Cultivation method of ketogulonigenium sp

A technology of ketoglobulina and its cultivation method, which is applied in the field of cultivation of ketoglobulina, and can solve problems such as application limitations of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

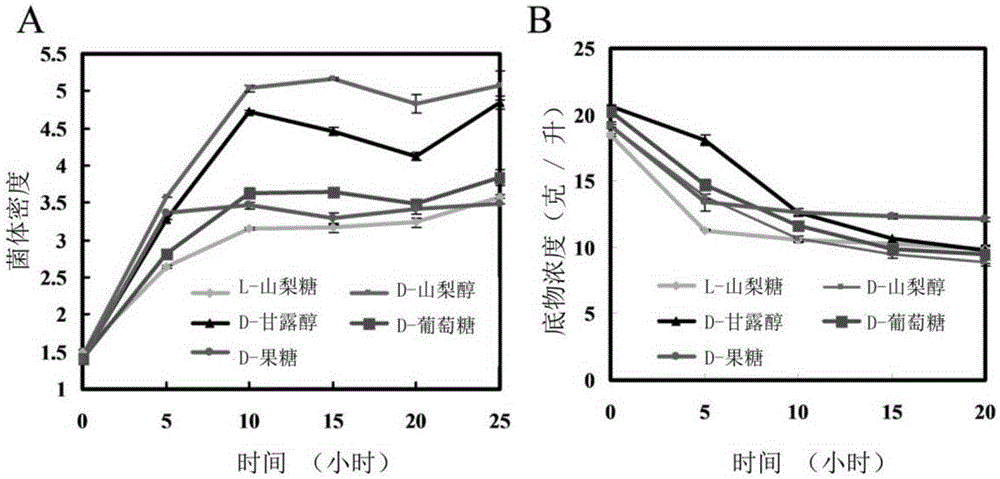

[0040] Taking the growth of sorbose-added seed medium as a control, sorbitol, mannitol, fructose, and glucose, which have similar molecular weights to sorbose, were selected as carbon sources that were more beneficial to their growth. Compared with raw materials that are easier to obtain in large-scale industrial applications, sorbitol, as a precursor of sorbose, is cheaper. K.vulgare was cultured for 48 hours to observe the growth and substrate conversion over time, as shown in the figure. The growth of K.vulgare in sorbitol and mannitol was significantly better than that in sorbose, which was 40.72% and 62.97% higher than that in sorbose, which may be related to their transport into the bacteria to participate in multi-step reactions. The curves of the consumption rate of the five substrates over time were obtained by high performance liquid chromatography, such as figure 1 shown. See Table 1 to Table 10 for the original data:

[0041] figure 1 A's original data:

[004...

