Patents

Literature

102results about How to "Green production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural osmanthus fragrans fragrant tea seed oil and preparation method thereof

ActiveCN103642583AGreen smellEnvironmental protectionFatty-oils/fats refiningFatty-oils/fats productionCAMELLIA SINENSIS SEED OILChemistry

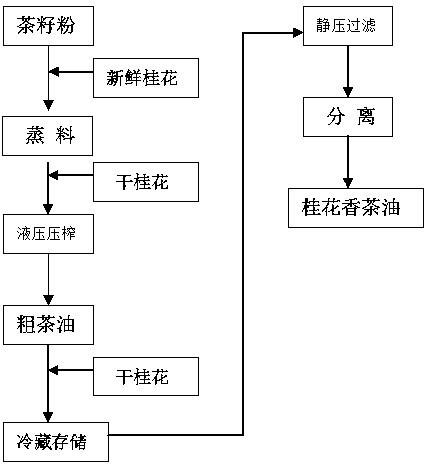

The invention discloses natural osmanthus fragrans fragrant tea seed oil and a preparation method thereof. The preparation method comprises the steps: firstly, respectively filling water, fresh osmanthus fragrans flowers and tea seed powder into a bottom layer, a middle layer and an upper layer of a steam cooker; secondly, raising the temperature by heating to enable the bottom layer to generate vapor, introducing the vapor into the fresh osmanthus fragrans flowers at the middle layer, enabling the vapor to penetrate through the osmanthus fragrans layer and enter the tea seed powder, and enabling the tea seed powder to fully absorb osmanthus fragrans fragrance to obtain osmanthus fragrans fragrant tea seed powder; thirdly, mixing the osmanthus fragrans fragrant tea seed powder and dry osmanthus fragrans flowers, and squeezing a mixture to obtain crude osmanthus fragrans fragrant tea seed oil; fourthly, pouring the crude osmanthus fragrans fragrant tea seed oil into a stainless steel barrel which contains the dry osmanthus fragrans flowers with a proper amount, sealing, and storing at low temperature; fifthly, filtering to obtain a natural osmanthus fragrans fragrant tea seed oil product. The fragrance of the natural osmanthus fragrans fragrant tea seed oil product is mixed by strong natural osmanthus fragrans fragrance and light natural tea seed oil fragrance. The natural osmanthus fragrans fragrant tea seed oil is simple in the process, is green, is environment-friendly and has the actions of refreshing the brain, raising up the spirit, tenderizing the skin, delaying senescence and the like; the quality and the taste of the natural osmanthus fragrans fragrant tea seed oil are obviously superior to those of ordinary tea oil.

Owner:湖南金叶油业有限公司

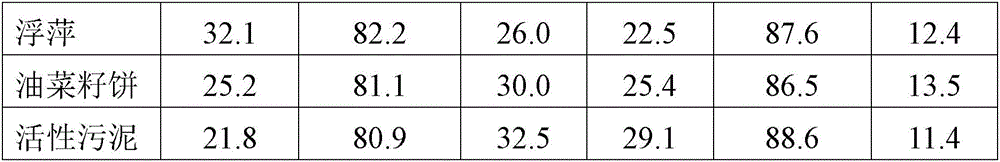

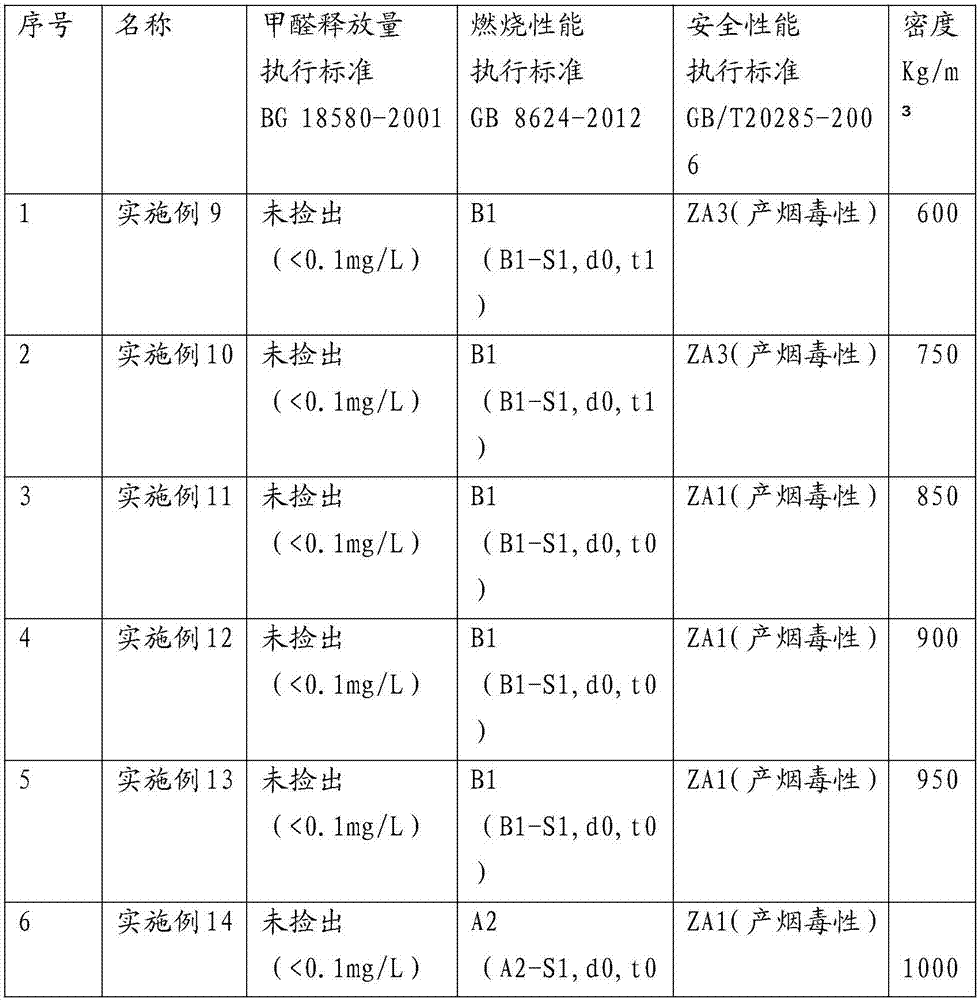

Flame retardant environmentally friendly adhesive and producing method of plant fiberboard

ActiveCN105331294ARaw materials are easy to getFlame retardantNon-macromolecular adhesive additivesWood working apparatusFire retardantFiberboard

The present invention provides a flame retardant environmentally friendly adhesive, and the raw materials comprise magnesium sulfate, magnesium chloride, water, magnesium oxide, sodium dihydrogen phosphate, boric acid, and methyl cellulose. The flame retardant environmentally friendly adhesive is a formaldehyde-free environmentally friendly inorganic adhesive, not only has flame-retardant effect, but also can make a plant fiberboard highly stable in fiber structure and high in mechanical properties, and also allows the plant fiberboard to have waterproof, moistureproof, fireproof, rot-resistant, pest control and other functions; in addition, the flame retardant environmentally friendly adhesive has readily available raw materials, and cheap in price, so that the production cost of the flame retardant environmentally friendly adhesive is relatively low. The present invention also provides a producing method of the plant fiberboard by use of the flame retardant environmentally friendly adhesive.

Owner:河南国信联投环保科技有限公司

Method for producing aluminum-magnesium alloy by utilizing liquid aluminum cathode method

The invention discloses a method for producing an aluminum-magnesium alloy by utilizing a liquid aluminum cathode method. The method is used for high-efficiently producing the high-quality aluminum-magnesium alloy. The method comprises the following steps of dissolving the high-purity magnesium oxide (MgO) in an electrolyte system consisting of Na3PO3-MgF2-NaCl in an electrolytic cell under the electrolytic temperature of 850DEG C to 900DEG C, wherein the aluminum liquid which is formed by melting a high-purity aluminum ingot is used as a liquid cathode; and applying a coil magnetic field with the intensity of 30mT to 40mT outside the electrolytic cell so as to enable the aluminum liquid to rotate under the electrolytic conditions that the anode current density is 0.47 to 0.52A / cm<2> and the high-purity graphite is adopted as an anode, reducing the magnesium ions on the rotating aluminum liquid cathode into elemental magnesium under the electromagnetic stirring effect to be uniformly dispersed into the aluminum liquid so as to form the aluminum-magnesium alloy product, and producing CO2 gas on the anode. The alloy prepared through the method is uniform in components and contains no impurity. The production process is continuous and easy to control.

Owner:UNIV OF SCI & TECH LIAONING

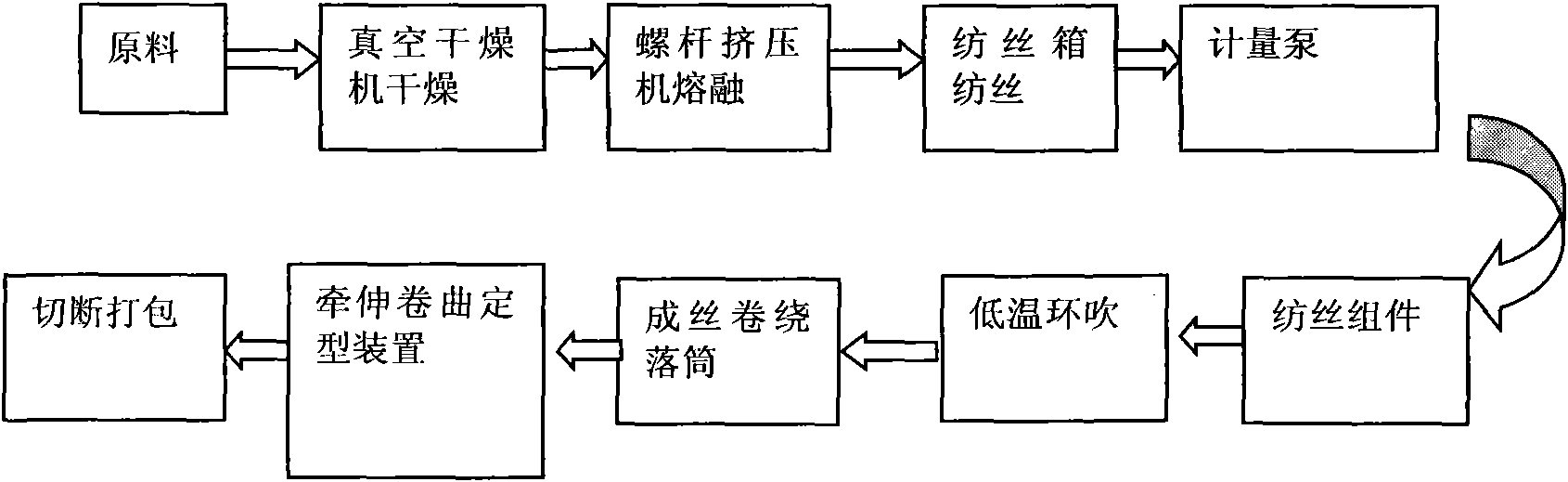

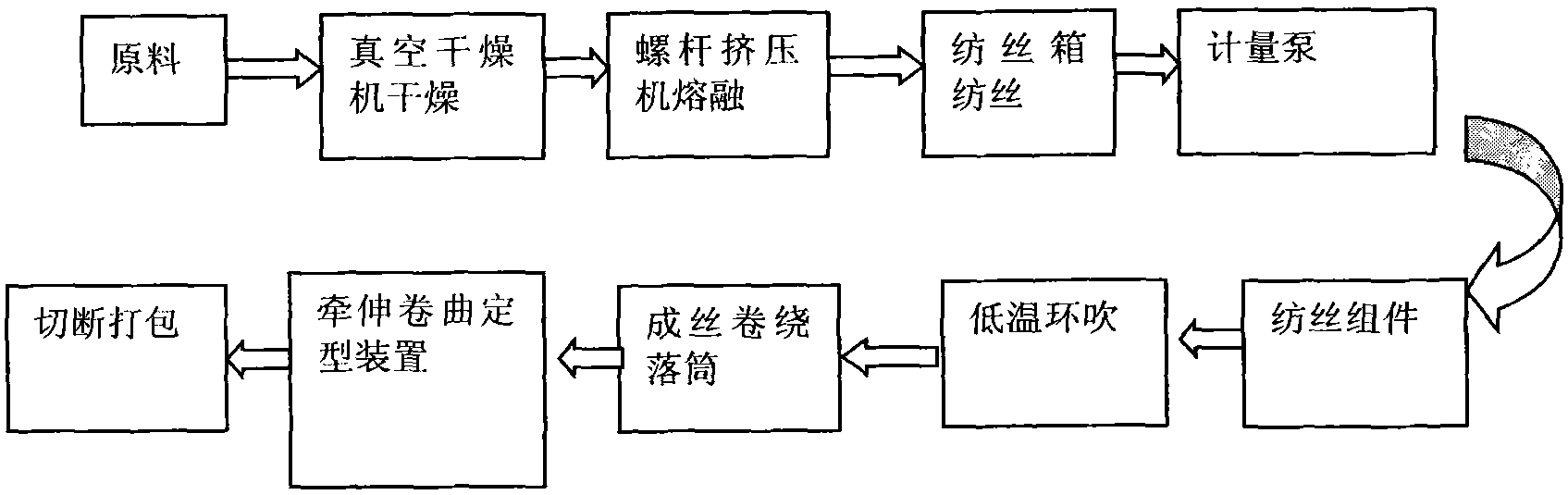

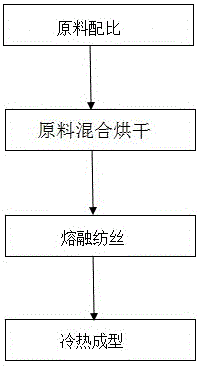

Process for producing nanometer bamboo carbon fiber by adopting polylactic acid group

ActiveCN101857981AGreen production processNo petrochemicalMelt spinning methodsMonocomponent polyesters artificial filamentFiberSpinning

The invention discloses a process for producing nanometer bamboo carbon fiber by adopting a polylactic acid group. In the process, the nanometer bamboo carbon fiber is produced from polylactic acid as a carrier and nanometer bamboo carbon powder by a dry spinning technology. The nanometer bamboo carbon fiber produced by the invention has the advantages of greenness, environmental protection, easy recovery and degradation, low carbon emission during production, simple production process, easy operation and low cost.

