Ketogulonigenium vulgare lacking ED metabolic pathways and 2-KGA production method thereof

A technology of gulonic acid and gulonic acid bacteria, which is applied in the field of microbial fermentation, can solve the problems of unseen natural ketogronic acid bacteria and genetically engineered strains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: See SEQ ID: 1, SEQ ID: 2, SEQ ID: 3, and SEQ ID: 4 for the four key enzymes lacking in ketoglobulina SPU B805 and their gene sequences.

Embodiment 2

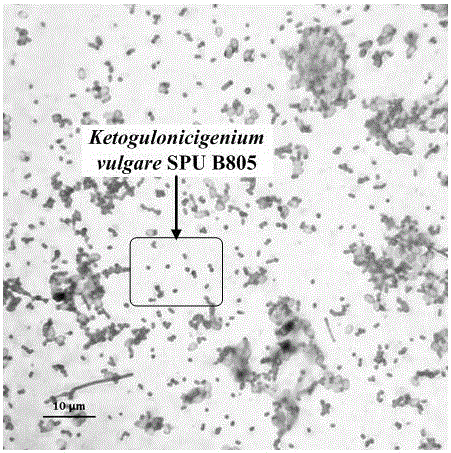

[0039] Implementation example 2: biological characteristics of ketoglobulina SPU B805

[0040]After Gram staining, SPU B805 is a Gram-negative brevibacterium, which can form short chains or filaments, but cannot form spores. The bacterium was grown on the slant medium for 4 days, and its colony form was point-like, raised, complete, smooth circular colony, and the surface of the colony was oily, transparent, and brown pigment was produced.

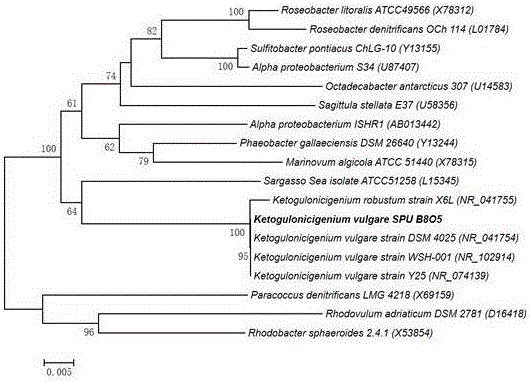

[0041] Genomic DNA of strain SPU B805 was extracted, and Primer(S): 5'AGA GTT TGA TCC TGG CTC AG3'; and Primer(A): 5'AAG GAG GTG ATC CAG CCG CA 3' were used as primers for PCR amplification of 16s rRNA After the gene was purified, the gene was sequenced, and the measured sequence was compared with the rRNA homologous sequence in Genbank, and 7 strains with high homology were selected, and the phylogenetic tree of the strain was constructed using the software Mega5. Strain SPU B805 had the highest homology with Ketogulonicigenium vulgare. ...

Embodiment 3

[0042] Implementation example 3: strain SPU B805 shake flask fermentation characteristics

[0043] The mixed bacteria slant (SPU B805 and Bacillus megaterium) was inoculated in the seed medium, and after 18 hours of shaking flask culture at 30°C and 220rpm, it was inoculated in the fermentation medium with 15% replanting amount, and the fermentation medium contained 8% Sorbitose, cultivated at 26-34°C, shaking at 220r / min for 44h. Samples were taken every 4 hours, and the yield and conversion rate of 2-KGA were measured. The experimental results are shown in Table 2. It can be seen that the fermentation of the strain SPU B805 at 32°C for 36 hours can complete the fermentation, and the average conversion rate of 2-KGA can reach 95.34%.

[0044] Table 2. Shake flask fermentation characteristics of strain SPU B805.

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com