Embodiment 2

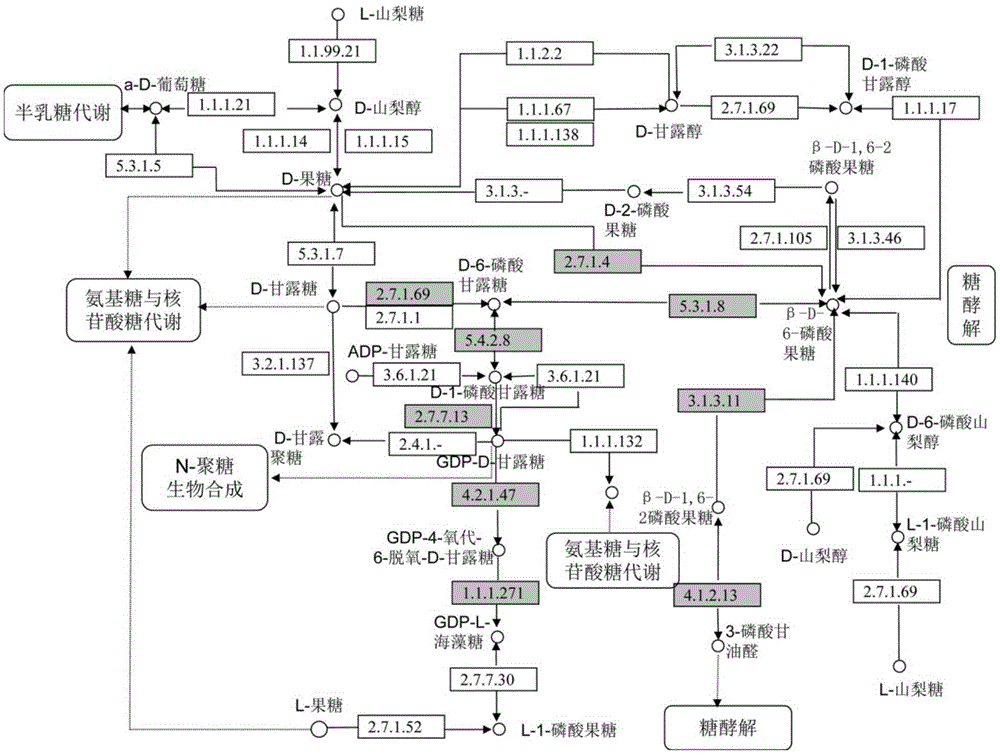

[0065] With the help of next-generation sequencing technology, the whole genome sequencing results of the strain were obtained, and a chromosome and two plasmids were obtained, and the sequences were submitted to the website of the National Center for Biotechnology Information (NCBI) in the United States, and the obtained numbers were CP012908, CP012909 and CP012910 . With the help of KEGGserver online analysis software to obtain the main metabolic pathway for substrate utilization, it was found that the key conversion pathway of carbohydrates in Bacillus ketogenes was seriously lacking. The utilization of different monosaccharides may be mainly realized by its large number of transmembrane dehydrogenase proteins.

Embodiment 3

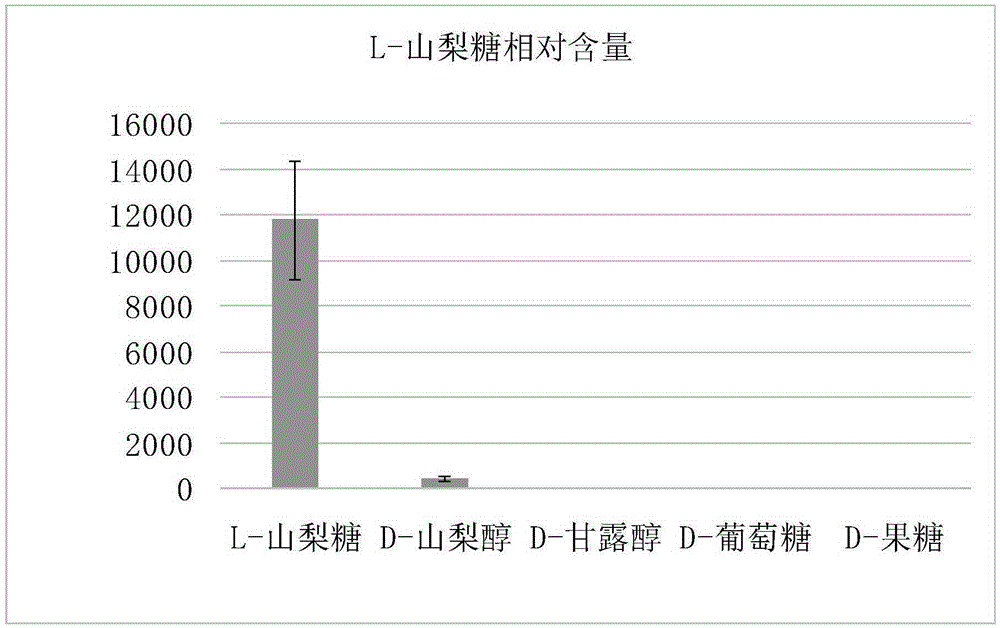

[0067] In order to further observe the metabolic changes after the utilization of different substrates in cells, the changes of intracellular metabolites in the logarithmic growth phase (12 hours) were obtained by means of metabolomics analysis, and the relative differences of different acidic products were obtained. Among them, sorbitol and 2-keto-L-gulonic acid were detected when sorbitol was used as the substrate. It shows that the strain also has the mechanism of metabolizing sorbitol to produce acid. Mannose was detected when mannitol was used as the substrate. In addition, under the five substrates, the products 2-keto-D-gluconic acid, L-gluconic acid, glucaric acid, and D-gluconic acid have obvious differences, which are related to different metabolic methods. The raw data are shown in Tables 11-15 (relative quantity, no unit):

[0068] Table 11 The content of different products in the cells under the addition of sorbose in the logarithmic phase

[0069]

[0070] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com