Owner:ANHUI HANLIAN TEXTILE CO LTD

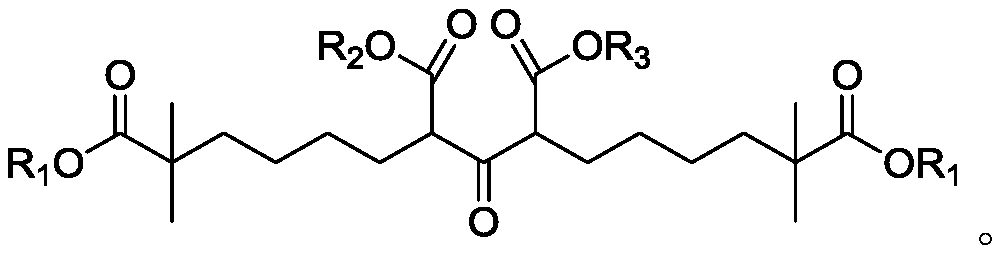

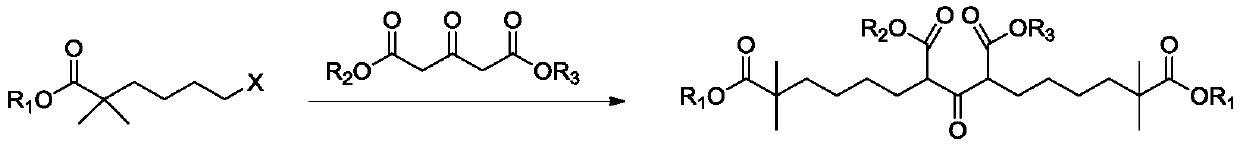

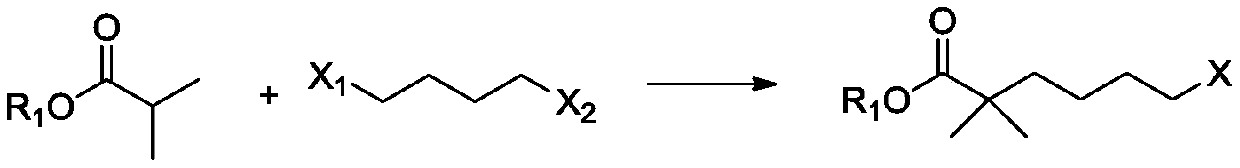

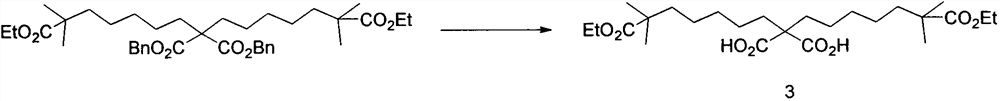

Compound and method for synthesizing 8-hydroxy-2,2,14,14-tetramethyl pentadecanedioic acid by adopting compound

ActiveCN111170855AReduce usageShort reaction stepsOrganic compound preparationCarboxylic acid esters preparationChemical synthesisBiochemical engineering

The invention belongs to the field of chemical synthesis, and relates to a compound with a structural formula as described in the specification. In the structural formula, R1, R2 and R3 are independently selected from C1-C6 alkyl groups, alkenyl groups and cycloalkyl groups respectively. The invention also provides a method for synthesizing 8-hydroxy-2,2,14,14-tetramethyl pentadecanedioic acid byusing the compound. The method has the advantages of short reaction steps, simplified operation and greatly reduced production cost; and the use of raw materials with high toxicity and danger is avoided, so the method is safer.

Owner:AURISCO PHARM(TIANJIN) INC +2

Method for preparing cyclic sulfate by directly oxidizing hydrogen peroxide

PendingCN111909129ALess impuritiesHigh purityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCatalytic oxidation

The method comprises the following steps: dropwise adding hydrogen peroxide into a mixture of cyclic sulfite, an organic solvent and a solid catalyst to carry out catalytic oxidation reaction, filtering out the solid catalyst after the reaction is finished, standing filtrate for layering, taking an organic layer, and performing distilling and concentrating to obtain a cyclic sulfate product. Cheaphydrogen peroxide is used for directly catalyzing and oxidizing cyclic sulfite to prepare cyclic sulfate, so that on one hand, the reaction is mild and easy to control, and the reaction conversion rate is high; on the other hand, no waste salt is generated, the evaporation capacity of water is small, energy consumption is low, generated waste water is little, and the production process is more environmentally friendly; the used solid catalyst contains an active component, an active auxiliary agent and an oxide carrier, and can be recycled, so that the consumption of noble metals is reduced, and the production cost is greatly reduced; the cyclic sulfate prepared by the method is few in impurities, high in purity and wide in market prospect.

Owner:CHANGSHU CHANGJI CHEM +1

Flame retardant composite board and manufacture method thereof

InactiveCN104552488AHigh mechanical strengthGood nail gripWood veneer joiningDomestic articlesBruciteComposite plate

The invention provides a flame retardant composite board. The flame retardant composite board comprises a homogeneous naked panel and a facing layer arranged on at least one surface of the homogeneous naked panel, wherein the homogeneous naked panel is prepared from raw materials of, based on weight parts, 65-98.5 parts of plant straw particles, 3-10 parts of binder and 3-10 parts of fire retardant, wherein the fire retardant is prepared from raw materials of magnesium oxide, calcium sulfate, aluminum hydroxide, brucite, zinc molybdate and zinc borate. The flame retardant composite board has good chemical properties of fire retarding, water prevention, insect prevention and the like, and good physical and mechanical properties, can replace wood artificial boards, and is used in various fields. The invention further provides a manufacture method of the flame retardant composite board. The manufacture method of the flame retardant composite board mainly adopts a normal temperature cold press molding technology to solidify and shape the raw materials of the naked panel, not only greatly saves energy, but also improves product performance, enables the flame retardant composite board to have water prevention and fire prevention functions, and simultaneously can substantially reduce equipment cost, achieves a whole green production process, and does not cause pollution during the whole production process.

Owner:信阳美丽真好秸秆新材科技有限公司

Supported nickel-copper alloy nano-catalyst and preparation method thereof and application to catalytic hydrogenation

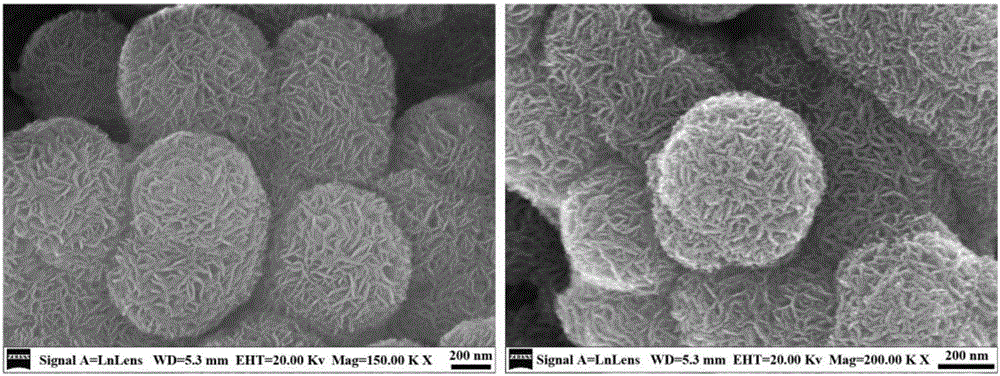

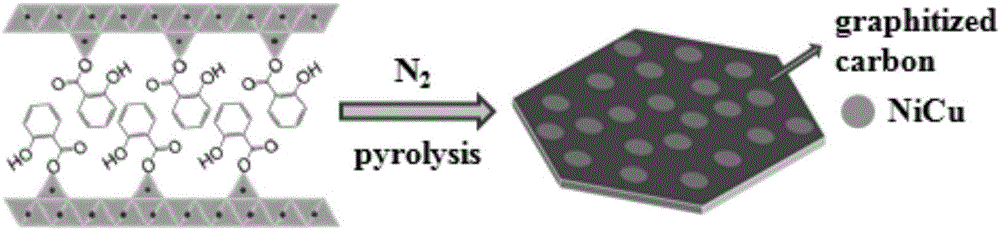

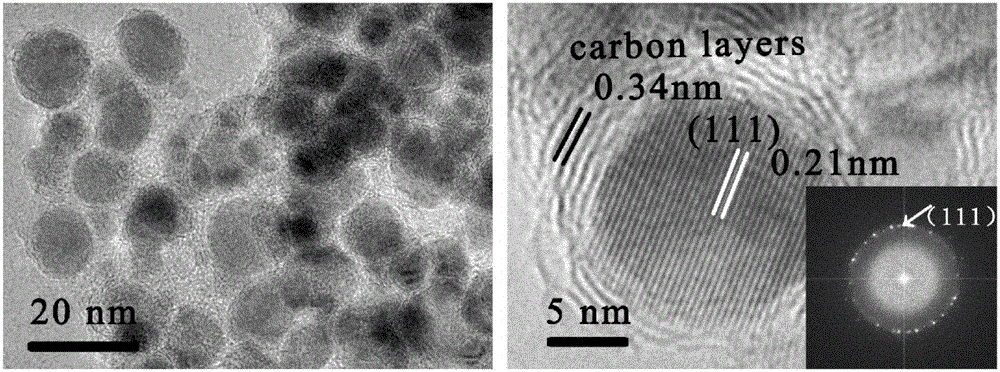

InactiveCN106179353ALarge specific surface areaHigh catalytic activityOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsNano catalystCrystallinity

The invention discloses a supported nickel-copper alloy nano-catalyst and a preparation method thereof and application to catalytic hydrogenation. Self-assembly is carried out in a water solution through the simple coprecipitation synthetic technology, layered copper nickel hydroxide intercalated by a large amount of organic anions is obtained and serves as a precursor, and the nickel-copper alloy / carbon nano composite catalyst with high catalytic activity and stability is obtained through one-step in-situ solid-state pyrolysis in the inert atmosphere. According to the method, high-crystallinity nickel-copper alloy nano-particles can be evenly dispersed in a graphitized carbon matrix, and metal and a carrier have high interaction. No additional reducing agent or surfactant or organic solvent is used, the production cost is reduced, and the product purity is improved. In a catalytic hydrogenation reaction performance test, the prepared nickel-copper alloy / carbon nano composite catalyst shows higher catalytic activity and stability compared with a commercialized platinum / carbon catalyst, and high catalytic efficiency is still achieved after eight times of magnetic separation, recycling and cyclic utilization.

