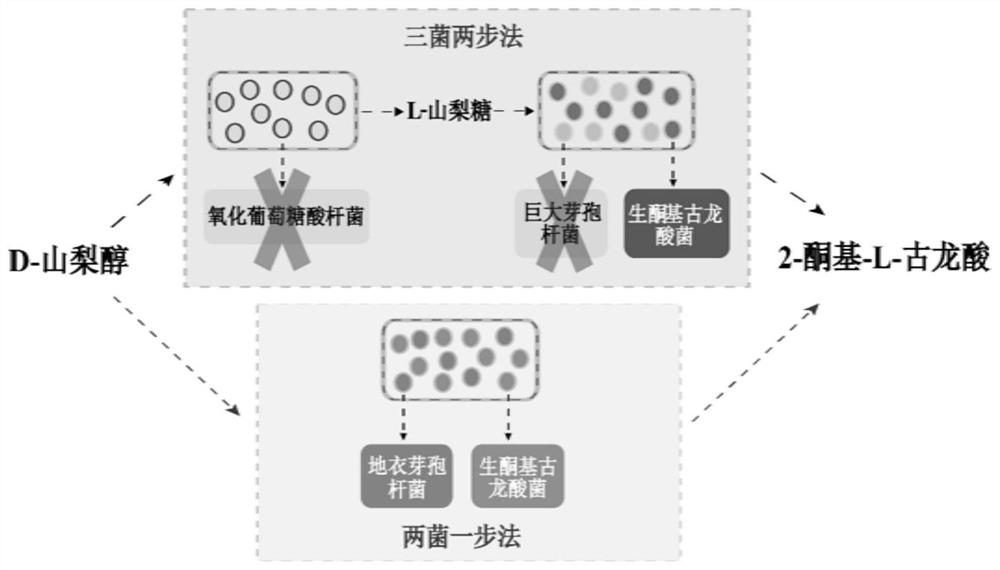

A kind of method for fermenting and producing vitamin C precursor 2-keto-l-gulonic acid

A technology for gulonic acid and vitamins, which is applied in the field of fermentation production of 2-keto-L-gulonic acid, can solve problems such as affecting conversion efficiency, and achieve the effects of good side effects, improved stability, and improved conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

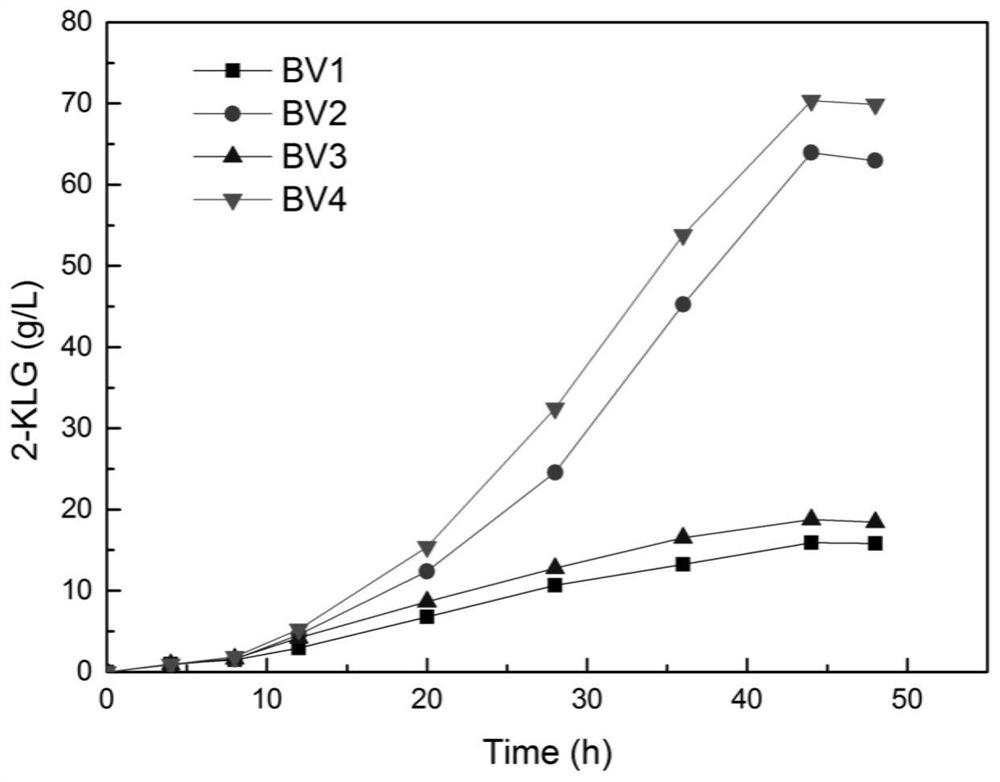

[0035] Example 1 Screening of Bacillus licheniformis with high activity of D-sorbitol dehydrogenase (SLDH)

[0036] Medium: sorbitol 2%, yeast extract powder 0.5%, K 2 HPO 4 0.3%, MgSO 4 ·7H 2 O 0.1%, Sodium Glutamate 0.1%. Sterilization of various media was carried out at 121°C for 20 minutes in a high-pressure steam sterilizer.

