Engineering strain for efficient biosynthesis of glucaric acid (GA) and application of engineering strain

A technology of glucaric acid and engineering strains, which is applied in the field of engineering strains for efficient biosynthesis of glucaric acid, can solve the problems of difficulty in obtaining high-yield glucaric acid, long metabolic pathways, and low glucaric acid yield, etc., and achieves the concentration of the product. The conversion rate of the reaction is improved, the conversion route is short, and the production cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Construction of recombinant escherichia coli

[0032] Udh genomes derived from Pseudomonas synxantha strain KENGFT3 (Pseudomonas synxantha strain KENGFT3) and Pseudomonas fragilis P121 (Pseudomonas fragi strain P121) were respectively used as templates to amplify glucuronate dehydrogenase (Udh) primers F1, R1, F2, R2, primers are as follows:

[0033] F1: 5'-ATGCGTCCGGCGTAGA-3'

[0034] R1: 5'-GATTATGCGGCCGTGTACAA-3'

[0035] F2: 5'-TTGTACACGGCCGCATAATC-3'

[0036] R2: 5'GCTAGTTATTGCTCAGCGG3'

[0037] Introduce the Udh gene into the pETDuet-1 vector, connect it through the restriction site, construct the recombinant plasmid pETDuet-2×Udh, and transform the expression vector into the host strain E.coli BL21(DE3); spread / streak on the plate , select the positive clones to extract the plasmid, and verify it by enzyme digestion and electrophoresis. The verification is correct and sent to Shanghai Shining Molecular Biotechnology Co., Ltd. for sequencing. The...

Embodiment 2

[0038] Embodiment 2: Recombinant escherichia coli produces glucaric acid

[0039] Pick a single colony from the LB plate containing ampicillin antibiotic resistance, inoculate it into a 25mL test tube containing 5mL medium, and cultivate it at 37°C and 220rpm for 12h; transfer the cultured seed solution to In a 250mL Erlenmeyer flask with 50mL LB medium, culture at 37°C and 220rpm, when OD 600 When the value was 1.0, 0.1mM TPTG was added for induction, and cultured at 32°C and 220rpm for 18h; after the cultivation, 1mL of fermentation broth was taken and centrifuged at 12000rpm for 5min. Take 0.9 mL supernatant, add 50 mg Affi-Gel for treatment, and filter the treated liquid through a 0.22 μm filter membrane for mass spectrometry and liquid phase analysis.

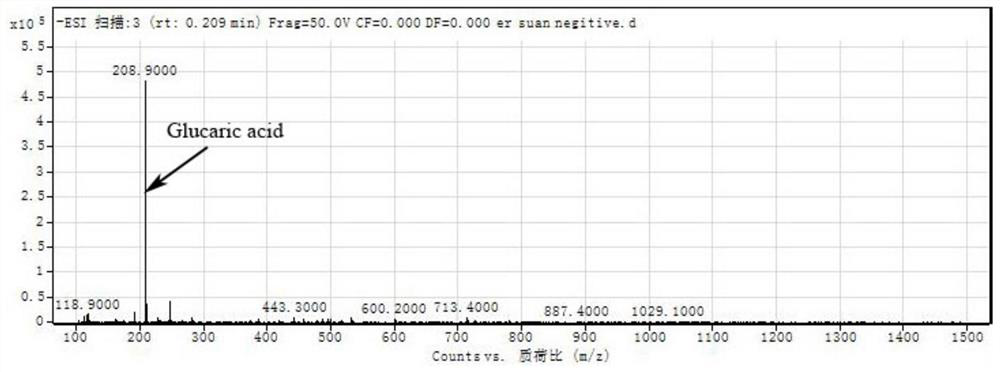

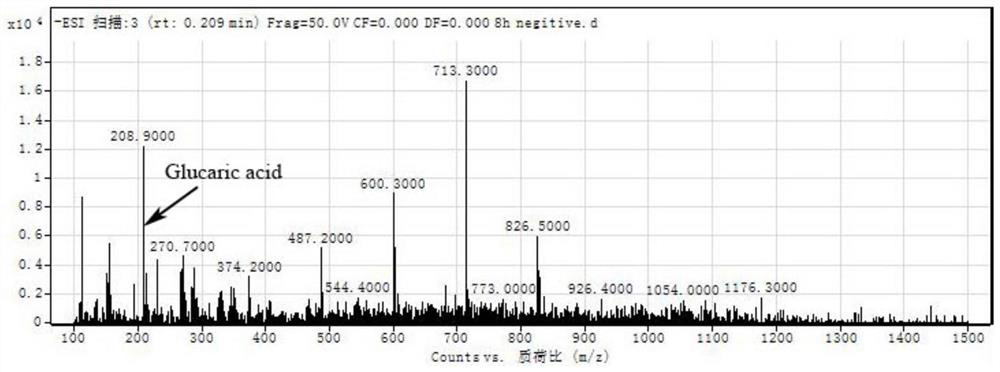

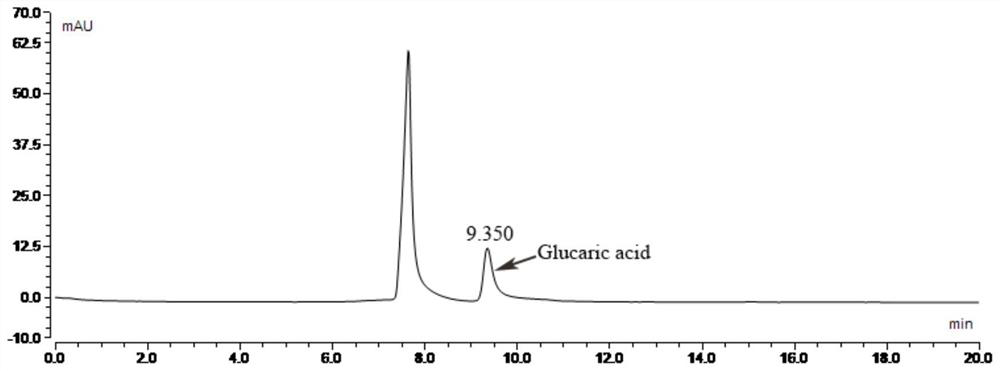

[0040] Such as Figure 1-4 as shown, figure 1 , image 3 They are the mass spectrogram of the glucaric acid standard and the liquid chromatogram of the glucaric acid standard respectively, and the [M-1] of the glucaric...

Embodiment 3

[0041] Embodiment 3: the method that recombinant escherichia coli prepares glucaric acid

[0042] Recombinant Escherichia coli was inoculated on the LB solid medium, and the medium composition was (g / L): tryptone 10, yeast extract 5, sodium chloride 10, agar 15, pH 7.0, and the concentration of ampicillin finally reached 100 μg / L. mL, incubate at 37°C for 16h; pick a single colony and inoculate it on LB slant medium, and incubate at 37°C for 24h; take a loop and inoculate in a 25mL test tube containing 5mL LB liquid medium, at 36.5°C, 220rpm , shaker culture 12h;

[0043] Inoculate the bacterial liquid in the test tube into a 250mL shake flask containing 50mL LB medium at an inoculum amount of 1%, the concentration of ampicillin finally reaches 100μg / mL, the pH is 6.9, and culture on a shaking table at 36°C and 220rpm 2-3h, to OD 600 When the value reaches 0.6, add IPTG to make the final concentration reach 0.4mM, and culture on a shaker at 32°C and 220rpm for 24h;

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com