Owner:BEIJING UNIV OF CHEM TECH

Antiflaming straw big core board and manufacturing method thereof

ActiveCN105269642AAchieve recyclingFlame retardantNon-macromolecular adhesive additivesLaminationPolyvinyl alcoholChloride

The invention provides an antiflaming straw big core board. The antiflaming straw big core board comprises two wood single boards and a homogenization straw core board arranged between the two wood single boards. The homogenization straw core board comprises, by mass, 8 parts to 9 parts of straw particles and 1.8 parts to 2.4 parts of an antiflaming binding agent, wherein the antiflaming binding agent comprises raw material including magnesium chloride, magnesium oxide, polyvinyl alcohol, sodium silicate, tartaric acid and ammonium polyphosphate. The antiflaming straw big core board has the good chemical properties of inflaming retarding, water prevention, mosquito prevention and the like and has the good physical mechanical performance, a wood large core board can be replaced with the antiflaming straw big core board, and the antiflaming straw big core board can be applied to various fields. The invention further provides a manufacturing method of the antiflaming straw big core board. The manufacturing method is simple and environment-friendly.

Owner:信阳美丽真好秸秆新材科技有限公司

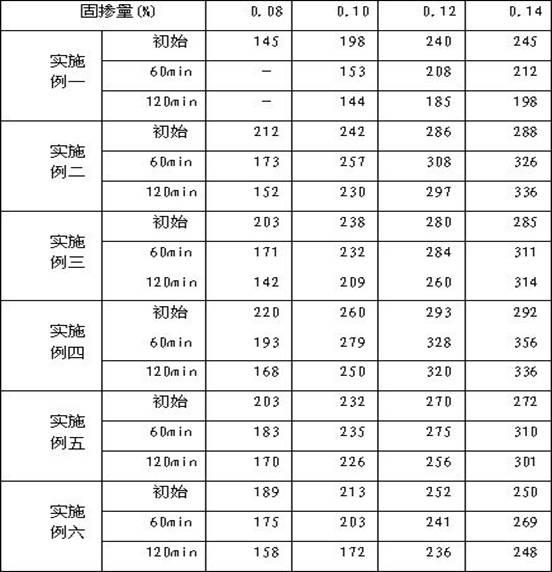

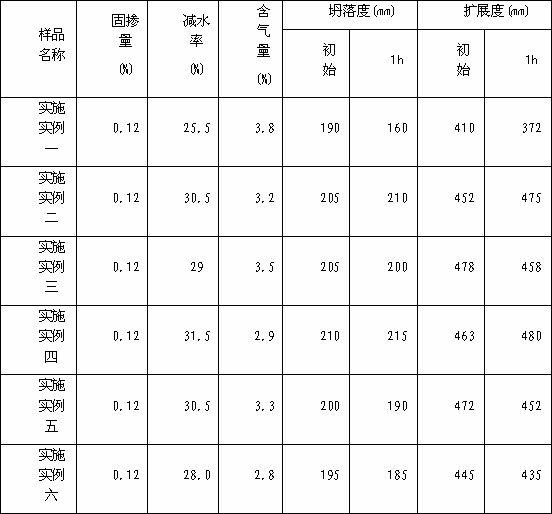

Polycarboxylic acid water reducer with solid raw materials and preparing process of the polycarboxylic acid water reducer

The invention relates to a polycarboxylic acid water reducer for concrete, and belongs to the technical field of concrete admixture. The water reducer is prepared from the following solid raw materials: unsaturated polyoxyethylene macromonomer, unsaturated dicarboxylic acid or anhydride thereof, unsaturated sulfonate monomer, an oxidant, a reducer and sodium hydroxide at a molar ratio of 1:1-4:0.2-1:0.05-0.2:0.015-0.08:0.5-3. The polycarboxylic acid water reducer has the following beneficial effects: the producing condition requirements are less, so that the water reducer is easy to produce industrially; the raw materials are convenient to transport and store, and obvious pungent smells are not generated from the raw materials and in the process of production, environmental conditions for production are greatly improved, and discharge of waste gas, waste water and waste materials is avoided. The obtained product is featured with high water reducing performance, high slump loss resistance, good adaptability to various admixtures of cement and concrete at a low mixing amount, and high cost performance, and is suitable for popularization and application.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

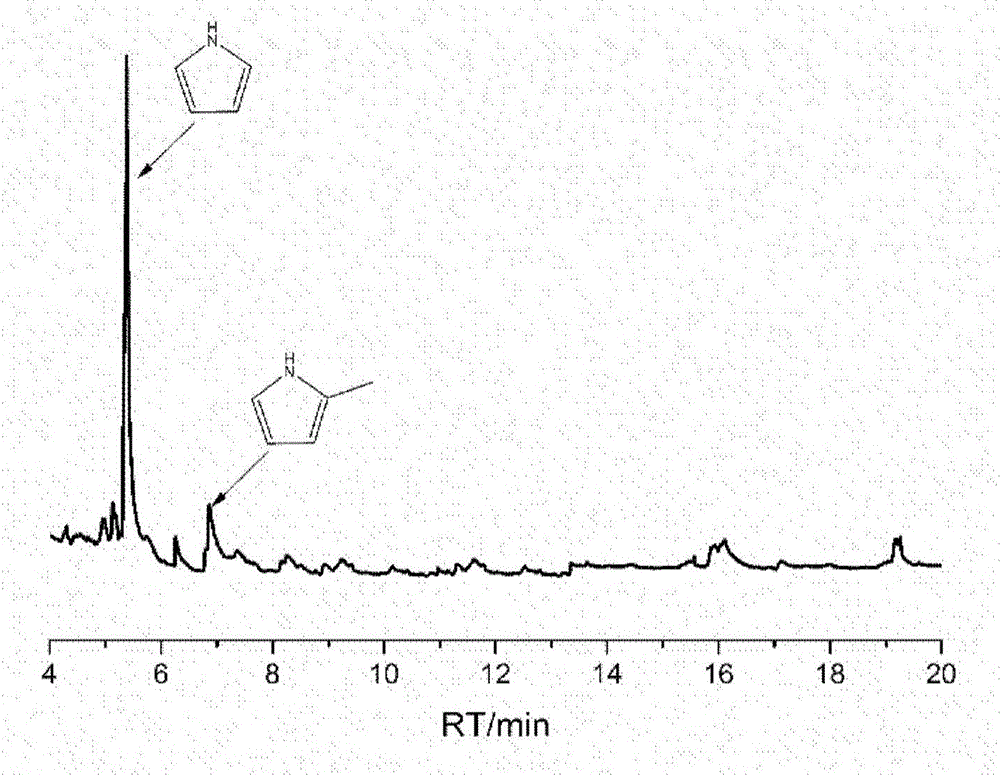

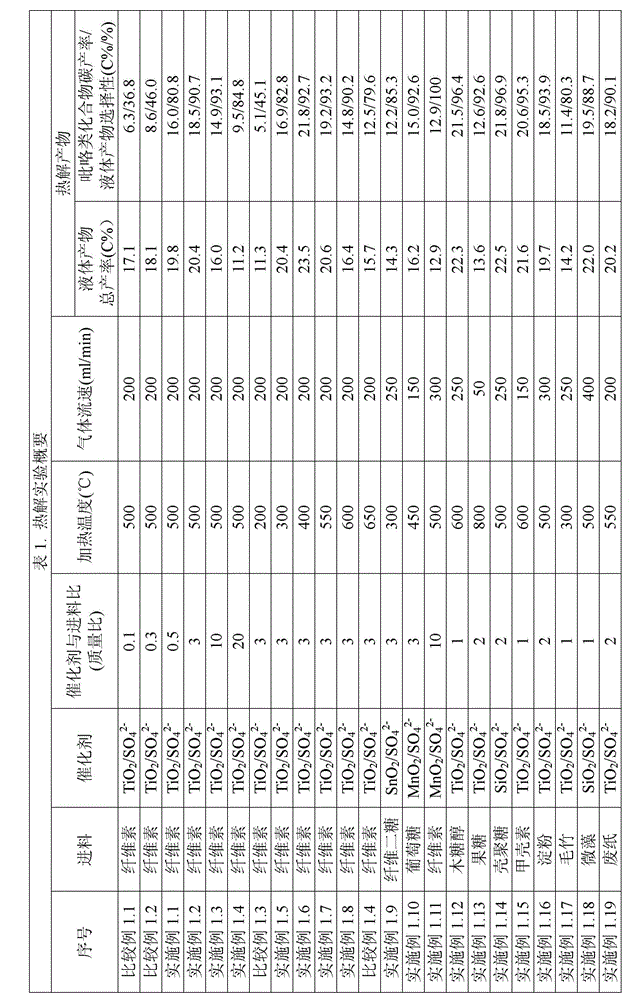

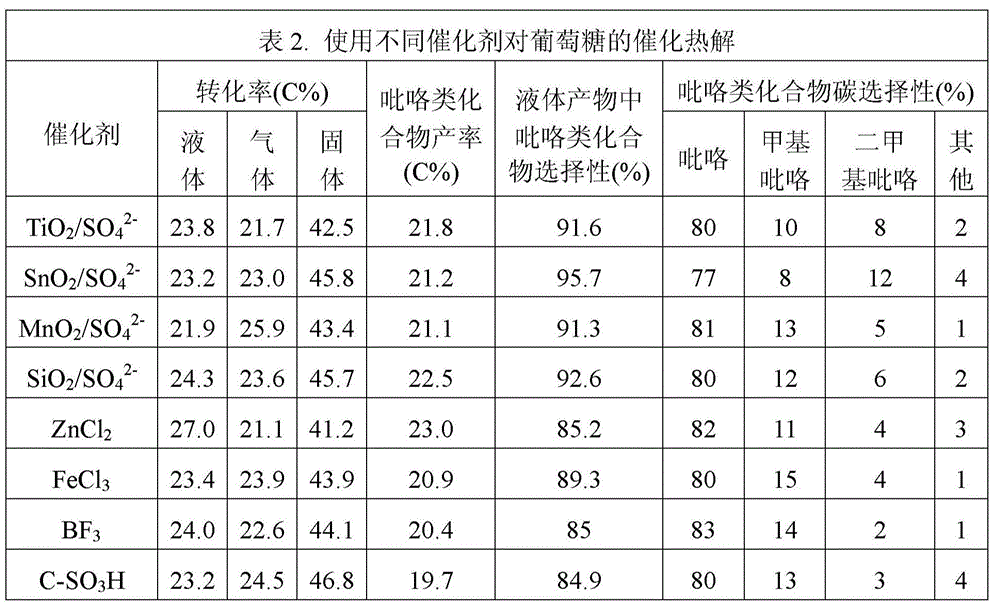

High-selectivity preparation method of pyrrole compounds

The invention relates to a high-selectivity preparation method of pyrrole compounds, which comprises the following steps: feeding organic materials and an acidic catalyst into a reactor; and reacting the organic materials in the reactor in the presence of gas containing reactive nitrogen compounds under heating conditions under the action of the catalyst, thereby generating a reaction system stream comprising one or more nitrogenous aromatic compounds, wherein the selectivity of the pyrrole compounds is up to higher than 80%.