[0037] Screening: Wash and scrape the activated slant bacteria with sterile physiological saline to prepare a bacterial suspension, dilute it appropriately, spread it on a plate, and place it in an incubator at 28°C for 72 hours. Pick a single colony on a solid slant medium, and then place it in an incubator at 28°C for 72 hours. Shake flask culture, detect bacterial biomass and sorbitol dehydrogenase activity, thereby select the strain with the highest biomass and sorbitol dehydrogenase activity.

Embodiment 2

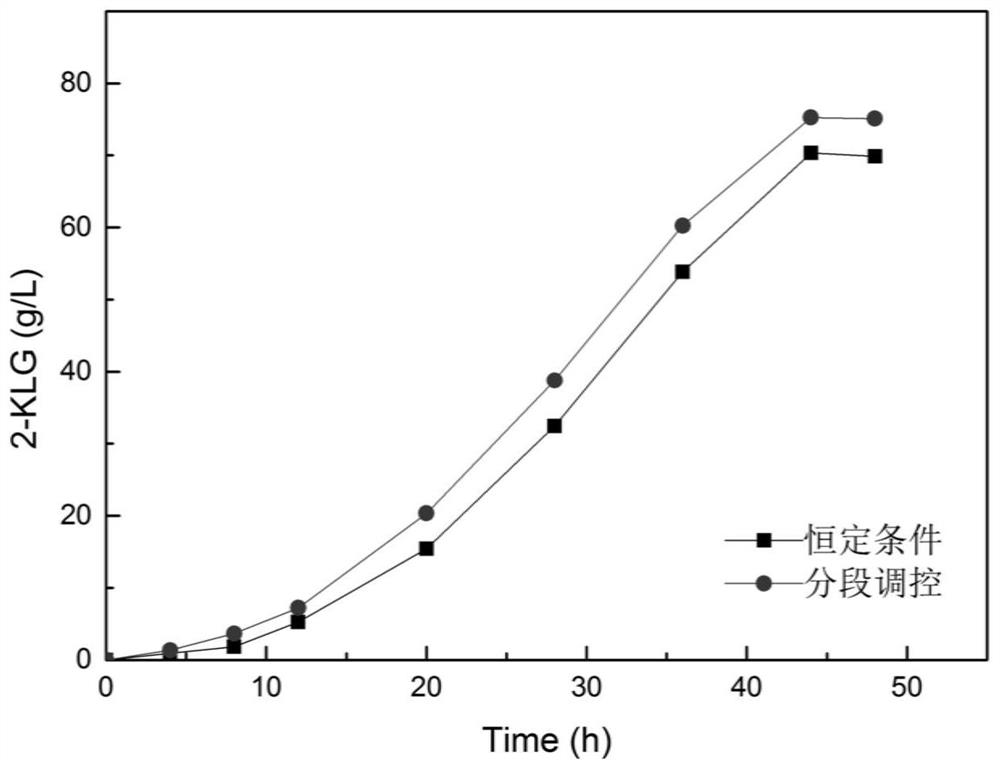

[0038] Embodiment 2 mutagenesis improves bacillus licheniformis D-sorbitol dehydrogenase (SLDH) activity

[0039] According to the measured bacterial cell growth curve, the logarithmic phase of bacterial cell growth is reached when the OD600 value is 0.6-0.8. Use a suction gun on the ultra-clean workbench to draw an appropriate amount of bacterial suspension and dilute it with normal saline to an appropriate multiple, then draw 10 μL of the diluted bacterial suspension onto the special carrier sheet for ARTP equipment mutagenesis, and put it into the ARTP equipment for mutagenesis treatment. The mutagenesis time was set as 50s, 60s, 70s, 80s, 90s and 100s. After the mutagenesis treatment is completed, take out the carrier sheet, put it into a 2mL sterile PE tube prepared in advance and add 1mL of normal saline, and then place the PE tube on a rotary shaker for 2-3 minutes to make the PE tube The bacteria in the medium were mixed evenly; at the same time, 10 μL of the diluted ...

Embodiment 3

[0040] The mensuration of embodiment 3 sorbitol dehydrogenase enzymatic activity

[0041] The enzyme reaction system includes 100mM Tris-HCl buffer solution (pH 9.0), 1mM NAD+50mM sorbitol, an appropriate amount of mutagenized Bacillus licheniformis cells, and measures the rise of absorbance at 340nm at 30°C. Enzyme activity is defined as the amount of enzyme needed to generate 1 μmol NADH per minute as one enzyme activity unit U.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com