Method for recycling all chemical components in filament melting molybdenum-containing waste acid

A technology of filament filament and chemical composition, applied in chemical instruments and methods, inorganic chemistry, molybdenum compounds, etc., can solve the problems of inability to further improve molybdenum recovery rate, sale, and inability to be used as commercial-grade products, etc. The effect of improving product purity and improving molybdenum recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

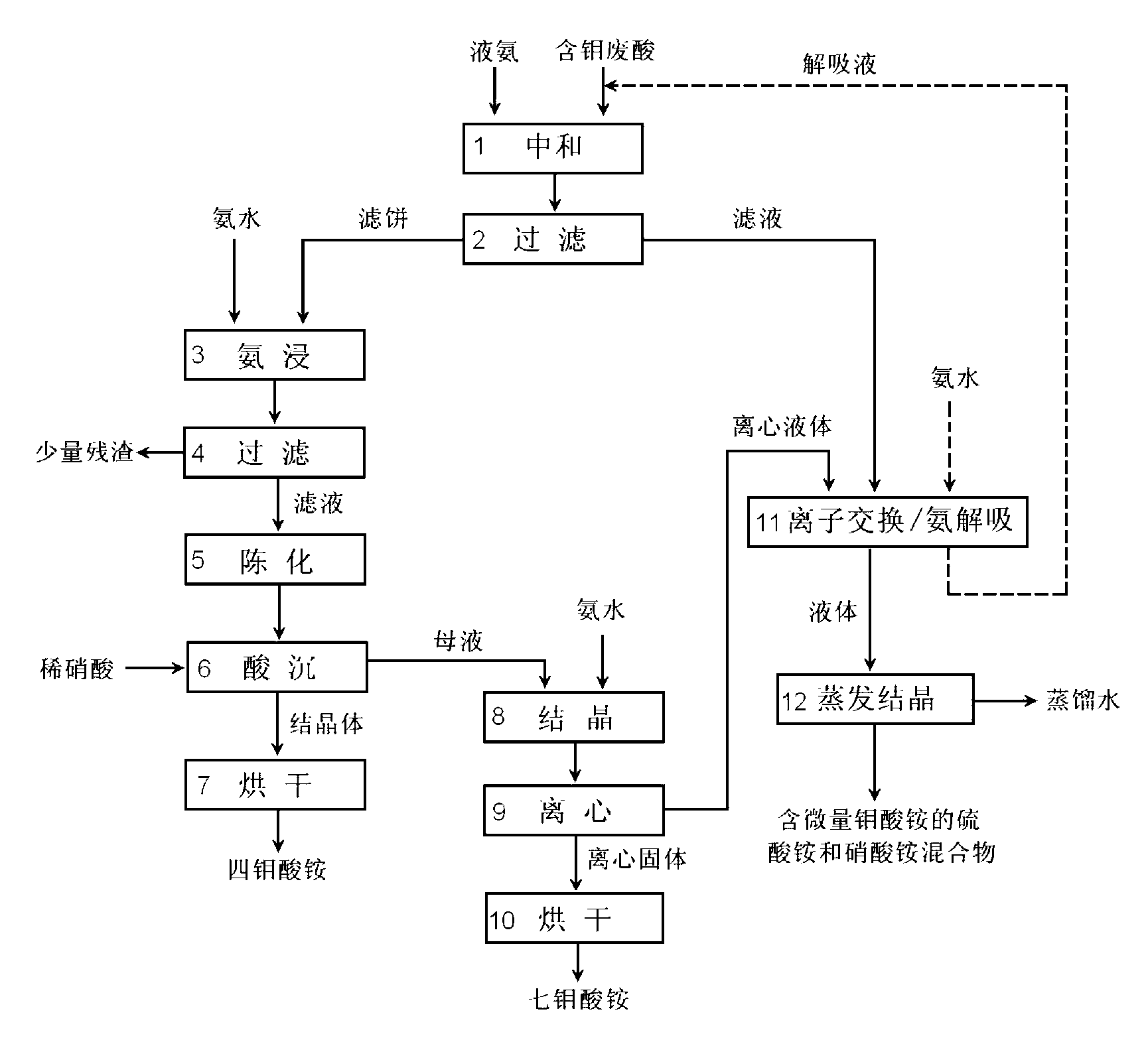

Image

Examples

Embodiment 2

[0053] On the basis of Example 1, step 2) recovery of molybdenum from the press filtrate, the pH value of the molybdenum-containing filtrate is 4.0-5.0.

[0054] The macroporous styrene-based weakly basic anion exchange resin produced by Xi'an Lanxiao Technology Co., Ltd., Tianjin Nankai Hecheng Technology Co., Ltd., Zhejiang Zhengguang Resin Company or Shanghai Jinyang Resin Technology Company was selected. Soak the above-mentioned anion-exchange resin with 1% nitric acid solution for 1 hour, then put it into the F40'450mm exchange column, add the above-mentioned embodiment 1 step 2) from the exchange column above the filter press, and the adding speed is controlled so that the filtrate and the ion-exchange resin The contact time is about 20 minutes. Use a test tube for every 5 mL of the exchange column effluent, and use the spectrophotometric analysis method to monitor the molybdenum content in each test tube. When the molybdenum content increases from the blank level to the...

Embodiment 3

[0056] On the basis of Example 1, step 2) recovery of molybdenum from the press filtrate, the pH value of the molybdenum-containing filtrate is 4.0-5.0.

[0057] Select the macroporous acrylic acid weakly basic anion exchange resin produced by Xi'an Lanxiao Technology Co., Ltd., Tianjin Nankai Hecheng Technology Co., Ltd., Zhejiang Zhengguang Resin Company or Shanghai Jinyang Resin Technology Company. Soak the above-mentioned anion exchange resin with 1% nitric acid solution for 1 hour, then put it into the F40′450mm exchange column, add the press filtrate of the above-mentioned process route 1 from the top of the exchange column, and control the adding speed so that the contact time between the filtrate and the ion exchange resin is about 20min. Use a test tube for every 5 mL of the exchange column effluent, and use the spectrophotometric analysis method to monitor the molybdenum content in each test tube. When the molybdenum content increases from the blank level to the begi...

Embodiment 4

[0059] On the basis of Example 1, in step 9) recovery of the molybdenum mixture in the centrifuge, the pH value of the molybdenum-containing filtrate is 6.9-7.2.

[0060] Select the macroporous acrylic acid weakly basic anion exchange resin produced by Xi'an Lanxiao Technology Co., Ltd., Tianjin Nankai Hecheng Technology Co., Ltd., Zhejiang Zhengguang Resin Company or Shanghai Jinyang Resin Technology Company. Soak the above-mentioned anion exchange resin with 1% nitric acid solution for 1 hour, then put it into the F40′450mm exchange column, add the above-mentioned embodiment 1 step 9) centrifugate mixture from the top of the exchange column, and control the adding speed so that the filtrate and ion The exchange resin contact time is about 20min. Use a test tube for every 5 mL of the exchange column effluent, and use the spectrophotometric analysis method to monitor the molybdenum content in each test tube. When the molybdenum content increases from the blank level to the beg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com