Owner:UNIV OF SCI & TECH OF CHINA

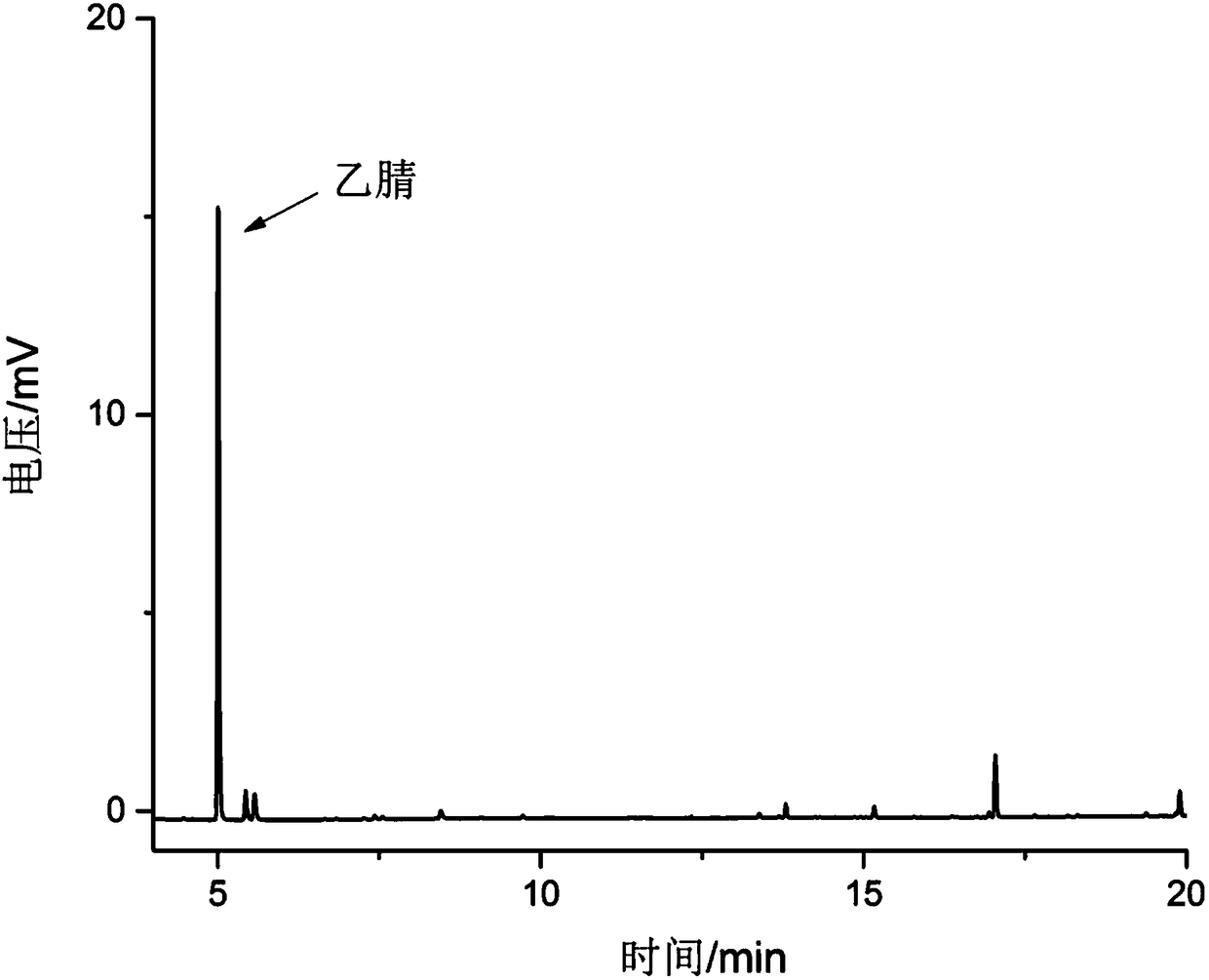

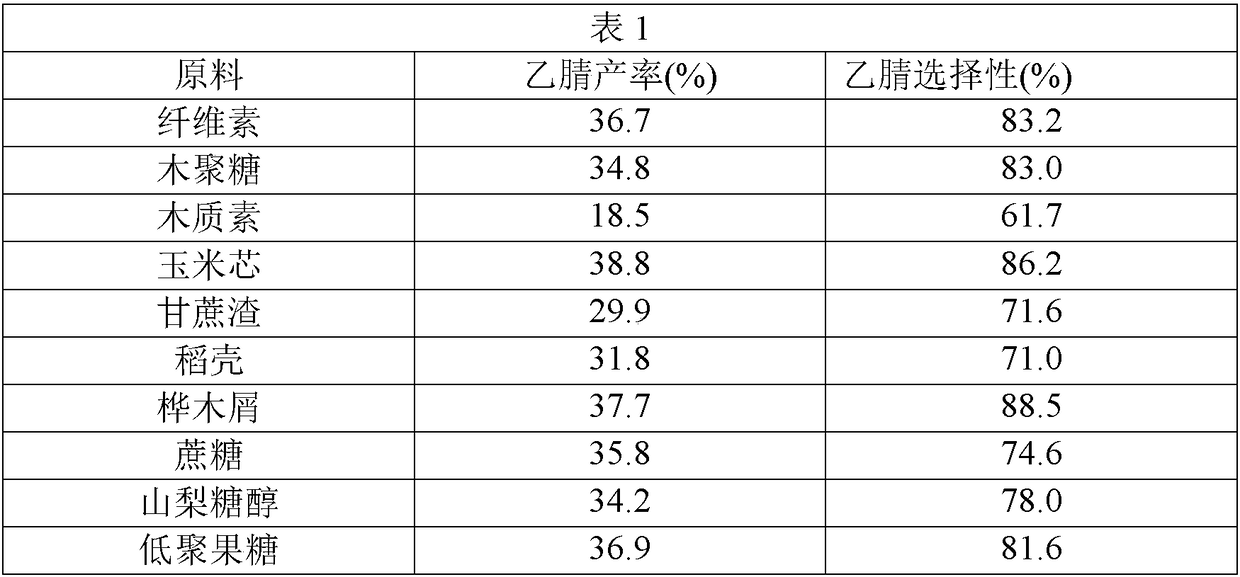

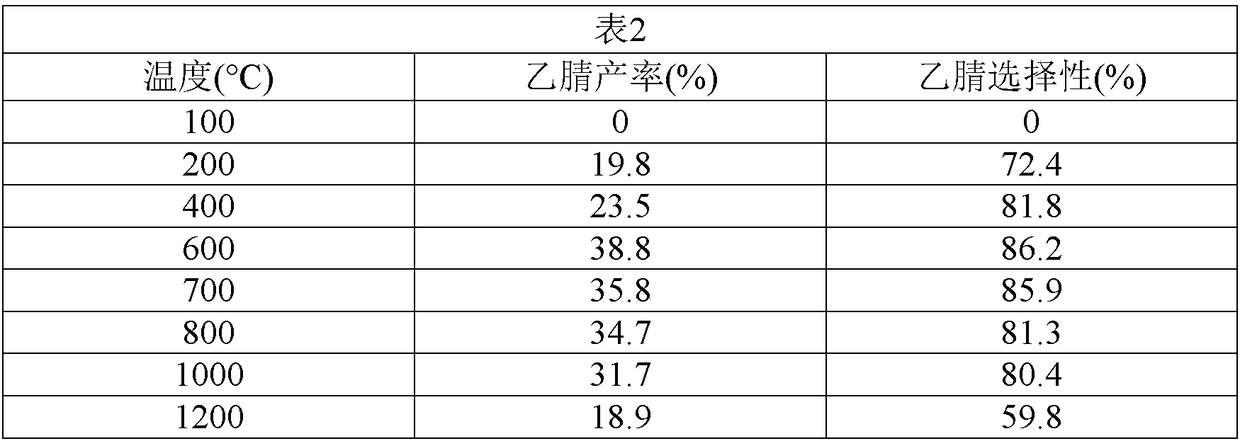

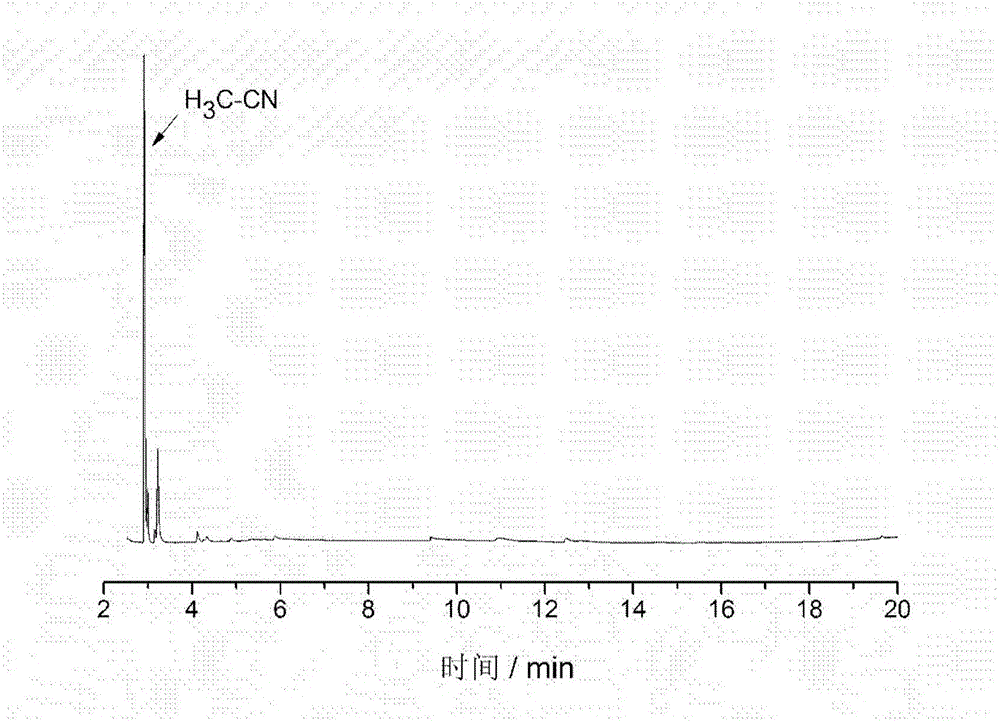

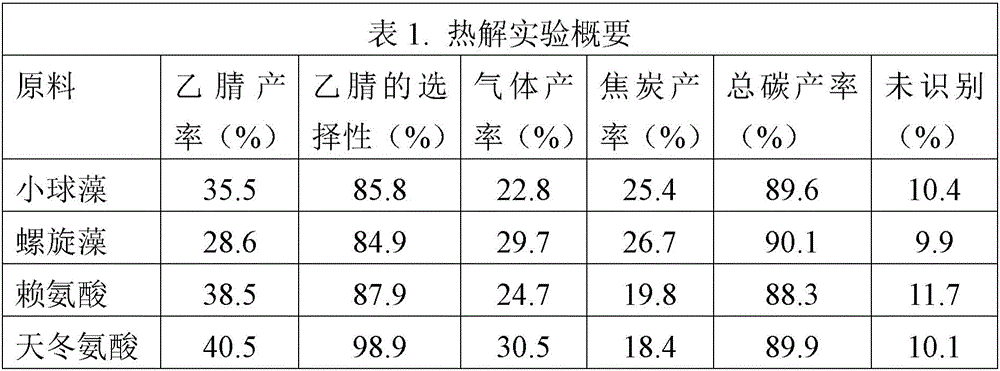

Method for preparing acetonitrile from lignocellulosic biomass material

ActiveCN108084053AHigh yieldHigh selectivityCarboxylic acid nitrile preparationOrganic compound preparationAcetonitrileLignocellulosic biomass

The invention relates to a method for preparing acetonitrile from a lignocellulosic biomass material. The method comprises feeding a lignocellulosic biomass material into a reactor, heating the material for a reaction in the presence of a reactive nitrogen compound and an acidic catalyst, and carrying out condensation and separation to obtain a product acetonitrile. Through the method, acetonitrile is high selectively prepared from the lignocellulosic biomass material. The method is simple and easy, utilizes cheap and easily available raw materials in a wide resource and provides a reproducible and eco-friendly synthesis route from raw material acquisition to product production. The product acetonitrile can be widely used in the fields of medicines, pesticides, spices, fabric dyeing and photosensitive materials.

Owner:UNIV OF SCI & TECH OF CHINA

High-selectivity acetonitrile preparation method

ActiveCN106117082AHigh yieldHigh selectivityCarboxylic acid nitrile preparationOrganic compound preparationAcetonitrileRenewable resource

The invention relates to a high-selectivity acetonitrile preparation method. The method comprises the steps that in a reactor, under the condition that gas containing a reactive nitrogen compound is used as carrier gas, organic materials are reacted under catalysis of a catalyst in a heated mode; liquid is condensed and collected, and acetonitrile is obtained through separation. According to the method, renewable resources are utilized, and acetonitrile is prepared in a high-selectivity mode through an appropriate reaction method. The whole process from raw materials to the production process is renewable, green and environmentally friendly.

Owner:UNIV OF SCI & TECH OF CHINA

Flame-retardance formaldehyde-free industrial hemp straw fiberboard and manufacturing method thereof

InactiveCN107322745AWith flame retardant functionClear componentsDomestic articlesFlat articlesSolventFiberboard

The invention provides a flame-retardance formaldehyde-free industrial hemp straw fiberboard. The fiberboard comprises raw materials of industrial hemp straw all-straw core fragments and flame-retardance adhesive being 18-48 weight% of the fragments; and the fiberboard is prepared by such steps as cold pressing and curing. Aiming at a hot pressing process and a method for applying solvent adhesive in traditional fiberboard manufacturing, the flame-retardance formaldehyde-free industrial hemp straw fiberboard is prepared by using a cold pressing process and special flame-retardance formaldehyde-free adhesive. Compared with a traditional fiberboard preparation method, the method has the advantages of simple process, low energy consumption and no environmental pollution; and compared a wood fiberboard, the obtained product has such characteristics as flame retardance, low smoke, no irritation, no poison, no formaldehyde, bacteria resistance, insect resistance, water resistance, high strength and possession of both medium density and high density.

Owner:洪家敏

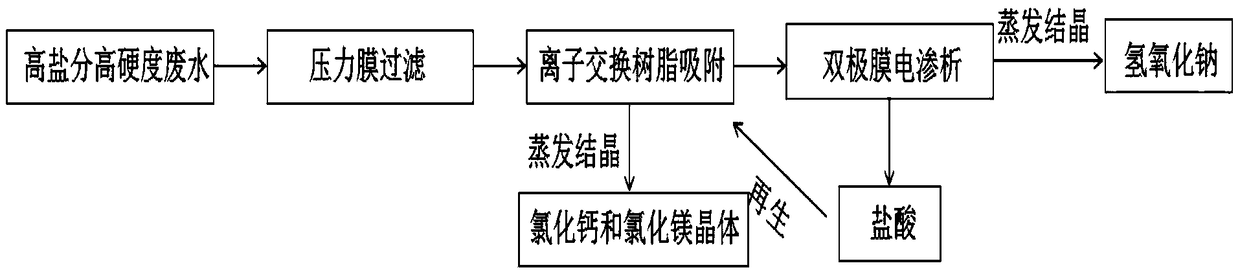

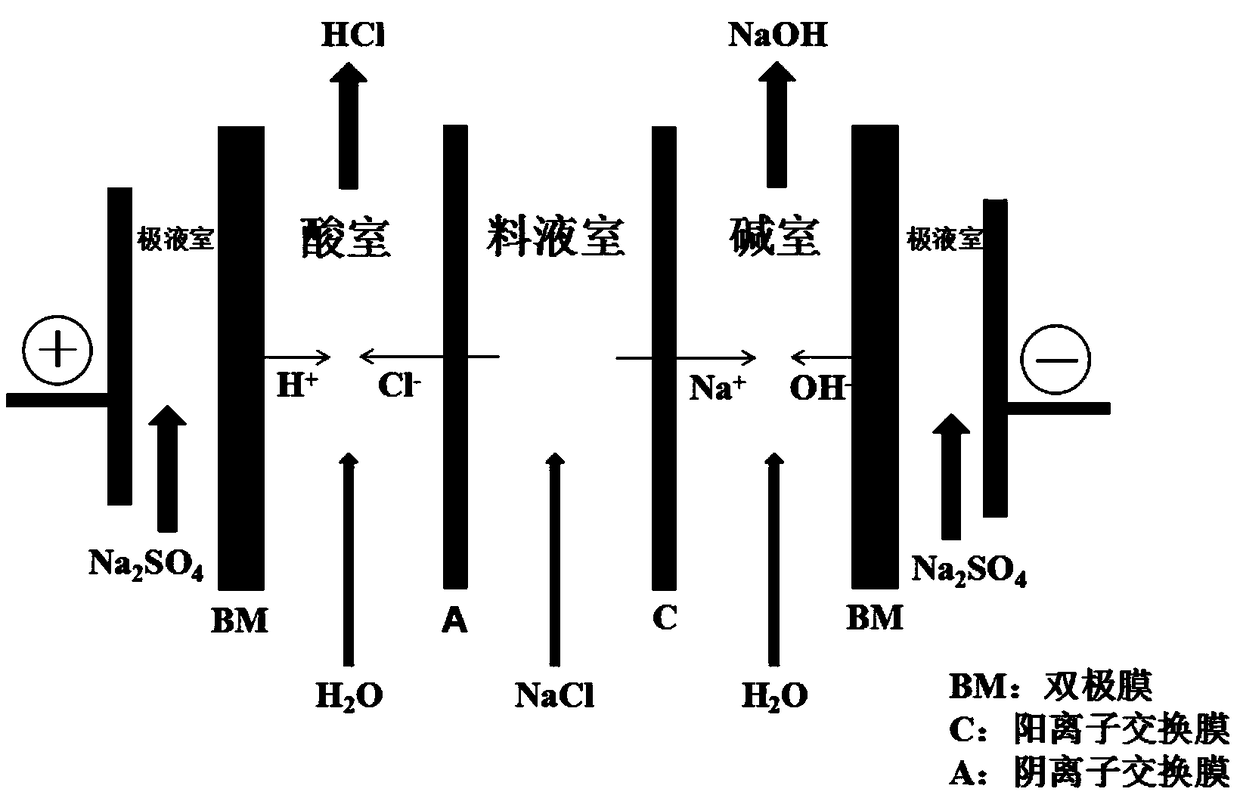

Novel process for resource recycling of acid and alkali from high-salinity and high-hardness wastewater

InactiveCN109231623ASolve pollutionGreen production processWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisParticulatesImpurity

The invention relates to a process for the resource recycling of acid and alkali from high-salinity and high-hardness wastewater. The process comprises the following steps: (1) pre-treating the high-salinity and high-hardness wastewater by virtue of a pressure film device to remove suspended solids in the wastewater until the suspended solids are lower than 1ppm; (2) introducing clarified wastewater pretreated in the step (1) into a cation exchange resin column, so as to decrease the hardness; (3) adjusting the pH value of the wastewater treated in the step (2) to be neutral, adding the wastewater into double-electrode film electroosmosis equipment, and preparing acid and alkali, so as to obtain products, namely sodium hydroxide and hydrochloric acid; and (4) diluting partial hydrochloricacid obtained in the step (3) into the cation exchange resin column, regenerating cation exchange resin, and simultaneously evaporating and concentrating eluant for crystlization, so as to obtain calcium chloride crystals and magnesium chloride crystals. The process is pollution-free in the whole process, the recovery rates of products, namely acid and alkali are high, and the wastewater treatmentcost is greatly lowered.

Owner:ZHEJIANG UNIV OF TECH

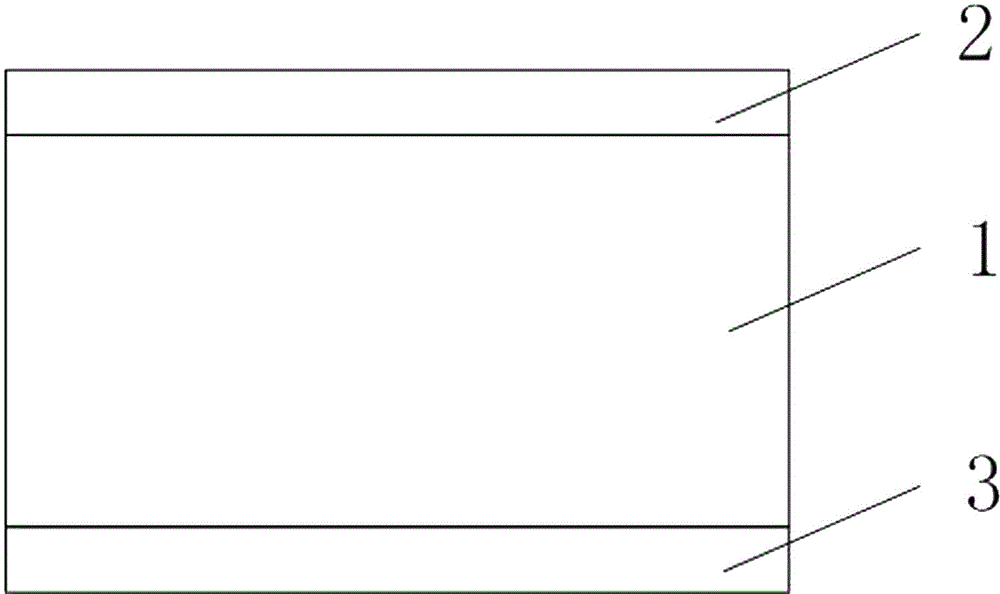

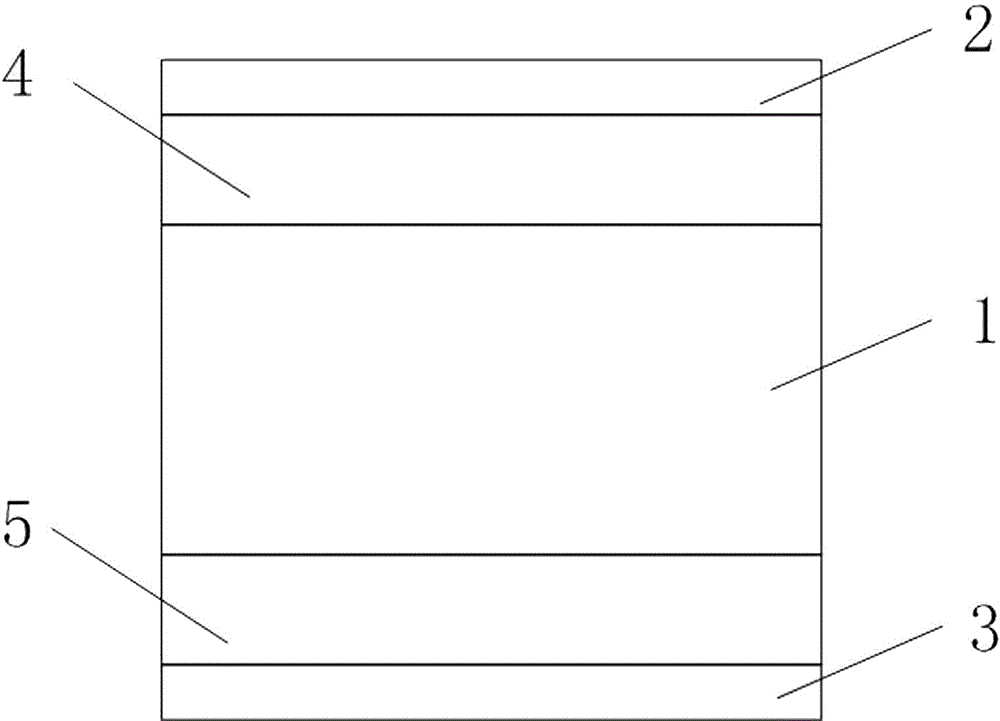

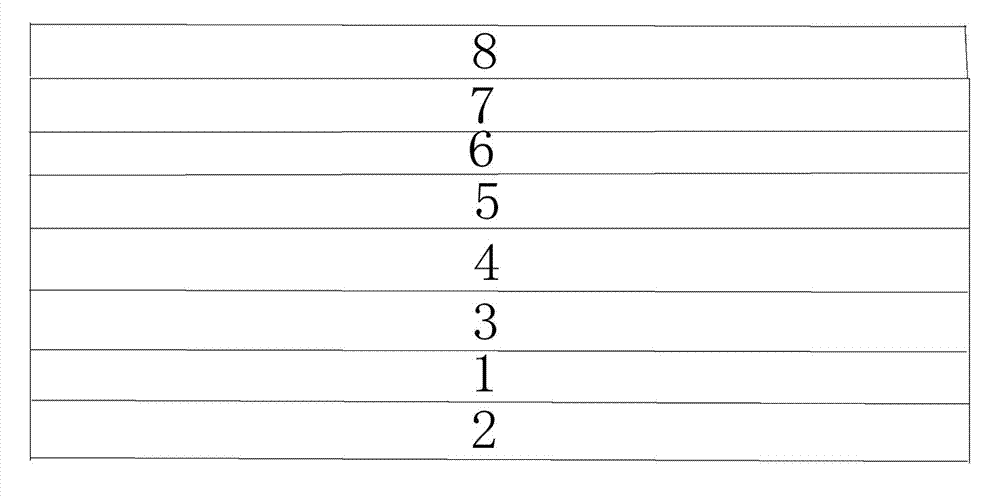

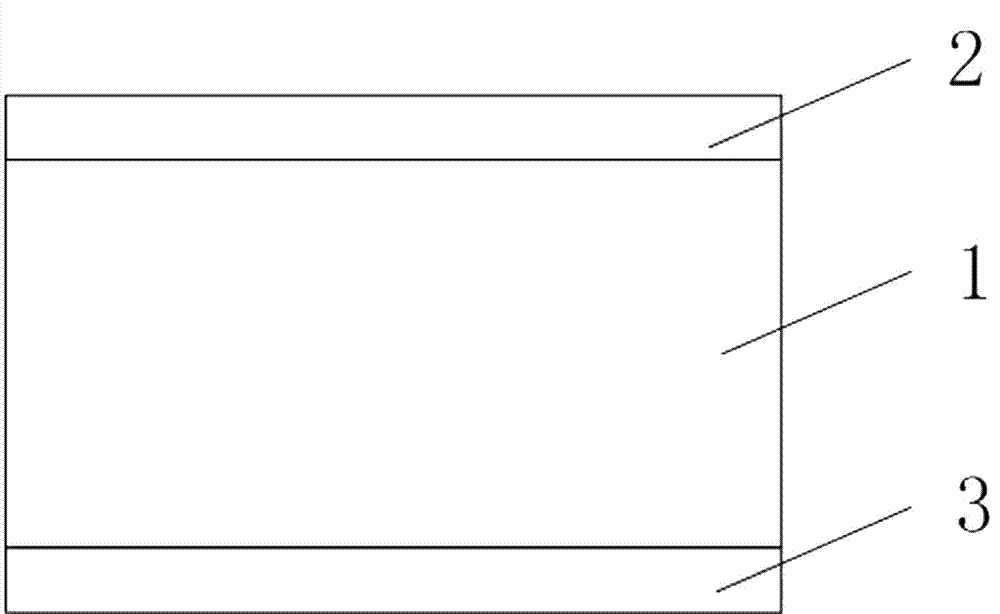

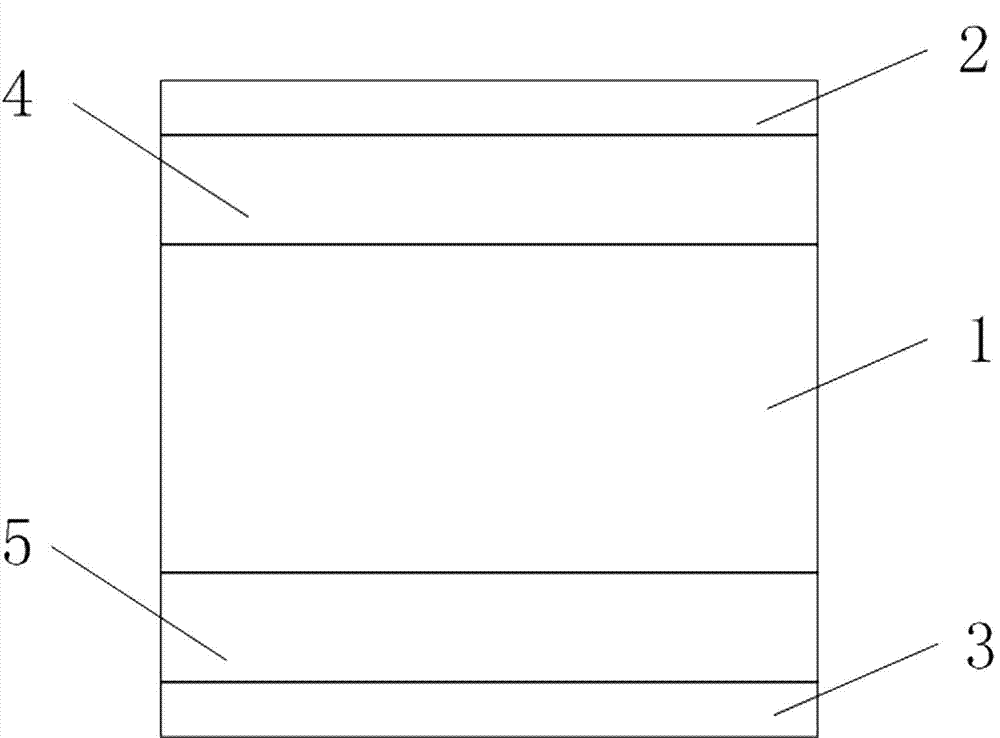

Direct-plating tipping paper with laser effect for cigarette and production process thereof

InactiveCN102828444AImprove the decorative effectSimple preparation processSpecial paperPaper/cardboardMetallurgyPaper based

The invention belongs to the technical field of cigarette packaging paper, and relates to direct-plating tipping paper with laser effect for cigarettes and a production process thereof. The direct-plating tipping paper with laser effect for cigarettes disclosed by the invention comprises, from the bottom up, a back coating layer 2, common tipping paper base paper 1, a surface coating layer 3, a direct-plating glue layer 4, and a laser grain decoration layer 5; the decoration layer has a vacuum aluminized layer 6 on the laser grain decoration layer 5; a printing ink layer or paint layer 7, and an electrochemical aluminium stamped foil layer 8 are on the vacuum aluminized layer 6. The invention also discloses a production process, which comprises the following steps: performing back coating and surface coating of waterborne coatings on common direct-plating paper, coating the direct-plating glue, manufacturing patterns with laser effect on the front surface layer by mold pressing equipment, performing vacuum aluminizing, printing or printing ink or paint coating, embossing or non-embossing, electrochemical aluminium gold stamping, and slitting. The direct-plating tipping paper with laser effect for cigarettes manufactured by the invention has good decoration effect, is simple and environment-friendly in production process.

Owner:DARE TECH

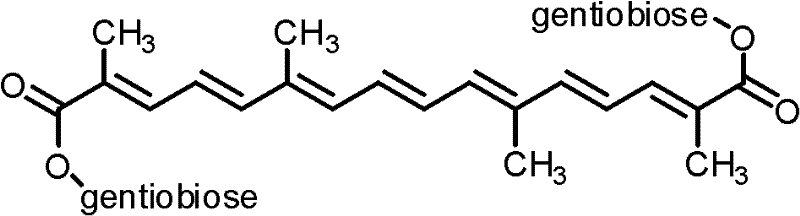

Method for extracting gardenia yellow pigment from gardeniae longicarpae fruit

The invention discloses a method for extracting gardenia yellow pigment from a gardeniae longicarpae fruit, which comprises the following steps of: feeding gardeniae longicarpae fruit powder and a solid-phase reagent in a ball grinding mill for ball milling to be uniform; taking out powder formed by ball milling; adding water in the powder formed by ball milling; fully stirring and uniformly mixing, filtering and obtaining supernate; feeding the supernate to a macroporous resin chromatography column; eluting with 60 percent by weight of ethanol aqueous solution; collecting an eluent; condensing and evaporating to remove a solvent; drying and feeding the mixed solution to pass through the macroporous resin chromatography column; condensing and evaporating to remove the solvent; and drying to obtain the gardenia yellow pigment. The method disclosed by the invention is based on an extraction technology of mechanochemical reactions; and the solid-phase reagent used by the method can be selectively combined with the gardenia yellow pigment. Compared with a traditional extraction technology, the extraction rate and the purity of products can be improved by 10-20 percentage points.

Owner:ZHEJIANG UNIV OF TECH +1

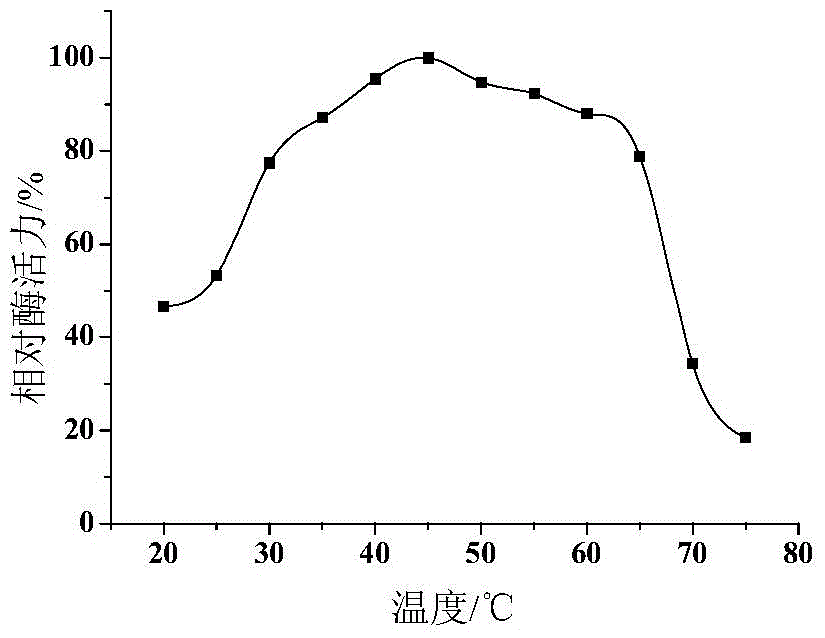

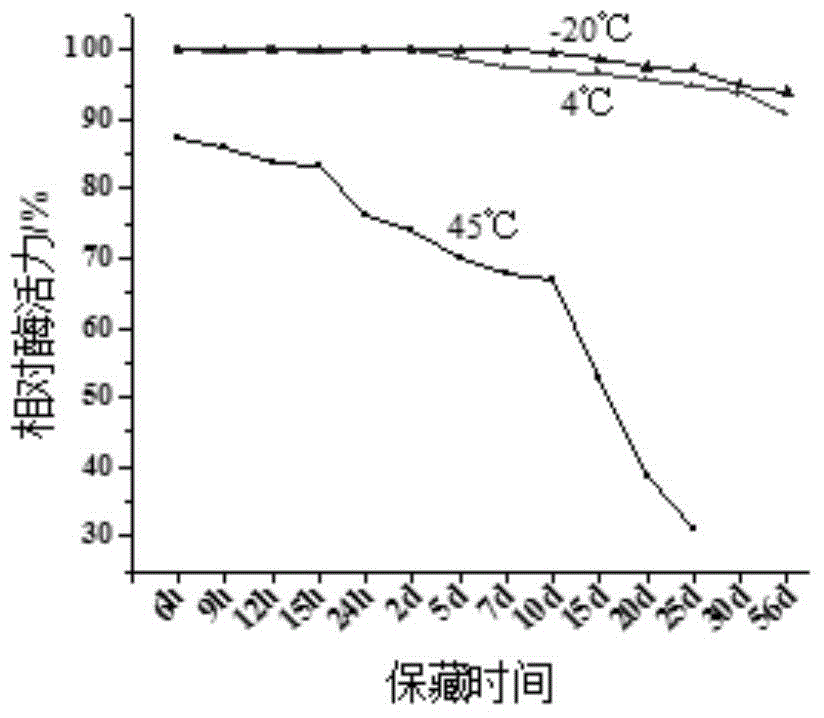

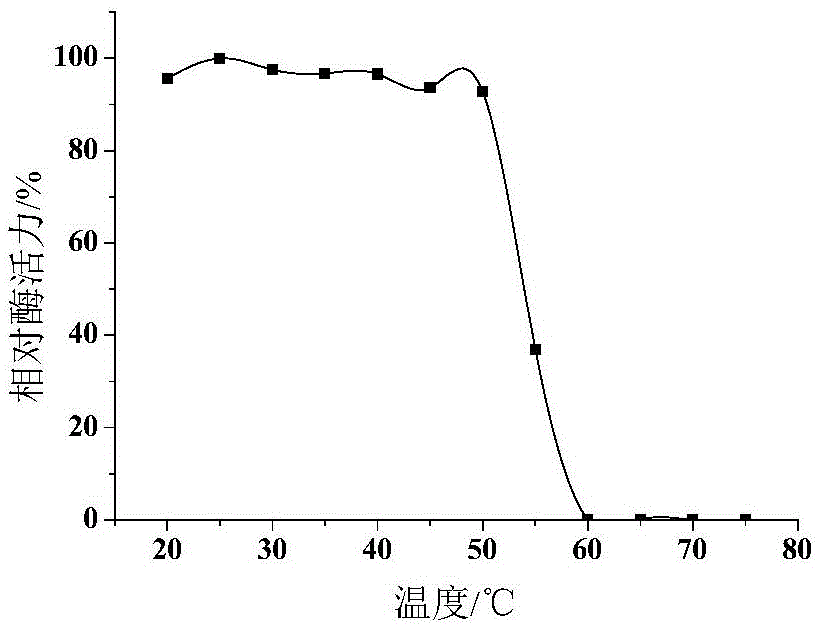

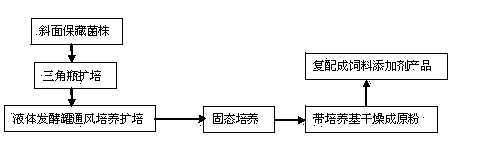

Hypocrea lixii strain and method for preparing dextran enzyme with the Hypocrea lixii strain

ActiveCN102220244AQuality improvementGreen production processFungiMicroorganism based processesMicroorganismBiotechnology

The invention discloses a dextran enzyme producing strain with a high enzyme activity, and a method for preparing dextran enzyme with the strain. The strain is characterized by being a Hypocrea lixii F1002 strain separated from soil and being preserved by the Chinese General Microbiological Culture Collection Center, wherein the preservation number of the strain is CGMCC No. 4725. In the invention, dextran enzyme is prepared successfully by Hypocrea lixii F1002 fermentation, and dextran enzyme prepared by the method has a high enzyme activity and is an extracellular enzyme. The dextran enzymeprepared by the method is characterized in that an optimal action temperature is in a range of 25 to 30 DEG C; an optimal PH is in a range of 5.0 to 5.5; and a stabilization PH is in a range of 4.0 to 6.5. A degree of producing dextran enzyme by Hypocrea lixii F1002 fermentation is greater than 60 U / ml.

Owner:SHANDONG JINYANG PHARMA

Flame-retardant straw artificial composite board and manufacturing method thereof

InactiveCN104772796AEnvironmental protection is goodGood flame retardantLaminationLamination apparatusZinc borateSulfate

The invention provides a flame-retardant straw artificial composite board. The flame-retardant straw artificial composite board comprises a naked panel and a decorative finish layer which is arranged on at least one surface of the naked panel, wherein the naked panel comprises the following raw materials in parts by weight: 7 to 8 parts of crop straw particles, 0.8 to 1 part of adhesion agent and 0.8 to 1 part of flame retardant, wherein the flame retardant comprises magnesium oxide, calcium sulfate, aluminum hydroxide, brucite and zinc borate. The flame-retardant straw artificial composite board has very high chemical, physical and mechanical properties of flame retardancy, water resistance, insect resistance and the like, and can be applied to various fields instead of wood-based panels. The invention also provides a manufacturing method for the flame-retardant straw artificial composite board. According to the manufacturing method, the raw materials are subjected to curing and shaping processing by adopting a normal temperature cold pressing molding technology; energy resources are greatly saved; the product performance can also be improved; the product has the functions of preventing water and preventing fire; meanwhile, the equipment cost can also be greatly reduced; the overall production process is green and pollution-free.

Owner:杨光伟

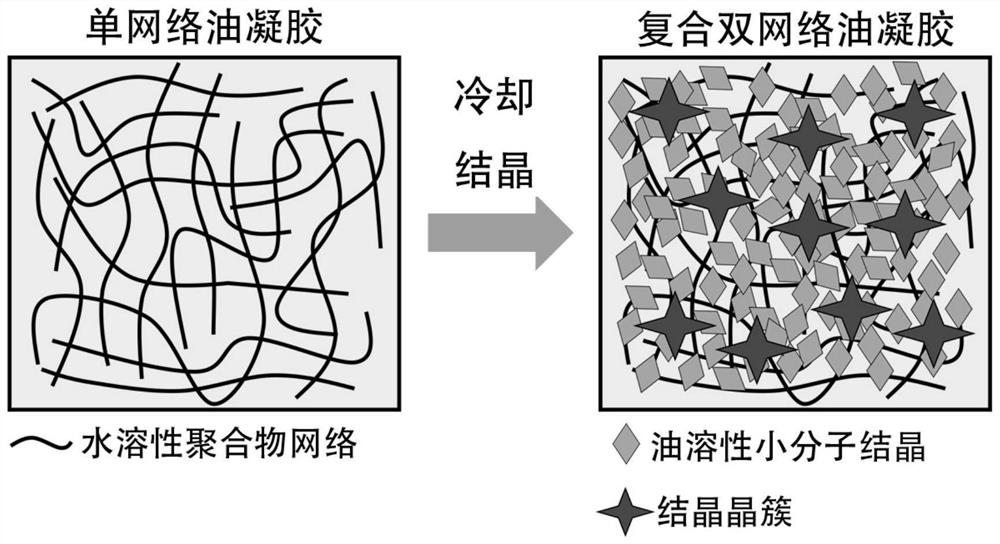

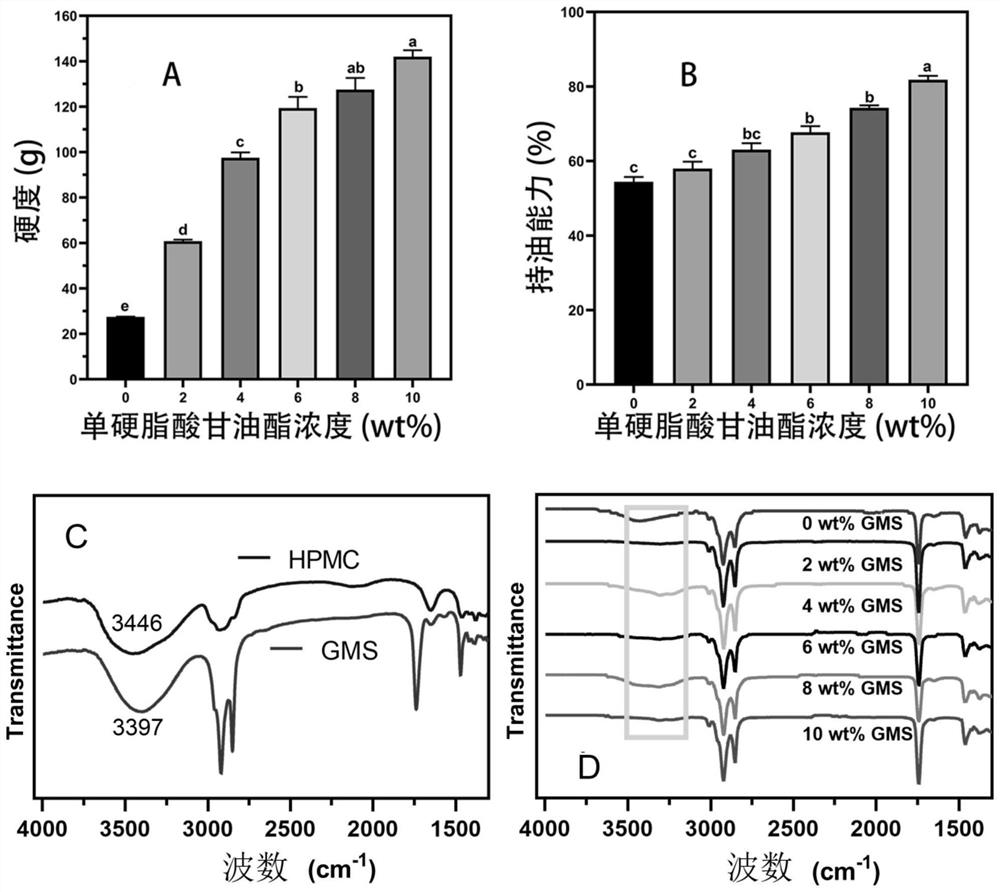

Preparation and application of composite dual-network zero-trans low-saturated fatty acid oleogel

ActiveCN114467997AHigh requirements for biocompatibilityGood for healthCosmetic preparationsDough treatmentVegetable oilBiopolymer

The invention discloses preparation and application of composite dual-network zero-trans low-saturated fatty acid oleogel, and belongs to the technical field of healthy grease processing and food application. The preparation method comprises the following steps: by taking water-soluble polysaccharide, an oil-soluble small molecular substance and vegetable oil as raw materials, preparing the water-soluble polysaccharide into water foam by taking the water-soluble polysaccharide as a construction raw material of a biopolymer network, freezing the water foam, and freeze-drying to form porous aerogel; the porous aerogel is used for absorbing a heated oil solution or grease of oil-soluble micromolecules, and the aerogel after oil absorption is homogenized and cooled to prepare the composite dual-network zero-trans low-saturated fatty acid oleogel. The oleogel disclosed by the invention is a soft solid which has plasticity and semi-solid characteristics and can show plastic fat-like characters, and can be used as a substitute of traditional plastic fat in products with high biocompatibility requirements, such as healthy foods, cosmetics, medicines and the like.

Owner:JIANGNAN UNIV

Environment-friendly polymer cement wall waterproof slurry and preparation method thereof

The invention provides environment-friendly polymer cement wall waterproof slurry and a preparation method thereof. The slurry comprises a liquid material and a powder material, wherein the mass ratio of the liquid material to the powder material is 1:(3-5); the power material comprises, by weight, 35-40 parts of cement, 35-40 parts of quartz sand, 20-25 parts of ground calcium carbonate, 0.1-0.3 part of lubricating agent and 0.2-0.5 part of water reducing agent; the liquid material comprises, by weight, 0.4-0.6 part of dispersing agent, 44-50 parts of water, 0.2-0.4 part of defoaming agent and 45-55 parts of polymer emulsion, the polymer emulsion comprises pure an acrylic emulsion and a styrene-acrylic emulsion, and the mass ratio of the acrylic emulsion to the styrene-acrylic emulsion is 1:(3-5). The slurry and the preparation method thereof have the advantages that the materials used by the slurry use water as the medium, so that the slurry is a waterborne product; the preparation method is green in process, low in energy consumption and free of environment pollution, does not generate three wastes and satisfies the requirements of environment protection.

Owner:台州中峰建筑材料有限公司

Water-based transfer laser paint and preparation method thereof

InactiveCN108977028AImprove temperature resistanceImprove water resistancePolyurea/polyurethane coatingsEmulsion paintsWater basedAcrylic resin

The invention belongs to the technical field of transfer paint, and in particular relates to water-based transfer laser paint and a preparation method thereof. The water-based transfer laser paint isprepared from following components in parts by weight: 30% to 60% of three-dimensional water-based polyurethane resin, 20% to 30% of water-based acrylic resin, 10% to 50% of deionized water, 1% to 3%of a film forming aid and 0 to 1% of a functional additive. For the preparation of the water-based transfer laser paint, the following steps are carried out: Step 1, preparation of a three-dimensionalprecursor; Step 2, preparation of a polyurethane prepolymer; Step 3, preparation of a three-dimensional water-based polyurethane resin; Step 4, preparation of water-based transfer laser paint; Step 5, filtering and removing the impurities to eliminate the bubbles, detecting and adjusting the viscosity of the water-based transfer laser paint to meet the requirements of application on a machine toachieve a finished product. The preparation method makes the paint have excellent coating performance, temperature resistance, moldability and printing adaptability by a reasonable combination of resins, thereby providing a brand new solution for the transfer laser paint in aspects of green property, safety and environmental protection.

Owner:YANTAI BOYUAN TECH MATERIALS

Water heating synthesis of yttrium-diethyltriamine pentacetate

InactiveCN1680393AImprove reaction efficiencyAdapt to the needs of industrial productionGroup 3/13 element organic compoundsChemical synthesisAcetic acid

A hydrothermal synthesis of gadolinium-diethylentriaminepentaacetic acid is carried out by using gadolinium oxide and diethylentriaminepentaacetic acid, hydrothermal synthesizing, and obtaining gadolinium- diethylentriaminepentaacetic. It is an inorganic complex chemical synthetic technology. Its advantages include less impurities, high reacting speed and output efficiency.

Owner:EAST CHINA NORMAL UNIV

Penicillium pinophilum strain and method for preparation of dextranase from the same

ActiveCN104911106APromote degradationIncrease contactFungiMicroorganism based processesMicroorganismBiotechnology

The invention provides a dextranase producing strain with high enzyme activity and a method for preparation of dextranase from the strain. The strain is characterized in that it is Penicillium pinophilum H6 separated from soil, the strain is preserved by China General Microbiological Culture Collection Center with a preservation number of CGMCC No.9260. The invention successfully utilizes Penicillium pinophilum H6 fermentation to prepare dextranase, also can produce dextranase with high enzyme activity, and the produced dextranase is extracellular enzyme. Preparation of dextranase by Penicillium pinophilum H6 fermentation process is characterized in that the most suitable action temperature is 40DEG-50DEG C, the most suitable pH is 5.0-6.0, and the stable pH is 3.0-10.0. The level of Penicillium pinophilum H6 fermentation for production of dextranase is 345U / ml.

Owner:SHANGHAI HUAMAO PHARMA

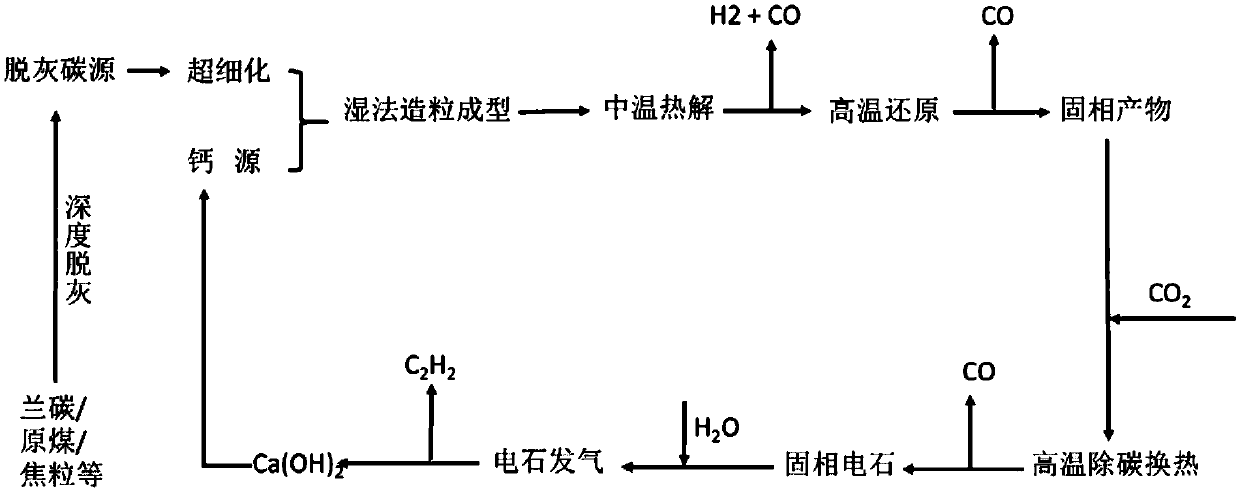

Calcium carbide acetylene production technology capable of reducing generation of calcium carbide slag

ActiveCN108675911AIncrease the deep deashing processAdd carbon removal processHydrocarbon from carbon oxidesCalcium carbideSource materialSlag

The invention discloses a calcium carbide acetylene production technology capable of reducing generation of calcium carbide slag. The calcium carbide acetylene production technology comprises the following reaction steps: S1, preparing an ultrafine deashed carbon source material and a calcium source material; S2, adding mixture of the ultrafine deasehd carbon source material and the calcium sourcematerial into a binding agent, feeding in a pelletizer, and forming by adopting wet granulation, thus obtaining calcium carbide raw material balls in certain size; S3, putting the obtained raw material balls in a calcium carbide synthetic furnace for heating and smelting; S4, introducing CO2 gas in certain concentration in a high-temperature solid-phase product obtained through reaction, and carrying out decarbonization and heat exchange; merging a produced gas into furnace gas, separating and purifying the mixed gas after carrying out heat exchange and dedusting, and feeding the treated gasinto a storage tank or to next process; S5, developing gas by calcium carbide, thus obtaining an acetylene gas and calcium hydroxide slurry; S6, recycling the calcium source material; S7, stopping recycling of the calcium source material when the amount of impurities in the calcium hydroxide slurry exceeds 20 weight percent of calcium groups, and removing the calcium hydroxide slurry, thus obtaining calcium carbide slag. According to the calcium carbide acetylene production technology disclosed by the invention, the calcium source material is recycled, and meanwhile, no scorification / less scorification during a calcium carbide process and great improvement of quality of the calcium carbide can be realized.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

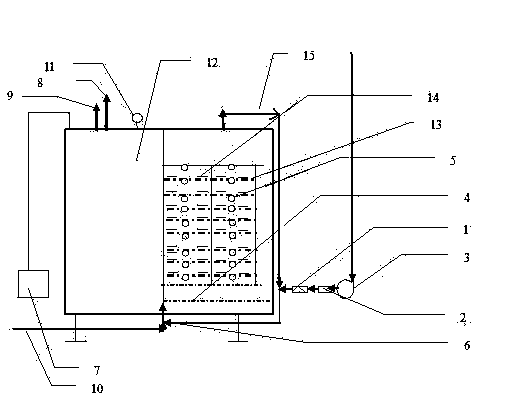

Method for producing cordyceps sinensis feed additive and product

InactiveCN104381615AImprove breathabilityPromote absorptionFungiMicroorganism based processesYeastFeed additive

The invention relates to a method for producing a cordyceps sinensis feed additive and a product, and belongs to the technical field of feed fermentation. The method comprises the following steps: firstly, quickly producing a large amount of mycelia through liquid fermentation by taking low-price beer dry yeasts and beer grains as raw materials; secondly, inoculating a large amount of mycelia into a solid culture medium for solid fermentation. According to the method, shallow tray type static and solid fermentation equipment is adopted for fermentation and is simple and convenient to operate, the fermentation cycle is short, the pollution is alleviated, the production cost is reduced, and the cordyceps sinensis mycelia can be efficiently produced to serve as the feed additive.

Owner:FUJIAN AGRI & FORESTRY UNIV +1

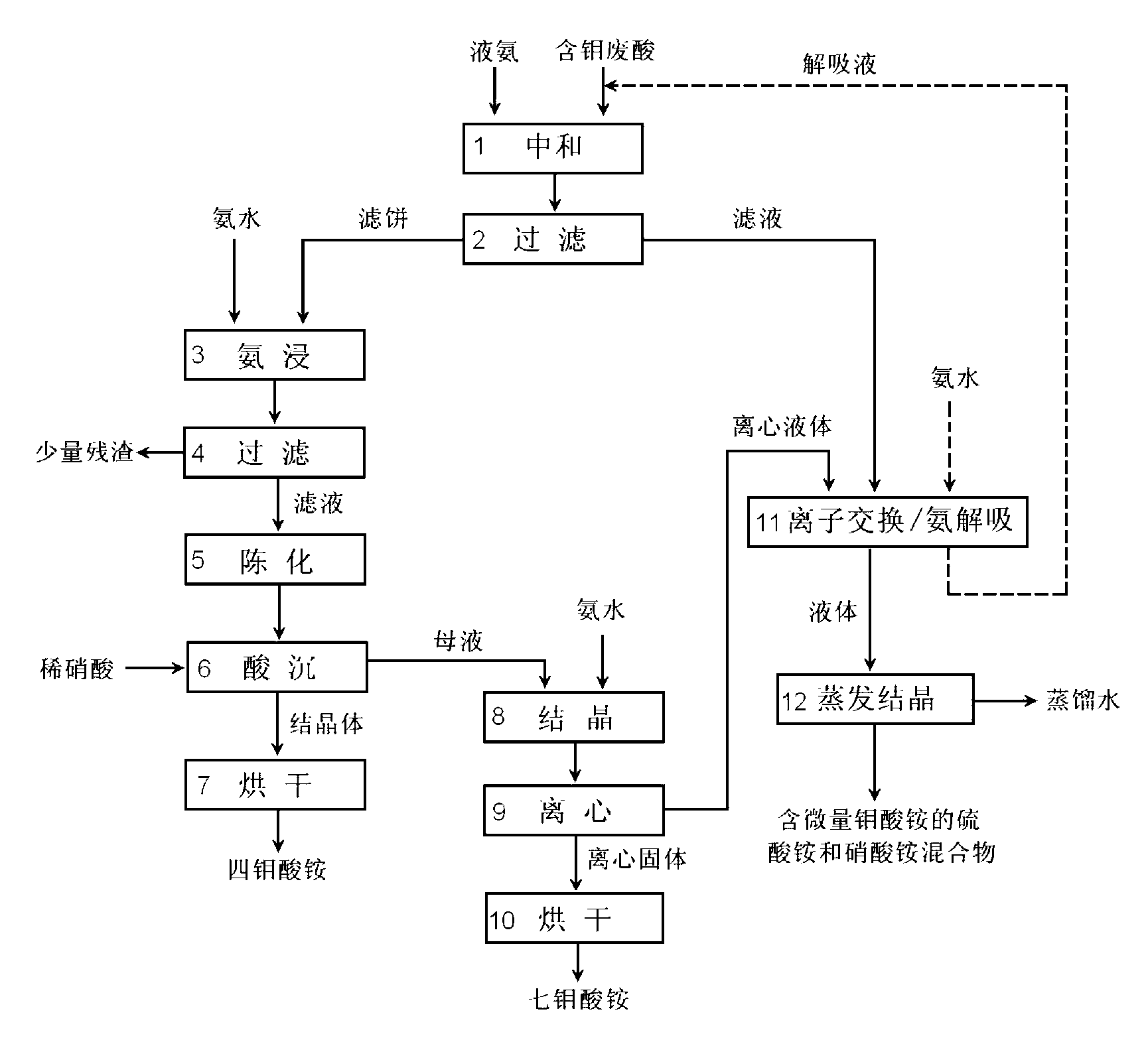

Method for recycling all chemical components in filament melting molybdenum-containing waste acid

ActiveCN103288135AHigh recovery rateEfficient recyclingMolybdeum compoundsFertilizer mixturesIon exchangeAmmonium nitrate

The invention relates to a method for recycling all chemical components in a filament melting molybdenum-containing waste acid. The method comprises the following steps of: 1) neutralization: slowly adding liquid ammonia to the waste acid and stopping adding the liquid ammonia until pH is in the range from 4.8 to 5.5; 2) filtering: generating a filter cake and a filtrate; 3) ammonia leaching: dissolving the filter cake by using ammonia water; 4) filtering: removing few insoluble impurities by using filter cloth; 5) acid precipitation and centrifuging: obtaining ammonium molybdate product; 6) ion exchange / ammonia desorption; 7) evaporative crystallization: infiltrating the liquid obtained through ion exchange into a two-effect evaporator for evaporative crystallization, thereby obtaining a mixture of ammonium sulfate and ammonium nitrate containing a trace of ammonium molybdate, wherein the mixture is used as a molybdenum-containing chemical fertilizer product. The overall process route of the method provided by the invention realizes recycling of all chemical components of the molybdenum-containing waste acid; the production process is free of pollution and green.

Owner:杭州临安慧尔钼业科技有限公司

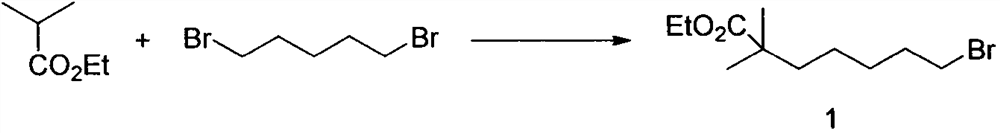

Synthetic method of bepidic acid

ActiveCN112479856AEasy to operateReduce manufacturing costElectrolysis componentsOrganic compound preparationPotassium hydroxideMalonate

The invention belongs to the field of medicine synthesis, and relates to a novel synthesis method of a compound bepidic acid. The preparation method comprises the following steps: (1) carrying out primary alkylation on ethyl isobutyrate and 1, 5-dibromopentane under the action of lithium diisopropylamide to generate a compound 1; (2) carrying out alkylation twice on dibenzyl malonate and the compound 1 under the action of sodium hydride to generate a compound 2; (3) removing benzyl from the compound 2 under the action of Pd / C and hydrogen to obtain a compound 3; (4) carrying out electrochemical reaction on the compound 3 in a methanol solution of methanol and ammonia to obtain a compound 4; (5) finally carrying out sodium borohydride hydrolysis and potassium hydroxide hydrolysis on the compound 4, and acidifying to obtain the final bepidic acid. The method is carried out under electrochemical conditions, is mild in conditions and high in efficiency, and is suitable for industrial production.

Owner:NANJING UNIV OF TECH

Process method for producing antibacterial and deodorant polyester fibers by adopting monocarboxy-chitosan

InactiveCN105803576AGreen production processReduce manufacturing costFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterAntibacterial activity

The invention relates to a process method for producing antibacterial and deodorant polyester fibers by adopting monocarboxy-chitosan. An antibacterial and deodorant polyester fiber production process comprises the following processing steps of mixing a polyester solution and a water solution of 75% water-soluble antibacterial monocarboxy-chitosan and drying, fusing and spinning, and coldly and hotly molding and the like. The method is simple to operate, rapid in reaction speed and easy to control; prepared carboxy-chitosan modified cotton fibers have lasting and efficient antibacterial activity and good wearability, are green and environmentally friendly, and overcome negative effects on the wearability of the polyether fibers and human health, caused by a chemical cross-linking agent. The process method is wide in raw material source; crustacean organisms are renewable resources and a production process is environmentally friendly; and the process method is low in production cost, low in production energy consumption and remarkable in environment load properties.

Owner:ANHUI HANLIAN TEXTILE CO LTD

Green and efficient heterogeneous catalyst for compounding 2,4-di-tert-butylphenol

InactiveCN106975517AImprove catalytic performanceSolution to short lifeOrganic chemistryOrganic compound preparationSolid acidCatalytic effect

The invention relates to a green and efficient heterogeneous catalyst for compounding 2,4-di-tert-butylphenol. The catalyst is a porous solid acid resin catalyst with high specific surface area. Phenol and isobutene are taken as reaction raw materials for producing 2,4-di-tert-butylphenol under a catalytic effect of the nontoxic harmless green solid acid resin catalyst. The catalyst provided by the invention is used for replacing a carclazyte catalyst in the present production, can be repeatedly reused, has the characteristics of long service life, is capable of greatly reducing the production cost of the catalyst, is capable of greatly reducing the solid waste generated by disposable use of the carclazyte catalyst and can realize the greening of the production process. Meanwhile, the heterogeneous catalyst for compounding 2,4-di-tert-butylphenol provided by the invention is simply separated, recycled and reused, the separating time of the present carclazyte catalyst is greatly shortened and the production efficiency is obviously increased.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com